Method 2G - Determination of Stack Gas Velocity and Volumetric Flow Rate With Two-Dimensional Probes

Note: This method does not include all of the

specifications (e.g., equipment and supplies) and procedures (e.g., sampling)

essential to its performance. Some material has been incorporated from other

methods in this part. Therefore, to obtain reliable results, those using this

method should have a thorough knowledge of at least the following additional

test methods: Methods 1, 2,

3 or 3A, and 4.

3.1. Angle-measuring

Device Rotational Offset (RADO).

3.4 Full Scale of

Pressure-measuring Device.

3.6 ‘‘May,’’ ‘‘Must,’’

‘‘Shall,’’ ‘‘Should,’’ and the imperative form of verbs for method provisions

3.15 Reference Scribe

Line Rotational Offset (RSLO).

3.18 Three-dimensional

(3-D) Probe.

3.19 Two-dimensional

(2-D) Probe.

3.21 Wind Tunnel

Calibration Location.

3.22 Wind Tunnel with

Documented Axial Flow.

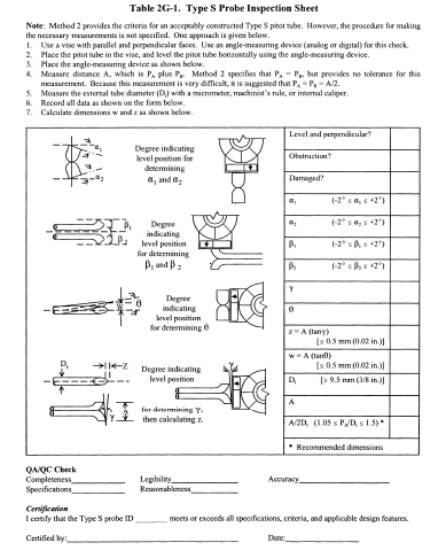

6.1.1 Type S

(Stausscheibe or reverse type) pitot tube.

6.1.2 Three-dimensional

probes used in 2-D mode.

6.1.3 Other probes.

[Reserved]

6.1.6 Probe and system

characteristics to ensure horizontal stability.

6.2 Yaw Angle-measuring

Device.

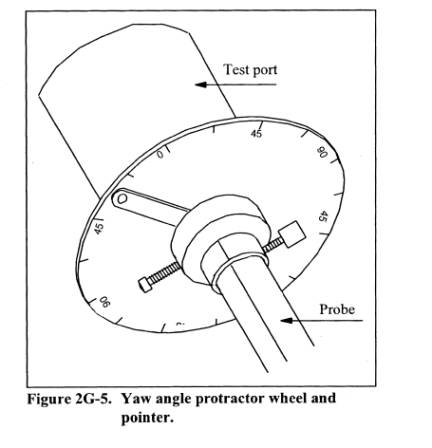

6.2.2 Protractor wheel

and pointer assembly.

6.2.3 Other yaw

angle-measuring devices.

6.3 Probe Supports and

Stabilization Devices.

6.4 Differential

Pressure Gauges.

6.4.1 Differential

pressure-measuring device.

6.4.2 Gauge used for

yaw nulling.

6.4.3 Devices for

calibrating differential pressure-measuring devices.

6.4.4 Devices used for

post-test calibration check.

6.5 Data Display and

Capture Devices.

6.7 Stack or Duct

Static Pressure Measurement.

6.8 Barometer. Same as

Method 2, section 2.5.

6.9 Gas Density

Determination Equipment.

6.11 Wind Tunnel for

Probe Calibration.

6.11.1 Test section

cross-sectional area.

6.11.2 Velocity range

and stability.

6.11.3 Flow profile at

the calibration location.

6.11.4 Entry ports in

the wind tunnel test section.

7.0 Reagents and

Standards. [Reserved]

8.0 Sample Collection

and Analysis

8.1 Equipment

Inspection and Set Up

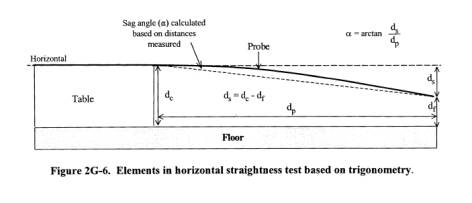

8.2 Horizontal

Straightness Check.

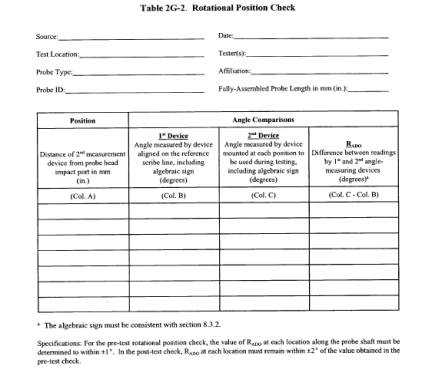

8.3 Rotational Position

Check.

8.3.1 Angle-measuring

device rotational offset.

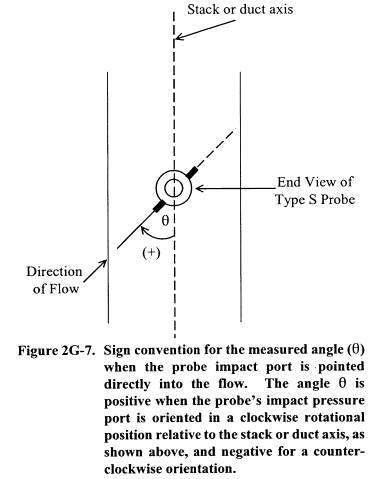

8.3.2 Sign of

angle-measuring device rotational offset.

8.3.3 Angle-measuring

devices that can be independently adjusted

8.5 Zeroing the

Differential Pressure-measuring Device.

8.6 Traverse Point

Verification.

8.9.1 Yaw angle

measurement protocol.

8.9.4 Yaw angle

determination.

8.9.5 Impact velocity

determination.

8.15 Data Recording and

Calculations.

9.1 Quality Control

Activities.

9.1.1 Range of the

differential pressure gauge.

9.1.2 Horizontal

stability check.

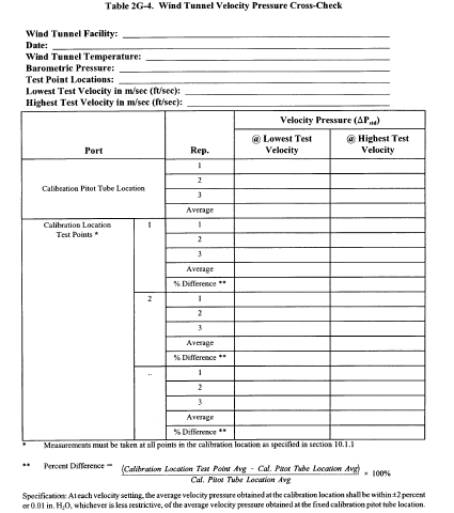

10.1 Wind Tunnel

Qualification Checks.

10.1.1 Velocity

pressure cross-check.

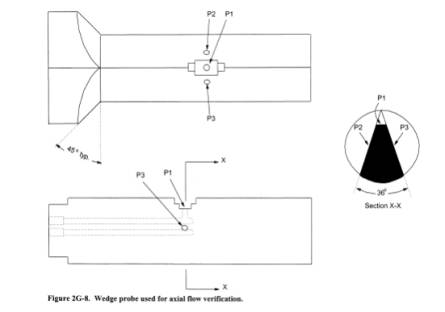

10.1.2 Axial flow

verification.

10.3 Pre-Calibration

Procedures.

10.4 Placement of

Reference Scribe Line.

10.5 Yaw Angle

Calibration Procedure.

10.6 Velocity

Calibration Procedure.

10.8 Calibration of

pressure-measuring devices used in the field.

10.8.1 Post-test

calibration check.

12.0 Data Analysis and

Calculations

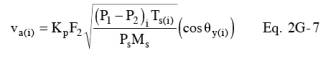

12.2 Traverse Point

Velocity Calculations.

12.2.1 Selection of

calibration coefficient.

12.2.2 Near-axial

traverse point velocity.

12.2.3 Handling

multiple measurements at a traverse point.

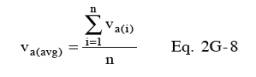

12.3 Average Near-Axial

Velocity in Stack or Duct.

12.4 Acceptability of

Results.

12.5 Average Gas

Volumetric Flow Rate in Stack or Duct (Wet Basis).

12.6 Average Gas

Volumetric Flow Rate in Stack or Duct (Dry Basis).

13.0 Method

Performance. [Reserved]

14.0 Pollution

Prevention. [Reserved]

15.0 Waste Management.

[Reserved]

16.1.1 Description of

the source.

18.1 Annex A -

Rotational Position Check.

18.1.1 Rotational

position check with probe outside stack.

18.1.2 Rotational

position check with probe in stack.

18.2 Annex B - Angle

Measurement Protocol for Protractor Wheel and Pointer Device.

18.3 Annex C -

Guideline for Reference Scribe Line Placement.

18.4 Annex D -

Determination of Reference Scribe Line Rotational Offset.

1.0 Scope and Application

1.1 This

method is applicable for the determination of yaw angle, near-axial velocity,

and the volumetric flow rate of a gas stream in a stack or duct using a

two-dimensional (2-D) probe.

2.0 Summary of Method

2.1 A 2–D

probe is used to measure the velocity pressure and the yaw angle of the flow velocity

vector in a stack or duct.

Alternatively, these measurements may be made by operating one of the

three-dimensional (3-D) probes described in Method 2F,

in yaw determination mode only. From these measurements and a determination of

the stack gas density, the average near-axial velocity of the stack gas is

calculated. The near-axial velocity accounts for the yaw, but not the pitch,

component of flow. The average gas volumetric flow rate in the stack or duct is

then determined from the average near-axial velocity.

3.0 Definitions

3.1. Angle-measuring Device Rotational Offset (RADO).

The rotational

position of an angle-measuring device relative to the reference scribe line, as

determined during the pre-test rotational position check described in section 8.3.

3.2 Calibration Pitot Tube.

The standard (Prandtl type) pitot tube used as a reference

when calibrating a probe under this method.

3.3 Field Test.

A set of measurements conducted at a specific unit or

exhaust stack/ duct to satisfy the applicable regulation (e.g., a three-run

boiler performance test, a single or multiple-load nine-run relative accuracy

test).

3.4 Full Scale of Pressure-measuring Device.

Full scale

refers to the upper limit of the measurement range displayed by the device. For

bi-directional pressure gauges, full scale includes the entire pressure range

from the lowest negative value to the highest positive value on the pressure

scale.

3.5 Main probe.

Refers to the

probe head and that section of probe sheath directly attached to the probe

head. The main probe sheath is distinguished from probe extensions, which are

sections of sheath added onto the main probe to extend its reach.

3.6 ‘‘May,’’ ‘‘Must,’’ ‘‘Shall,’’

‘‘Should,’’ and the imperative form of verbs for method provisions

3.6.1 ‘‘May’’

is used to indicate that

a provision of this method is optional.

3.6.2 ‘‘Must,’’

‘‘Shall,’’ and the

imperative form of verbs (such as ‘‘record’’ or ‘‘enter’’) are used to indicate

that a provision of this method is mandatory.

3.6.3 ‘‘Should’’

is used to indicate that

a provision of this method is not mandatory, but is highly recommended as good

practice.

3.7 Method 1.

Refers to 40 CFR part 60, appendix A, ‘‘Method 1 - Sample

and velocity traverses for stationary sources.’’

3.8 Method 2.

Refers to 40 CFR part 60, appendix A, ‘‘Method 2 -

Determination of stack gas velocity and volumetric flow rate (Type S pitot

tube).’’

3.9 Method 2F.

Refers to 40

CFR part 60, appendix A, ‘‘Method 2F - Determination of stack gas velocity and

volumetric flow rate with three-dimensional probes.’’

3.10 Near-axial Velocity.

The velocity

vector parallel to the axis of the stack or duct that accounts for the yaw

angle component of gas flow. The term ‘‘near-axial’’ is used herein to indicate

that the velocity and volumetric flow rate results account for the measured yaw

angle component of flow at each measurement point.

3.11 Nominal Velocity.

Refers to a wind tunnel velocity setting that approximates

the actual wind tunnel velocity to within Ī1.5 m/ sec (Ī5 ft/sec).

3.12 Pitch Angle.

The angle

between the axis of the stack or duct and the pitch component of flow, i.e.,

the component of the total velocity vector in a plane defined by the traverse

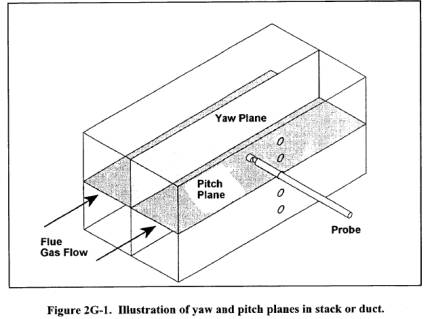

line and the axis of the stack or duct. (Figure 2G-1

illustrates the ‘‘pitch plane.’’) From the standpoint of a tester facing a test

port in a vertical stack, the pitch component of flow is the vector of flow

moving from the center of the stack toward or away from that test port. The

pitch angle is the angle described by this pitch component of flow and the

vertical axis of the stack.

3.13 Readability.

For the purposes of this method, readability for an analog

measurement device is one half of the smallest scale division. For a digital

measurement device, it is the number of decimals displayed by the device.

3.14 Reference Scribe Line.

A line permanently inscribed on the main probe sheath (in

accordance with section 6.1.5.1) to serve as a

reference mark for determining yaw angles.

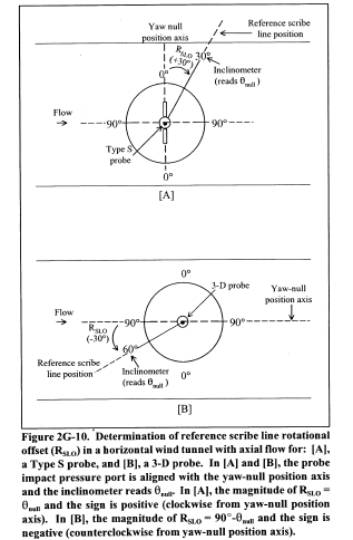

3.15 Reference Scribe Line Rotational Offset (RSLO).

The rotational

position of a probe’s reference scribe line relative to the probe’s yaw-null

position, as determined during the yaw angle calibration described in section 10.5.

3.16 Response Time.

The time

required for the measurement system to fully respond to a change from zero

differential pressure and ambient temperature to the stable stack or duct

pressure and temperature readings at a traverse point.

3.17 Tested Probe.

A probe that is being calibrated.

3.18 Three-dimensional (3-D) Probe.

A directional probe used to determine the velocity pressure

and the yaw and pitch angles in a flowing gas stream.

3.19 Two-dimensional (2-D) Probe.

A directional

probe used to measure velocity pressure and yaw angle in a flowing gas stream.

3.20 Traverse Line.

A diameter or axis extending across a stack or duct on which

measurements of velocity pressure and flow angles are made.

3.21 Wind Tunnel Calibration Location.

A point, line, area, or volume within the wind tunnel test

section at, along, or within which probes are calibrated. At a particular wind

tunnel velocity setting, the average velocity pressures at specified points at,

along, or within the calibration location shall vary by no more than 2 percent

or 0.3 mm H20 (0.01 in. H2O), whichever is less restrictive, from the average

velocity pressure at the calibration pitot tube location. Airflow at this

location shall be axial, i.e., yaw and pitch angles within Ī3 of 0. Compliance

with these flow criteria shall be demonstrated by performing the procedures

prescribed in sections 10.1.1 and 10.1.2. For

circular tunnels, no part of the calibration location may be closer to the

tunnel wall than 10.2 cm (4 in.) or 25 percent of the tunnel diameter,

whichever is farther from the wall. For elliptical or rectangular tunnels, no

part of the calibration location may be closer to the tunnel wall than 10.2 cm

(4 in.) or 25 percent of the applicable cross-sectional axis, whichever is

farther from the wall.

3.22 Wind Tunnel with Documented Axial Flow.

A wind tunnel

facility documented as meeting the provisions of sections 10.1.1 (velocity

pressure crosscheck) and 10.1.2 (axial flow verification) using the procedures

described in these sections or alternative procedures determined to be

technically equivalent.

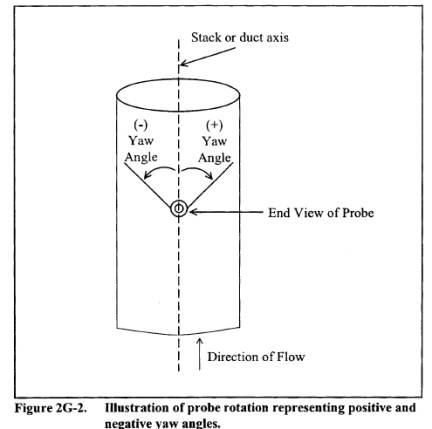

3.23 Yaw Angle.

The angle

between the axis of the stack or duct and the yaw component of flow, i.e., the

component of the total velocity vector in a plane perpendicular to the traverse

line at a particular traverse point. (Figure 2G-1 illustrates the ‘‘yaw

plane.’’) From the standpoint of a tester facing a test port in a vertical

stack, the yaw component of flow is the vector of flow moving to the left or

right from the center of the stack as viewed by the tester. (This is sometimes

referred to as ‘‘vortex flow,’’ i.e., flow around the centerline of a stack or

duct.) The yaw angle is the angle described by this yaw component of flow and

the vertical axis of the stack. The algebraic sign convention is illustrated in

Figure 2G-2.

3.24 Yaw Nulling.

A procedure in

which a Type-S pitot tube or a 3-D probe is rotated about its axis in a stack

or duct until a zero differential pressure reading (‘‘yaw null’’) is obtained.

When a Type S probe is yaw-nulled, the rotational position of its impact port

is 90° from the direction of flow in the stack or duct and the Delta P reading

is zero. When a 3-D probe is yaw-nulled, its impact pressure port (P1) faces

directly into the direction of flow in the stack or duct and the differential

pressure between pressure ports P2 and P3 is zero.

4.0 Interferences. [Reserved]

5.0 Safety

5.1 This test

method may involve hazardous operations and the use of hazardous materials or

equipment. This method does not purport to address all of the safety problems

associated with its use. It is the responsibility of the user to establish and

implement appropriate safety and health practices and to determine the

applicability of regulatory limitations before using this test method.

6.0 Equipment and Supplies

6.1 Two-dimensional Probes.

Probes that

provide both the velocity pressure and the yaw angle of the flow vector in a

stack or duct, as listed in sections 6.1.1 and 6.1.2, qualify for use based on

comprehensive wind tunnel and field studies involving both inter- and

intra-probe comparisons by multiple test teams. Each 2-D probe shall have a

unique identification number or code permanently marked on the main probe

sheath. Each probe shall be calibrated prior to use according to the procedures

in section 10. Manufacturer-supplied calibration data shall be used as example

information only, except when the manufacturer calibrates the probe as

specified in section 10 and provides complete documentation.

6.1.1 Type S (Stausscheibe or reverse type) pitot tube.

This is the

same as specified in Method 2, section 2.1, except for the following additional

specifications that enable the pitot tube to accurately determine the yaw

component of flow. For the purposes of this method, the external diameter of

the tubing used to construct the Type S pitot tube (dimension Dt in Figure 2-2 of Method 2) shall be no less than

9.5 mm (3/8 in.). The pitot tube shall also meet the following alignment

specifications. The angles a1, a2, b1, and b2, as shown in Method 2, Figure 2-3, shall not exceed Ī2°. The

dimensions w and z, shown in Method 2, Figure 2-3 shall not

exceed 0.5 mm (0.02 in.).

6.1.1.1 Manual

Type S probe.

This refers to

a Type S probe that is positioned at individual traverse points and yaw-nulled

manually by an operator.

6.1.1.2

Automated Type S probe. This refers to a system that uses a computer-controlled

motorized mechanism to position the Type S pitot head at individual traverse

points and perform yaw angle determinations.

6.1.2 Three-dimensional probes used in 2-D mode.

A 3-D probe,

as specified in sections 6.1.1 through

6.1.3 of Method 2F, may, for the purposes of this method, be used in a

two-dimensional mode (i.e., measuring yaw angle, but not pitch angle). When the

3-D probe is used as a 2-D probe, only the velocity pressure and yaw-null

pressure are obtained using the pressure taps referred to as P1, P2, and P3.

The differential pressure P1-P2 is a function of total velocity and corresponds

to the Delta P obtained using the Type S probe. The differential pressure P2-P3

is used to yaw-null the probe and determine the yaw angle. The differential

pressure P4-P5, which is a function of pitch angle, is not measured when the

3-D probe is used in 2-D mode.

6.1.3 Other probes. [Reserved]

6.1.4 Probe sheath.

The probe

shaft shall include an outer sheath to: (1) provide a surface for inscribing a

permanent reference scribe line, (2) accommodate attachment of an

angle-measuring device to the probe shaft, and (3) facilitate precise

rotational movement of the probe for determining yaw angles. The sheath shall

be rigidly attached to the probe assembly and shall enclose all pressure lines

from the probe head to the farthest position away from the probe head where an

angle-measuring device may be attached during use in the field. The sheath of

the fully assembled probe shall be sufficiently rigid and straight at all

rotational positions such that, when one end of the probe shaft is held in a

horizontal position, the fully extended probe meets the horizontal straightness

specifications indicated in section 8.2 below.

6.1.5 Scribe lines.

6.1.5.1

Reference scribe line. A permanent line, no greater than 1.6 mm (1/16 in.) in

width, shall be inscribed on each manual probe that will be used to determine yaw

angles of flow. This line shall be placed on the main probe sheath in

accordance with the procedures described in section 10.4 and is used as a

reference position for installation of the yaw angle-measuring device on the

probe. At the discretion of the tester, the scribe line may be a single line

segment placed at a particular position on the probe sheath (e.g., near the

probe head), multiple line segments placed at various locations along the

length of the probe sheath (e.g., at every position where a yaw angle-measuring

device may be mounted), or a single continuous line extending along the full

length of the probe sheath.

6.1.5.2 Scribe

line on probe extensions. A permanent line may also be inscribed on any probe

extension that will be attached to the main probe in performing field testing.

This allows a yaw angle-measuring device mounted on the extension to be readily

aligned with the reference scribe line on the main probe sheath.

6.1.5.3

Alignment specifications. This specification shall be met separately, using the

procedures in section 10.4.1, on the main probe and

on each probe extension. The rotational position of the scribe line or scribe

line segments on the main probe or any probe extension must not vary by more

than 2°. That is, the difference between the minimum and maximum of all of the

rotational angles that are measured along the full length of the main probe or

the probe extension must not exceed 2°.

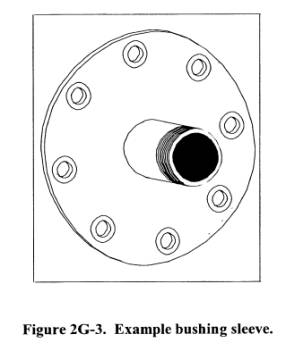

6.1.6 Probe and system characteristics to ensure horizontal stability.

6.1.6.1 For

manual probes, it is recommended that the effective length of the probe

(coupled with a probe extension, if necessary) be at least 0.9 m (3 ft.) longer

than the farthest traverse point mark on the probe shaft away from the probe

head. The operator should maintain the probe’s horizontal stability when it is

fully inserted into the stack or duct. If a shorter probe is used, the probe

should be inserted through a bushing sleeve, similar to the one shown in Figure 2G-3, that is installed on the test port; such a

bushing shall fit snugly around the probe and be secured to the stack or duct

entry port in such a manner as to maintain the probe’s horizontal stability

when fully inserted into the stack or duct.

6.1.6.2 An

automated system that includes an external probe casing with a transport system

shall have a mechanism for maintaining horizontal stability comparable to that

obtained by manual probes following the provisions of this method. The automated

probe assembly shall also be constructed to maintain the alignment and position

of the pressure ports during sampling at each traverse point. The design of the

probe casing and transport system shall allow the probe to be removed from the

stack or duct and checked through direct physical measurement for angular

position and insertion depth.

6.1.7 Tube Connect Diameter

The tubing

that is used to connect the probe and the pressure-measuring device should have

an inside diameter of at least 3.2 mm (1ŕ8 in.), to reduce the time required

for pressure equilibration, and should be as short as practicable.

6.1.8 Detachable Probe Head

If a

detachable probe head without a sheath [e.g., a pitot tube, typically 15.2 to

30.5 cm (6 to 12 in.) in length] is coupled with a probe sheath and calibrated

in a wind tunnel in accordance with the yaw angle calibration procedure in section 10.5, the probe head shall remain

attached to the probe sheath during field testing in the same configuration and

orientation as calibrated. Once the detachable probe head is uncoupled or

re-oriented, the yaw angle calibration of the probe is no longer valid and must

be repeated before using the probe in subsequent field tests.

6.2 Yaw Angle-measuring Device.

One of the

following devices shall be used for measurement of the yaw angle of flow.

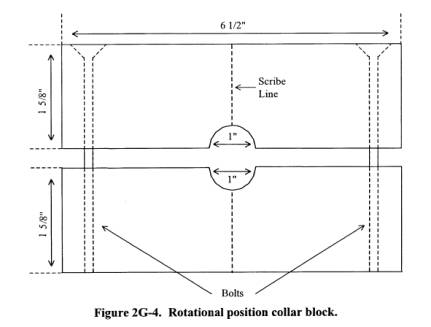

6.2.1 Digital inclinometer.

This refers to

a digital device capable of measuring and displaying the rotational position of

the probe to within Ī1°. The device shall be able to be locked into position on

the probe sheath or probe extension, so that it indicates the probe’s

rotational position throughout the test. A rotational position collar block

that can be attached to the probe sheath (similar to the collar shown in Figure 2G-4) may be required to lock the digital

inclinometer into position on the probe sheath.

6.2.2 Protractor wheel and pointer assembly.

This

apparatus, similar to that shown in Figure 2G-5,

consists of the following components.

6.2.2.1 A

protractor wheel that can be attached to a port opening and set in a fixed

rotational position to indicate the yaw angle position of the probe’s scribe

line relative to the longitudinal axis of the stack or duct. The protractor

wheel must have a measurement ring on its face that is no less than 17.8 cm (7

in.) in diameter, shall be able to be rotated to any angle and then locked into

position on the stack or duct test port, and shall indicate angles to a resolution

of 1°.

6.2.2.2 A

pointer assembly that includes an indicator needle mounted on a collar that can

slide over the probe sheath and be locked into a fixed rotational position on

the probe sheath. The pointer needle shall be of sufficient length, rigidity,

and sharpness to allow the tester to determine the probe’s angular position to

within 1° from the markings on the protractor wheel. Corresponding to the

position of the pointer, the collar must have a scribe line to be used in

aligning the pointer with the scribe line on the probe sheath.

6.2.3 Other yaw angle-measuring devices.

Other

angle-measuring devices with a manufacturer’s specified precision of 1° or

better may be used, if approved by the Administrator.

6.3 Probe Supports and Stabilization Devices.

When probes

are used for determining flow angles, the probe head should be kept in a stable

horizontal position. For probes longer than 3.0 m (10 ft.), the section of the

probe that extends outside the test port shall be secured. Three alternative

devices are suggested for maintaining the horizontal position and stability of

the probe shaft during flow angle determinations and velocity pressure

measurements: (1) monorails installed above each port, (2) probe stands on which

the probe shaft may be rested, or (3) bushing sleeves of sufficient length

secured to the test ports to maintain probes in a horizontal position.

Comparable provisions shall be made to ensure that automated systems maintain

the horizontal position of the probe in the stack or duct. The physical

characteristics of each test platform may dictate the most suitable type of

stabilization device. Thus, the choice of a specific stabilization device is

left to the judgment of the testers.

6.4 Differential Pressure Gauges.

The velocity

pressure (Delta P) measuring devices used during wind tunnel calibrations and

field testing shall be either electronic manometers (e.g., pressure

transducers), fluid manometers, or mechanical pressure gauges (e.g.,

Magnehelic® gauges). Use of electronic manometers is recommended. Under low

velocity conditions, use of electronic manometers may be necessary to obtain

acceptable measurements.

6.4.1 Differential pressure-measuring device.

This refers to

a device capable of measuring pressure differentials and having a readability

of Ī1 percent of full scale. The device shall be capable of accurately

measuring the maximum expected pressure differential. Such devices are used to

determine the following pressure measurements: velocity pressure, static

pressure, and yaw-null pressure. For an inclined-vertical manometer, the

readability specification of Ī1 percent shall be met separately using the

respective full-scale upper limits of the inclined and vertical portions of the

scales. To the extent practicable, the device shall be selected such that most

of the pressure readings are between 10 and 90 percent of the device’s

full-scale measurement range (as defined in section 3.4). In addition,

pressure-measuring devices should be selected such that the zero does not drift

by more than 5 percent of the average expected pressure readings to be

encountered during the field test. This is particularly important under low

pressure conditions.

6.4.2 Gauge used for yaw nulling.

The

differential pressure-measuring device chosen for yaw nulling the probe during

the wind tunnel calibrations and field testing shall be bi-directional, i.e.,

capable of reading both positive and negative differential pressures. If a

mechanical, bi-directional pressure gauge is chosen, it shall have a full-scale

range no greater than 2.6 cm (i.e., -1.3 to +1.3 cm) [1 in. H2O (i.e., -0.5 in.

to +0.5 in.)].

6.4.3 Devices for calibrating differential pressure-measuring devices.

A precision

manometer (e.g., a U-tube, inclined, or inclined-vertical manometer, or

micromanometer) or NIST (National Institute of Standards and Technology)

traceable pressure source shall be used for calibrating differential

pressure-measuring devices. The device shall be maintained under laboratory

conditions or in a similar protected environment (e.g., a climate-controlled

trailer). It shall not be used in field tests. The precision manometer shall

have a scale gradation of 0.3 mm H2O (0.01 in. H2O), or less, in the range of 0

to 5.1 cm H2O (0 to 2 in. H2O) and 2.5 mm H2O (0.1 in. H2O), or less, in the

range of 5.1 to 25.4 cm H2O (2 to 10 in. H2O). The manometer shall have

manufacturer’s documentation that it meets an accuracy specification of at

least 0.5 percent of full scale. The NIST-traceable pressure source shall be

recertified annually.

6.4.4 Devices used for post-test calibration check.

A precision

manometer meeting the specifications in section 6.4.3, a pressure-measuring

device or pressure source with a documented calibration traceable to NIST, or

an equivalent device approved by the Administrator shall be used for the

post-test calibration check. The pressure-measuring device shall have a

readability equivalent to or greater than the tested device. The pressure

source shall be capable of generating pressures between 50 and 90 percent of

the range of the tested device and known to within Ī1 percent of the full scale

of the tested device. The pressure source shall be recertified annually.

6.5 Data Display and Capture Devices.

Electronic

manometers (if used) shall be coupled with a data display device (such as a

digital panel meter, personal computer display, or strip chart) that allows the

tester to observe and validate the pressure measurements taken during testing.

They shall also be connected to a data recorder (such as a data logger or a

personal computer with data capture software) that has the ability to compute

and retain the appropriate average value at each traverse point, identified by

collection time and traverse point.

6.6 Temperature Gauges.

For field

tests, a thermocouple or resistance temperature detector (RTD) capable of

measuring temperature to within Ī3°C (Ī5°F) of the stack or duct temperature

shall be used. The thermocouple shall be attached to the probe such that the

sensor tip does not touch any metal. The position of the thermocouple relative

to the pressure port face openings shall be in the same configuration as used

for the probe calibrations in the wind tunnel. Temperature gauges used for wind

tunnel calibrations shall be capable of measuring temperature to within Ī0.6°C

(Ī1°F) of the temperature of the flowing gas stream in the wind tunnel.

6.7 Stack or Duct Static Pressure Measurement.

The

pressure-measuring device used with the probe shall be as specified in section

6.4 of this method. The static tap of a standard (Prandtl type) pitot tube or

one leg of a Type S pitot tube with the face opening planes positioned parallel

to the gas flow may be used for this measurement. Also acceptable is the

pressure differential reading of P1-Pbar from a five-hole prism-shaped 3-D

probe, as specified in section 6.1.1 of Method 2F (such as the Type DA or DAT

probe), with the P1 pressure port face opening positioned parallel to the gas

flow in the same manner as the Type S probe. However, the 3-D spherical probe,

as specified in section 6.1.2 of Method 2F, is unable to provide this

measurement and shall not be used to take static pressure measurements. Static

pressure measurement is further described in section 8.11.

6.8 Barometer. Same as Method 2, section 2.5.

6.9 Gas Density Determination Equipment.

Method 3 or 3A shall be used to determine the dry molecular weight of the stack or duct gas.

Method 4 shall be used for moisture content determination and computation of

stack or duct gas wet molecular weight. Other methods may be used, if approved

by the Administrator.

6.10 Calibration Pitot Tube.

Same as Method

2, section 2.7.

6.11 Wind Tunnel for Probe Calibration.

Wind tunnels

used to calibrate velocity probes must meet the following design

specifications.

6.11.1 Test section cross-sectional area.

The flowing

gas stream shall be confined within a circular, rectangular, or elliptical

duct. The cross-sectional area of the tunnel must be large enough to ensure

fully developed flow in the presence of both the calibration pitot tube and the

tested probe. The calibration site, or ‘‘test section,’’ of the wind tunnel

shall have a minimum diameter of 30.5 cm (12 in.) for circular or elliptical

duct cross-sections or a minimum width of 30.5 cm (12 in.) on the shorter side

for rectangular cross-sections. Wind tunnels shall meet the probe blockage

provisions of this section and the qualification requirements prescribed in

section 10.1. The projected area of the portion of the probe head, shaft, and attached

devices inside the wind tunnel during calibration shall represent no more than

4 percent of the cross-sectional area of the tunnel. The projected area shall

include the combined area of the calibration pitot tube and the tested probe if

both probes are placed simultaneously in the same cross-sectional plane in the

wind tunnel, or the larger projected area of the two probes if they are placed

alternately in the wind tunnel.

6.11.2 Velocity range and stability.

The wind

tunnel should be capable of maintaining velocities between 6.1 m/sec and 30.5

m/sec (20 ft/sec and 100 ft/sec). The wind tunnel shall produce fully developed

flow patterns that are stable and parallel to the axis of the duct in the test

section.

6.11.3 Flow profile at the calibration location.

The wind

tunnel shall provide axial flow within the test section calibration location

(as defined in section 3.21). Yaw and pitch angles in the calibration location

shall be within Ī3° of 0°. The procedure for determining that this requirement

has been met is described in section 10.1.2.

6.11.4 Entry ports in the wind tunnel test section.

6.11.4.1 Port

for tested probe. A port shall be constructed for the tested probe. This port

shall be located to allow the head of the tested probe to be positioned within

the wind tunnel calibration location (as defined in section 3.21). The tested

probe shall be able to be locked into the 0° pitch angle position. To

facilitate alignment of the probe during calibration, the test section should

include a window constructed of a transparent material to allow the tested

probe to be viewed.

6.11.4.2 Port

for verification of axial flow. Depending on the equipment selected to conduct

the axial flow verification prescribed in section 10.1.2, a second port,

located 90° from the entry port for the tested probe, may be needed to allow

verification that the gas flow is parallel to the central axis of the test

section. This port should be located and constructed so as to allow one of the

probes described in section 10.1.2.2 to access the same test point(s) that are

accessible from the port described in section 6.11.4.1.

6.11.4.3 Port

for calibration pitot tube. The calibration pitot tube shall be used in the

port for the tested probe or in a separate entry port. In either case, all

measurements with the calibration pitot tube shall be made at the same point

within the wind tunnel over the course of a probe calibration. The measurement

point for the calibration pitot tube shall meet the same specifications for

distance from the wall and for axial flow as described in section 3.21 for the

wind tunnel calibration location.

7.0 Reagents and Standards. [Reserved]

8.0 Sample Collection and Analysis

8.1 Equipment Inspection and Set Up

8.1.1 All 2-D

and 3-D probes, differential pressure-measuring devices, yaw angle measuring

devices, thermocouples, and barometers shall have a current, valid calibration

before being used in a field test. (See sections 10.3.3, 10.3.4, and 10.5

through 10.10 for the applicable calibration requirements.)

8.1.2 Before

each field use of a Type S probe, perform a visual inspection to verify the

physical condition of the pitot tube. Record the results of the inspection. If

the face openings are noticeably misaligned or there is visible damage to the

face openings, the probe shall not be used until repaired, the dimensional

specifications verified (according to the procedures in section 10.2.1), and

the probe recalibrated.

8.1.3 Before

each field use of a 3-D probe, perform a visual inspection to verify the

physical condition of the probe head according to the procedures in section

10.2 of Method 2F. Record the inspection results on a form similar to Table 2F-1 presented in Method 2F. If there is

visible damage to the 3-D probe, the probe shall not be used until it is

recalibrated.

8.1.4 After

verifying that the physical condition of the probe head is acceptable, set up

the apparatus using lengths of flexible tubing that are as short as

practicable. Surge tanks installed between the probe and pressure-measuring

device may be used to dampen pressure fluctuations provided that an adequate

measurement system response time (see section 8.8) is maintained.

8.2 Horizontal Straightness Check.

A horizontal

straightness check shall be performed before the start of each field test,

except as otherwise specified in this section. Secure the fully assembled probe

(including the probe head and all probe shaft extensions) in a horizontal

position using a stationary support at a point along the probe shaft

approximating the location of the stack or duct entry port when the probe is

sampling at the farthest traverse point from the stack or duct wall. The probe

shall be rotated to detect bends. Use an angle-measuring device or trigonometry

to determine the bend or sag between the probe head and the secured end. (See Figure 2G-6.) Probes that are bent or sag by more than 5°

shall not be used. Although this check does not apply when the probe is used

for a vertical traverse, care should be taken to avoid the use of bent probes

when conducting vertical traverses. If the probe is constructed of a rigid

steel material and consists of a main probe without probe extensions, this

check need only be performed before the initial field use of the probe, when

the probe is recalibrated, when a change is made to the design or material of

the probe assembly, and when the probe becomes bent. With such probes, a visual

inspection shall be made of the fully assembled probe before each field test to

determine if a bend is visible. The probe shall be rotated to detect bends. The

inspection results shall be documented in the field test report. If a bend in

the probe is visible, the horizontal straightness check shall be performed

before the probe is used.

8.3 Rotational Position Check.

Before each

field test, and each time an extension is added to the probe during a field

test, a rotational position check shall be performed on all manually operated

probes (except as noted in section 8.3.5 below) to ensure that, throughout

testing, the angle-measuring device is either: aligned to within Ī1° of the rotational

position of the reference scribe line; or is affixed to the probe such that the

rotational offset of the device from the reference scribe line is known to

within Ī1°. This check shall consist of direct measurements of the rotational

positions of the reference scribe line and angle-measuring device sufficient to

verify that these specifications are met. Annex A in

section 18 of this method gives recommended procedures for performing the

rotational position check, and Table 2G-2 gives an

example data form. Procedures other than those recommended in Annex A in

section 18 may be used, provided they demonstrate whether the alignment

specification is met and are explained in detail in the field test report.

8.3.1 Angle-measuring device rotational offset.

The tester

shall maintain a record of the angle-measuring device rotational offset, RADO,

as defined in section 3.1. Note that RADO is assigned a value of 0°

when the angle-measuring device is aligned to within Ī1° of the rotational

position of the reference scribe line. The RADO shall be used to

determine the yaw angle of flow in accordance with section 8.9.4.

8.3.2 Sign of angle-measuring device rotational offset.

The sign of RADO

is positive when the angle-measuring device (as viewed from the ‘‘tail’’ end of

the probe) is positioned in a clockwise direction from the reference scribe

line and negative when the device is positioned in a counterclockwise direction

from the reference scribe line.

8.3.3 Angle-measuring devices that can be independently adjusted

Angle-measuring

devices that can be independently adjusted (e.g., by means of a set screw),

after being locked into position on the probe sheath, may be used. However, the

RADO must also take into account this adjustment.

8.3.4 Post-test check.

If probe

extensions remain attached to the main probe throughout the field test, the

rotational position check shall be repeated, at a minimum, at the completion of

the field test to ensure that the angle-measuring device has remained within

Ī2° of its rotational position established prior to testing. At the discretion

of the tester, additional checks may be conducted after completion of testing

at any sample port or after any test run. If the Ī2° specification is not met,

all measurements made since the last successful rotational position check must

be repeated. Section 18.1.1.3 of Annex A provides an example procedure for

performing the post-test check.

8.3.5 Exceptions.

8.3.5.1 A

rotational position check need not be performed if, for measurements taken at

all velocity traverse points, the yaw angle-measuring device is mounted and

aligned directly on the reference scribe line specified in sections 6.1.5.1 and

6.1.5.3 and no independent adjustments, as described in section 8.3.3, are made

to device’s rotational position.

8.3.5.2 If

extensions are detached and reattached to the probe during a field test, a

rotational position check need only be performed the first time an extension is

added to the probe, rather than each time the extension is re-attached, if the

probe extension is designed to be locked into a mechanically fixed rotational

position (e.g., through the use of interlocking grooves), that can re-establish

the initial rotational position to within Ī1°.

8.4 Leak Checks.

A pre-test

leak check shall be conducted before each field test. A post-test check shall

be performed at the end of the field test, but additional leak checks may be

conducted after any test run or group of test runs. The post-test check may

also serve as the pre-test check for the next group of test runs. If any leak

check is failed, all runs since the last passed leak check are invalid. While

performing the leak check procedures, also check each pressure device’s

responsiveness to changes in pressure.

8.4.1 To

perform the leak check on a Type S pitot tube, pressurize the pitot impact

opening until at least 7.6 cm H2O (3 in. H2O) velocity pressure, or a pressure

corresponding to approximately 75 percent of the pressure device’s measurement

scale, whichever is less, registers on the pressure device; then, close off the

impact opening. The pressure shall remain stable (Ī2.5 mm H2O, Ī0.10 in. H2O)

for at least 15 seconds. Repeat this procedure for the static pressure side,

except use suction to obtain the required pressure. Other leak-check procedures

may be used, if approved by the Administrator.

8.4.2 To

perform the leak check on a 3-D probe, pressurize the probe’s impact (P1)

opening until at least 7.6 cm H2O (3 in. H2O) velocity pressure, or a pressure

corresponding to approximately 75 percent of the pressure device’s measurement

scale, whichever is less, registers on the pressure device; then, close off the

impact opening. The pressure shall remain stable (Ī2.5 mm H2O, Ī0.10 in. H2O)

for at least 15 seconds. Check the P2 and P3 pressure ports in the same

fashion. Other leak-check procedures may be used, if approved by the

Administrator.

8.5 Zeroing the Differential Pressure-measuring Device.

Zero each

differential pressure-measuring device, including the device used for yaw

nulling, before each field test. At a minimum, check the zero after each field

test. A zero check may also be performed after any test run or group of test

runs. For fluid manometers and mechanical pressure gauges (e.g., Magnehelic®

gauges), the zero reading shall not deviate from zero by more than Ī0.8 mm H2O

(Ī0.03 in. H2O) or one minor scale division, whichever is greater, between

checks. For electronic manometers, the zero reading shall not deviate from zero

between checks by more than: Ī0.3 mm H2O (Ī0.01 in. H2O), for full scales less

than or equal to 5.1 cm H2O (2.0 in. H2O); or Ī0.8 mm H2O (Ī0.03 in. H2O), for

full scales greater than 5.1 cm H2O (2.0 in. H2O). (Note: If negative zero drift is not directly

readable, estimate the reading based on the position of the gauge oil in the

manometer or of the needle on the pressure gauge.) In addition, for all

pressure-measuring devices except those used exclusively for yaw nulling, the

zero reading shall not deviate from zero by more than 5 percent of the average

measured differential pressure at any distinct process condition or load level.

If any zero check is failed at a specific process condition or load level, all

runs conducted at that process condition or load level since the last passed

zero check are invalid.

8.6 Traverse Point Verification.

The number and

location of the traverse points shall be selected based on Method 1 guidelines.

The stack or duct diameter and port nipple lengths, including any extension of

the port nipples into the stack or duct, shall be verified the first time the

test is performed; retain and use this information for subsequent field tests,

updating it as required. Physically measure the stack or duct dimensions or use

a calibrated laser device; do not use engineering drawings of the stack or

duct. The probe length necessary to reach each traverse point shall be recorded

to within Ī6.4 mm (Ī1ŕ4 in.) and, for manual probes, marked on the probe

sheath. In determining these lengths, the tester shall take into account both

the distance that the port flange projects outside of the stack and the depth

that any port nipple extends into the gas stream. The resulting point positions

shall reflect the true distances from the inside wall of the stack or duct, so

that when the tester aligns any of the markings with the outside face of the

stack port, the probe’s impact port shall be located at the appropriate

distance from the inside wall for the respective Method 1 traverse point.

Before beginning testing at a particular location, an out-of-stack or duct

verification shall be performed on each probe that will be used to ensure that

these position markings are correct. The distances measured during the

verification must agree with the previously calculated distances to within Ī1ŕ4

in. For manual probes, the traverse point positions shall be verified by

measuring the distance of each mark from the probe’s impact pressure port (the

P1 port for a 3-D probe). A comparable out-of-stack test shall be performed on

automated probe systems. The probe shall be extended to each of the prescribed

traverse point positions. Then, the accuracy of the positioning for each

traverse point shall be verified by measuring the distance between the port

flange and the probe’s impact pressure port.

8.7 Probe Installation.

Insert the

probe into the test port. A solid material shall be used to seal the port.

8.8 System Response Time.

Determine the

response time of the probe measurement system. Insert and position the ‘‘cold’’

probe (at ambient temperature and pressure) at any Method 1 traverse point.

Read and record the probe differential pressure, temperature, and elapsed time

at 15-second intervals until stable readings for both pressure and temperature

are achieved. The response time is the longer of these two elapsed times.

Record the response time.

8.9 Sampling.

8.9.1 Yaw angle measurement protocol.

With manual

probes, yaw angle measurements may be obtained in two alternative ways during

the field test, either by using a yaw angle-measuring device (e.g., digital

inclinometer) affixed to the probe, or using a protractor wheel and pointer

assembly. For horizontal traversing, either approach may be used. For vertical

traversing, i.e., when measuring from on top or into the bottom of a horizontal

duct, only the protractor wheel and pointer assembly may be used. With

automated probes, curve-fitting protocols may be used to obtain yaw angle

measurements.

8.9.1.1 If a

yaw angle-measuring device affixed to the probe is to be used, lock the device

on the probe sheath, aligning it either on the reference scribe line or in the

rotational offset position established under section 8.3.1.

8.9.1.2 If a

protractor wheel and pointer assembly is to be used, follow the procedures in Annex B of this method.

8.9.1.3

Curve-fitting procedures. Curve-fitting routines sweep through a range of yaw

angles to create curves correlating pressure to yaw position. To find the zero

yaw position and the yaw angle of flow, the curve found in the stack is

computationally compared to a similar curve that was previously generated under

controlled conditions in a wind tunnel. A probe system that uses a

curve-fitting routine for determining the yaw-null position of the probe head

may be used, provided that it is verified in a wind tunnel to be able to

determine the yaw angle of flow to within Ī1°.

8.9.1.4 Other

yaw angle determination procedures. If approved by the Administrator, other

procedures for determining yaw angle may be used, provided that they are

verified in a wind tunnel to be able to perform the yaw angle calibration

procedure as described in section 10.5.

8.9.2 Sampling strategy.

At each

traverse point, first yaw-null the probe, as described in section 8.9.3, below.

Then, with the probe oriented into the direction of flow, measure and record

the yaw angle, the differential pressure and the temperature at the traverse

point, after stable readings are achieved, in accordance with sections 8.9.4

and 8.9.5. At the start of testing in each port (i.e., after a probe has been

inserted into the flue gas stream), allow at least the response time to elapse

before beginning to take measurements at the first traverse point accessed from

that port. Provided that the probe is not removed from the flue gas stream,

measurements may be taken at subsequent traverse points accessed from the same

test port without waiting again for the response time to elapse.

8.9.3 Yaw-nulling procedure.

In preparation

for yaw angle determination, the probe must first be yaw nulled. After

positioning the probe at the appropriate traverse point, perform the following

procedures.

8.9.3.1 For

Type S probes, rotate the probe until a null differential pressure reading is

obtained. The direction of the probe rotation shall be such that the

thermocouple is located downstream of the probe pressure ports at the yaw-null

position. Rotate the probe 90° back from the yaw-null position to orient the

impact pressure port into the direction of flow. Read and record the angle

displayed by the angle-measuring device.

8.9.3.2 For

3-D probes, rotate the probe until a null differential pressure reading (the

difference in pressures across the P2 and P3 pressure ports is zero, i.e., P2 =

P3) is indicated by the yaw angle pressure gauge. Read and record the angle

displayed by the angle-measuring device.

8.9.3.3 Sign

of the measured angle. The angle displayed on the angle-measuring device is

considered positive when the probe’s impact pressure port (as viewed from the

‘‘tail’’ end of the probe) is oriented in a clockwise rotational position

relative to the stack or duct axis and is considered negative when the probe’s

impact pressure port is oriented in a counterclockwise rotational position (see

Figure 2G-7).

8.9.4 Yaw angle determination.

After

performing the applicable yaw-nulling procedure in section 8.9.3, determine the

yaw angle of flow according to one of the following procedures. Special care

must be observed to take into account the signs of the recorded angle reading

and all offsets.

8.9.4.1

Direct-reading. If all rotational offsets are zero or if the angle-measuring

device rotational offset (RADO) determined in section 8.3 exactly

compensates for the scribe line rotational offset (RSLO) determined

in section 10.5, then the magnitude of the yaw angle is equal to the displayed

angle-measuring device reading from section 8.9.3.1 or 8.9.3.2. The algebraic

sign of the yaw angle is determined in accordance with section 8.9.3.3. [Note:

Under certain

circumstances (e.g., testing of horizontal ducts) a 90° adjustment to the

angle-measuring device readings may be necessary to obtain the correct yaw

angles.]

8.9.4.2

Compensation for rotational offsets during data reduction. When the angle-measuring

device rotational offset does not compensate for reference scribe line

rotational offset, the following procedure shall be used to determine the yaw

angle:

(a) Enter the reading indicated by the

angle-measuring device from section 8.9.3.1 or 8.9.3.2.

(b) Associate

the proper algebraic sign from section 8.9.3.3 with the reading in step (a).

(c) Subtract

the reference scribe line rotational offset, RSLO, from the reading

in step (b).

(d) Subtract

the angle-measuring device rotational offset, RADO, if any, from the

result obtained in step (c).

(e) The final

result obtained in step (d) is the yaw angle of flow.

[Note: It may be necessary to first apply a 90°

adjustment to the reading in step (a), in order to obtain the correct yaw

angle.]

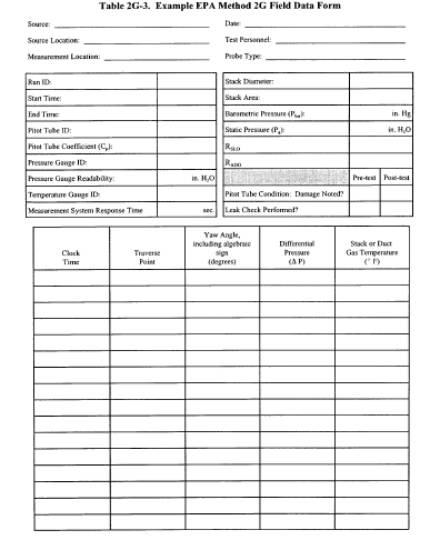

8.9.4.3 Record

the yaw angle measurements on a form similar to Table 2G-3.

8.9.5 Impact velocity determination.

Maintain the

probe rotational position established during the yaw angle determination. Then,

begin recording the pressure-measuring device readings. These pressure

measurements shall be taken over a sampling period of sufficiently long

duration to ensure representative readings at each traverse point. If the

pressure measurements are determined from visual readings of the pressure

device or display, allow sufficient time to observe the pulsation in the

readings to obtain a sight-weighted average, which is then recorded manually.

If an automated data acquisition system (e.g., data logger, computer-based data

recorder, strip chart recorder) is used to record the pressure measurements,

obtain an integrated average of all pressure readings at the traverse point.

Stack or duct gas temperature measurements shall be recorded, at a minimum,

once at each traverse point. Record all necessary data as shown in the example

field data form (Table 2G-3).

8.9.6 Alignment check.

For manually

operated probes, after the required yaw angle and differential pressure and

temperature measurements have been made at each traverse point, verify (e.g.,

by visual inspection) that the yaw angle-measuring device has remained in

proper alignment with the reference scribe line or with the rotational offset

position established in section 8.3. If, for a particular traverse point, the

angle-measuring device is found to be in proper alignment, proceed to the next

traverse point; otherwise, re-align the device and repeat the angle and

differential pressure measurements at the traverse point. In the course of a

traverse, if a mark used to properly align the angle-measuring device (e.g., as

described in section 18.1.1.1) cannot be located, re-establish the alignment

mark before proceeding with the traverse.

8.10 Probe Plugging.

Periodically

check for plugging of the pressure ports by observing the responses on the

pressure differential readouts. Plugging causes erratic results or sluggish

responses. Rotate the probe to determine whether the readouts respond in the

expected direction. If plugging is detected, correct the problem and repeat the

affected measurements.

8.11 Static Pressure.

Measure the

static pressure in the stack or duct using the equipment described in section

6.7.

8.11.1 If a

Type S probe is used for this measurement, position the probe at or between any

traverse point(s) and rotate the probe until a null differential pressure

reading is obtained. Disconnect the tubing from one of the pressure ports; read

and record the Delta P. For pressure devices with one-directional scales, if a

deflection in the positive direction is noted with the negative side

disconnected, then the static pressure is positive. Likewise, if a deflection

in the positive direction is noted with the positive side disconnected, then

the static pressure is negative.

8.11.2 If a

3-D probe is used for this measurement, position the probe at or between any

traverse point(s) and rotate the probe until a null differential pressure

reading is obtained at P2-P3. Rotate the probe 90°. Disconnect the P2 pressure

side of the probe and read the pressure P1-Pbar and record as the static pressure.

(Note: The spherical

probe, specified in section 6.1.2 of Method 2F, is unable to provide this

measurement and shall not be used to take static pressure measurements.)

8.12 Atmospheric Pressure.

Determine the

atmospheric pressure at the sampling elevation during each test run following

the procedure described in section 2.5 of Method 2.

8.13 Molecular Weight.

Determine the

stack or duct gas dry molecular weight. For combustion processes or processes

that emit essentially CO2, O2, CO, and N2, use Method 3 or 3A. For processes

emitting essentially air, an analysis need not be conducted; use a dry

molecular weight of 29.0. Other methods may be used, if approved by the

Administrator.

8.14 Moisture.

Determine the

moisture content of the stack gas using Method 4 or equivalent.

8.15 Data Recording and Calculations.

Record all

required data on a form similar to Table 2G-3.

8.15.1 2-D

probe calibration coefficient. When a Type S pitot tube is used in the field,

the appropriate calibration coefficient as determined in section 10.6 shall be

used to perform velocity calculations. For calibrated Type S pitot tubes, the

A-side coefficient shall be used when the A-side of the tube faces the flow,

and the B-side coefficient shall be used when the B-side faces the flow.

8.15.2 3-D

calibration coefficient. When a 3-D probe is used to collect data with this

method, follow the provisions for the calibration of 3-D probes in section 10.6

of Method 2F to obtain the appropriate velocity calibration coefficient (F2 as

derived using Equation 2F-2 in Method 2F)

corresponding to a pitch angle position of 0°.

8.15.3

Calculations. Calculate the yaw-adjusted velocity at each traverse point using

the equations presented in section 12.2. Calculate the test run average stack

gas velocity by finding the arithmetic average of the point velocity results in

accordance with sections 12.3 and 12.4, and calculate the stack gas volumetric flow

rate in accordance with section 12.5 or 12.6, as applicable.

9.0 Quality Control

9.1 Quality Control Activities.

In conjunction

with the yaw angle determination and the pressure and temperature measurements

specified in section 8.9, the following quality control checks should be

performed.

9.1.1 Range of the differential pressure gauge.

In accordance

with the specifications in section 6.4, ensure that the proper differential

pressure gauge is being used for the range of Delta P values encountered. If it

is necessary to change to a more sensitive gauge, replace the gauge with a

gauge calibrated according to section 10.3.3, perform the leak check described

in section 8.4 and the zero check described in section 8.5, and repeat the

differential pressure and temperature readings at each traverse point.

9.1.2 Horizontal stability check.

For horizontal

traverses of a stack or duct, visually check that the probe shaft is maintained

in a horizontal position prior to taking a pressure reading. Periodically, during

a test run, the probe’s horizontal stability should be verified by placing a

carpenter’s level, a digital inclinometer, or other angle-measuring device on

the portion of the probe sheath that extends outside of the test port. A

comparable check should be performed by automated systems.

10.0 Calibration

10.1 Wind Tunnel Qualification Checks.

To qualify for

use in calibrating probes, a wind tunnel shall have the design features

specified in section 6.11 and satisfy the following qualification criteria. The

velocity pressure cross-check in section 10.1.1 and axial flow verification in

section 10.1.2 shall be performed before the initial use of the wind tunnel and

repeated immediately after any alteration occurs in the wind tunnel’s

configuration, fans, interior surfaces, straightening vanes, controls, or other

properties that could reasonably be expected to alter the flow pattern or

velocity stability in the tunnel. The owner or operator of a wind tunnel used

to calibrate probes according to this method shall maintain records documenting

that the wind tunnel meets the requirements of sections 10.1.1 and 10.1.2 and

shall provide these records to the Administrator upon request.

10.1.1 Velocity pressure cross-check.

To verify that

the wind tunnel produces the same velocity at the tested probe head as at the

calibration pitot tube impact port, perform the following cross-check. Take

three differential pressure measurements at the fixed calibration pitot tube

location, using the calibration pitot tube specified in section 6.10, and take

three measurements with the calibration pitot tube at the wind tunnel

calibration location, as defined in section 3.21. Alternate the measurements

between the two positions. Perform this procedure at the lowest and highest

velocity settings at which the probes will be calibrated. Record the values on

a form similar to Table 2G-4. At each velocity setting,

the average velocity pressure obtained at the wind tunnel calibration location

shall be within Ī2 percent or 2.5 mm H2O (0.01 in. H2O), whichever is less

restrictive, of the average velocity pressure obtained at the fixed calibration

pitot tube location. This comparative check shall be performed at 2.5-cm

(1-in.), or smaller, intervals across the full length, width, and depth (if

applicable) of the wind tunnel calibration location. If the criteria are not

met at every tested point, the wind tunnel calibration location must be

redefined, so that acceptable results are obtained at every point. Include the results

of the velocity pressure cross-check in the calibration data section of the

field test report. (See section 16.1.4.)

10.1.2 Axial flow verification.

The following

procedures shall be performed to demonstrate that there is fully developed

axial flow within the wind tunnel calibration location and at the calibration

pitot tube location. Two options are available to conduct this check.

10.1.2.1 Using

a calibrated 3-D probe. A probe that has been previously calibrated in a wind

tunnel with documented axial flow (as defined in section 3.22) may be used to

conduct this check. Insert the calibrated 3-D probe into the wind tunnel test

section using the tested probe port. Following the procedures in sections 8.9 and 12.2 of Method 2F, determine

the yaw and pitch angles at all the point(s) in the test section where the

velocity pressure cross-check, as specified in section 10.1.1, is performed.

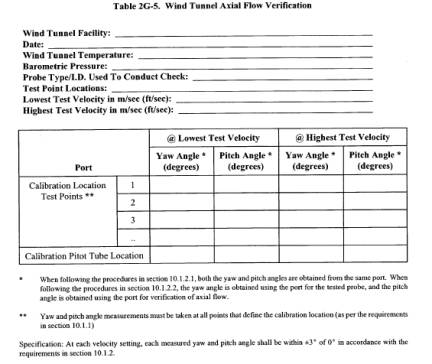

This includes all the points in the calibration location and the point where

the calibration pitot tube will be located. Determine the yaw and pitch angles

at each point. Repeat these measurements at the highest and lowest velocities

at which the probes will be calibrated. Record the values on a form similar to

Table 2G-5. Each measured yaw and pitch angle shall be within Ī3@ of 0@.

Exceeding the limits indicates unacceptable flow in the test section. Until the

problem is corrected and acceptable flow is verified by repetition of this

procedure, the wind tunnel shall not be used for calibration of probes. Include

the results of the axial flow verification in the calibration data section of

the field test report. (See section 16.1.4.)

10.1.2.2 Using

alternative probes. Axial flow verification may be performed using an

uncalibrated prism-shaped 3-D probe (e.g., DA or DAT probe) or an uncalibrated

wedge probe. (Figure 2G-8 illustrates a typical wedge

probe.) This approach requires use of two ports: the tested probe port and a

second port located 90° from the tested probe port. Each port shall provide

access to all the points within the wind tunnel test section where the velocity

pressure cross-check, as specified in section 10.1.1, is conducted. The probe

setup shall include establishing a reference yaw-null position on the probe

sheath to serve as the location for installing the angle-measuring device.

Physical design features of the DA, DAT, and wedge probes are relied on to

determine the reference position. For the DA or DAT probe, this reference

position can be determined by setting a digital inclinometer on the flat facet

where the P1 pressure port is located and then identifying the rotational

position on the probe sheath where a second angle-measuring device would give

the same angle reading. The reference position on a wedge probe shaft can be

determined either geometrically or by placing a digital inclinometer on each

side of the wedge and rotating the probe until equivalent readings are

obtained. With the latter approach, the reference position is the rotational

position on the probe sheath where an angle-measuring device would give a

reading of 0°. After installation of the angle-measuring device in the

reference yaw-null position on the probe sheath, determine the yaw angle from

the tested port. Repeat this measurement using the 90° offset port, which

provides the pitch angle of flow. Determine the yaw and pitch angles at all the

point(s) in the test section where the velocity pressure cross-check, as

specified in section 10.1.1, is performed. This includes all the points in the

wind tunnel calibration location and the point where the calibration pitot tube

will be located. Perform this check at the highest and lowest velocities at

which the probes will be calibrated. Record the values on a form similar to Table 2G-5. Each measured yaw and pitch angle shall be

within Ī3° of 0°. Exceeding the limits indicates unacceptable flow in the test

section. Until the problem is corrected and acceptable flow is verified by

repetition of this procedure, the wind tunnel shall not be used for calibration

of probes. Include the results in the probe calibration report.

10.1.3 Wind tunnel audits.

10.1.3.1

Procedure. Upon the request of the Administrator, the owner or operator of a

wind tunnel shall calibrate a 2-D audit probe in accordance with the procedures

described in sections 10.3 through 10.6. The calibration shall be performed at

two velocities that encompass the velocities typically used for this method at

the facility. The resulting calibration data shall be submitted to the Agency

in an audit test report. These results shall be compared by the Agency to

reference calibrations of the audit probe at the same velocity settings

obtained at two different wind tunnels.

10.1.3.2

Acceptance criterion. The audited tunnel’s calibration coefficient is

acceptable if it is within 3 percent of the reference calibrations obtained at

each velocity setting by one (or both) of the wind tunnels. If the acceptance

criterion is not met at each calibration velocity setting, the audited wind

tunnel shall not be used to calibrate probes for use under this method until

the problems are resolved and acceptable results are obtained upon completion

of a subsequent audit.

10.2 Probe Inspection.

10.2.1 Type S probe.

Before each

calibration of a Type S probe, verify that one leg of the tube is permanently

marked A, and the other, B. Carefully examine the pitot tube from the top,

side, and ends. Measure the angles (a1, a2, b1, and b2) and the dimensions (w

and z) illustrated in Figures 2-2 and 2-3 in

Method 2. Also measure the dimension A, as shown in the diagram in Table 2G-1,

and the external tubing diameter (dimension Dt, Figure 2-2b in Method 2). For

the purposes of this method, Dt shall be no less than 9.5 mm (3ŕ8 in.). The

base-to-opening plane distances PA and PB in Figure 2-3 of Method 2 shall be

equal, and the dimension A in Table 2G-1 should be between 2.10Dt and 3.00Dt.

Record the inspection findings and probe measurements on a form similar to

Table CD2-1 of the ‘‘Quality Assurance Handbook for Air Pollution Measurement

Systems: Volume III, Stationary Source- Specific Methods’ (EPA/600/R-94/038c,

September 1994). For reference, this form is reproduced herein as Table 2G-1.

The pitot tube shall not be used under this method if it fails to meet the

specifications in this section and the alignment specifications in section

6.1.1. All Type S probes used to collect data with this method shall be

calibrated according to the procedures outlined in sections 10.3 through 10.6

below. During calibration, each Type S pitot tube shall be configured in the

same manner as used, or planned to be used, during the field test, including

all components in the probe assembly (e.g., thermocouple, probe sheath,

sampling nozzle). Probe shaft extensions that do not affect flow around the

probe head need not be attached during calibration.

10.2.2 3-D probe.

If a 3-D probe

is used to collect data with this method, perform the pre-calibration

inspection according to procedures in Method

2F, section 10.2.

10.3 Pre-Calibration Procedures.

Prior to

calibration, a scribe line shall have been placed on the probe in accordance

with section 10.4. The yaw angle and velocity calibration procedures shall not

begin until the pre-test requirements in sections 10.3.1 through 10.3.4 have

been met.

10.3.1 Perform

the horizontal straightness check described in section 8.2 on the probe

assembly that will be calibrated in the wind tunnel.

10.3.2 Perform

a leak check in accordance with section 8.4.

10.3.3 Except

as noted in section 10.3.3.3, calibrate all differential pressure-measuring

devices to be used in the probe calibrations, using the following procedures.

At a minimum, calibrate these devices on each day that probe calibrations are

performed.

10.3.3.1

Procedure. Before each wind tunnel use, all differential pressure-measuring

devices shall be calibrated against the reference device specified in section

6.4.3 using a common pressure source. Perform the calibration at three

reference pressures representing 30, 60, and 90 percent of the full-scale range

of the pressure-measuring device being calibrated. For an inclined vertical

manometer, perform separate calibrations on the inclined and vertical portions

of the measurement scale, considering each portion of the scale to be a

separate full-scale range. [For example, for a manometer with a 0-to 2.5-cm H2O

(0-to 1- in. H2O) inclined scale and a 2.5-to 12.7-cm H2O (1-to 5-in. H2O)

vertical scale, calibrate the inclined portion at 7.6, 15.2, and 22.9 mm H2O

(0.3, 0.6, and 0.9 in. H2O), and calibrate the vertical portion at 3.8, 7.6, and

11.4 cm H2O (1.5, 3.0, and 4.5 in. H2O).] Alternatively, for the vertical

portion of the scale, use three evenly spaced reference pressures, one of which

is equal to or higher than the highest differential pressure expected in field

applications.

10.3.3.2

Acceptance criteria. At each pressure setting, the two pressure readings made

using the reference device and the pressure-measuring device being calibrated

shall agree to within #2 percent of full scale of the device being calibrated

or 0.5 mm H2O (0.02 in. H2O), whichever is less restrictive. For an

inclined-vertical manometer, these requirements shall be met separately using

the respective full-scale upper limits of the inclined and vertical portions of

the scale. Differential pressure-measuring devices not meeting the #2 percent

of full scale or 0.5 mm H2O (0.02 in. H2O) calibration requirement shall not be

used.

10.3.3.3

Exceptions. Any precision manometer that meets the specifications for a

reference device in section 6.4.3 and that is not used for field testing does

not require calibration, but must be leveled and zeroed before each wind tunnel

use. Any pressure device used exclusively for yaw nulling does not require

calibration, but shall be checked for responsiveness to rotation of the probe

prior to each wind tunnel use.

10.3.4

Calibrate digital inclinometers on each day of wind tunnel or field testing

(prior to beginning testing) using the following procedures. Calibrate the inclinometer

according to the manufacturer’s calibration procedures. In addition, use a

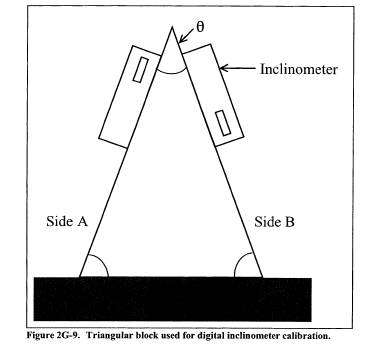

triangular block (illustrated in Figure 2G-9) with a

known angle, ’’, independently determined using a protractor or equivalent

device, between two adjacent sides to verify the inclinometer readings. (Note:

If other angle-measuring

devices meeting the provisions of section 6.2.3 are used in place of a digital

inclinometer, comparable calibration procedures shall be performed on such

devices.) Secure the triangular block in a fixed position. Place the

inclinometer on one side of the block (side A) to measure the angle of

inclination (R1). Repeat this measurement on the adjacent side of the block

(side B) using the inclinometer to obtain a second angle reading (R2). The

difference of the sum of the two readings from 180° (i.e., 180R1R2) shall be

within #2 of the known angle, ‘‘.

10.4 Placement of Reference Scribe Line.

Prior to the

first calibration of a probe, a line shall be permanently inscribed on the main

probe sheath to serve as a reference mark for determining yaw angles. Annex C

in section 18 of this method gives a guideline for placement of the reference

scribe line.

10.4.1

This reference scribe line shall meet the specifications in sections 6.1.5.1

and 6.1.5.3 of this method. To verify that the alignment specification in

section 6.1.5.3 is met, secure the probe in a horizontal position and measure

the rotational angle of each scribe line and scribe line segment using an

angle-measuring device that meets the specifications in section 6.2.1 or 6.2.3.

For any scribe line that is longer than 30.5 cm (12 in.), check the line’s

rotational position at 30.5-cm (12-in.) intervals. For each line segment that

is 12 in. or less in length, check the rotational position at the two endpoints

of the segment. To meet the alignment specification in section 6.1.5.3, the

minimum and maximum of all of the rotational angles that are measured along the

full length of main probe must not differ by more than 2°. (Note: A short reference scribe line segment

[e.g., 15.2 cm (6 in.) or less in length] meeting the alignment specifications

in section 6.1.5.3 is fully acceptable under this method. See section 18.1.1.1

of Annex A for an example of a probe marking procedure, suitable for use with a

short reference scribe line.)

10.4.2 The

scribe line should be placed on the probe first and then its offset from the

yaw-null position established (as specified in section 10.5). The rotational

position of the reference scribe line relative to the yaw-null position of the

probe, as determined by the yaw angle calibration procedure in section 10.5, is

the reference scribe line rotational offset, RSLO. The reference

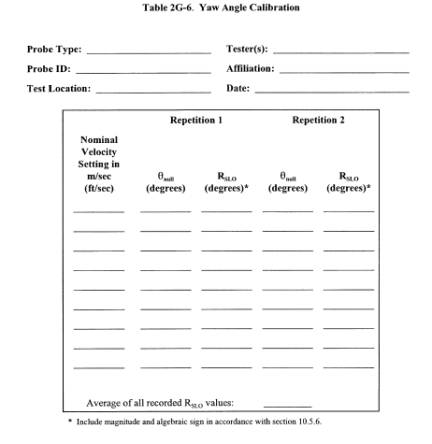

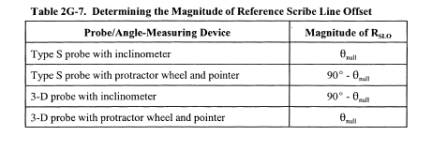

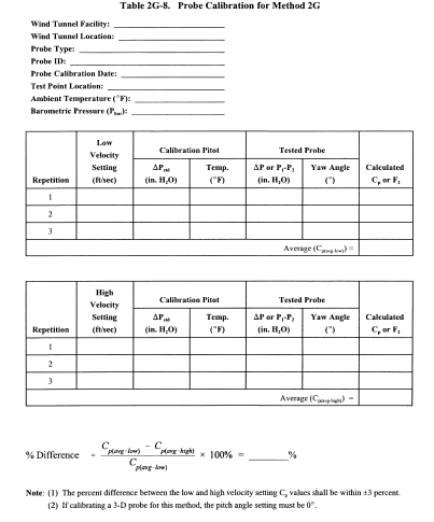

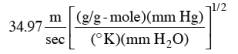

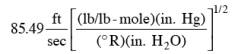

scribe line rotational offset shall be recorded and retained as part of the