METHOD

16 - SEMICONTINUOUS DETERMINATION OF SULFUR EMISSIONS FROM STATIONARY SOURCES

NOTE: This method does not include all of the

specifications (e.g.,

equipment and supplies) and procedures (e.g., sampling and analytical) essential to its

performance. Some material is incorporated by reference from other methods in

this part. Therefore, to obtain reliable results, persons using this method

should have a thorough knowledge of at least the following additional test

methods: Method 1, Method 4,

Method 15, and Method 16A.

4.2 Carbon Monoxide

(CO) and Carbon Dioxide (CO2).

8.0 Sample Collection,

Preservation, Storage, and Transport.

10.0 Calibration and

Standardization.

12.0 Data Analysis and

Calculations.

14.0 Pollution

Prevention. [Reserved]

15.0 Waste Management.

[Reserved]

17.0 Tables, Diagrams,

Flowcharts, and Validation Data.

1.0 Scope and Application.

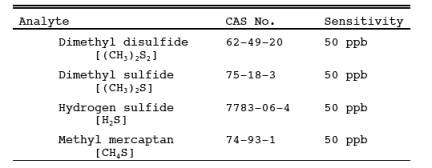

1.1 Analytes.

1.2 Applicability.

This method is

applicable for the determination of total reduced sulfur (TRS) compounds from

recovery furnaces, lime kilns, and smelt dissolving tanks at Kraft pulp mills

and fuel gas combustion devices at petroleum refineries.

NOTE: The method described below uses the principle of

gas chromatographic (GC) separation and flame photometric detection (FPD).

Since there are many systems or sets of operating conditions that represent

useable methods of determining sulfur emissions, all systems which employ this

principle, but differ only in details of equipment and operation, may be used

as alternative methods, provided that the calibration precision and sample line

loss criteria are met.

1.3 Data Quality Objectives.

Adherence to the requirements

of this method will enhance the quality of the data obtained from air pollutant

sampling methods.

2.0 Summary of Method.

2.1 A gas sample is

extracted from the emission source and an aliquot is analyzed for hydrogen

sulfide (H2S), methyl mercaptan (MeSH), dimethyl sulfide

(DMS), and dimethyl disulfide (DMDS) by GC/FPD. These four compounds are known

collectively as TRS.

3.0 Definitions. [Reserved]

4.0 Interferences.

4.1 Moisture.

Moisture condensation

in the sample delivery system, the analytical column, or the FPD burner block

can cause losses or interferences. This is prevented by maintaining the probe,

filter box, and connections at a temperature of at least 120 ûC (248 ûF). Moisture

is removed in the SO2

scrubber and heating the sample

beyond this point is not necessary when the ambient temperature is above 0 ûC

(32 ûF). Alternatively, moisture may be eliminated by heating the sample line,

and by conditioning the sample with dry dilution air to lower its dew point

below the operating temperature of the GC/FPD analytical system prior to

analysis.

4.2 Carbon Monoxide (CO) and Carbon Dioxide (CO2).

CO and CO2 have a substantial desensitizing effect on the flame photometric

detector even after dilution. Acceptable systems must demonstrate that they

have eliminated this interference by some procedure such as eluting these

compounds before any of the compounds to be measured. Compliance with this

requirement can be demonstrated by submitting chromatograms of calibration

gases with and without CO2

in the diluent gas. The CO2 level should be approximately 10 percent for the case with CO2 present. The two chromatograms should show agreement within the

precision limits of Section 10.2.

4.3 Particulate Matter.

Particulate matter in

gas samples can cause interference by eventual clogging of the analytical

system. This interference is eliminated by using the Teflon filter after the

probe.

4.4 Sulfur Dioxide (SO2).

Sulfur dioxide is not

a specific interferent but may be present in such large amounts that it cannot

effectively be separated from the other compounds of interest. The SO2 scrubber described in Section 6.1.3 will

effectively remove SO2

from the sample.

5.0 Safety.

5.1 Disclaimer.

This method may

involve hazardous materials, operations, and equipment. This test method may

not address all of the safety problems associated with its use. It is the

responsibility of the user of this test method to establish appropriate safety

and health practices and determine the applicability of regulatory limitations

prior to performing this test method.

5.2 Hydrogen Sulfide.

A flammable,

poisonous gas with the odor of rotten eggs. H2S is

extremely hazardous and can cause collapse, coma, and death within a few

seconds of one or two inhalations at sufficient concentrations. Low

concentrations irritate the mucous membranes and may cause nausea, dizziness,

and headache after exposure.

6.0 Equipment and Supplies.

6.1. Sample Collection.

The following items

are needed for sample collection.

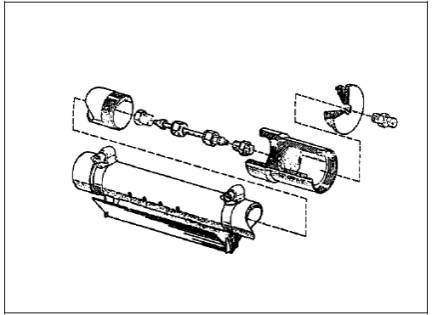

6.1.1 Probe.

Teflon or

Teflon-lined stainless steel. The probe must be heated to prevent moisture

condensation. It must be designed

to allow calibration gas to enter the probe at or near the sample point entry.

Any portion of the probe that contacts the stack gas must be heated to prevent

moisture condensation. Figure 16-1 illustrates the probe

used in lime kilns and other sources where significant amounts of particulate

matter are present. The probe is designed with the deflector shield placed

between the sample and the gas inlet holes to reduce clogging of the filter and

possible adsorption of sample gas. As an alternative, the probe described in Section 6.1.1 of Method 16A having a nozzle

directed away from the gas stream may be used at sources having significant

amounts of particulate matter.

6.1.2 Particulate Filter.

50-mm Teflon filter

holder and a 1- to 2-micron porosity Teflon filter (available through Savillex

Corporation, 5325 Highway 101, Minnetonka, Minnesota 55343). The filter holder

must be maintained in a hot box at a temperature of at least 120 ûC (248 ûF).

6.1.3 SO2 Scrubber.

Three 300-ml Teflon

segmented impingers connected in series with flexible, thick-walled, Teflon

tubing. (Impinger parts and tubing available through Savillex.) The first two

impingers contain 100 ml of citrate buffer and the third impinger is initially

dry. The tip of the tube inserted into the solution should be constricted to

less than 3 mm (1/8 in.) ID and should be immersed to a depth of at least 5 cm

(2 in.). Immerse the impingers in an ice water bath and maintain near 0 ûC (32

ûF). The scrubber solution will normally last for a 3-hour run before needing

replacement. This will depend upon the effects of moisture and particulate

matter on the solution strength and pH. Connections between the probe,

particulate filter, and SO2

scrubber must be made of Teflon and

as short in length as possible. All portions of the probe, particulate filter,

and connections prior to the SO2 scrubber (or

alternative point of moisture removal) must be maintained at a temperature of at

least 120 ûC (248 ûF).

6.1.4 Sample Line.

Teflon, no greater

than 1.3 cm (1/2 in.) ID. Alternative materials, such as virgin Nylon, may be

used provided the line loss test is acceptable.

6.1.5 Sample Pump.

The sample pump must

be a leakless Teflon-coated diaphragm type or equivalent.

6.2 Analysis.

The following items

are needed for sample analysis:

6.2.1 Dilution System. Needed only for high

sample concentrations. The dilution system must be constructed such that all

sample contacts are made of Teflon, glass, or stainless steel.

6.2.2 Gas

Chromatograph. The gas chromatograph must have at least the following

components:

6.2.2.1 Oven. Capable

of maintaining the separation column at the proper operating temperature ± 1 ûC

(2 ûF).

6.2.2.2 Temperature

Gauge. To monitor column oven, detector, and exhaust temperature ± 1 ûC (2 ûF).

6.2.2.3 Flow System.

Gas metering system to measure sample, fuel, combustion gas, and carrier gas

flows.

6.2.2.4 Flame

Photometric Detector.

6.2.2.4.1

Electrometer. Capable of full scale amplification of linear ranges of 10-9 to 10-4 amperes

full scale.

6.2.2.4.2 Power

Supply. Capable of delivering up to 750 volts.

6.2.2.4.3 Recorder.

Compatible with the output voltage range of the electrometer.

6.2.2.4.4 Rotary Gas

Valves. Multiport Teflon-lined valves equipped with sample loop. Sample loop

volumes must be chosen to provide the needed analytical range. Teflon tubing

and fittings must be used throughout to present an inert surface for sample

gas. The gas chromatograph must be calibrated with the sample loop used for

sample analysis.

6.2.3 Gas

Chromatogram Columns. The column system must be demonstrated to be capable of

resolving the four major reduced sulfur compounds: H2S, MeSH, DMS, and DMDS. It must also demonstrate freedom from known

interferences. To demonstrate that adequate resolution has been achieved, submit a chromatogram of a calibration

gas containing all four of the TRS compounds in the concentration range of the

applicable standard. Adequate resolution will be defined as base line

separation of adjacent peaks when the amplifier attenuation is set so that the

smaller peak is at least 50 percent of full scale. Baseline separation is

defined as a return to zero ±5 percent in the interval between peaks. Systems

not meeting this criteria may be considered alternate methods subject to the

approval of the Administrator.

6.3 Calibration.

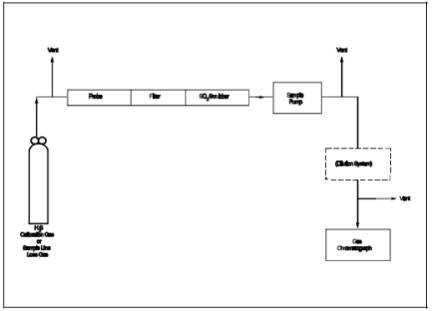

A calibration system,

containing the following components, is required (see Figure

16-2).

6.3.1 Tube Chamber.

Chamber of glass or Teflon of sufficient dimensions to house permeation tubes.

6.3.2 Flow System. To

measure air flow over permeation tubes at ±2 percent. Flow over the permeation

device may also be determined using a soap bubble flow meter.

6.3.3 Constant

Temperature Bath. Device capable of maintaining the permeation tubes at the

calibration temperature within 0.1 ûC (0.2 ûF).

6.3.4 Temperature

Gauge. Thermometer or equivalent to monitor bath temperature within 1 ûC (2

ûF).

7.0 Reagents and Standards.

7.1 Fuel. Hydrogen (H2), prepurified grade or better.

7.2 Combustion Gas.

Oxygen (O2) or air, research purity or better.

7.3 Carrier Gas.

Prepurified grade or better.

7.4 Diluent (if required).

Air containing less than 50 ppb total sulfur compounds and less than 10 ppmv

each of moisture and total hydrocarbons.

7.5 Calibration

Gases.

7.5.1 Permeation

tubes, one each of H2S, MeSH, DMS, and DMDS, gravimetrically

calibrated and certified at some convenient operating temperature. These tubes

consist of hermetically sealed FEP Teflon tubing in which a liquefied gaseous

substance is enclosed. The enclosed gas permeates through the tubing wall at a

constant rate. When the temperature is constant, calibration gases covering a

wide range of known concentrations can be generated by varying and accurately

measuring the flow rate of diluent gas passing over the tubes. These

calibration gases are used to calibrate the GC/FPD system and the dilution system.

7.5.2 Cylinder Gases.

Cylinder gases may be used as alternatives to permeation devices. The gases

must be traceable to a primary standard (such as permeation tubes) and not used

beyond the certification expiration date.

7.6 Citrate Buffer

and Sample Line Loss Gas. Same as Method 15,

Sections 7.6 and 7.7.

8.0 Sample Collection, Preservation, Storage, and

Transport.

Same as Method 15, Section 8.0, except that the references

to the dilution system may not be applicable.

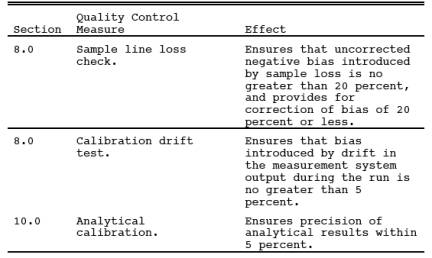

9.0 Quality Control.

10.0 Calibration and Standardization.

Same as Method 15, Section 10.0, with the following

addition and exceptions:

10.1 Use the four

compounds that comprise TRS instead of the three reduced sulfur compounds

measured by Method 15.

10.2

Flow Meter. Calibration before each test run is recommended, but not required;

calibration following each test series is mandatory. Calibrate each flow meter

after each complete test series with a wet-test meter. If the flow measuring

device differs from the wet-test meter by 5 percent or more, the completed test

runs must be voided. Alternatively, the flow data that yield the lower flow

measurement may be used. Flow over the permeation device may also be determined

using a soap bubble flow meter.

11.0 Analytical Procedure.

Sample collection and

analysis are concurrent for this method (see Section 8.0).

12.0 Data Analysis and Calculations.

12.1 Concentration of

Reduced Sulfur Compounds. Calculate the average concentration of each of the

four analytes (i.e., DMDS,

DMS, H2S, and MeSH) over the sample run (specified in Section 8.2 of Method 15 as 16 injections).

![]()

where:

Si = Concentration of any reduced sulfur compound from the ith sample injection, ppm.

C = Average

concentration of any one of the reduced sulfur compounds for the entire run,

ppm.

N = Number of injections

in any run period.

12.2 TRS

Concentration. Using Equation 16-2, calculate the TRS concentration for each

sample run.

![]()

where:

CTRS = TRS concentration, ppmv.

CH2S = Hydrogen sulfide concentration, ppmv.

CMeSH = Methyl mercaptan concentration, ppmv.

CDMS = Dimethyl sulfide concentration, ppmv.

CDMDS = Dimethyl disulfide concentration, ppmv.

d = Dilution factor,

dimensionless.

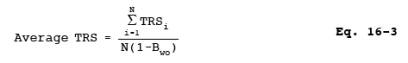

12.3 Average TRS

Concentration. Calculate the average TRS concentration for all sample runs

performed.

where:

Average TRS = Average

total reduced sulfur in ppm.

TRSi = Total reduced sulfur in ppm as determined by Equation 16-2.

N = Number of

samples.

Bwo = Fraction of volume of water vapor in the gas

stream as determined by Method 4 -Determination of Moisture in Stack Gases.

13.0 Method Performance.

13.1 Analytical

Range. The analytical range will vary with the sample loop size. Typically, the

analytical range may extend from 0.1 to 100 ppmv using 10- to 0.1-ml sample

loop sizes. This eliminates the need for sample dilution in most cases.

13.2 Sensitivity.

Using the 10-ml sample size, the minimum detectable concentration is

approximately 50 ppb.

14.0 Pollution Prevention. [Reserved]

15.0 Waste Management. [Reserved]

16.0 References.

1. O'Keeffe, A.E.,

and G.C. Ortman. "Primary Standards for Trace Gas Analysis."

Analytical Chemical Journal, 38,76. 1966.

2. Stevens, R.K.,

A.E. O'Keeffe, and G.C. Ortman. "Absolute Calibration of a Flame

Photometric Detector to Volatile Sulfur Compounds at Sub-Part-Per-Million Levels."

Environmental Science and Technology, 3:7. July 1969.

3. Mulik, J.D., R.K.

Stevens, and R. Baumgardner. "An Analytical System Designed to Measure

Multiple Malodorous Compounds Related to Kraft Mill Activities." Presented

at the 12th Conference on Methods in Air Pollution and Industrial Hygiene

Studies, University of Southern California, Los Angeles, CA. April 6-8, 1971.

4. Devonald, R.H.,

R.S. Serenius, and A.D. McIntyre. "Evaluation of the Flame Photometric

Detector for Analysis of Sulfur Compounds." Pulp and Paper Magazine of

Canada, 73,3. March 1972.

5. Grimley, K.W.,

W.S. Smith, and R.M. Martin. "The Use of a Dynamic Dilution System in the

Conditioning of Stack Gases for Automated Analysis by a Mobile Sampling

Van." Presented at the 63rd Annual APCA Meeting, St. Louis, MO. June

14-19, 1970.

6. General Reference.

Standard Methods of Chemical Analysis, Volumes III-A and III-B Instrumental

Methods. Sixth Edition. Van Nostrand Reinhold Co.

17.0 Tables, Diagrams, Flowcharts, and Validation Data.

Figure

16-1. Probe used for Sample Gas Containing High Particulate Matter Loading.

Figure

16-2. Calibration System.