METHOD 5F -

DETERMINATION OF NONSULFATE PARTICULATE MATTER EMISSIONS FROM STATIONARY

SOURCES

NOTE: This method does not include all of the

specifications (e.g.,

equipment and supplies) and procedures (e.g., sampling and analytical) essential to its

performance. Some material is incorporated by reference from other methods in

this part. Therefore, to obtain reliable results, persons using this method

should have a thorough knowledge of at least the following additional test

methods: Method 1, Method 2,

Method 3, and Method 5.

6.1 Sample Collection

and Recovery.

7.3.2 Stock Standard

Solution, 1 mg (NH4)2SO4/ml.

7.3.3 Working Standard

Solution

7.3.6 Phenolphthalein

Indicator.

8.0 Sample Collection,

Preservation, Storage, and Transport.

9.1 Miscellaneous

Quality Control Measures.

9.2 Volume Metering

System Checks.

10.0 Calibration and

Standardization.

10.1 Determination of

Ion Chromatograph Calibration Factor S.

12.0 Data Analysis and

Calculations.

12.2 Water Blank

Concentration.

12.3 Mass of Ammonium

Sulfate.

12.4 Mass of Nonsulfate

Particulate Matter.

13.0 Method Performance.

[Reserved]

14.0 Pollution

Prevention. [Reserved]

15.0 Waste Management.

[Reserved]

18.0 Tables, Diagrams,

Flowcharts, and Validation Data.

[Reserved]

1.0 Scope and Applications.

1.1 Analyte.

Nonsulfate particulate matter (PM). No CAS number assigned.

1.2 Applicability.

This method is applicable for the determination of nonsulfate PM emissions from

stationary sources. Use of this method must be specified by an applicable

subpart of the standards, or approved by the Administrator for a particular

application.

1.3 Data Quality

Objectives. Adherence to the requirements of this method will enhance the

quality of the data obtained from air pollutant sampling methods.

2.0 Summary of Method.

Particulate matter is

withdrawn isokinetically from the source and collected on a filter maintained

at a temperature in the range 160 ± 14 ¡C (320 ± 25 ¡F). The collected sample

is extracted with water. A portion of the extract is analyzed for sulfate

content by ion chromatography. The remainder is neutralized with ammonium

hydroxide (NH4OH), dried, and weighed. The weight of sulfate

in the sample is calculated as ammonium sulfate [(NH4)2SO4], and is

subtracted from the total particulate weight; the result is reported as

nonsulfate particulate matter.

3.0 Definitions. [Reserved]

4.0 Interferences. [Reserved]

5.0 Safety.

5.1 Disclaimer. This

method may involve hazardous materials, operations, and equipment. This test

method may not address all of the safety problems associated with its use. It

is the responsibility of the user of this test method to establish appropriate

safety and health practices and to determine the applicability of regulatory

limitations prior to performing this

test method.

6.0 Equipment and Supplies.

6.1 Sample Collection and Recovery.

Same as Method 5, Sections 6.1 and 6.2, respectively.

6.2 Sample Analysis.

Same as Method 5, Section 6.3, with the addition of the

following:

6.2.1 Erlenmeyer

Flasks. 125-ml, with ground glass joints.

6.2.2 Air Condenser.

With ground glass joint compatible with the Erlenmeyer flasks.

6.2.3 Beakers.

600-ml.

6.2.4 Volumetric

Flasks. 1-liter, 500-ml (one for each sample), 200-ml, and 50-ml (one for each

sample and standard).

6.2.5 Pipet. 5-ml

(one for each sample and standard).

6.2.6

Ion Chromatograph. The ion chromatograph should have at least the following

components.

6.2.6.1 Columns. An

anion separation column or other column capable of resolving the sulfate ion

from other species present and a standard anion suppressor column. Suppressor

columns are produced as proprietary items; however, one can be produced in the

laboratory using the resin available from BioRad Company, 32nd and Griffin

Streets, Richmond, California. Other systems which do not use suppressor

columns may also be used.

6.2.6.2 Pump. Capable

of maintaining a steady flow as required by the system.

6.2.6.3 Flow Gauges.

Capable of measuring the specified system flow rate.

6.2.6.4 Conductivity

Detector.

6.2.6.5 Recorder.

Compatible with the output voltage range of the detector.

7.0 Reagents and Standards.

Unless otherwise

indicated, it is intended that all reagents conform to the specifications

established by the Committee on Analytical Reagents of the American Chemical Society,

where such specifications are available; otherwise, use the best available

grade.

7.1 Sample Collection.

Same as Method 5, Section 7.1.

7.2 Sample Recovery.

Same as Method 5, Section 7.2, with the addition of the

following:

7.2.1

Water. Deionized distilled, to conform to ASTM D 1193-77 or 91 Type 3 incorporated by reference - see

¤60.17). The potassium permanganate (KMnO4) test for

oxidizable organic matter may be omitted when high concentrations of organic

matter are not expected to be present.

7.3 Analysis.

Same as Method 5,

Section 7.3, with the addition of the following:

7.3.1 Water.

Same as in Section

7.2.1.

7.3.2 Stock Standard Solution, 1 mg (NH4)2SO4/ml.

Dry an adequate

amount of primary standard grade ammonium sulfate [(NH4)2SO4] at 105

to 110 ¡C (220 to 230 ¡F) for a minimum of 2 hours before preparing the

standard solution. Then dissolve exactly 1.000 g of dried (NH4)2SO4 in water

in a 1-liter volumetric flask, and dilute to 1 liter. Mix well.

7.3.3 Working Standard Solution

25 µg (NH4)2SO4/ml. Pipet

5 ml of the stock standard solution into a 200-ml volumetric flask. Dilute to

200 ml with water.

7.3.4 Eluent Solution.

Weigh 1.018 g of

sodium carbonate (Na2CO3) and

1.008 g of sodium bicarbonate (NaHCO3), and

dissolve in 4 liters of water. This solution is 0.0024 M Na2CO3/0.003 M NaHCO3.

Other eluents appropriate to the column type and capable of resolving sulfate

ion from other species present may be used.

7.3.5 Ammonium Hydroxide.

Concentrated, 14.8 M.

7.3.6 Phenolphthalein Indicator.

3,3-Bis(4-

hydroxyphenyl)-1-(3H)-isobenzo-furanone. Dissolve 0.05 g in 50 ml of ethanol

and 50 ml of water.

8.0 Sample Collection, Preservation, Storage, and Transport.

Same as Method 5, Section 8.0, with the exception of the

following:

8.1 Sampling Train Operation.

Same as Method 5, Section 8.5, except that the

probe outlet and filter temperatures shall be maintained at 160 ± 14 ¡C (320 ±

25 ¡F).

8.2 Sample Recovery.

Same as Method 5, Section 8.7, except that the

recovery solvent shall be water instead of acetone, and a clean filter from the

same lot as those used during testing shall be saved for analysis as a blank.

9.0 Quality Control.

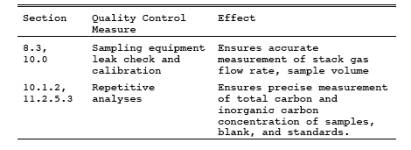

9.1 Miscellaneous Quality Control Measures.

9.2 Volume Metering System Checks.

Same as Method 5, Section 9.2.

10.0 Calibration and Standardization.

Same as Method 5, Section 10.0, with the addition of

the following:

10.1 Determination of Ion Chromatograph Calibration Factor S.

Prepare a series of

five standards by adding 1.0, 2.0, 4.0, 6.0, and 10.0 ml of working standard

solution (25 µg/ml) to a series of five 50-ml volumetric flasks. (The standard

masses will equal 25, 50, 100, 150, and 250 µg.) Dilute each flask to the mark with water, and mix well.

Analyze each standard according to the chromatograph manufacturer's

instructions. Take peak height measurements with symmetrical peaks; in all

other cases, calculate peak areas. Prepare or calculate a linear regression

plot of the standard masses in µg (x-axis) versus their responses (y-axis).

From this line, or equation, determine the slope and calculate its reciprocal

which is the calibration factor, S. If any point deviates from the line by more

than 7 percent of the concentration at that point, remake and reanalyze that

standard. This deviation can be determined by multiplying S times the response

for each standard. The resultant concentrations must not differ by more than 7

percent from each known standard mass (i.e., 25, 50, 100, 150, and 250 µg).

10.2 Conductivity Detector.

Calibrate according

to manufacturer's specifications prior to initial use.

11.0 Analytical Procedure.

11.1 Sample Extraction.

11.1.1 Note on the

analytical data sheet, the level of the liquid in the container, and whether

any sample was lost during shipment. If a noticeable amount of leakage has

occurred, either void the sample or use methods, subject to the approval of the

Administrator, to correct the final results.

11.1.2 Cut the filter

into small pieces, and place it in a 125-ml Erlenmeyer flask with a ground

glass joint equipped with an air condenser. Rinse the shipping container with

water, and pour the rinse into the flask. Add additional water to the flask

until it contains about 75 ml, and place the flask on a hot plate. Gently

reflux the contents for 6 to 8 hours. Cool the solution, and transfer it to a

500-ml volumetric flask. Rinse the Erlenmeyer flask with water, and transfer

the rinsings to the volumetric flask including the pieces of filter.

11.1.3

Transfer the probe rinse to the same 500-ml volumetric flask with the filter

sample. Rinse the sample bottle with water, and add the rinsings to the

volumetric flask. Dilute the contents of the flask to the mark with water.

11.1.4 Allow the contents

of the flask to settle until all solid material is at the bottom of the flask.

If necessary, remove and centrifuge a portion of the sample.

11.1.5 Repeat the

procedures outlined in Sections 11.1.1 through 11.1.4 for each sample and for

the filter blank.

11.2 Sulfate (SO4) Analysis.

11.2.1 Prepare a

standard calibration curve according to the procedures outlined in Section

10.1.

11.2.2 Pipet 5 ml of

the sample into a 50-ml volumetric flask, and dilute to 50 ml with water.

(Alternatively, eluent solution may be used instead of water in all sample,

standard, and blank dilutions.) Analyze the set of standards followed by the

set of samples, including the filter blank, using the same injection volume

used for the standards.

11.2.3 Repeat the

analyses of the standards and the samples, with the standard set being done

last. The two peak height or peak area responses for each sample must agree

within 5 percent of their arithmetic mean for the analysis to be valid. Perform

this analysis sequence on the same day. Dilute any sample and the blank with

equal volumes of water if the concentration exceeds that of the highest

standard.

11.2.4 Document each

sample chromatogram by listing the following analytical parameters: injection

point, injection volume, sulfate retention time, flow rate, detector

sensitivity setting, and recorder chart speed.

11.3 Sample Residue.

11.3.1 Transfer the

remaining contents of the volumetric flask to a tared 600-ml beaker or similar

container. Rinse the volumetric flask with water, and add the rinsings to the

tared beaker. Make certain that all particulate matter is transferred to the

beaker. Evaporate the water in an oven at 105 ¡C (220 ¡F) until only about 100

ml of water remains. Remove the beakers from the oven, and allow them to cool.

11.3.2 After the

beakers have cooled, add five drops of phenolphthalein indicator, and then add

concentrated ammonium hydroxide until the solution turns pink. Return the

samples to the oven at 105 ¡C (220 ¡F), and evaporate the samples to dryness.

Cool the samples in a desiccator, and weigh the samples to constant weight.

12.0 Data Analysis and Calculations.

Same as Method 5, Section 12.0, with the addition of the

following:

12.1 Nomenclature.

Cw = Water blank residue concentration, mg/ml.

F = Dilution factor

(required only if sample dilution was needed to reduce the concentration into

the range of calibration).

Hs = Arithmetic mean response of duplicate sample analyses, mm for

height or mm2 for area.

Hb = Arithmetic mean response of duplicate filter blank analyses, mm

for height or mm2 for area.

mb = Mass of beaker used to dry sample, mg.

mf = Mass of sample filter, mg.

mn = Mass of nonsulfate particulate matter in the sample as collected,

mg.

ms = Mass of ammonium sulfate in the sample as collected, mg.

mt = Mass of beaker, filter, and dried sample, mg.

mw = Mass of residue after evaporation of water blank, mg.

S = Calibration

factor, µg/mm.

Vb = Volume of water blank, ml.

Vs = Volume of sample collected, 500 ml.

12.2 Water Blank Concentration.

![]()

12.3 Mass of Ammonium Sulfate.

![]()

where:

100 = Aliquot factor,

495 ml/5 ml

1000 = Constant,

µg/mg

12.4 Mass of Nonsulfate Particulate Matter.

![]()

13.0 Method Performance. [Reserved]

14.0 Pollution Prevention. [Reserved]

15.0 Waste Management. [Reserved]

16.0 Alternative Procedures

16.1 The following

procedure may be used as an alternative to the procedure in Section

11.0

16.1.1 Apparatus.

Same as for Method 6, Sections 6.3.3 to

6.3.6 with the following additions.

16.1.1.1 Beakers.

250-ml, one for each sample, and 600-ml.

16.1.1.2 Oven.

Capable of maintaining temperatures of 75 ± 5¡C (167 ± 9¡F) and 105 ± 5¡C (221

± 9¡F).

16.1.1.3 Buchner

Funnel.

16.1.1.4 Glass

Columns. 25-mm x 305-mm (1-in. x 12-in.) with Teflon stopcock.

16.1.1.5 Volumetric

Flasks. 50-ml and 500-ml, one set for each sample, and 100-ml, 200-ml, and

1000-ml.

16.1.1.6 Pipettes.

Two 20-ml and one 200-ml, one set for each sample, and 5-ml.

16.1.1.7 Filter

Flasks. 500-ml.

16.1.1.8 Polyethylene

Bottle. 500-ml, one for each sample.

16.1.2 Reagents. Same

as Method 6, Sections 7.3.2 to 7.3.5 with

the following additions:

16.1.2.1 Water,

Ammonium Hydroxide, and Phenolphthalein. Same as Sections

7.2.1, 7.3.5, and 7.3.6 of this method, respectively.

16.1.2.2 Filter.

Glass fiber to fit Buchner funnel.

16.1.2.3 Hydrochloric

Acid (HCl), 1 m. Add 8.3 ml of concentrated HCl (12 M) to 50 ml of water in a

100-ml volumetric flask. Dilute to 100 ml with water.

16.1.2.4 Glass Wool.

16.1.2.5 Ion Exchange

Resin. Strong cation exchange resin, hydrogen form, analytical grade.

16.1.2.6 pH Paper.

Range of 1 to 7.

16.1.3 Analysis.

16.1.3.1 Ion Exchange

Column Preparation. Slurry the resin with 1 M HCl in a 250-ml beaker, and allow

to stand overnight. Place 2.5 cm (1 in.) of glass wool in the bottom of the

glass column. Rinse the slurried resin twice with water. Resuspend the resin in

water, and pour sufficient resin into the column to make a bed 5.1 cm (2 in.)

deep. Do not allow air bubbles to become entrapped in the resin or glass wool to

avoid channeling, which may produce erratic results. If necessary, stir the

resin with a glass rod to remove air bubbles, after the column has been

prepared, never let the liquid level fall below the top of the upper glass wool

plug. Place a 2.5-cm (1-in.) plug of glass wool on top of the resin. Rinse the

column with water until the eluate gives a pH of 5 or greater as measured with

pH paper.

16.1.3.2 Sample

Extraction. Followup the procedure given in Section

11.1.3 except do not dilute the sample to 500 ml.

16.1.3.3 Sample

Residue.

16.1.3.3.1 Place at

least one clean glass filter for each sample in a Buchner funnel, and rinse the

filters with water. Remove the filters from the funnel, and dry them in an oven

at 105 ± 5¡C (221 ± 9¡F); then cool in a desiccator. Weigh each filter to

constant weight according to the procedure in Method

5, Section 11.0. Record the weight of each filter to the nearest 0.1 mg.

16.1.3.3.2 Assemble the

vacuum filter apparatus, and place one of the clean, tared glass fiber filters

in the Buchner funnel. Decant the liquid portion of the extracted sample

(Section 16.1.3.2) through the tared glass fiber filter into a clean, dry,

500-ml filter flask. Rinse all the particulate matter remaining in the

volumetric flask onto the glass fiber filter with water. Rinse the particulate

matter with additional water. Transfer the filtrate to a 500-ml volumetric

flask, and dilute to 500 ml with water. Dry the filter overnight at 105 ± 5¡C

(221 ± 9¡F), cool in a desiccator, and weigh to the nearest 0.1 mg.

16.1.3.3.3 Dry a

250-ml beaker at 75 ± 5¡C (167 ± 9¡F), and cool in a desiccator; then weigh to

constant weight to the nearest 0.1 mg. Pipette 200 ml of the filtrate that was

saved into a tared 250-ml beaker; add five drops of phenolphthalein indicator

and sufficient concentrated ammonium hydroxide to turn the solution pink.

Carefully evaporate the contents of the beaker to dryness at 75 ± 5¡C (167 ±

9¡F). Check for dryness every 30 minutes. Do not continue to bake the sample

once it has dried. Cool the sample in a desiccator, and weigh to constant

weight to the nearest 0.1 mg.

16.1.3.4 Sulfate

Analysis. Adjust the flow rate through the ion exchange column to 3 ml/min.

Pipette a 20-ml aliquot of the filtrate onto the top of the ion exchange

column, and collect the eluate in a 50-ml volumetric flask. Rinse the column

with two 15-ml portions of water. Stop collection of the eluate when the volume

in the flask reaches 50-ml. Pipette a 20-ml aliquot of the eluate into a 250-ml

Erlenmeyer flask, add 80 ml of 100 percent isopropanol and two to four drops of

thorin indicator, and titrate to a pink end point using 0.0100 N barium

perchlorate. Repeat and average the titration volumes. Run a blank with each

series of samples. Replicate titrations must agree within 1 percent or 0.2 ml,

whichever is larger. Perform the ion exchange and titration procedures on

duplicate portions of the filtrate. Results should agree within 5 percent.

Regenerate or replace the ion exchange resin after 20 sample aliquots have been

analyzed or if the end point of the titration becomes unclear.

NOTE: Protect the 0.0100 N barium perchlorate solution

from evaporation at all times.

16.1.3.5 Blank

Determination. Begin with a sample of water of the same volume as the samples

being processed and carry it through the analysis steps described in Sections

16.1.3.3 and 16.1.3.4. A blank value larger than 5 mg should not be subtracted

from the final particulate matter mass. Causes for large blank values should be

investigated and any problems resolved before proceeding with further analyses.

16.1.4 Calibration.

Calibrate the barium perchlorate solutions as in Method

6, Section 10.5.

16.1.5 Calculations.

16.1.5.1

Nomenclature. Same as Section 12.1 with the

following additions:

ma = Mass of clean analytical filter, mg.

md = Mass of dissolved particulate matter, mg.

me = Mass of beaker and dissolved particulate matter after evaporation

of filtrate, mg.

mp = Mass of insoluble particulate matter, mg.

mr = Mass of analytical filter, sample filter, and insoluble

particulate matter, mg.

mbk = Mass of nonsulfate particulate matter in blank

sample, mg.

mn = Mass of nonsulfate particulate matter, mg.

ms = Mass of Ammonium sulfate, mg.

N = Normality of

Ba(Cl04) titrant, meq/ml.

Va = Volume of aliquot taken for titration, 20 ml.

Vc = Volume of titrant used for titration blank, ml.

Vd = Volume of filtrate evaporated, 200 ml.

Ve = Volume of eluate collected, 50 ml.

Vf = Volume of extracted sample, 500 ml.

Vi = Volume of filtrate added to ion exchange column, 20 ml.

Vt = Volume of Ba(C104)2 titrant, ml.

W = Equivalent weight

of ammonium sulfate, 66.07 mg/meq.

16.1.5.2 Mass of

Insoluble Particulate Matter.

mp = mr-ma-mf Eq. 5F-4

16.1.5.3 Mass of

Dissolved Particulate Matter.

md = (me - (Vf/Vd)mb) Eq.

5F-5

16.1.5.4 Mass of

Ammonium Sulfate.

16.1.5.5 Mass of Nonsulfate

Particulate Matter.

mn = mp + md - ms - mbk Eq. 5F-7

17.0 References.

Same as Method 5, Section 17.0, with the addition of the

following:

1. Mulik, J.D. and E.

Sawicki. Ion Chromatographic Analysis of Environmental Pollutants. Ann Arbor,

Ann Arbor Science Publishers, Inc. Vol. 2, 1979.

2. Sawicki, E., J.D.

Mulik, and E. Wittgenstein. Ion Chromatographic Analysis of Environmental Pollutants.

Ann Arbor, Ann Arbor Science Publishers, Inc. Vol. 1. 1978.

3. Siemer, D.D.

Separation of Chloride and Bromide from Complex Matrices Prior to Ion

Chromatographic Determination. Analytical Chemistry 52(12): 1874-1877. October

1980.

4. Small, H., T.S.

Stevens, and W.C. Bauman. Novel Ion Exchange Chromatographic Method Using

Conductimetric Determination. Analytical Chemistry. 47(11):1801. 1975.

18.0 Tables, Diagrams, Flowcharts, and Validation Data. [Reserved]