METHOD

8 - DETERMINATION OF SULFURIC ACID AND SULFUR

DIOXIDE

EMISSIONS FROM STATIONARY SOURCES

NOTE: This method does not include all of the

specifications (e.g.,

equipment and supplies) and procedures (e.g., sampling and analytical) essential to its performance.

Some material is incorporated by reference from other methods in this part.

Therefore, to obtain reliable results, persons using this method should have a

thorough knowledge of at least the following additional test methods: Method 1, Method 2, Method 3, Method 5, and Method 6.

8.0 Sample Collection,

Preservation, Storage, and Transport.

8.2 Preliminary

Determinations.

8.3 Preparation of

Sampling Train.

8.4 Metering System

Leak-Check Procedure.

8.5 Pretest Leak-Check

Procedure.

8.7 Calculation of

Percent Isokinetic.

9.1 Miscellaneous

Quality Control Measures.

9.2 Volume Metering

System Checks.

10.0 Calibration and

Standardization.

12.0 Data Analysis and

Calculations.

12.2 Average Dry Gas

Meter Temperature and Average Orifice Pressure Drop.

12.4 Volume of Water

Vapor Condensed and Moisture Content.

12.5 Sulfuric Acid Mist

(Including SO3) Concentration.

12.6 Sulfur Dioxide

Concentration.

12.8 Stack Gas Velocity

and Volumetric Flow Rate.

12.9 Relative Error

(RE) for QA Audit Samples.

14.0 Pollution

Prevention. [Reserved]

15.0 Waste Management.

[Reserved]

17.0 Tables, Diagrams,

Flowcharts, and Validation Data.

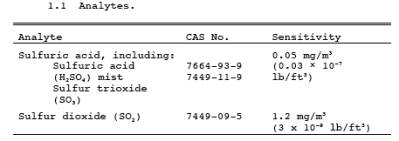

1.0 Scope and Application.

1.1 Analytes.

1.2 Applicability.

This method is

applicable for the determination of H2SO4 (including H2SO4 mist and SO3)

and gaseous SO2 emissions from stationary sources.

NOTE: Filterable particulate matter may be

determined along with H2SO4 and

SO2 (subject to the approval of the

Administrator) by inserting a heated glass fiber filter between the probe and

isopropanol impinger (see Section 6.1.1 of

Method 6). If this option is chosen, particulate analysis is gravimetric only;

sulfuric acid is not determined separately.

1.3 Data Quality Objectives.

Adherence to the

requirements of this method will enhance the quality of the data obtained from

air pollutant sampling methods.

2.0 Summary of Method.

A gas sample is

extracted isokinetically from the stack. The H2SO4 and the SO2 are

separated, and both fractions are measured separately by the barium-thorin

titration method.

3.0 Definitions. [Reserved]

4.0 Interferences.

4.1 Possible

interfering agents of this method are fluorides, free ammonia, and dimethyl

aniline. If any of these interfering agents is present (this can be determined

by knowledge of the process), alternative methods, subject to the approval of

the Administrator, are required.

5.0 Safety.

5.1 Disclaimer.

This method may

involve hazardous materials, operations, and equipment. This test method may

not address all of the safety problems associated with its use. It is the

responsibility of the user of this test method to establish appropriate safety

and health practices and determine the applicability of regulatory limitations

prior to performing this test method.

5.2 Corrosive reagents.

Same as Method 6, Section 5.2.

6.0 Equipment and Supplies.

6.1 Sample Collection.

Same as Method 5, Section 6.1, with the following

additions and exceptions:

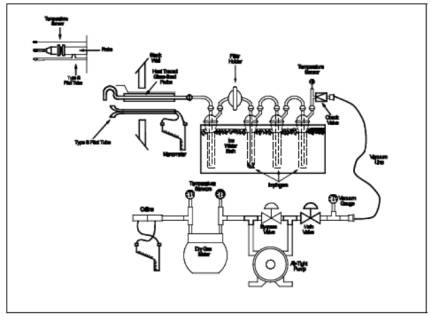

6.1.1 Sampling

Train. A schematic of the sampling train used in this method is shown in Figure

8-1; it is similar to the Method 5 sampling train, except that the filter

position is different, and the filter holder does not have to be heated. See

Method 5, Section 6.1.1, for details and guidelines on operation and

maintenance.

6.1.1.1 Probe

Liner. Borosilicate or quartz glass, with a heating system to prevent visible

condensation during sampling. Do not use metal probe liners.

6.1.1.2 Filter

Holder. Borosilicate glass, with a glass frit filter support and a silicone

rubber gasket. Other gasket materials (e.g., Teflon or Viton) may be used, subject to

the approval of the Administrator. The holder design shall provide a positive

seal against leakage from the outside or around the filter. The filter holder

shall be placed between the first and second impingers. Do not heat the filter

holder.

6.1.1.3 Impingers.

Four, of the Greenburg-Smith design, as shown in Figure

8-1. The first and third impingers must have standard tips. The second and

fourth impingers must be modified by replacing the insert with an approximately

13-mm (1/2-in.) ID glass tube, having an unconstricted tip located 13 mm (1/2

in.) from the bottom of the impinger. Similar collection systems, subject to

the approval of the Administrator, may be used.

6.1.1.4

Temperature Sensor. Thermometer, or equivalent, to measure the temperature of

the gas leaving the impinger train to within 1 ¡C (2 ¡F).

6.2 Sample Recovery.

The following

items are required for sample recovery:

6.2.1 Wash

Bottles. Two polyethylene or glass bottles, 500-ml.

6.2.2 Graduated

Cylinders. Two graduated cylinders (volumetric flasks may be used), 250-ml,

1-liter.

6.2.3 Storage

Bottles. Leak-free polyethylene bottles, 1-liter size (two for each sampling

run).

6.2.4 Trip

Balance. 500-g capacity, to measure to ± 0.5 g (necessary only if a moisture

content analysis is to be done).

6.3 Analysis.

The following

items are required for sample analysis:

6.3.1 Pipettes.

Volumetric 10-ml, 100-ml.

6.3.2 Burette.

50-ml.

6.3.3 Erlenmeyer

Flask. 250-ml (one for each sample, blank, and standard).

6.3.4 Graduated

Cylinder. 100-ml.

6.3.5 Dropping

Bottle. To add indicator solution, 125-ml size.

7.0 Reagents and Standards.

NOTE: Unless otherwise indicated, all reagents are

to conform to the specifications established by the Committee on Analytical

Reagents of the American Chemical Society, where such specifications are

available. Otherwise, use the best available grade.

7.1 Sample Collection.

The following

reagents are required for sample collection:

7.1.1 Filters and

Silica Gel. Same as in Method 5, Sections 7.1.1

and 7.1.2, respectively.

7.1.2 Water. Same

as in Method 6, Section 7.1.1.

7.1.3 Isopropanol,

80 Percent by Volume. Mix 800 ml of isopropanol with 200 ml of water.

NOTE: Check for peroxide impurities using the procedure

outlined in Method 6, Section 7.1.2.1.

7.1.4 Hydrogen

Peroxide (H2O2), 3

Percent by Volume. Dilute 100 ml of 30 percent H2O2 to 1 liter with water. Prepare fresh daily.

7.1.5 Crushed Ice.

7.2 Sample Recovery.

The reagents and

standards required for sample recovery are:

7.2.1 Water. Same

as in Section 7.1.2.

7.2.2 Isopropanol,

80 Percent. Same as in Section 7.1.3.

7.3 Sample Analysis.

Same as Method 6, Section 7.3.

7.3.1 Quality

Assurance Audit Samples. When making compliance determinations, and upon

availability, audit samples may be obtained from the appropriate EPA Regional

Office or from the responsible enforcement authority.

NOTE: The responsible enforcement authority should

be notified at least 30 days prior to the test date to allow sufficient time

for sample delivery.

8.0 Sample Collection, Preservation, Storage, and Transport.

8.1 Pretest Preparation.

Same as Method 5, Section 8.1, except that filters

should be inspected but need not be desiccated, weighed, or identified. If the

effluent gas can be considered dry (i.e., moisture-free), the silica gel need not be weighed.

8.2 Preliminary Determinations.

Same as Method 5, Section 8.2.

8.3 Preparation of Sampling Train.

Same as Method 5, Section 8.3, with the following

exceptions:

8.3.1 Use Figure 8-1 instead of Figure 5-1.

8.3.2 Replace the

second sentence of Method 5, Section 8.3.1 with: Place 100 ml of 80 percent

isopropanol in the first impinger, 100 ml of 3 percent H2O2 in

both the second and third impingers; retain a portion of each reagent for use

as a blank solution. Place about 200 g of silica gel in the fourth impinger.

8.3.3 Ignore any

other statements in Section 8.3 of Method 5 that are obviously not applicable

to the performance of Method 8.

NOTE: If moisture content is to be determined by

impinger analysis, weigh each of the first three impingers (plus absorbing

solution) to the nearest 0.5 g, and record these weights. Weigh also the silica

gel (or silica gel plus container) to the nearest 0.5 g, and record.)

8.4 Metering System Leak-Check Procedure.

Same as Method 5, Section 8.4.1.

8.5 Pretest Leak-Check Procedure.

Follow the basic

procedure in Method 5, Section 8.4.2, noting that the probe heater shall be

adjusted to the minimum temperature required to prevent condensation, and also

that verbiage such as "...plugging the inlet to the filter holder..."

found in Section 8.4.2.2 of Method 5 shall be replaced by "...plugging the

inlet to the first impinger...". The pretest leak-check is recommended,

but is not required.

8.6 Sampling Train Operation.

Follow the basic

procedures in Method 5, Section 8.5, in

conjunction with the following special instructions:

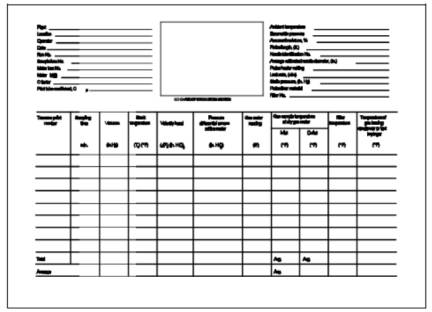

8.6.1 Record the

data on a sheet similar to that shown in Figure 8-2

(alternatively, Figure 5-2 in Method 5 may be

used). The sampling rate shall not exceed 0.030 m3/min

(1.0 cfm) during the run. Periodically during the test, observe the connecting

line between the probe and first impinger for signs of condensation. If

condensation does occur, adjust the probe heater setting upward to the minimum

temperature required to prevent condensation. If component changes become

necessary during a run, a leak-check shall be performed immediately before each

change, according to the procedure outlined in Section

8.4.3 of Method 5 (with appropriate modifications, as mentioned in Section

8.5 of this method); record all leak rates. If the leakage rate(s) exceeds the

specified rate, the tester shall either void the run or plan to correct the

sample volume as outlined in Section 12.3 of

Method 5. Leak-checks immediately after component changes are recommended,

but not required. If these leak-checks are performed, the procedure in Section

8.4.2 of Method 5 (with appropriate modifications) shall be used.

8.6.2 After

turning off the pump and recording the final readings at the conclusion of each

run, remove the probe from the stack. Conduct a post-test (mandatory)

leak-check as outlined in Section 8.4.4 of Method 5 (with appropriate

modifications), and record the leak rate. If the post-test leakage rate exceeds

the specified acceptable rate,

either correct the sample volume, as outlined in Section 12.3 of Method

5, or void the run.

8.6.3 Drain the

ice bath and, with the probe disconnected, purge the remaining part of the

train by drawing clean ambient air through the system for 15 minutes at the

average flow rate used for sampling.

NOTE: Clean ambient air can be provided by passing

air through a charcoal filter. Alternatively, ambient air (without cleaning)

may be used.

8.7 Calculation of Percent Isokinetic.

Same as Method 5, Section 8.6.

8.8 Sample Recovery.

Proper cleanup

procedure begins as soon as the probe is removed from the stack at the end of

the sampling period. Allow the probe to cool. Treat the samples as follows:

8.8.1 Container

No. 1.

8.8.1.1 If a

moisture content analysis is to be performed, clean and weigh the first

impinger (plus contents) to the nearest

0.5 g, and record this weight.

8.8.1.2 Transfer

the contents of the first impinger to a 250-ml graduated cylinder. Rinse the probe, first impinger,

all connecting glassware before the filter, and the front half of the filter

holder with 80 percent isopropanol. Add the isopropanol rinse solution to the

cylinder. Dilute the contents of the cylinder to 225 ml with 80 percent

isopropanol, and transfer the cylinder contents to the storage container. Rinse the cylinder with 25 ml of 80

percent isopropanol, and transfer the rinse to the storage container. Add the filter to the solution in the

storage container and mix. Seal the container to protect the solution against

evaporation. Mark the level of liquid on the container, and identify the sample

container.

8.8.2 Container

No. 2.

8.8.2.1 If a

moisture content analysis is to be performed, clean and weigh the second and

third impingers (plus contents) to the nearest 0.5 g, and record the weights. Also, weigh the spent silica

gel (or silica gel plus impinger) to the nearest 0.5 g, and record the weight.

8.8.2.2 Transfer

the solutions from the second and third impingers to a 1-liter graduated

cylinder. Rinse all connecting glassware (including back half of filter holder)

between the filter and silica gel impinger with water, and add this rinse water

to the cylinder. Dilute the contents of the cylinder to 950 ml with water.

Transfer the solution to a storage container. Rinse the cylinder with 50 ml of

water, and transfer the rinse to the storage container. Mark the level of liquid on the

container. Seal and identify the sample container.

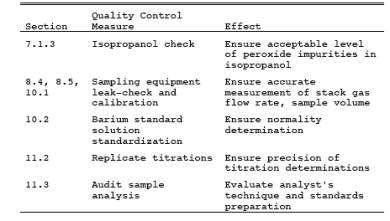

9.0 Quality Control.

9.1 Miscellaneous Quality Control Measures.

9.2 Volume Metering System Checks.

Same as Method 5, Section 9.2.

10.0 Calibration and Standardization.

10.1 Sampling

Equipment. Same as Method 5, Section 10.0.

10.2 Barium Standard

Solution. Same as Method 6, Section 10.5.

11.0 Analytical Procedure.

11.1. Sample Loss.

Same as Method 6, Section 11.1.

11.2. Sample Analysis.

11.2.1 Container

No. 1. Shake the container holding the isopropanol solution and the filter. If

the filter breaks up, allow the fragments to settle for a few minutes before

removing a sample aliquot. Pipette a 100-ml aliquot of this solution into a

250-ml Erlenmeyer flask, add 2 to 4 drops of thorin indicator, and titrate to a

pink endpoint using 0.0100 N barium standard solution. Repeat the titration

with a second aliquot of sample, and average the titration values. Replicate

titrations must agree within 1 percent or 0.2 ml, whichever is greater.

11.2.2 Container

No. 2. Thoroughly mix the solution in the container holding the contents of the

second and third impingers. Pipette a 10-ml aliquot of sample into a 250-ml Erlenmeyer

flask. Add 40 ml of isopropanol, 2 to 4 drops of thorin indicator, and titrate

to a pink endpoint using 0.0100 N barium standard solution. Repeat the

titration with a second aliquot of sample, and average the titration values.

Replicate titrations must agree within 1 percent or 0.2 ml, whichever is

greater.

11.2.3 Blanks.

Prepare blanks by adding 2 to 4 drops of thorin indicator to 100 ml of 80

percent isopropanol. Titrate the blanks in the same manner as the samples.

11.3 Audit Sample Analysis.

11.3.1 When the

method is used to analyze samples to demonstrate compliance with a source

emission regulation, EPA audit samples must be analyzed, subject to

availability.

11.3.2

Concurrently analyze audit samples and the compliance samples in the same

manner to evaluate the technique of the analyst and the standards preparation.

NOTE: It is recommended that known quality control

samples be analyzed prior to the compliance and audit sample analyses to

optimize the system accuracy and precision. These quality control samples may be obtained by contacting

the appropriate EPA regional Office or the responsible enforcement authority.

11.3.3 The same

analyst, analytical reagents, and analytical system shall be used for the

compliance samples and the EPA audit samples. If this condition is met,

duplicate auditing of subsequent compliance analyses for the same enforcement

agency within a 30-day period is waived.

Audit samples may not be used to validate different compliance samples

under the jurisdiction of separate enforcement agencies, unless prior

arrangements have been made with both enforcement agencies.

11.4 Audit Sample Results.

11.4.1 Calculate

the audit sample concentrations in mg/dscm and submit results using the

instructions provided with the audit samples.

11.4.2 Report the

results of the audit samples and the compliance determination samples along

with their identification numbers, and the analyst's name to the responsible

enforcement authority. Include this information with reports of any subsequent

compliance analyses for the same enforcement authority during the 30-day

period.

11.4.3 The

concentrations of the audit samples obtained by the analyst shall agree within

5 percent of the actual concentrations. If the 5 percent specification is not

met, reanalyze the compliance and audit samples, and include initial and

reanalysis values in the test report.

11.4.4 Failure to

meet the 5 percent specification may require retests until the audit problems

are resolved. However, if the

audit results do not affect the compliance or noncompliance status of the

affected facility, the Administrator may waive the reanalysis requirement,

further audits, or retests and accept the results of the compliance test. While

steps are being taken to resolve audit analysis problems, the Administrator may

also choose to use the data to determine the compliance or noncompliance status

of the affected facility.

12.0 Data Analysis and Calculations.

Carry out

calculations retaining at least one extra significant figure beyond that of the

acquired data. Round off figures after final calculation.

12.1 Nomenclature.

Same as Method 5, Section 12.1, with the following

additions and exceptions:

Ca = Actual concentration of SO2 in audit sample, mg/dscm.

Cd = Determined concentration of SO2 in audit sample, mg/dscm.

CH2SO4 = Sulfuric acid (including SO3) concentration, g/dscm (lb/dscf).

CSO2 = Sulfur dioxide concentration, g/dscm

(lb/dscf).

N = Normality of

barium perchlorate titrant, meq/ml.

RE = Relative

error of QA audit sample analysis, percent

Va = Volume of sample aliquot titrated, 100 ml

for H2SO4 and

10 ml for SO2.

Vsoln = Total volume of solution in which the

sample is contained, 250 ml for the SO2 sample

and 1000 ml for the H2SO4 sample.

Vt = Volume of barium standard solution titrant

used for the sample, ml.

Vtb = Volume of barium standard solution titrant

used for the blank, ml.

12.2 Average Dry Gas Meter Temperature and Average Orifice Pressure Drop.

See data sheet (Figure 8-2).

12.3 Dry Gas Volume.

Same as Method 5,

Section 12.3.

12.4 Volume of Water Vapor Condensed and Moisture Content.

Calculate the

volume of water vapor using Equation 5-2 of Method

5; the weight of water collected in the impingers and silica gel can be

converted directly to milliliters (the specific gravity of water is 1 g/ml).

Calculate the moisture content of the stack gas (Bws) using Equation 5-3 of Method 5. The NOTE

in Section 12.5 of Method 5 also applies to this

method. Note that if the effluent gas stream can be considered dry, the volume

of water vapor and moisture content need not be calculated.

12.5 Sulfuric Acid Mist (Including SO3)

Concentration.

![]()

where:

K3 = 0.04904 g/meq for metric units,

= 1.081 x 10-4 lb/meq for English units.

12.6 Sulfur Dioxide Concentration.

![]()

where:

K4 = 0.03203 g/meq for metric units,

= 7.061 x 10-5 lb/meq for English units.

12.7 Isokinetic Variation.

Same as Method 5, Section 12.11.

12.8 Stack Gas Velocity and Volumetric Flow Rate.

Calculate the average

stack gas velocity and volumetric flow rate, if needed, using data obtained in

this method and the equations in Sections 12.6

and 12.7 of Method 2.

12.9 Relative Error (RE) for QA Audit Samples.

Same as Method 6, Section 12.4.

13.0 Method Performance.

13.1 Analytical Range.

Collaborative

tests have shown that the minimum detectable limits of the method are 0.06 mg/m3 (4 x 10-9 lb/ft3) for H2SO4 and 1.2 mg/m3 (74

x 10-9 lb/ft3)

for SO2. No upper limits have been established.

Based on theoretical calculations for 200 ml of 3 percent H2O2 solution,

the upper concentration limit for SO2 in

a 1.0 m3 (35.3 ft3)

gas sample is about 12,000 mg/m3 (7.7 x 10-4 lb/ft3). The

upper limit can be extended by increasing the quantity of peroxide solution in

the impingers.

14.0 Pollution Prevention. [Reserved]

15.0 Waste Management. [Reserved]

16.0 References.

Same as Section 17.0 of Methods 5 and 6.

17.0 Tables, Diagrams, Flowcharts, and Validation Data.

Figure

8-1. Sulfuric Acid Sampling Train.