METHOD

1 - SAMPLE AND VELOCITY TRAVERSES FOR STATIONARY SOURCES

NOTE: This method does not include all of the

specifications (e.g.,

equipment and supplies) and procedures (e.g., sampling) essential to its performance. Some

material is incorporated by reference from other methods in this part. Therefore,

to obtain reliable results, persons using this method should have a thorough

knowledge of at least the following additional test method: Method

2.

6.1.2 Differential Pressure

Gauges.

7.0 Reagents and Standards.

[Reserved]

8.0 Sample Collection,

Preservation, Storage, and Transport. [Reserved]

9.0 Quality Control.

[Reserved]

10.0 Calibration and

Standardization. [Reserved]

11.1 Selection of Measurement

Site.

11.2 Determining the Number of

Traverse Points.

11.2.2 Velocity

(Non-Particulate) Traverses.

11.3 Cross-Sectional Layout

and Location of Traverse Points.

11.3.2 Stacks With Diameters

Greater Than 0.61 m (24 in.).

11.3.3 Stacks With Diameters

Equal To or Less Than 0.61 m (24 in.).

11.4 Verification of Absence

of Cyclonic Flow.

11.5 The Alternative Site

Selection

11.5.1 Alternative Measurement

Site Selection Procedure.

12.0 Data Analysis and

Calculations.

12.2 For a rectangular cross

section

12.3 If use of the alternative

site selection procedure (Section 11.5 of this method) is required

13.0 Method Performance.

[Reserved]

14.0 Pollution Prevention.

[Reserved]

15.0 Waste Management.

[Reserved]

17.0 Tables, Diagrams,

Flowcharts, and Validation Data.

1.0 Scope and Application.

1.1 Measured Parameters.

The purpose of the

method is to provide guidance for the selection of sampling ports and traverse

points at which sampling for air pollutants will be performed pursuant to

regulations set forth in this part. Two procedures are presented: a simplified

procedure, and an alternative procedure (see Section 11.5).

The magnitude of cyclonic flow of effluent gas in a stack or duct is the only

parameter quantitatively measured in the simplified procedure.

1.2 Applicability.

This method is applicable

to gas streams flowing in ducts, stacks, and flues. This method cannot be used

when: (1) the flow is cyclonic or swirling; or (2) a stack is smaller than 0.30

meter (12 in.) in diameter, or 0.071 m2 (113 in.2) in cross-sectional area. The simplified procedure cannot be used

when the measurement site is less than two stack or duct diameters downstream

or less than a half diameter upstream from a flow disturbance.

1.3 Data Quality Objectives.

Adherence to the

requirements of this method will enhance the quality of the data obtained from

air pollutant sampling methods.

NOTE: The requirements of this method must be

considered before construction of a new facility from which emissions are to be

measured; failure to do so may require subsequent alterations to the stack or

deviation from the standard procedure. Cases involving variants are subject to

approval by the Administrator.

2.0 Summary of Method.

2.1 This method is

designed to aid in the representative measurement of pollutant emissions and/or

total volumetric flow rate from a stationary source. A measurement site where

the effluent stream is flowing in a known direction is selected, and the

cross-section of the stack is divided into a number of equal areas. Traverse

points are then located within each of these equal areas.

3.0 Definitions. [Reserved]

4.0 Interferences. [Reserved]

5.0 Safety.

5.1 Disclaimer.

This method may

involve hazardous materials, operations, and equipment. This test method may

not address all of the safety problems associated with its use. It is the

responsibility of the user of this test method to establish appropriate safety

and health practices and determine the applicability of regulatory limitations prior

to performing this test method.

6.0 Equipment and Supplies.

6.1 Apparatus.

The apparatus

described below is required only when utilizing the alternative site selection

procedure described in Section 11.5 of this method.

6.1.1 Directional Probe.

Any directional

probe, such as United Sensor Type DA Three-Dimensional Directional Probe,

capable of measuring both the pitch and yaw angles of gas flows is acceptable.

Before using the probe, assign an identification number to the directional

probe, and permanently mark or engrave the number on the body of the probe. The

pressure holes of directional probes are susceptible to plugging when used in

particulate-laden gas streams. Therefore, a procedure for cleaning the pressure

holes by "back-purging" with pressurized air is required.

6.1.2 Differential Pressure Gauges.

Inclined manometers,

U-tube manometers, or other differential pressure gauges (e.g., magnehelic gauges) that meet the

specifications described in Method

2, Section 6.2.

NOTE: If the differential pressure gauge produces both

negative and positive readings, then both negative and positive pressure

readings shall be calibrated at a minimum of three points as specified in

Method 2, Section 6.2.

7.0 Reagents and Standards. [Reserved]

8.0 Sample Collection, Preservation, Storage, and Transport. [Reserved]

9.0 Quality Control. [Reserved]

10.0 Calibration and Standardization. [Reserved]

11.0 Procedure.

11.1 Selection of Measurement Site.

11.1.1

Sampling and/or velocity measurements are performed at a site located at least

eight stack or duct diameters downstream and two diameters upstream from any

flow disturbance such as a bend, expansion, or contraction in the stack, or

from a visible flame. If necessary, an alternative location may be selected, at

a position at least two stack or duct diameters downstream and a half diameter

upstream from any flow disturbance.

11.1.2 An alternative

procedure is available for determining the acceptability of a measurement

location not meeting the criteria above. This procedure described in Section

11.5 allows for the determination of gas flow angles at the sampling points and

comparison of the measured results with acceptability criteria.

11.2 Determining the Number of Traverse Points.

11.2.1 Particulate Traverses.

11.2.1.1 When the

eight- and two-diameter criterion can be met, the minimum number of traverse

points shall be: (1) twelve, for circular or rectangular stacks with diameters

(or equivalent diameters) greater than 0.61 meter (24 in.); (2) eight, for

circular stacks with diameters between 0.30 and 0.61 meter (12 and 24 in.); and

(3) nine, for rectangular stacks with equivalent diameters between 0.30 and

0.61 meter (12 and 24 in.).

11.2.1.2 When the

eight- and two-diameter criterion cannot be met, the minimum number of traverse

points is determined from Figure 1-1. Before referring to

the figure, however, determine the distances from the measurement site to the

nearest upstream and downstream disturbances, and divide each distance by the

stack diameter or equivalent diameter, to determine the distance in terms of

the number of duct diameters. Then, determine from Figure 1-1 the minimum

number of traverse points that corresponds: (1) to the number of duct diameters

upstream; and (2) to the number of diameters downstream. Select the higher of

the two minimum numbers of traverse points, or a greater value, so that for

circular stacks the number is a multiple of 4, and for rectangular stacks, the

number is one of those shown in Table 1-1.

11.2.2 Velocity (Non-Particulate) Traverses.

When velocity or

volumetric flow rate is to be determined (but not particulate matter), the same

procedure as that used for particulate traverses (Section 11.2.1) is followed,

except that Figure 1-2 may be used instead of Figure 1-1.

11.3 Cross-Sectional Layout and Location of

Traverse Points.

11.3.1 Circular Stacks.

11.3.1.1 Locate the

traverse points on two perpendicular diameters according to Table

1-2 and the example shown in Figure 1-3. Any equation

(see examples in References 2 and 3 in Section 16.0) that

gives the same values as those in Table 1-2 may be used in lieu of Table 1-2.

11.3.1.2 For

particulate traverses, one of the diameters must coincide with the plane

containing the greatest expected concentration variation (e.g., after bends); one diameter shall be congruent

to the direction of the bend. This requirement becomes less critical as the

distance from the disturbance increases; therefore, other diameter locations

may be used, subject to the approval of the Administrator.

11.3.1.3 In addition,

for elliptical stacks having unequal perpendicular diameters, separate traverse

points shall be calculated and located along each diameter. To determine the

cross-sectional area of the elliptical stack, use the following equation:

Square Area = D1

X D2 X

0.7854

Where: D1

= Stack diameter 1

D2 = Stack diameter 2

11.3.1.4 In addition,

for stacks having diameters greater than 0.61 m (24 in.), no traverse points

shall be within 2.5 centimeters (1.00 in.) of the stack walls; and for stack

diameters equal to or less than 0.61 m (24 in.), no traverse points shall be

located within 1.3 cm (0.50 in.) of the stack walls. To meet these criteria,

observe the procedures given below.

11.3.2 Stacks With Diameters Greater Than 0.61 m (24 in.).

11.3.2.1 When any of

the traverse points as located in Section 11.3.1 fall within 2.5 cm (1.0 in.)

of the stack walls, relocate them away from the stack walls to: (1) a distance

of 2.5 cm (1.0 in.); or (2) a distance equal to the nozzle inside diameter,

whichever is larger. These relocated traverse points (on each end of a

diameter) shall be the "adjusted" traverse points.

11.3.2.2 Whenever two

successive traverse points are combined to form a single adjusted traverse

point, treat the adjusted point as two separate traverse points, both in the

sampling and/or velocity measurement procedure, and in recording of the data.

11.3.3 Stacks With Diameters Equal To or Less Than 0.61 m (24 in.).

Follow the procedure

in Section 11.3.1.1, noting only that any "adjusted" points should be

relocated away from the stack walls to: (1) a distance of 1.3 cm (0.50 in.); or

(2) a distance equal to the nozzle inside diameter, whichever is larger.

11.3.4 Rectangular Stacks.

11.3.4.1 Determine

the number of traverse points as explained in Sections 11.1 and 11.2 of this

method. From Table 1-1, determine the grid configuration. Divide the stack cross-section

into as many equal rectangular elemental areas as traverse points, and then

locate a traverse point at the centroid of each equal area according to the

example in Figure 1-4.

11.3.4.2 To use more

than the minimum number of traverse points, expand the "minimum number of

traverse points" matrix (see Table 1-1) by adding the extra traverse

points along one or the other or both legs of the matrix; the final matrix need

not be balanced. For example, if a 4 x 3 "minimum number of points"

matrix were expanded to 36 points, the final matrix could be 9 x 4 or 12 x 3,

and would not necessarily have to be 6 x 6. After constructing the final

matrix, divide the stack cross-section into as many equal rectangular, elemental

areas as traverse points, and locate a traverse point at the centroid of each

equal area.

11.3.4.3 The

situation of traverse points being too close to the stack walls is not expected

to arise with rectangular stacks. If this problem should ever arise, the Administrator

must be contacted for resolution of the matter.

11.4 Verification of Absence of Cyclonic Flow.

11.4.1 In most

stationary sources, the direction of stack gas flow is essentially parallel to

the stack walls. However, cyclonic flow may exist (1) after such devices as

cyclones and inertial demisters following venturi scrubbers, or (2) in stacks

having tangential inlets or other duct configurations which tend to induce

swirling; in these instances, the presence or absence of cyclonic flow at the sampling

location must be determined. The following techniques are acceptable for this

determination.

11.4.2 Level and zero

the manometer. Connect a Type S pitot tube to the manometer and leak-check

system. Position the Type S pitot tube at each traverse point, in succession,

so that the planes of the face openings of the pitot tube are perpendicular to

the stack cross-sectional plane; when the Type S pitot tube is in this

position, it is at "0¡ reference." Note the differential pressure

(¥p) reading at each traverse point. If a null (zero) pitot reading is obtained

at 0¡ reference at a given traverse point, an acceptable flow condition exists

at that point. If the pitot reading is not zero at 0¡ reference, rotate the

pitot tube (up to ±90¡ yaw angle), until a null reading is obtained. Carefully

determine and record the value of the rotation angle (¥) to the nearest degree.

After the null technique has been applied at each traverse point, calculate the

average of the absolute values of ¥; assign ¥ values of 0¡ to those points for

which no rotation was required, and include these in the overall average. If

the average value of ¥ is greater than 20¡, the overall flow condition in the

stack is unacceptable, and alternative methodology, subject to the approval of the

Administrator, must be used to perform accurate sample and velocity traverses.

11.5 The Alternative Site Selection

The alternative site

selection procedure may be used to determine the rotation angles in lieu of the

procedure outlined in Section 11.4.

11.5.1 Alternative Measurement Site Selection Procedure.

This alternative

applies to sources where measurement locations are less than 2 equivalent or

duct diameters downstream or less than one-half duct diameter upstream from a

flow disturbance. The alternative should be limited to ducts larger than 24 in.

in diameter where blockage and wall effects are minimal. A directional

flowsensing probe is used to measure pitch and yaw angles of the gas flow at 40

or more traverse points; the resultant angle is calculated and compared with

acceptable criteria for mean and standard deviation.

NOTE: Both the pitch and yaw angles are measured from

a line passing through the traverse point and parallel to the stack axis. The

pitch angle is the angle of the gas flow component in the plane that INCLUDES

the traverse line and is parallel to the stack axis. The yaw angle is the angle

of the gas flow component in the plane PERPENDICULAR to the traverse line at

the traverse point and is measured from the line passing through the traverse

point and parallel to the stack axis.

11.5.2 Traverse Points.

Use a minimum of 40

traverse points for circular ducts and 42 points for rectangular ducts for the

gas flow angle determinations. Follow the procedure outlined in Section 11.3

and Table 1-1 or 1-2 for the location and layout of the traverse points. If the

measurement location is determined to be acceptable according to the criteria

in this alternative procedure, use the same traverse point number and locations

for sampling and velocity measurements.

11.5.3 Measurement Procedure.

11.5.3.1 Prepare the

directional probe and differential pressure gauges as recommended by the

manufacturer. Capillary tubing or surge tanks may be used to dampen pressure

fluctuations. It is recommended, but not required, that a pretest leak check be

conducted. To perform a leak check, pressurize or use suction on the impact

opening until a reading of at least 7.6 cm (3 in.) H20 registers on the differential pressure gauge, then plug the

impact opening. The pressure of a leak-free system will remain stable for at

least 15 seconds.

11.5.3.2 Level and

zero the manometers. Since the manometer level and zero may drift because of

vibrations and temperature changes, periodically check the level and zero

during the traverse.

11.5.3.3 Position the

probe at the appropriate locations in the gas stream, and rotate until zero

deflection is indicated for the yaw angle pressure gauge. Determine and record

the yaw angle. Record the pressure gauge readings for the pitch angle, and

determine the pitch angle from the calibration curve. Repeat this procedure for

each traverse point. Complete a "back-purge" of the pressure lines

and the impact openings prior to measurements of each traverse point.

11.5.3.4 A post-test

check as described in Section 11.5.3.1 is required. If the criteria for a

leak-free system are not met, repair the equipment, and repeat the flow angle

measurements.

11.5.4 Calibration.

Use a flow system as

described in Sections 10.1.2.1 and 10.1.2.2 of Method 2. In addition, the flow

system shall have the capacity to generate two test-section velocities: one

between 365 and 730 m/min (1,200 and 2,400 ft/min) and one between 730 and

1,100 m/min (2,400 and 3,600 ft/min).

11.5.4.1 Cut two

entry ports in the test section. The axes through the entry ports shall be

perpendicular to each other and intersect in the centroid of the test section.

The ports should be elongated slots parallel to the axis of the test section

and of sufficient length to allow measurement of pitch angles while maintaining

the pitot head position at the test-section centroid. To facilitate alignment

of the directional probe during calibration, the test section should be

constructed of plexiglass or some other transparent material. All calibration

measurements should be made at the same point in the test section, preferably

at the centroid of the test section.

11.5.4.2 To ensure

that the gas flow is parallel to the central axis of the test section, follow

the procedure outlined in Section 11.4 for cyclonic flow determination to

measure the gas flow angles at the centroid of the test section from two test

ports located 90¡ apart. The gas flow angle measured in each port must be ± 2¡

of 0¡. Straightening vanes should be installed, if necessary, to meet this

criterion.

11.5.4.3 Pitch Angle

Calibration. Perform a calibration traverse according to the manufacturer's

recommended protocol in 5¡ increments for angles from -60¡ to +60¡ at one

velocity in each of the two ranges specified above. Average the pressure ratio

values obtained for each angle in the two flow ranges, and plot a calibration

curve with the average values of the pressure ratio (or other suitable

measurement factor as recommended by the manufacturer) versus the pitch angle.

Draw a smooth line through the data points. Plot also the data values for each

traverse point. Determine the differences between the measured data values and

the angle from the calibration curve at the same pressure ratio. The difference

at each comparison must be within 2¡ for angles between 0¡ and 40¡ and within

3¡ for angles between 40¡ and 60¡.

11.5.4.4 Yaw Angle

Calibration. Mark the three-dimensional probe to allow the determination of the

yaw position of the probe. This is usually a line extending the length of the

probe and aligned with the impact opening. To determine the accuracy of

measurements of the yaw angle, only the zero or null position need be

calibrated as follows: Place the directional probe in the test section, and

rotate the probe until the zero position is found. With a protractor or other

angle-measuring device, measure the angle indicated by the yaw angle indicator

on the three-dimensional probe. This should be within 2¡ of 0¡. Repeat this

measurement for any other points along the length of the pitot where yaw angle measurements

could be read in order to account for variations in the pitot markings used to

indicate pitot head positions.

12.0 Data Analysis and Calculations.

12.1 Nomenclature.

L = length

n = total number of

traverse points.

Pi = pitch angle at traverse point i, degree.

Ravg = average resultant angle, degree.

Ri = resultant angle at traverse point i, degree.

Sd = standard deviation, degree.

W = width.

Yi = yaw angle at traverse point i, degree.

12.2 For a rectangular cross section

An equivalent diameter

(De) shall be calculated using the following

equation, to determine the upstream and downstream distances:

![]()

12.3 If use of the alternative site selection procedure (Section 11.5 of this method) is required

Perform the following

calculations using the equations below: the resultant angle at each traverse

point, the average resultant angle, and the standard deviation. Complete the

calculations retaining at least one extra significant figure beyond that of the

acquired data. Round the values after the final calculations.

12.3.1 Calculate the

resultant angle at each traverse point:

![]()

12.3.2 Calculate the

average resultant for the measurements:

![]()

12.3.3 Calculate the

standard deviations:

12.3.4 Acceptability

Criteria. The measurement location is acceptable if Ravg ² 20¡ and Sd ² 10¡.

13.0 Method Performance. [Reserved]

14.0 Pollution Prevention. [Reserved]

15.0 Waste Management. [Reserved]

16.0 References.

1. Determining Dust Concentration

in a Gas Stream, ASME Performance Test Code No. 27. New York. 1957.

2. DeVorkin, Howard,

et al. Air Pollution Source Testing Manual. Air Pollution Control District. Los

Angeles, CA. November 1963.

3. Methods for

Determining of Velocity, Volume, Dust and Mist Content of Gases. Western

Precipitation Division of Joy Manufacturing Co. Los Angeles, CA. Bulletin

WP-50. 1968.

4. Standard Method

for Sampling Stacks for Particulate Matter. In: 1971 Book of ASTM Standards,

Part 23. ASTM Designation D 2928-71. Philadelphia, PA. 1971.

5. Hanson, H.A., et

al. Particulate Sampling Strategies for Large Power Plants Including Nonuniform

Flow. USEPA, ORD, ESRL, Research Triangle Park, NC. EPA-600/2-76-170. June

1976.

6. Entropy

Environmentalists, Inc. Determination of the Optimum Number of Sampling Points:

An Analysis of Method 1 Criteria. Environmental Protection Agency. Research

Triangle Park, NC. EPA Contract No. 68-01-3172, Task 7.

7. Hanson, H.A., R.J.

Davini, J.K. Morgan, and A.A. Iversen. Particulate Sampling Strategies for

Large Power Plants Including Nonuniform Flow. USEPA, Research Triangle Park,

NC. Publication No. EPA-600/2-76-170. June 1976. 350 pp.

8. Brooks, E.F., and

R.L. Williams. Flow and Gas Sampling Manual. U.S. Environmental Protection

Agency. Research Triangle Park, NC. Publication No. EPA-600/2-76- 203. July

1976. 93 pp.

9. Entropy

Environmentalists, Inc. Traverse Point Study. EPA Contract No. 68-02-3172. June

1977. 19 pp.

10. Brown, J. and K.

Yu. Test Report: Particulate Sampling Strategy in Circular Ducts. Emission

Measurement Branch. U.S. Environmental Protection Agency, Research Triangle

Park, NC 27711. July 31, 1980. 12 pp.

11. Hawksley, P.G.W.,

S. Badzioch, and J.H. Blackett. Measurement of Solids in Flue Gases.

Leatherhead, England, The British Coal Utilisation Research Association. 1961.

pp. 129-133.

12. Knapp, K.T. The

Number of Sampling Points Needed for Representative Source Sampling. In:

Proceedings of the Fourth National Conference on Energy and Environment.

Theodore, L. et al. (ed). Dayton, Dayton Section of the American Institute of

Chemical Engineers. October 3-7, 1976. pp. 563-568.

13. Smith, W.S. and

D.J. Grove. A Proposed Extension of EPA Method 1 Criteria. Pollution

Engineering. XV (8):36-37. August 1983.

14. Gerhart, P.M. and

M.J. Dorsey. Investigation of Field Test Procedures for Large Fans. University

of Akron. Akron, OH. (EPRI Contract CS-1651). Final Report (RP-1649- 5).

December 1980.

15. Smith, W.S. and

D.J. Grove. A New Look at Isokinetic Sampling - Theory and Applications. Source

Evaluation Society Newsletter. VIII(3):19-24. August 1983.

17.0 Tables, Diagrams, Flowcharts, and Validation Data.

Figure

1-1. Minimum number of traverse points for particulate traverses.

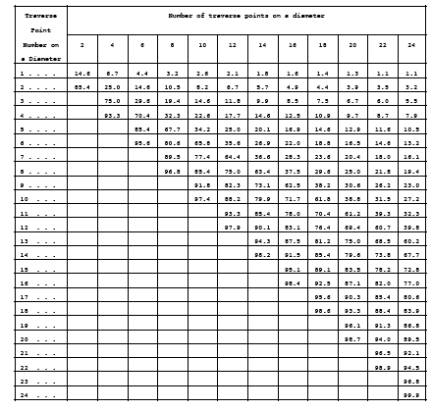

TABLE 1-1. CROSS-SECTION LAYOUT FOR

RECTANGULAR

STACKS

_____________________________________________

Number

of tranverse points Matrix

layout

_____________________________________________

9 . . . . . . . . . . . . . . . . 3 x 3

12

. . . . . . . . . . . . . . . . 4 x 3

16

. . . . . . . . . . . . . . . . 4 x 4

20

. . . . . . . . . . . . . . . . 5 x 4

25

. . . . . . . . . . . . . . . . 5 x 5

30

. . . . . . . . . . . . . . . . 6 x 5

36

. . . . . . . . . . . . . . . . 6 x 6

42

. . . . . . . . . . . . . . . . 7 x 6

49

. . . . . . . . . . . . . . . . 7 x 7

_____________________________________________

Figure

1-2. Minimum number of traverse points for velocity (nonparticulate) traverses.

LOCATION

OF TRAVERSE POINTS IN CIRCULAR STACKS

(Percent

of stack diameter from inside wall to traverse point)

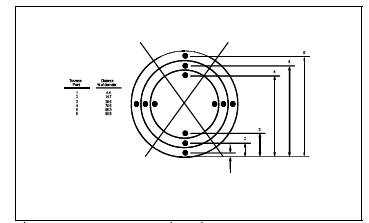

Figure

1-3. Example showing circular stack cross section divided into 12 equal areas,

with location of traverse points.

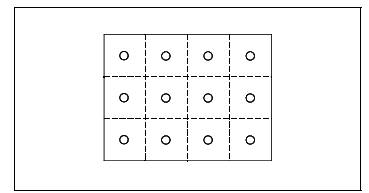

Figure

1-4. Example showing rectangular stack cross section divided into 12 equal

areas, with traverse points at centroid of each area.