Method 202 -

Determination of Condensable Particulate Emissions from Stationary Sources

1.

APPLICABILITY AND PRINCIPLE

5.2.1 Post-test N2

Purge for Sources Emitting SO2.

5.2.2.1 Container Nos.

1, 2, and 3.

5.2.2.2 Container No. 4

(Impinger Contents).

5.2.2.3 Container No. 5

(MeCl2 Rinse).

5.2.2.4 Container No. 6

(Water Blank).

5.2.2.5 Container No. 7

(MeCl2 Blank).

5.3.1 Container Nos. 1,

2, and 3.

5.3.2.2 Organic

Fraction Weight Determination (Organic Phase from Container Nos. 4 and 5).

5.3.2.3 Inorganic

Fraction Weight Determination.

5.3.2.4 Analysis of

Sulfate by IC to Determine Ammonium Ion (NH4 +) Retained in the

Sample.

5.3.3 Analysis of Water

and MeCl2 Blanks (Container Nos. 6 and 7).

5.3.4 Analysis of

Acetone Blank (Container No. 8).

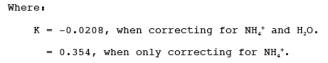

7.2 Correction for NH4

+ and H2O.

8.1 Determination of

NH4+ Retained in Sample by

Titration.

8.2 Analysis of

Chlorides by IC.

8.3 Air Purge to Remove

SO 2 from Impinger Contents.

8.4 Chloroform-ether

Extraction.

8.5 Improving

Collection Efficiency.

1. APPLICABILITY AND PRINCIPLE

1.1 Applicability.

1.1.1 This method applies to the determination of

condensable particulate matter (CPM) emissions from stationary sources. It is

intended to represent condensable matter as material that condenses after

passing through a filter and as measured by this method (Note: The filter catch can be analyzed according to the

appropriate method).

1.1.2 This method may be used in conjunction with Method

201 or 201A if the probes are glass-lined. Using Method 202 in conjunction with

Method 201 or 201A, only the impinger train configuration and analysis is

addressed by this method. The sample train operation and front-end recovery and

analysis shall be conducted according to Method 201 or 201A.

1.1.3 This method may also be modified to measure material

that condenses at other temperatures by specifying the filter and probe

temperature. A heated Method 5 out-of-stack filter may be used instead of the

in-stack filter to determine condensable emissions at wet sources.

1.2 Principle.

1.2.1 The CPM is collected in the impinger portion of a

Method 17 (Appendix A, 40 CFR Part 60) type sampling train. The impinger

contents are immediately purged after the run with nitrogen (N2) to remove dissolved sulfur dioxide (SO2) gases from

the impinger contents. The impinger solution is then extracted with methylene

chloride (MeCl2). The organic and aqueous fractions are then taken

to dryness and the residues weighed. The total of both fractions represents the

CPM.

1.2.2 The potential for low collection efficiency exist at

oil-fired boilers. To improve the collection efficiency at these type of

sources, an additional filter placed between the second and third impinger is

recommended.

2. PRECISION AND INTERFERENCE

2.1 Precision.

The precision based on

method development tests at an oil-fired boiler and a catalytic cracker were

11.7 and 4.8 percent, respectively.

2.2 Interference.

Ammonia. In sources that

use ammonia injection as a control technique for hydrogen chloride (HCl), the

ammonia interferes by reacting with HCl in the gas stream to form ammonium

chloride (NH4Cl) which would be measured as CPM. The sample may be

analyzed for chloride and the equivalent amount of NH4Cl can be subtracted from the CPM weight. However, if NH4Cl is to be counted as CPM, the inorganic fraction should be taken to

near dryness (less than 1 ml liquid) in the oven and then allowed to air dry at

ambient temperature to prevent any NH4Cl from vaporizing.

3. APPARATUS

3.1 Sampling Train.

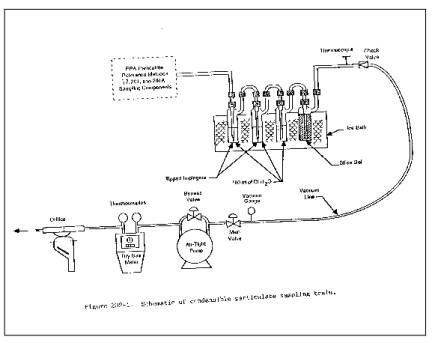

Same as in Method 17,

Section 2.1, with the following exceptions noted below (see Figure 202-1). Note:

Mention of trade names or specific

products does not constitute endorsement by EPA.

3.1.1 The probe extension shall be glass-lined or Teflon.

3.1.2 Both the first and second impingers shall be of the

Greenburg-Smith design with the standard tip.

Figure 202-1. Schematic of Condensable Particulate

Sampling Train

3.1.3 All sampling train glassware shall be cleaned prior

to the test with soap and tap water, water, and rinsed using tap water, water,

acetone, and finally, MeCl2. It is important to completely remove all silicone

grease from areas that will be exposed to the MeCl2 during sample recovery.

3.2 Sample Recovery.

Same as in Method 17,

Section 2.2, with the following additions:

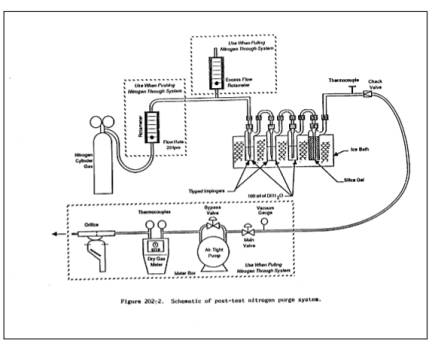

3.2.1 N2 Purge Line.

Inert tubing and fittings

capable of delivering 0 to 28 liters/min of N2 gas to the

impinger train from a standard gas cylinder (see Figure 202-2). Standard 0.95

cm (3/8-inch) plastic tubing and compression fittings in conjunction with an

adjustable pressure regulator and needle valve may be used.

3.2.2 Rotameter.

Capable of measuring gas

flow at 20 liters/min.

Figure 202-2. Schematic of Post-Test Nitrogen Purge

System

3.3 Analysis.

The following equipment is

necessary in addition to that listed in Method 17, Section 2.3:

3.3.1 Separatory

Funnel. Glass, 1-liter.

3.3.2 Weighing Tins. 350-ml.

3.3.3 Drying Equipment.

Hot plate and oven with temperature

control.

3.3.4 Pipets. 5-ml.

3.3.5 Ion

Chromatograph. Same as in Method 5F,

Section 2.1.6.

4. REAGENTS

Unless otherwise

indicated, all reagents must conform to the specifications established by the

Committee on Analytical Reagents of the American Chemical Society. Where such

specifications are not available, use the best available grade.

4.1 Sampling.

Same as in Method 17,

Section 3.1, with the addition of deionized distilled water to conform to the

American Society for Testing and Materials Specification D 1193-74, Type II and

the omittance of Section 3.1.4.

4.2 Sample Recovery.

Same as in Method 17,

Section 3.2, with the following additions:

4.2.1 N2 Gas.

Zero grade N2 gas at delivery pressures high enough to provide a

flow of 20 liters/min for 1 hour through the sampling train.

4.2.2 Methylene

Chloride, ACS grade. Blanks shall be

run prior to use and only methylene chloride with low blank values (0.001

percent) shall be used.

4.2.3 Water. Same as in Section 4.1.

4.3 Analysis. Same as in Method 17, Section 3.3, with the

following additions:

4.3.1 Methylene

Chloride. Same as Section 4.2.2.

4.3.2 Ammonium

Hydroxide. Concentrated (14.8 M) NH4OH.

4.3.3 Water. Same as in Section 4.1.

4.3.4 Phenolphthalein. The pH indicator solution, 0.05 percent in 50 percent

alcohol.

5. PROCEDURE

5.1 Sampling.

Same as in Method 17,

Section 4.1, with the following exceptions:

5.1.1 Place 100 ml of water in the first three impingers.

5.1.2 The use of silicone grease in train assembly is not

recommended because it is very soluble in MeCl2 which may

result in sample contamination. Teflon tape or similar means may be used to

provide leak-free connections between glassware.

5.2 Sample Recovery.

Same as in Method 17,

Section 4.2 with the addition of a post-test N2 purge and

specific changes in handling of individual samples as described below.

5.2.1 Post-test N2 Purge for Sources Emitting SO2.

(Note: This step is recommended, but is optional. When

little or no SO2 is present in the gas stream, i.e., the pH of the

impinger solution is greater than 4.5, purging has been found to be

unnecessary.) As soon as possible after the post-test leak check, detach the

probe and filter from the impinger train. Leave the ice in the impinger box to

prevent removal of moisture during the purge. If necessary, add more ice during

the purge to maintain the gas temperature below 20ûC. With no flow of gas

through the clean purge line and fittings, attach it to the input of the

impinger train (see Figure 202-2). To avoid over- or under-pressurizing the

impinger array, slowly commence the N2 gas flow through

the line while simultaneously opening the meter box pump valve(s). Adjust the

pump bypass and N2 delivery rates to obtain the following conditions:

(1) 20 liters/min or ¥H

@ and (2) an overflow rate through the

rotameter of less than 2 liters/min. Condition (2) guarantees that the N2 delivery system is operating at greater than ambient pressure and

prevents that possibility of passing ambient air (rather than N2) through the impingers. Continue the purge under these conditions for 1

hour, checking the rotameter and ¥H value(s) periodically. After 1 hour,

simultaneously turn off the delivery and pumping systems.

5.2.2 Sample Handling.

5.2.2.1 Container Nos. 1, 2, and 3.

If filter catch is to be

determined, as detailed in Method 17, Section 4.2.

5.2.2.2 Container No. 4 (Impinger Contents).

Measure the liquid in the

first three impingers to within 1 ml using a clean graduated cylinder or by

weighing it to within 0.5 g using a balance. Record the volume or weight of

liquid present to be used to calculate the moisture content of the effluent

gas. Quantitatively transfer this liquid into a clean sample bottle (glass or

plastic); rinse each impinger and the connecting glassware, including probe

extension, twice with water, recover the rinse water, and add it to the same

sample bottle. Mark the liquid level on the bottle.

5.2.2.3 Container No. 5 (MeCl2 Rinse).

Follow the water rinses of

each impinger and the connecting glassware, including the probe extension with

two rinses of MeCl2; save the rinse products in a clean, glass sample

jar. Mark the liquid level on the jar.

5.2.2.4 Container No. 6 (Water Blank).

Once during each field

test, place 500 ml of water in a separate sample container.

5.2.2.5 Container No. 7 (MeCl2 Blank).

Once during each field

test, place in a separate glass sample jar a volume of MeCl2 approximately equivalent to the volume used to conduct the MeCl2 rinse of the impingers.

5.3 Analysis.

Record the data required

on a sheet such as the one shown in Figure 202-3. Handle each sample container

as follows:

5.3.1 Container Nos. 1, 2, and 3.

If filter catch is

analyzed, as detailed in Method 17, Section 4.3.

5.3.2 Container Nos. 4 and 5.

Note the level of liquid

in the containers and confirm on the analytical data sheet whether leakage

occurred during transport. If a noticeable amount of leakage has occurred,

either void the sample or use methods, subject to the approval of the

Administrator, to correct the final results. Measure the liquid in Container

No. 4 either volumetrically to +1 ml or gravimetrically to +0.5

g. Remove a 5-ml aliquot and set aside for later ion chromatographic (IC)

analysis of sulfates. (Note: Do

not use this aliquot to determine chlorides since the HCl will be evaporated

during the first drying step; Section 8.2 details a procedure for this

analysis.)

5.3.2.1 Extraction.

Separate the organic

fraction of the sample by adding the contents of Container No. 5 (MeCl2) to the contents of Container No. 4 in a 1000-ml separatory funnel.

After mixing, allow the aqueous and organic phases to fully separate, and drain

off most of the organic/MeCl2 phase. Then add 75 ml of MeCl2 to the funnel, mix well, and drain off the lower organic phase. Repeat

with another 75 ml of MeCl2. This extraction should yield about 250 ml of

organic extract. Each time, leave a small amount of the organic/MeCl2 phase in the separatory funnel ensuring that no water is collected in

the organic phase. Place the organic extract in a tared 350-ml weighing tin.

5.3.2.2 Organic Fraction Weight Determination (Organic Phase from Container Nos. 4 and 5).

Evaporate the organic

extract at room temperature and pressure in a laboratory hood. Following

evaporation, desiccate the organic fraction for 24 hours in a desiccator

containing anhydrous calcium sulfate. Weigh to a constant weight and report the

results to the nearest 0.1 mg.

5.3.2.3 Inorganic Fraction Weight Determination.

[Note: If NH4Cl is to be counted

as CPM, the inorganic fraction should be taken to near dryness (less than 1 ml

liquid) in the oven and then allow to air dry at ambient temperature. If

multiple acid emissions are suspected, the ammonia titration procedure in

Section 8.1 may be preferred.] Using a hot plate, or equivalent, evaporate the

aqueous phase to approximately 50 ml; then, evaporate to dryness in a 105ûC

oven. Redissolve the residue in 100 ml of water. Add five drops of

phenolphthalein to this solution; then, add concentrated (14.8 M) NH4OH until the sample turns pink. Any excess NH40H will be evaporated during the drying step. Evaporate the sample to

dryness in a 105ûC oven, desiccate the sample for 24 hours, weigh to a constant

weight, and record the results to the nearest 0.1 mg. (Note: The addition of NH4OH is

recommended, but is optional when little or no SO2 is present in

the gas stream, i.e., when the pH of the impinger solution is greater than 4.5,

the addition of NH4OH is not necessary.)

5.3.2.4 Analysis of Sulfate by IC to Determine Ammonium Ion (NH4 +) Retained in the Sample.

(Note: If NH4OH is not added,

omit this step.) Determine the amount of sulfate in the aliquot taken from

Container No. 4 earlier as described in Method 5F (Appendix A, 40 CFR Part 60).

Based on the IC SO4-2 analysis of the aliquot, calculate the correction

factor to subtract the NH4+ retained in the sample and to add the combined water

removed by the acid-base reaction (see Section 7.2).

5.3.3 Analysis of Water and MeCl2 Blanks (Container Nos. 6 and 7).

Analyze these sample

blanks as described above in Sections 5.3.2.3 and 5.3.2.2, respectively.

5.3.4 Analysis of Acetone Blank (Container No. 8).

Same as in Method 17,

Section 4.3.

6. CALIBRATION

Same as in Method 17,

Section 5, except for the following:

6.1 IC Calibration.

Same as Method 5F, Section

5.

6.2 Audit Procedure.

Concurrently, analyze the

audit sample and a set of compliance samples in the same manner to evaluate the

technique of the analyst and the standards preparation. The same analyst,

analytical reagents, and analytical system shall be used both for compliance

samples and the EPA audit sample. If this condition is met, auditing of

subsequent compliance analyses for the same enforcement agency within 30 days

is not required. An audit sample set may not be used to validate different sets

of compliance samples under the jurisdiction of different enforcement agencies,

unless prior arrangements are made with both enforcement agencies.

6.3 Audit Samples.

Audit Sample Availability.

Audit samples will be supplied only to enforcement agencies for compliance

tests. The availability of audit samples may be obtained by writing:

Source Test Audit

Coordinator (MD-77B)

Quality Assurance Division

Atmospheric Research and

Exposure Assessment Laboratory

U.S. Environmental

Protection Agency

Research Triangle Park, NC

27711

or by calling the Source

Test Audit Coordinator (STAC) at (919) 541-7834. The request for the audit

sample must be made at least 30 days prior to the scheduled compliance sample

analysis.

6.4 Audit Results.

Calculate the audit sample

concentration according to the calculation procedure described in the audit

instructions included with the audit sample. Fill in the audit sample

concentration and the analyst's name on the audit response form included with

the audit instructions. Send one copy to the EPA Regional Office or the

appropriate enforcement agency and a second copy to the STAC. The EPA Regional

Office or the appropriate enforcement agency will report the results of the

audit to the laboratory being audited. Include this response with the results

of the compliance samples in relevant reports to the EPA Regional Office or the

appropriate enforcement agency.

7. CALCULATIONS

Same as in Method 17,

Section 6, with the following additions:

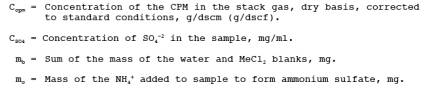

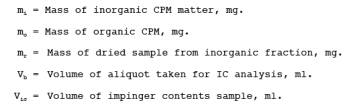

7.1 Nomenclature.

Same as in Method 17,

Section 6.1 with the following additions.

7.2 Correction for NH4 + and H2O.

Calculate the correction

factor to subtract the NH4+

retained in the sample based on the IC

SO4 -2 and if desired, add the combined water removed by

the acid-base reaction.

7.3 Mass of Inorganic CPM.

![]()

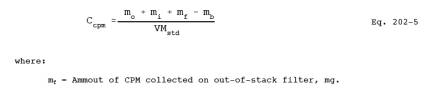

7.4 Concentration of CPM.

8. ALTERNATIVE PROCEDURES

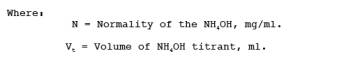

8.1 Determination of NH4+ Retained in Sample by Titration.

8.1.1 An alternative procedure to determine the amount of

NH4+ added to the inorganic fraction by titration may be

used. After dissolving the inorganic residue in 100 ml of water, titrate the

solution with 0.1 N NH4OH to a pH of 7.0, as indicated by a pH meter. The

0.1 N NH4OH is made as follows: Add 7 ml of concentrated (14.8

M) NH4OH to l liter of water. Standardize against

standardized 0.1 N H2 SO4 and calculate the exact

normality using a procedure parallel to that described in Section 5.5 of Method

6 (Appendix A, 40 CFR Part 60). Alternatively, purchase 0.1 N NH4OH that has been standardized against a National Institute of Standards

and Technology reference material.

8.1.2 Calculate the concentration of SO4-2 in the

sample using the following equation.

8.1.3 Calculate the CPM as described in Section 7.

8.2 Analysis of Chlorides by IC.

At the conclusion of the

final weighing as described in Section 5.3.2.3, redissolve the inorganic

fraction in 100 ml of water. Analyze an aliquot of the redissolved sample for

chlorides by IC using techniques similar to those described in Method 5F for

sulfates. Previous drying of the sample should have removed all HCl. Therefore,

the remaining chlorides measured by IC can be assumed to be NH4Cl, and this weight can be subtracted from the weight determined for

CPM.

8.3 Air Purge to Remove SO 2 from Impinger Contents.

As an alternative to the

post-test N2 purge described in Section 5.2.1, the tester may opt

to conduct the post-test purge with air at 20 liter/min. Note: The use of an air purge is not as effective as a N2 purge.

8.4 Chloroform-ether Extraction.

As an alternative to the

methylene chloride extraction described in Section 5.3.2.1, the tester may opt

to conduct a chloroform-ether extraction.

Note: The chloroform-ether was not as effective as the MeCl2 in removing the organics, but it was found to be an acceptable organic

extractant. Chloroform and diethlyether of ACS grade, with low blank values

(0.001 percent), shall be used. Analysis of the chloroform and diethlyether

blanks shall be conducted according to Section 5.3.3 for MeCl2.

8.4.1 Add the contents of Container No. 4 to a 1000-ml

separatory funnel. Then add 75 ml of chloroform to the funnel, mix well, and

drain off the lower organic phase. Repeat two more times with 75 ml of

chloroform. Then perform three extractions with 75 ml of diethylether. This

extraction should yield approximately 450 ml of organic extraction. Each time,

leave a small amount of the organic/MeCl2 phase in the

separatory funnel ensuring that no water is collected in the organic phase.

8.4.2 Add the contents of Container No. 5 to the organic

extraction. Place approximately 300 ml of the organic extract in a tared 350-ml

weighing tin while storing the remaining organic extract in a sample container.

As the organic extract evaporates, add the remaining extract to the weighing

tin.

8.4.3 Determine the weight of the organic phase as described

in Section 5.3.2.2.

8.5 Improving Collection Efficiency.

If low impinger collection

efficiency is suspected, the following procedure may be used.

8.5.1 Place an out-of-stack filter as described in Method 8

between the second and third impingers.

8.5.2 Recover and anaylze the filter according to Method

17, Section 4.2. Include the filter holder as part of the connecting glassware

and handle as described in Sections 5.2.2.2 and 5.2.2.3.

8.5.3 Calculate the Concentration of CPM as follows:

8.6 Wet Source Testing.

When testing at a wet

source, use a heated outof-stack filter as described in Method 5.

9. BIBLIOGRAPHY

1. DeWees, W.D., S.C.

Steinsberger, G.M. Plummer, L.T. Lay, G.D. McAlister, and R.T. Shigehara.

"Laboratory and Field Evaluation of the EPA Method 5 Impinger Catch for

Measuring Condensable Matter from Stationary Sources." Paper presented at

the 1989 EPA/AWMA International Symposium on Measurement of Toxic and Related

Air Pollutants. Raleigh, North Carolina. May 1-5, 1989.

2. DeWees, W.D. and K.C. Steinsberger. "Method

Development and Evaluation of Draft Protocol for Measurement of Condensable

Particulate Emissions." Draft Report. November 17, 1989.

3. Texas Air Control Board, Laboratory Division.

"Determination of Particulate in Stack Gases Containing Sulfuric Acid

and/or Sulfur Dioxide." Laboratory Methods for Determination of Air

Pollutants. Modified December 3, 1976.

4. Nothstein, Greg. Masters Thesis. University of

Washington. Department of Environmental Health. Seattle, Washington.

5. "Particulate Source Test Procedures Adopted by

Puget Sound Air Pollution Control Agency Board of Directors." Puget Sound

Air Pollution Control Agency, Engineering Division. Seattle, Washington. August

11, 1983.

6. Commonwealth of Pennsylvania, Department of

Environmental Resources. Chapter 139, Sampling and Testing (Title 25, Rules and

Regulations, Part I, Department of Environmental Resources, Subpart C,

Protection of Natural Resources, Article III, Air Resources). January 8, 1960.

7. Wisconsin Department of Natural Resources. Air

Management Operations Handbook, Revision 3. January 11, 1988.

Figure 202-3.

Analytical data sheet

Moisture Determination

Volume or weight of liquid

in impingers_______________ ml or g

Weight of moisture in

silica gel_______________________ g

Sample Preparation

(Container No. 4)

Amount of liquid lost

during transport________________ ml

Final volume

_________________________________________ ml

pH of sample prior to

analysis________________________

Addition of NH4OH required? __________________________

Sample extracted 2X with

75 ml MeCl2 ? ________________

For Titration of

Sulfate

Normality of NH4OH ___________________________________ N

Volume of sample titrated

____________________________ ml

Volume of titrant ____________________________________

ml

Sample Analysis

______________________________________________________

Weight of Condensable

Particulate, mg

Container

__________________________________________

number Final Weight Tare

Weight Weight Gain

_______________________________________________________

4 (Inorganic)

4 & 5 (Organic)

_______________________________________________________

Total _____________

Less Blank _____________

Weight of Condensable

Particulate _____________

_______________________