METHOD

204B--VOLATILE ORGANIC COMPOUNDS EMISSIONS IN CAPTURED STREAM

4.2 Captured Emissions

Volumetric Flow Rate.

5.1 Calibration and

Other Gases.

5.1.3 FIA Linearity

Calibration Gases.

6.1 Instrument Quality

Control Parameters

6.2.1 Analysis Audit

Procedure.

6.2.2 Audit Samples and

Audit Sample Availability.

7. CALIBRATION AND

STANDARDIZATION

7.1 FIA Calibration and

Linearity Check.

8.1. Determination of

Volumetric Flow Rate of Captured Emissions

8.2 Determination of

VOC Content of Captured Emissions

9. DATA ANALYSIS AND

CALCULATIONS

1. SCOPE AND APPLICATION

1.1 Applicability.

This procedure

is applicable for determining the volatile organic compounds (VOC) content of

captured gas streams. It is intended to be used in the development of a gas/gas

protocol for determining VOC capture efficiency (CE) for surface coating and

printing operations. The procedure may not be acceptable in certain

site-specific situations [e.g., when: (1) direct-fired heaters or other

circumstances affect the quantity of VOC at the control device inlet; and (2)

particulate organic aerosols are formed in the process and are present in the

captured emissions].

1.2 Principle.

The amount of

VOC captured (G) is calculated as the sum of the products of the VOC content (CGj), the flow rate (QGj), and the sample time (¥ C) from each captured emissions point.

1.3 Sampling Requirements.

A CE test shall

consist of at least three sampling runs. Each run shall cover at least one

complete production cycle, but shall be at least 3 hours long. The sampling

time for each run need not exceed 8 hours, even if the production cycle has not

been completed. Alternative sampling times may be used with the approval of the

Administrator.

2. SUMMARY OF METHOD

A gas sample is

extracted from the source though a heated sample line and, if necessary, a

glass fiber filter to a flame ionization analyzer (FIA).

3. SAFETY

Because this

procedure is often applied in highly explosive areas, caution and care should

be exercised in choosing, installing, and using the appropriate equipment.

4. EQUIPMENT AND SUPPLIES

Mention of trade

names or company products does not constitute endorsement. All gas

concentrations (percent, ppm) are by volume, unless otherwise noted.

4.1 Gas VOC Concentration.

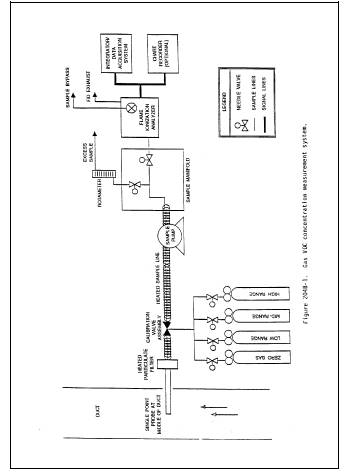

A schematic of

the measurement system is shown in

Figure 204B-1. The main components are as follows:

4.1.1 Sample

Probe. Stainless steel or

equivalent. The probe shall be heated to prevent VOC condensation.

4.1.2

Calibration Valve Assembly. Three-way

valve assembly at the outlet of the sample probe to direct the zero and

calibration gases to the analyzer. Other methods, such as quick-connect lines,

to route calibration gases to the outlet of the sample probe are acceptable.

4.1.3 Sample

Line. Stainless steel or

Teflon tubing to transport the sample gas to the analyzer. The sample line must

be heated to prevent condensation.

4.1.4 Sample

Pump. A leak-free pump, to

pull the sample gas through the system at a flow rate sufficient to minimize

the response time of the measurement system. The components of the pump that

contact the gas stream shall be constructed of stainless steel or Teflon. The

sample pump must be heated to prevent condensation.

4.1.5 Sample

Flow Rate Control. A

sample flow rate control valve and rotameter, or equivalent, to maintain a

constant sampling rate within 10 percent. The flow rate control valve and

rotameter must be heated to prevent condensation. A control valve may also be

located on the sample pump bypass loop to assist in controlling the sample

pressure and flow rate.

4.1.6 Organic

Concentration Analyzer. An

FIA with a span value of 1.5 times the expected concentration as propane;

however, other span values may be used if it can be demonstrated to the

Administrator's satisfaction that they would provide equally accurate

measurements. The system shall be capable of meeting or exceeding the following

specifications:

4.1.6.1 Zero

Drift. Less than ±3.0

percent of the span value.

4.1.6.2

Calibration Drift. Less

than ±3.0 percent of the span value.

4.1.6.3

Calibration Error. Less

than ±5.0 percent of the calibration gas value.

4.1.6.4

Response Time. Less than

30 seconds.

4.1.7

Integrator/Data Acquisition System. An

analog or digital device, or computerized data acquisition system used to

integrate the FIA response or compute the average response and record measurement

data. The minimum data sampling frequency for computing average or integrated

values is one measurement value every 5 seconds. The device shall be capable of

recording average values at least once per minute.

4.2 Captured Emissions Volumetric Flow Rate.

4.2.1 Method

2 or 2A Apparatus. For

determining volumetric flow rate.

4.2.2 Method

3 Apparatus and Reagents. For

determining molecular weight of the gas stream. An estimate of the molecular

weight of the gas stream may be used if approved by the Administrator.

4.2.3 Method

4 Apparatus and Reagents. For

determining moisture content, if necessary.

5. REAGENTS AND STANDARDS

5.1 Calibration and Other Gases.

Gases used for

calibration, fuel, and combustion air (if required) are contained in compressed

gas cylinders. All calibration gases shall be traceable to National Institute

of Standards and Technology standards and shall be certified by the

manufacturer to

5.1.1 Fuel.

The FIA

manufacturer's recommended fuel should be used. A 40 percent H2/60 percent He or 40 percent H2/60 percent N2 gas

mixture is recommended to avoid an oxygen synergism effect that reportedly

occurs when oxygen concentration varies significantly from a mean value. Other

mixtures may be used provided the tester can demonstrate to the Administrator

that there is no oxygen synergism effect

5.1.2 Carrier Gas.

High purity air

with less than 1 ppm of organic material (as propane or carbon equivalent) or

less than 0.1 percent of the span value, whichever is greater.

5.1.3 FIA Linearity Calibration Gases.

Low-, mid-, and

high-range gas mixture standards with nominal propane concentrations of 20-30,

45-55, and 70-80 percent of the span value in air, respectively. Other

calibration values and other span values may be used if it can be shown to the

Administrator's satisfaction that equally accurate measurements would be

achieved.

5.2 Particulate Filter.

An in-stack or

an out-of-stack glass fiber filter is recommended if exhaust gas particulate

loading is significant. An out-of-stack filter must be heated to prevent any

condensation unless it can be demonstrated that no condensation occurs.

6. QUALITY CONTROL

6.1 Instrument Quality Control Parameters

Required

instrument quality control parameters are found in the following sections:

6.1.1 The FIA system must be calibrated as specified

in section 7.1.

6.1.2 The system drift check must be performed as

specified in section 7.2.

6.1.3 The system check must be conducted as

specified in section 7.3.

6.2 Audits.

6.2.1 Analysis Audit Procedure.

Immediately

before each test, analyze an audit cylinder as described in section 7.2. The

analysis audit must agree with the audit cylinder concentration within 10

percent.

6.2.2 Audit Samples and Audit Sample Availability.

Audit samples

will be supplied only to enforcement agencies for compliance tests. The

availability of audit samples may be obtained by writing:

Source Test

Audit Coordinator (STAC) (MD-77B)

Quality

Assurance Division

Atmospheric

Research and Exposure Assessment Labortory

U.S.

Environmental Protection Agency

Research

Triangle Park, NC 27711

or by calling

the STAC at (919) 541-7834. The request for the audit sample must be made at

least 30 days prior to the scheduled compliance sample analysis.

6.2.3 Audit Results.

Calculate the

audit sample concentration according to the calculation procedure described in

the audit instructions included with the audit sample. Fill in the audit sample

concentration and the analyst's name on the audit response form included with

the audit instructions. Send one copy to the EPA Regional Office or the

appropriate enforcement agency, and a second copy to the STAC. The EPA Regional

Office or the appropriate enforcement agency will report the results of the

audit to the laboratory being audited. Include this response with the results

of the compliance samples in relevant reports to the EPA Regional Office or the

appropriate enforcement agency.

7. CALIBRATION AND STANDARDIZATION

7.1 FIA Calibration and Linearity Check.

Make necessary

adjustments to the air and fuel supplies for the FIA and ignite the burner.

Allow the FIA to warm up for the period recommended by the manufacturer. Inject

a calibration gas into the measurement system and adjust the back-pressure

regulator to the value required to achieve the flow rates specified by the

manufacturer. Inject the zero- and the high-range calibration gases and adjust

the analyzer calibration to provide the proper responses. Inject the low- and

mid-range gases and record the responses of the measurement system. The

calibration and linearity of the system are acceptable if the responses for all

four gases are within 5 percent of the respective gas values. If the

performance of the system is not acceptable, repair or adjust the system and

repeat the linearity check. Conduct a calibration and linearity check after

assembling the analysis system and after a major change is made to the system.

7.2 Systems Drift Checks.

Select the

calibration gas that most closely approximates the concentration of the

captured emissions for conducting the drift checks. Introduce the zero and

calibration gases at the calibration valve assembly and verify that the

appropriate gas flow rate and pressure are present at the FIA. Record the

measurement system responses to the zero and calibration gases. The performance

of the system is acceptable if the difference between the drift check

measurement and the value obtained in section 7.1 is less than 3 percent of the

span value. Alternatively, recalibrate the FIA as in section 7.1 and report the

results using both sets of calibration data (i.e., data determined prior to the

test period and data determined following the test period). The data that

results in the lowest CE value shall be reported as the results for the test

run. Conduct the system drift checks at the end of each run.

7.3 System Check.

Inject the

high-range calibration gas at the inlet of the sampling probe and record the

response. The performance of the system is acceptable if the measurement system

response is within 5 percent of the value obtained in section 7.1 for the high-range

calibration gas. Conduct a system check before and after each test run.

8. PROCEDURE

8.1. Determination of Volumetric Flow Rate of Captured Emissions

8.1.1 Locate all points where emissions are

captured from the affected facility. Using Method 1, determine the sampling

points. Be sure to check each site for cyclonic or swirling flow.

8.1.2 Measure the velocity at each sampling site

at least once every hour during each sampling run using Method 2 or 2A.

8.2 Determination of VOC Content of Captured Emissions

8.2.1

Analysis Duration. Measure

the VOC responses at each captured emissions point during the entire test run

or, if applicable, while the process is operating. If there are multiple

captured emission locations, design a sampling system to allow a single FIA to

be used to determine the VOC responses at all sampling locations.

8.2.2 Gas VOC

Concentration.

8.2.2.1 Assemble the sample train as shown in

Figure 204B-1. Calibrate the FIA according to the procedure in section 7.1.

8.2.2.2 Conduct a system check according to the

procedure in section 7.3.

8.2.2.3 Install the sample probe so that the probe

is centrally located in the stack, pipe, or duct, and is sealed tightly at the

stack port connection.

8.2.2.4 Inject zero gas at the calibration valve

assembly. Allow the measurement system response to reach zero. Measure the

system response time as the time required for the system to reach the effluent

concentration after the calibration valve has been returned to the effluent

sampling position.

8.2.2.5 Conduct a system check before, and a system

drift check after, each sampling run according to the procedures in sections

7.2 and 7.3. If the drift check following a run indicates unacceptable

performance (see section 7.3), the run is not valid. Alternatively, recalibrate

the FIA as in section 7.1 and report the results using both sets of calibration

data (i.e., data determined prior to the test period and data determined

following the test period). The data that results in the lowest CE value shall

be reported as the results for the test run. The tester may elect to perform

system drift checks during the run not to exceed one drift check per hour.

8.2.2.6 Verify that the sample lines, filter, and

pump temperatures are 120 ± 5¼C.

8.2.2.7 Begin sampling at the start of the test

period and continue to sample during the entire run. Record the starting and

ending times and any required process information as appropriate. If multiple

captured emission locations are sampled using a single FIA, sample at each

location for the same amount of time (e.g., 2 minutes) and continue to switch

from one location to another for the entire test run. Be sure that total

sampling time at each location is the same at the end of the test run. Collect

at least four separate measurements from each sample point during each hour of

testing. Disregard the measurements at each sampling location until two times

the response time of the measurement system has elapsed. Continue sampling for

at least 1 minute and record the concentration measurements.

8.2.3

Background Concentration. NOTE: Not

applicable when the building is used as the temporary total enclosure (TTE).

8.2.3.1 Locate all natural draft openings (NDO's)

of the TTE. A sampling point shall be at the center of each NDO, unless

otherwise specified by the Administrator. If there are more than six NDO's,

choose six sampling points evenly spaced among the NDO's.

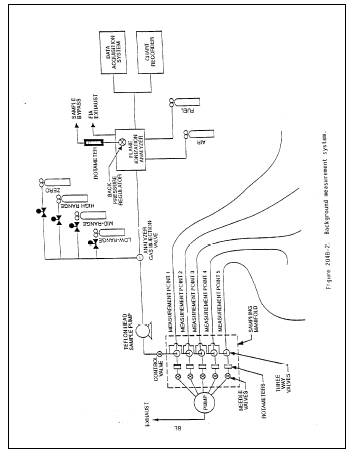

8.2.3.2 Assemble the sample train as shown in

Figure 204B-2. Calibrate the FIA and conduct a system check according to the

procedures in sections 7.1 and 7.3.

NOTE: This sample train shall be separate from

the sample train used to measure the captured emissions.

8.2.3.3 Position the probe at the sampling

location.

8.2.3.4 Determine the response time, conduct the

system check, and sample according to the procedures described in sections

8.2.2.4 through 8.2.2.7.

8.2.4

Alternative Procedure. The

direct interface sampling and analysis procedure described in section 7.2 of

Method 18 may be used to determine the gas VOC concentration. The system must

be designed to collect and analyze at least one sample every 10 minutes. If the

alternative procedure is used to determine the VOC concentration of the

captured emissions, it must also be used to determine the VOC concentration of

the uncaptured emissions.

9. DATA ANALYSIS AND CALCULATIONS

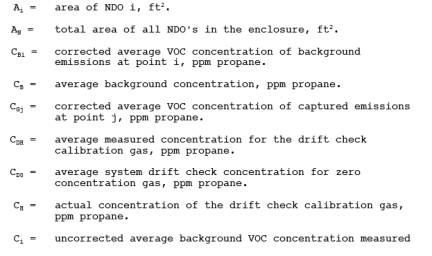

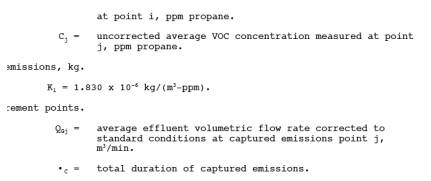

9.1 Nomenclature

9.2 Calculations

9.2.1 Total

VOC Captured Emissions.

9.2.2 VOC

Concentration of the Captured Emissions at Point j.

9.2.3

Background VOC Concentration at Point i.

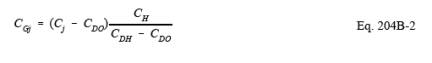

![]()

9.2.4 Average

Background Concentration.

NOTE: If the concentration at each point is

within 20 percent of the average concentration of all points, then use the

arithmetic average.

10. METHOD PERFORMANCE.

The measurement

uncertainties are estimated for each captured or uncaptured emissions point as

follows:

Q Gj = ±5.5 percent and CGj = ±5.0 percent. Based on these numbers, the

probable uncertainty for G is estimated at about ±7.4 percent.

11. DIAGRAMS

Figure 204B-1