METHOD 4 - DETERMINATION OF MOISTURE CONTENT IN STACK GASES

NOTE: This method does not include all the

specifications (e.g.,

equipment and supplies) and procedures (e.g., sampling) essential to its performance. Some

material is incorporated by reference from other methods in this part.

Therefore, to obtain reliable results, persons using this method should have a

thorough knowledge of at least the following additional test methods: Method 1, Method 5, and Method 6.

6.1.5 Barometer and

Graduated Cylinder and/or Balance.

6.2.9 Graduated

Cylinder. 25-ml.

7.0 Reagents and

Standards. [Reserved]

8.0 Sample Collection,

Preservation, Transport, and Storage.

8.1.1 Preliminary

Determinations.

8.1.2 Preparation of

Sampling Train.

8.1.4 Sampling Train

Operation.

10.0 Calibration and

Standardization.

12.0 Data Analysis and

Calculations.

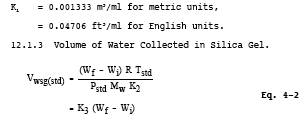

12.1.2 Volume of Water

Vapor Condensed.

12.1.3 Volume of Water Collected in Silica Gel

12.1.6 Verification of

Constant Sampling Rate.

12.1.7 In saturated or

moisture droplet-laden gas streams

12.2.2 Volume of Water

Vapor Collected.

12.2.4 Approximate

Moisture Content.

13.0 Method

Performance. [Reserved]

14.0 Pollution

Prevention. [Reserved]

15.0 Waste Management.

[Reserved]

18.0 Tables, Diagrams,

Flowcharts, and Validation Data.

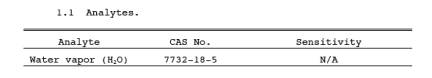

1.0 Scope and Application.

1.1 Analytes.

1.2 Applicability.

This method is

applicable for the determination of the moisture content of stack gas.

1.3 Data Quality Objectives.

Adherence to the

requirements of this method will enhance the quality of the data obtained from

air pollutant sampling methods.

2.0 Summary of Method.

2.1 A gas sample is

extracted at a constant rate from the source; moisture is removed from the

sample stream and determined either volumetrically or gravimetrically.

2.2 The method

contains two possible procedures: a reference method and an approximation

method.

2.2.1 The reference

method is used for accurate determinations of moisture content (such as are

needed to calculate emission data). The approximation method, provides

estimates of percent moisture to aid in setting isokinetic sampling rates prior

to a pollutant emission measurement run. The approximation method described

herein is only a suggested approach; alternative means for approximating the

moisture content (e.g.,

drying tubes, wet bulb-dry bulb techniques, condensation techniques,

stoichiometric calculations, previous experience, etc.) are also acceptable.

2.2.2 The reference

method is often conducted simultaneously with a pollutant emission measurement

run. When it is, calculation of percent isokinetic, pollutant emission rate,

etc., for the run shall be based upon the results of the reference method or

its equivalent. These calculations shall not be based upon the results of the

approximation method, unless the approximation method is shown, to the

satisfaction of the Administrator, to be

capable of yielding

results within one percent H2O of the reference

method.

3.0 Definitions. [Reserved]

4.0 Interferences.

4.1 The moisture

content of saturated gas streams or streams that contain water droplets, as

measured by the reference method, may be positively biased. Therefore, when

these conditions exist or are suspected, a second determination of the moisture

content shall be made simultaneously with the reference method, as

follows: Assume that the gas

stream is saturated. Attach a temperature sensor [capable of measuring to ±1 ¡C

(2 ¡F)] to the reference method probe. Measure the stack gas temperature at

each traverse point (see Section 8.1.1.1) during the

reference method traverse, and calculate the average stack gas temperature.

Next, determine the moisture percentage, either by: (1) using a psychrometric

chart and making appropriate corrections if the stack pressure is different

from that of the chart, or (2) using saturation vapor pressure tables. In cases

where the psychrometric chart or the saturation vapor pressure tables are not

applicable (based on evaluation of the process), alternative methods, subject

to the approval of the Administrator, shall be used.

5.0 Safety.

5.1 Disclaimer. This

method may involve hazardous materials, operations, and equipment. This test

method may not address all of the safety problems associated with its use. It

is the responsibility of the user of this test method to establish appropriate

safety and health practices and determine the applicability of regulatory

limitations prior to performing this test method.

6.0 Equipment and Supplies.

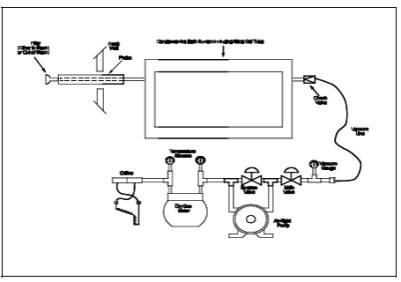

6.1 Reference Method.

A schematic of the

sampling train used in this reference method is shown in Figure

4-1.

6.1.1 Probe.

Stainless steel or

glass tubing, sufficiently heated to prevent water condensation, and equipped

with a filter, either in-stack (e.g., a plug of glass wool inserted into the end of the probe) or

heated out-of-stack (e.g.,

as described in Method 5), to remove particulate matter. When stack conditions

permit, other metals or plastic tubing may be used for the probe, subject to

the approval of the Administrator.

6.1.2 Condenser.

Same as Method 5, Section 6.1.1.8.

6.1.3 Cooling System.

An ice bath

container, crushed ice, and water (or equivalent), to aid in

condensingmoisture.

6.1.4 Metering System.

Same as in Method 5,

Section 6.1.1.9, except do not use sampling systems designed for flow rates

higher than 0.0283 m3/min (1.0 cfm). Other metering systems, capable

of maintaining a constant sampling rate to within 10 percent and determining

sample gas volume to within 2 percent, may be used, subject to the approval of

the Administrator.

6.1.5 Barometer and Graduated Cylinder and/or Balance.

Same as Method 5, Sections 6.1.2 and 6.2.5,

respectively.

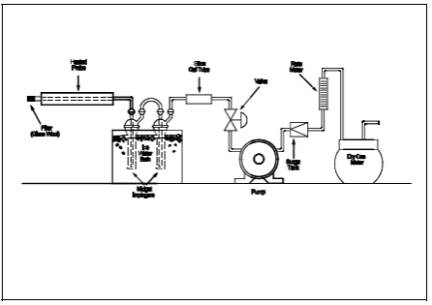

6.2. Approximation Method.

A schematic of the

sampling train used in this approximation method is shown in Figure

4-2.

6.2.1 Probe.

Same as Section

6.1.1.

6.2.2 Condenser.

Two midget impingers,

each with 30-ml capacity, or equivalent.

6.2.3 Cooling System.

Ice bath container,

crushed ice, and water, to aid in condensing moisture in impingers.

6.2.4 Drying Tube.

Tube packed with new

or regenerated 6- to 16-mesh indicating-type silica gel (or equivalent

desiccant), to dry the sample gas and to protect the meter and pump.

6.2.5 Valve.

Needle valve, to

regulate the sample gas flow rate.

6.2.6 Pump.

Leak-free, diaphragm

type, or equivalent, to pull the gas sample through the train.

6.2.7 Volume Meter.

Dry gas meter,

sufficiently accurate to measure the sample volume to within 2 percent, and

calibrated over the range of flow rates and conditions actually encountered

during sampling.

6.2.8 Rate Meter.

Rotameter, or equivalent,

to measure the flow range from 0 to 3 liters/min (0 to 0.11cfm).

6.2.9 Graduated Cylinder. 25-ml.

6.2.10 Barometer.

Same as Method 5,

Section 6.1.2.

6.2.11 Vacuum Gauge.

At least 760-mm

(30-in.) Hg gauge, to be used for the sampling leak check.

7.0 Reagents and Standards. [Reserved]

8.0 Sample Collection, Preservation, Transport, and Storage.

8.1 Reference Method.

The following

procedure is intended for a condenser system (such as the impinger system

described in Section 6.1.1.8 of Method 5) incorporating volumetric analysis to

measure the condensed moisture, and silica gel and gravimetric analysis to

measure the moisture leaving the condenser.

8.1.1 Preliminary Determinations.

8.1.1.1

Unless otherwise specified by the Administrator, a minimum of eight traverse

points shall be used for circular stacks having diameters less than 0.61 m (24

in.), a minimum of nine points shall be used for rectangular stacks having

equivalent diameters less than 0.61 m (24 in.), and a minimum of twelve

traverse points shall be used in all other cases. The traverse points shall be

located according to Method 1. The use of fewer points is subject to the

approval of the Administrator. Select a suitable probe and probe length such

that all traverse points can be sampled. Consider sampling from opposite sides

of the stack (four total sampling ports) for large stacks, to permit use of

shorter probe lengths. Mark the probe with heat resistant tape or by some other

method to

denote the proper

distance into the stack or duct for each sampling point.

8.1.1.2 Select a

total sampling time such that a minimum total gas volume of 0.60 scm (21 scf)

will be collected, at a rate no greater than 0.021 m3/min (0.75 cfm). When both moisture content and pollutant emission

rate are to be determined, the moisture determination shall be simultaneous

with, and for the same total length of time as, the pollutant emission rate

run, unless otherwise specified in an applicable subpart of the standards.

8.1.2 Preparation of Sampling Train.

8.1.2.1 Place known

volumes of water in the first two impingers; alternatively, transfer water into

the first two impingers and record the weight of each impinger (plus water) to

the nearest 0.5 g. Weigh and record the weight of the silica gel to the nearest

0.5 g, and transfer the silica gel to the fourth impinger; alternatively, the

silica gel may first be transferred to the impinger, and the weight of the

silica gel plus impinger recorded.

8.1.2.2 Set up the

sampling train as shown in Figure 4-1. Turn on the probe heater and (if

applicable) the filter heating system to temperatures of approximately 120 ¡C

(248 ¡F), to prevent water condensation ahead of the condenser. Allow time for

the temperatures to stabilize. Place crushed ice and water in the ice bath

container.

8.1.3 Leak Check Procedures.

It is recommended,

but not required, that the volume metering system and sampling train be

leak-checked as follows:

8.1.3.1 Metering

System. Same as Method 5, Section 8.4.1.

8.1.3.2 Sampling

Train. Disconnect the probe from the first impinger or (if applicable) from the

filter holder. Plug the inlet to the first impinger (or filter holder), and pull

a 380 mm (15 in.) Hg vacuum. A lower vacuum may be used, provided that it is

not exceeded during the test. A leakage rate in excess of 4 percent of the

average sampling rate or 0.00057 m3/min

(0.020 cfm), whichever is less, is unacceptable. Following the leak check,

reconnect the probe to the sampling train.

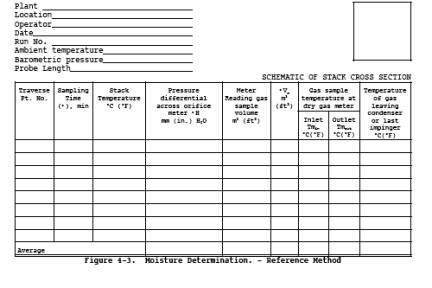

8.1.4 Sampling Train Operation.

During the sampling

run, maintain a sampling rate within 10 percent of constant rate, or as

specified by the Administrator. For each run, record the data required on a

data sheet similar to that shown in Figure 4-3. Be sure

to record the dry gas meter reading at the beginning and end of each sampling

time increment and whenever sampling is halted. Take other appropriate readings

at each sample point at least once during each time increment.

NOTE: When Method 4 is used concurrently with an

isokinetic method (e.g.,

Method 5) the sampling rate should be maintained at isokinetic conditions

rather than 10 percent of constant rate.

8.1.4.1 To begin

sampling, position the probe tip at the first traverse point. Immediately start

the pump, and adjust the flow to the desired rate. Traverse the cross section,

sampling at each traverse point for an equal length of time. Add more ice and,

if necessary, salt to maintain a temperature of less than 20 ¡C (68 ¡F) at the

silica gel outlet.

8.1.4.2 After

collecting the sample, disconnect the probe from the first impinger (or from

the filter holder), and conduct a leak check (mandatory) of the sampling train

as described in Section 8.1.3.2. Record the leak rate. If the leakage rate

exceeds the allowable rate, either reject the test results or correct the

sample volume as in Section 12.3 of Method 5.

8.2 Approximation Method.

NOTE: The approximation method described below is

presented only as a suggested method (see Section 2.0).

8.2.1 Place exactly 5

ml water in each impinger. Leak check the sampling train as follows:

Temporarily insert a vacuum gauge at or near the probe inlet. Then, plug the

probe inlet and pull a vacuum of at least 250 mm (10 in.) Hg. Note the time

rate of change of the dry gas meter dial; alternatively, a rotameter (0 to 40

ml/min) may be temporarily attached to the dry gas meter outlet to determine

the leakage rate. A leak rate not in excess of 2 percent of the average

sampling rate is acceptable.

NOTE: Release the probe inlet plug slowly before

turning off the pump.

8.2.2 Connect the

probe, insert it into the stack, and sample at a constant rate of 2 liters/min

(0.071 cfm). Continue sampling until the dry gas meter registers about 30

liters (1.1 ft3) or until visible liquid droplets are carried

over from the first impinger to the second. Record temperature, pressure, and

dry gas meter readings as indicated by Figure 4-4.

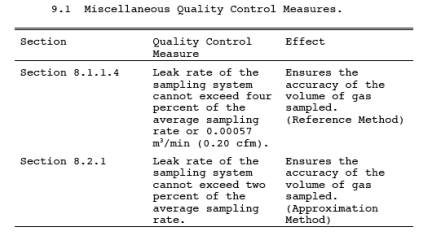

9.0 Quality Control.

9.1 Miscellaneous

Quality Control Measures.

9.2 Volume Metering

System Checks. Same as Method 5, Section 9.2.

10.0 Calibration and Standardization.

NOTE: Maintain a laboratory log of all calibrations.

10.1 Reference Method.

Calibrate the

metering system, temperature sensors, and barometer according to Method 5, Sections 10.3, 10.5, and 10.6,

respectively.

10.2 Approximation Method.

Calibrate the

metering system and the barometer according to Method

6, Section 10.1 and Method 5, Section 10.6,

respectively.

11.0 Analytical Procedure.

11.1 Reference

Method. Measure the volume of the moisture condensed in each of the impingers

to the nearest ml. Alternatively, if the impingers were weighed prior to

sampling, weigh the impingers after sampling and record the difference in

weight to the nearest 0.5 g. Determine the increase in weight of the silica gel

(or silica gel plus impinger) to the nearest 0.5 g. Record this information

(see example data sheet, Figure 4-5), and calculate the

moisture content, as described in Section 12.0.

11.2 Approximation

Method. Combine the contents of the two impingers, and measure the volume to

the nearest 0.5 ml.

12.0 Data Analysis and Calculations.

Carry out the

following calculations, retaining at least one extra significant figure beyond

that of the acquired data. Round off figures after final calculation.

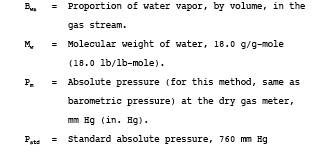

12.1 Reference Method

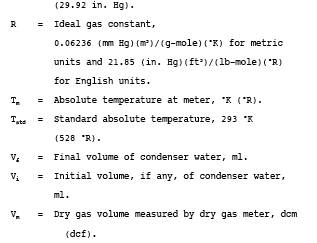

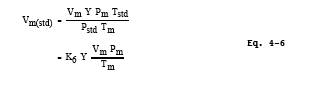

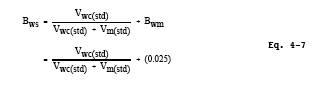

12.1.1 Nomenclature.

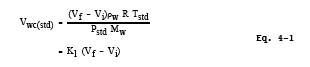

12.1.2 Volume of Water Vapor Condensed.

where:

where:

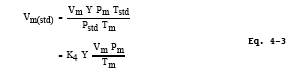

12.1.4 Sample Gas Volume.

K4 = 0.3855 ¡K/mm Hg for metric units,

= 17.64 ¡R/in. Hg for

English units.

NOTE: If the post-test leak rate (Section 8.1.4.2)

exceeds the allowable rate, correct the value of Vm in Equation 4-3, as described in Section

12.3 of Method 5.

12.1.5 Moisture Content.

![]()

12.1.6 Verification of Constant Sampling Rate.

For each time

increment, determine the áVm. Calculate the

average. If the value for any time increment differs from the average by more

than 10 percent, reject the results, and repeat the run.

12.1.7 In saturated or moisture droplet-laden gas streams

Two calculations of

the moisture content of the stack gas shall be made, one using a value based

upon the saturated conditions (see Section 4.1), and another based upon the

results of the impinger analysis. The lower of these two values of Bws shall be considered correct.

12.2 Approximation Method.

The approximation

method presented is designed to estimate the moisture in the stack gas;

therefore, other data, which are only necessary for accurate moisture

determinations, are not collected. The following equations adequately estimate

the moisture content for the purpose of determining isokinetic sampling rate

settings.

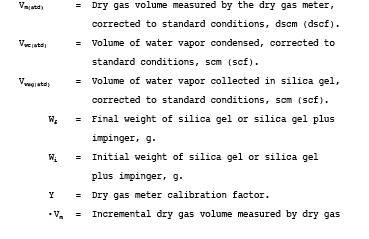

12.2.1 Nomenclature.

Bwm = Approximate proportion by volume of water

vapor in the gas stream leaving the second impinger, 0.025.

Bws = Water vapor in the gas stream, proportion by

volume.

Mw = Molecular weight of water, 18.0 g/g-mole (18.0 lb/lb-mole).

Pm = Absolute pressure (for this method, same as barometric pressure)

at the dry gas meter, mm Hg (in. Hg).

Pstd = Standard absolute pressure, 760 mm Hg (29.92

in. Hg).

R = Ideal gas

constant, 0.06236 [(mm Hg)(m3)]/[(g-mole)(K)] for

metric units and

21.85 [(in. Hg)(ft3)]/[(lb-mole)(¡R)] for English units.

Tm = Absolute temperature at meter, ¡K (¡R).

Tstd = Standard absolute temperature, 293 ¡K (528

¡R).

Vf = Final volume of impinger contents, ml.

Vi = Initial volume of impinger contents, ml.

Vm = Dry gas volume measured by dry gas meter, dcm (dcf).

Vm(std) = Dry gas volume measured by dry gas meter,

corrected to standard conditions, dscm (dscf).

Vwc(std) = Volume of water vapor condensed, corrected to

standard conditions, scm (scf).

Y = Dry gas meter

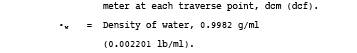

calibration factor.

![]()

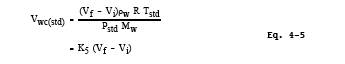

12.2.2 Volume of Water Vapor Collected.

where:

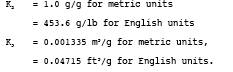

K5 = 0.001333 m3/ml for metric units,

= 0.04706 ft3/ml for English units.

12.2.3 Sample Gas Volume.

where:

K6 = 0.3855 ¡K/mm Hg for metric units,

= 17.64 ¡R/in. Hg for English

units.

12.2.4 Approximate Moisture Content.

13.0 Method Performance. [Reserved]

14.0 Pollution Prevention. [Reserved]

15.0 Waste Management. [Reserved]

16.0 Alternative Procedures.

The procedure

described in Method 5 for determining moisture content is acceptable as a

reference method.

17.0 References.

1. Air Pollution

Engineering Manual (Second Edition). Danielson, J.A. (ed.). U.S. Environmental

Protection Agency, Office of Air Quality Planning and Standards. Research

Triangle Park, NC. Publication No. AP-40. 1973.

2. Devorkin, Howard,

et al. Air Pollution Source Testing Manual. Air Pollution Control District, Los

Angeles, CA. November 1963.

3. Methods for

Determination of Velocity, Volume, Dust and Mist Content of Gases. Western Precipitation

Division of Joy Manufacturing Co. Los Angeles, CA. Bulletin WP-50.1968.

18.0 Tables, Diagrams, Flowcharts, and Validation Data.

Figure

4-1. Moisture Sampling Train -

Reference Method

Figure

4-2. Moisture Sampling Train -

Approximation Method.