METHOD 18 -

MEASUREMENT OF GASEOUS ORGANIC COMPOUND EMISSIONS BY GAS CHROMATOGRAPHY

NOTE: This method is not inclusive with respect to

specifications (e.g., equipment and supplies) and procedures (e.g., sampling and

analytical) essential to its performance. Some material is incorporated by

reference from other methods in this part. Therefore, to obtain reliable

results, persons using this method should have a thorough knowledge of at least

the following additional test methods: Method 1, Method 2, Method 3.

NOTE: This method should not be attempted by persons

unfamiliar with the performance characteristics of gas chromatography, nor by

those persons who are unfamiliar with source sampling. Particular care should

be exercised in the area of safety concerning choice of equipment and operation

in potentially explosive atmospheres.

8.0 Sample Collection,

Preservation, Storage, and Transport.

8.2 Final Sampling and

Analysis Procedure.

8.2.1 Integrated Bag

Sampling and Analysis.

8.2.2 Direct Interface

Sampling and Analysis Procedure.

8.2.3 Dilution

Interface Sampling and Analysis Procedure.

8.2.4 Adsorption Tube

Procedure.

8.4.1 Recovery Study

for Direct Interface or Dilution Interface Sampling.

8.4.2 Recovery Study

for Bag Sampling.

8.4.3 Recovery Study

for Adsorption Tube Sampling.

9.1 Miscellaneous

Quality Control Measures

9.2 Quality Assurance

for Laboratory Procedures.

10.0 Calibration and

Standardization.

10.2 Preparation of

Calibration Curves.

12.0 Data Analysis and

Calculations.

14.0 Pollution

Prevention. [Reserved]

15.0 Waste Management.

[Reserved]

16.1 Optional Presurvey

and Presurvey Sampling.

16.1.4 Determination of

Static Pressure.

16.1.5 Collection of

Presurvey Samples with Adsorption Tube.

18.0 Tables, Diagrams,

Flowcharts, and Validation Data.

1.0 Scope and Application.

1.1 Analyte.

Total gaseous organic

compounds.

1.2 Applicability.

1.2.1 This method is

designed to measure gaseous organics emitted from an industrial source. While

designed for ppm level sources, some detectors are quite capable of detecting

compounds at ambient levels, e.g., ECD, ELCD, and helium ionization detectors.

Some other types of detectors are evolving such that the sensitivity and

applicability may well be in the ppb range in only a few years.

1.2.2 This method

will not determine compounds that (1) are polymeric (high molecular weight),

(2) can polymerize before analysis, or (3) have very low vapor pressures at

stack or instrument conditions.

1.3 Range.

The lower range of

this method is determined by the sampling system; adsorbents may be used to concentrate

the sample, thus lowering the limit of detection below the 1 part per million

(ppm) typically achievable with direct interface or bag sampling. The upper

limit is governed by GC detector saturation or column overloading; the upper

range can be extended by dilution of sample with an inert gas or by using

smaller volume gas sampling loops. The upper limit can also be governed by

condensation of higher boiling compounds.

1.4 Sensitivity.

The sensitivity limit

for a compound is defined as the minimum detectable concentration of that

compound, or the concentration that produces a signal-to-noise ratio of three

to one. The minimum detectable concentration is determined during the presurvey

calibration for each compound.

2.0 Summary of Method.

The major organic

components of a gas mixture are separated by gas chromatography (GC) and

individually quantified by flame ionization, photoionization, electron capture,

or other appropriate detection principles. The retention times of each

separated component are compared with those of known compounds under identical

conditions. Therefore, the analyst confirms the identity and approximate

concentrations of the organic emission components beforehand. With this

information, the analyst then prepares or purchases commercially available

standard mixtures to calibrate the GC under conditions identical to those of

the samples. The analyst also determines the need for sample dilution to avoid

detector saturation, gas stream filtration to eliminate particulate matter, and

prevention of moisture condensation.

3.0 Definitions. [Reserved]

4.0 Interferences.

4.1 Resolution

interferences that may occur can be eliminated by appropriate GC column and

detector choice or by shifting the retention times through changes in the column

flow rate and the use of temperature programming.

4.2 The analytical

system is demonstrated to be essentially free from contaminants by periodically

analyzing blanks that consist of hydrocarbon-free air or nitrogen.

4.3 Sample cross-contamination

that occurs when high-level and low-level samples or standards are analyzed

alternately is best dealt with by thorough purging of the GC sample loop

between samples.

4.4 To assure

consistent detector response, calibration gases are contained in dry air. To

adjust gaseous organic concentrations when water vapor is present in the

sample, water vapor concentrations are determined for those samples, and a

correction factor is applied.

4.5 The gas

chromatograph run time must be sufficient to clear all eluting peaks from the

column before proceeding to the next run (in order to prevent sample

carryover).

5.0 Safety.

5.1 Disclaimer. This

method may involve hazardous materials, operations, and equipment. This test

method may not address all of the safety problems associated with its use. It

is the responsibility of the user of this test method to establish appropriate

safety and health practices and determine the applicability of regulatory

limitations prior to performing this test method. The analyzer users manual

should be consulted for specific precautions to be taken with regard to the

analytical procedure.

6.0 Equipment and Supplies.

6.1 Equipment needed

for the presurvey sampling procedure can be found in Section

16.1.1.

6.2 Equipment needed

for the integrated bag sampling and analysis procedure can be found in Section 8.2.1.1.1.

6.3 Equipment needed

for direct interface sampling and analysis can be found in Section 8.2.2.1.

6.4 Equipment needed

for the dilution interface sampling and analysis can be found in Section 8.2.3.1.

6.5 Equipment needed

for adsorbent tube sampling and analysis can be found in Section

8.2.4.1.

7.0 Reagents and Standards.

7.1 Reagents needed

for the presurvey sampling procedure can be found in Section

16.1.2.

7.2 Quality Assurance

Audit Samples. When making compliance determinations, and upon availability, an

audit sample may be obtained from the appropriate EPA Regional Office or from

the responsible enforcement authority.

NOTE: The responsible enforcement authority should be

notified at least 30 days prior to the test date to allow sufficient time for

sample delivery.

8.0 Sample Collection, Preservation, Storage, and Transport.

8.2 Final Sampling and Analysis Procedure.

Considering safety

(flame hazards) and the source conditions, select an appropriate sampling and

analysis procedure (Section 8.2.1, 8.2.2, 8.2.3 or 8.2.4). In situations where

a hydrogen flame is a hazard and no intrinsically safe GC is suitable, use the

flexible bag collection technique or an adsorption technique.

8.2.1 Integrated Bag Sampling and Analysis.

8.2.1.1

Evacuated Container Sampling Procedure. In this procedure, the bags are filled

by evacuating the rigid air-tight container holding the bags. Use a field

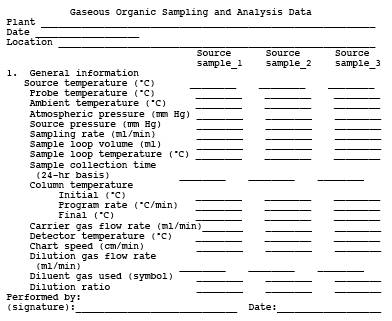

sample data sheet as shown in Figure 18-10. Collect

triplicate samples from each sample location.

8.2.1.1.1 Apparatus.

8.2.1.1.1.1 Probe.

Stainless steel, Pyrex glass, or Teflon tubing probe, according to the duct

temperature, with Teflon tubing of sufficient length to connect to the sample

bag. Use stainless steel or Teflon unions to connect probe and sample line.

8.2.1.1.1.2 Quick

Connects. Male (2) and female (2) of stainless steel construction.

8.2.1.1.1.3 Needle

Valve. To control gas flow.

8.2.1.1.1.4 Pump.

Leakless Teflon-coated diaphragm-type pump or equivalent. To deliver at least 1

liter/min.

8.2.1.1.1.5 Charcoal

Adsorption Tube. Tube filled with activated charcoal, with glass wool plugs at

each end, to adsorb organic vapors.

8.2.1.1.1.6

Flowmeter. O to 500-ml flow range; with manufacturer's calibration curve.

8.2.1.1.2 Sampling

Procedure. To obtain a sample, assemble the sample train as shown in Figure 18-9. Leak-check both the bag and the container.

Connect the vacuum line from the needle valve to the Teflon sample line from

the probe. Place the end of the probe at the centroid of the stack or at a

point no closer to the walls than 1 m, and start the pump. Set the flow rate so

that the final volume of the sample is approximately 80 percent of the bag

capacity. After allowing sufficient time to purge the line several times,

connect the vacuum line to the bag, and evacuate until the rotameter indicates

no flow. Then position the sample and vacuum lines for sampling, and begin the actual

sampling, keeping the rate proportional to the stack velocity. As a precaution,

direct the gas exiting the rotameter away from sampling personnel. At the end

of the sample period, shut off the pump, disconnect the sample line from the

bag, and disconnect the vacuum line from the bag container. Record the source

temperature, barometric pressure, ambient temperature, sampling flow rate, and

initial and final sampling time on the data sheet shown in Figure 18-10.

Protect the Tedlar bag and its container from sunlight. Record the time lapsed

between sample collection and analysis, and then conduct the recovery procedure

in Section 8.4.2.

8.2.1.2 Direct Pump Sampling

Procedure. Follow 8.2.1.1, except place the pump and needle valve between the

probe and the bag. Use a pump and needle valve constructed of inert material

not affected by the stack gas. Leak-check the system, and then purge with stack

gas before connecting to the previously evacuated bag.

8.2.1.3 Explosion

Risk Area Bag Sampling Procedure. Follow 8.2.1.1 except replace the pump with

another evacuated can (see Figure 18-9a). Use this

method whenever there is a possibility of an explosion due to pumps, heated

probes, or other flame producing equipment.

8.2.1.4 Other

Modified Bag Sampling Procedures. In the event that condensation is observed in

the bag while collecting the sample and a direct interface system cannot be

used, heat the bag during collection, and maintain it at a suitably elevated

temperature during all subsequent operations. (NOTE: Take care to leak-check

the system prior to the dilutions so as not to create a potentially explosive

atmosphere.) As an alternative, collect the sample gas, and simultaneously

dilute it in the Tedlar bag.

8.2.1.4.1 First

Alternative Procedure. Heat the box containing the sample bag to 120 ¡C (± 5

¡C). Then transport the bag as rapidly as possible to the analytical area while

maintaining the heating, or cover the box with an insulating blanket. In the

analytical area, keep the box heated to 120 ¡C (±5 ¡C) until analysis. Be sure

that the method of heating the box and the control for the heating circuit are

compatible with the safety restrictions required in each area.

8.2.1.4.2 Second

Alternative Procedure. Prefill the Tedlar bag with a known quantity of inert

gas. Meter the inert gas into the bag according to the procedure for the

preparation of gas concentration standards of volatile liquid materials

(Section 10.1.2.2), but eliminate the midget impinger section. Take the partly

filled bag to the source, and meter the source gas into the bag through heated

sampling lines and a heated flowmeter, or Teflon positive displacement pump.

Verify the dilution factors before sampling each bag through dilution and

analysis of gases of known concentration.

8.2.1.5 Analysis of

Bag Samples.

8.2.1.5.1 Apparatus.

Same as Section 8.1. A minimum of three gas standards are required.

8.2.1.5.2 Procedure.

8.2.1.5.2.1 Establish

proper GC operating conditions as described in Section

10.2, and record all data listed in Figure 18-7. Prepare the GC so that gas

can be drawn through the sample valve. Flush the sample loop with calibration

gas mixture, and activate the valve (sample pressure at the inlet to the GC

introduction valve should be similar during calibration as during actual sample

analysis). Obtain at least three chromatograms for the mixture. The results are

acceptable when the peak areas for the three injections agree to within 5

percent of their average. If they do not agree, run additional samples or

correct the analytical techniques until this requirement is met. Then analyze

the other two calibration mixtures in the same manner. Prepare a calibration

curve as described in Section 10.2.

8.2.1.5.2.2 Analyze

the two field audit samples as described in Section 9.2

by connecting each Tedlar bag containing an audit gas mixture to the sampling

valve. Calculate the results; record and report the data to the audit

supervisor.

8.2.1.5.2.3 Analyze

the three source gas samples by connecting each bag to the sampling valve with

a piece of Teflon tubing identified with that bag. Analyze each bag sample

three times. Record the data in Figure 18-11. If

certain items do not apply, use the notation "N.A." If the bag has

been maintained at an elevated temperature as described in Section 8.2.1.4,

determine the stack gas water content by Method 4. After all samples have been

analyzed, repeat the analysis of the mid-level calibration gas for each

compound. Compare the average response factor of the pre- and post-test

analysis for each compound. If they differ by > 5 percent, analyze the other

calibration gas levels for that compound, and prepare a calibration curve using

all the pre- and post-test calibration gas mixture values. If the two response

factor averages (pre- and post-test) differ by less than 5 percent from their

mean value, the tester has the option of using only the pre-test calibration

curve to generate the concentration values.

8.2.1.6 Determination

of Bag Water Vapor Content. Measure the ambient temperature and barometric

pressure near the bag. From a water saturation vapor pressure table, determine

and record the water vapor content of the bag as a decimal figure. (Assume the

relative humidity to be 100 percent unless a lesser value is known.) If the bag

has been maintained at an elevated temperature as described in Section 8.2.1.4,

determine the stack gas water content by Method 4.

8.2.1.7 Audit Gas

Analysis. Immediately prior to the analysis of the stack gas samples, perform

audit analyses as described in Section 9.2.

8.2.1.8 Emission

Calculations. From the calibration curve described in Section 8.2.1.5, select

the value of Cs that corresponds to the peak area. Calculate the

concentration Cc in ppm, dry basis, of each organic in the sample

using Equation 18-5 in Section 12.6.

8.2.2 Direct Interface Sampling and Analysis Procedure.

The direct interface

procedure can be used provided that the moisture content of the gas does not

interfere with the analysis procedure, the physical requirements of the

equipment can be met at the site, and the source gas concentration falls within

the linear range of the detector. Adhere to all safety requirements with this

method.

8.2.2.1 Apparatus.

8.2.2.1.1 Probe.

Constructed of stainless steel, Pyrex glass, or Teflon tubing as dictated by

duct temperature and reactivity of target compounds. A filter or glass wool

plug may be needed if particulate is present in the stack gas. If necessary,

heat the probe with heating tape or a special heating unit capable of

maintaining a temperature greater than 110¡C.

8.2.2.1.2 Sample

Lines. 6.4-mm OD (or other diameter as needed) Teflon lines, heat-traced to

prevent condensation of material (greater than 110¡C).

8.2.2.1.3 Quick

Connects. To connect sample line to gas sampling valve on GC instrument and to

pump unit used to withdraw source gas. Use a quick connect or equivalent on the

cylinder or bag containing calibration gas to allow connection of the

calibration gas to the gas sampling valve.

8.2.2.1.4

Thermocouple Readout Device. Potentiometer or digital thermometer, to measure

source temperature and probe temperature.

8.2.2.1.5 Heated Gas

Sampling Valve. Of two-position, six-port design, to allow sample loop to be

purged with source gas or to direct source gas into the GC instrument.

8.2.2.1.6 Needle

Valve. To control gas sampling rate from the source.

8.2.2.1.7 Pump.

Leakless Teflon-coated diaphragm-type pump or equivalent, capable of at least 1

liter/minute sampling rate.

8.2.2.1.8 Flowmeter.

Of suitable range to measure sampling rate.

8.2.2.1.9 Charcoal

Adsorber. To adsorb organic vapor vented from the source to prevent exposure of

personnel to source gas.

8.2.2.1.10 Gas

Cylinders. Carrier gas, oxygen and fuel as needed to run GC and detector.

8.2.2.1.11 Gas

Chromatograph. Capable of being moved into the field, with detector, heated gas

sampling valve, column required to complete separation of desired components,

and option for temperature programming.

8.2.2.1.12

Recorder/Integrator. To record results.

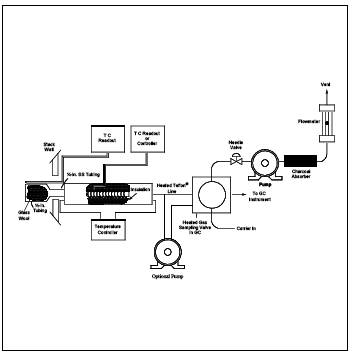

8.2.2.2 Procedure.

Calibrate the GC using the procedures in Section 8.2.1.5.2.1. To obtain a stack

gas sample, assemble the sampling system as shown in Figure

18-12. Make sure all connections are tight. Turn on the probe and sample

line heaters. As the temperature of the probe and heated line approaches the

target temperature as indicated on the thermocouple readout device, control the

heating to maintain a temperature greater than 110¡C. Conduct a 3-point

calibration of the GC by analyzing each gas mixture in triplicate. Generate a

calibration curve. Place the inlet of the probe at the centroid of the duct, or

at a point no closer to the walls than 1 m, and draw source gas into the probe,

heated line, and sample loop. After thorough flushing, analyze the stack gas

sample using the same conditions as for the calibration gas mixture. For each

run, sample, analyze, and record five consecutive samples. A test consists of three

runs (five samples per run times three runs, for a total of fifteen samples).

After all samples have been analyzed, repeat the analysis of the mid-level

calibration gas for each compound. For each calibration standard, compare the

pre- and post-test average response factors (RF) for each compound. If the two

calibration RF values (pre and post-analysis) differ by more than 5 percent

from their mean value, then analyze the other calibration gas levels for that

compound and determine the stack gas sample concentrations by comparison to

both calibration curves (this is done by preparing a calibration curve using

all the pre and post-test calibration gas mixture values). If the two

calibration RF values differ by less than 5 percent from their mean value, the

tester has the option of using only the pre-test calibration curve to generate

the concentration values. Record this calibration data and the other required

data on the data sheet shown in Figure 18-11, deleting

the dilution gas information. (NOTE: Take care to draw all samples, calibration

mixtures, and audits through the sample loop at the same pressure.)

8.2.2.3 Determination

of Stack Gas Moisture Content. Use Method 4 to

measure the stack gas moisture content.

8.2.2.4 Quality

Assurance. Same as Section 8.2.1.7. Introduce the audit gases in the sample

line immediately following the probe.

8.2.2.5 Emission

Calculations. Same as Section 8.2.1.8.

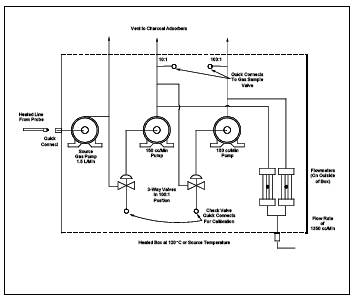

8.2.3 Dilution Interface Sampling and Analysis Procedure.

Source samples that

contain a high concentration of organic materials may require dilution prior to

analysis to prevent saturating the GC detector. The apparatus required for this

direct interface procedure is basically the same as that described in the

Section 8.2.2, except a dilution system is added between the heated sample line

and the gas sampling valve. The apparatus is arranged so that either a 10:1 or

100:1 dilution of the source gas can be directed to the chromatograph. A pump of

larger capacity is also required, and this pump must be heated and placed in

the system between the sample line and the dilution apparatus.

8.2.3.1 Apparatus.

The equipment required in addition to that specified for the direct interface

system is as follows:

8.2.3.1.1 Sample

Pump. Leakless Teflon-coated diaphragm-type that can withstand being heated to

120¡C and deliver 1.5 liters/minute.

8.2.3.1.2 Dilution

Pumps. Two Model A-150 Komhyr Teflon positive displacement type delivering 150

cc/minute, or equivalent. As an option, calibrated flowmeters can be used in

conjunction with Teflon-coated diaphragm pumps.

8.2.3.1.3 Valves. Two

Teflon three-way valves, suitable for connecting to Teflon tubing.

8.2.3.1.4 Flowmeters.

Two, for measurement of diluent gas.

8.2.3.1.5 Diluent Gas

with Cylinders and Regulators. Gas can be nitrogen or clean dry air, depending

on the nature of the source gases.

8.2.3.1.6 Heated Box.

Suitable for being heated to 120¡C, to contain the three pumps, three-way

valves, and associated connections. The box should be equipped with quick

connect fittings to facilitate connection of: (1) the heated sample line from

the probe, (2) the gas sampling valve, (3) the calibration gas mixtures, and

(4) diluent gas lines. A schematic diagram of the components and connections is

shown in Figure 18-13. The heated box shown in Figure

18-13 is designed to receive a heated line from the probe. An optional design

is to build a probe unit that attaches directly to the heated box. In this way,

the heated box contains the controls for the probe heaters, or, if the box is

placed against the duct being sampled, it may be possible to eliminate the

probe heaters. In either case, a heated Teflon line is used to connect the

heated box to the gas sampling valve on the chromatograph.

NOTE: Care must be taken to leak-check the system

prior to the dilutions so as not to create a potentially explosive atmosphere.

8.2.3.2 Procedure.

8.2.3.2.1 Assemble the

apparatus by connecting the heated box, shown in Figure 18-13, between the

heated sample line from the probe and the gas sampling valve on the

chromatograph. Vent the source gas from the gas sampling valve directly to the

charcoal filter, eliminating the pump and rotameter. Heat the sample probe,

sample line, and heated box. Insert the probe and source thermocouple at the

centroid of the duct, or to a point no closer to the walls than 1 m. Measure

the source temperature, and adjust all heating units to a temperature 0 to 3¡C

above this temperature. If this temperature is above the safe operating

temperature of the Teflon components, adjust the heating to maintain a

temperature high enough to prevent condensation of water and organic compounds

(greater than 110¡C). Calibrate the GC through the dilution system by following

the procedures in Section 8.2.1.5.2.1. Determine the concentration of the

diluted calibration gas using the dilution factor and the certified

concentration of the calibration gas. Record the pertinent data on the data

sheet shown in Figure 18-11.

8.2.3.2.2 Once the

dilution system and GC operations are satisfactory, proceed with the analysis

of source gas, maintaining the same dilution settings as used for the

standards.

8.2.3.2.3 Analyze the

audit samples using either the dilution system, or directly connect to the gas

sampling valve as required. Record all data and report the results to the audit

supervisor.

8.2.3.3 Determination

of Stack Gas Moisture Content. Same as Section 8.2.2.3.

8.2.3.4 Quality

Assurance. Same as Section 8.2.2.4.

8.2.3.5 Emission

Calculations. Same as section 8.2.2.5, with the dilution factor applied.

8.2.4 Adsorption Tube Procedure.

Any commercially

available adsorbent is allowed for the purposes of this method, as long as the

recovery study criteria in Section 8.4.3 are met.

Help in choosing the adsorbent may be found by calling the distributor, or the

tester may refer to National Institute for Occupational Safety and Health (NIOSH)

methods for the particular organics to be sampled. For some adsorbents, the

principal interferent will be water vapor. If water vapor is thought to be a

problem, the tester may place a midget impinger in an ice bath before the

adsorbent tubes. If this option is chosen, the water catch in the midget

impinger shall be analyzed for the target compounds. Also, the spike for the

recovery study (in Section 8.4.3) shall be conducted in both the midget

impinger and the adsorbent tubes. The combined recovery (add the recovered

amount in the impinger and the adsorbent tubes to calculate R) shall then meet

the criteria in Section 8.4.3. NOTE: Post-test leak-checks are not allowed for this technique since this

can result in sample contamination.

8.2.4.1 Additional

Apparatus. The following items (or equivalent) are suggested.

8.2.4.1.1 Probe.

Borosilicate glass or stainless steel, approximately 6-mm ID, with a heating

system if water condensation is a problem, and a filter (either in-stack or

out-of-stack, heated to stack temperature) to remove particulate matter. In

most instances, a plug of glass wool is a satisfactory filter.

8.2.4.1.2 Flexible

Tubing. To connect probe to adsorption tubes. Use a material that exhibits

minimal sample adsorption.

8.2.4.1.3 Leakless

Sample Pump. Flow controlled, constant rate pump, with a set of limiting

(sonic) orifices.

8.2.4.1.4 Bubble-Tube

Flowmeter. Volume accuracy within 1 percent, to calibrate pump.

8.2.4.1.5 Stopwatch.

To time sampling and pump rate calibration.

8.2.4.1.6 Adsorption

Tubes. Precleaned adsorbent, with mass of adsorbent to be determined by

calculating breakthrough volume and expected concentration in the stack.

8.2.4.1.7 Barometer. Accurate

to 5 mm Hg, to measure atmospheric pressure during sampling and pump

calibration.

8.2.4.1.8 Rotameter.

O to 100 cc/min, to detect changes in flow rate during sampling.

8.2.4.2 Sampling and

Analysis.

8.2.4.2.1 Calibrate

the pump and limiting orifice flow rate through adsorption tubes with the

bubble tube flowmeter before sampling. The sample system can be operated as a

"recirculating loop" for this operation. Record the ambient

temperature and barometric pressure. Then, during sampling, use the rotameter

to verify that the pump and orifice sampling rate remains constant.

8.2.4.2.2 Use a

sample probe, if required, to obtain the sample at the centroid of the duct, or

at a point no closer to the walls than 1 m. Minimize the length of flexible

tubing between the probe and adsorption tubes. Several adsorption tubes can be

connected in series, if the extra adsorptive capacity is needed. Adsorption

tubes should be maintained vertically during the test in order to prevent

channeling. Provide the gas sample to the sample system at a pressure

sufficient for the limiting orifice to function as a sonic orifice. Record the

total time and sample flow rate (or the number of pump strokes), the barometric

pressure, and ambient temperature. Obtain a total sample volume commensurate

with the expected concentration(s) of the volatile organic(s) present, and

recommended sample loading factors (weight sample per weight adsorption media).

Laboratory tests prior to actual sampling may be necessary to predetermine this

volume. If water vapor is present in the sample at concentrations above 2 to 3

percent, the adsorptive capacity may be severely reduced. Operate the gas

chromatograph according to the manufacturer's instructions. After establishing

optimum conditions, verify and document these conditions during all operations.

Calibrate the instrument. Analyze the audit samples (see Section 16.1.4.3),

then the emission samples.

8.2.4.3 Standards and

Calibration. If using thermal desorption, obtain calibration gases using the procedures

in Section 10.1. If using solvent extraction, prepare liquid standards in the

desorption solvent. Use a minimum of three different standards; select the

concentrations to bracket the expected average sample concentration. Perform

the calibration before and after each day's sample analyses using the

procedures in Section 8.2.1.5.2.1.

8.2.4.4 Quality

Assurance.

8.2.4.4.1 Determine

the recovery efficiency of the pollutants of interest according to Section

8.4.3.

8.2.4.4.2

Determination of Sample Collection Efficiency (Optional). If sample

breakthrough is thought to be a problem, a routine procedure for determining

breakthrough is to analyze the primary and backup portions of the adsorption

tubes separately. If the backup portion exceeds 10 percent of the total amount

(primary and back-up), it is usually a sign of sample breakthrough. For the

purposes of this method, only the recovery efficiency value (Section 8.4.3) is

used to determine the appropriateness of the sampling and analytical procedure.

8.2.4.4.3 Volume Flow

Rate Checks. Perform this check immediately after sampling with all sampling

train components in place. Use the bubble-tube flowmeter to measure the pump

volume flow rate with the orifice used in the test sampling, and record the result.

If it has changed by more than 5 but less than 20 percent, calculate an average

flow rate for the test. If the flow rate has changed by more than 20 percent,

recalibrate the pump and repeat the sampling.

8.2.4.4.4

Calculations. Correct all sample volumes to standard conditions. If a sample

dilution system has been used, multiply the results by the appropriate dilution

ratio. Correct all results according to the applicable procedure in Section

8.4.3. Report results as ppm by volume, dry basis.

8.3 Reporting of Results.

At the completion of

the field analysis portion of the study, ensure that the data sheets shown in

Figure 18-11 have been completed. Summarize this data on the data sheets shown

in Figure 18-15.

8.4 Recovery Study.

After conducting the

presurvey and identifying all of the pollutants of interest, conduct the

appropriate recovery study during the test based on the sampling system chosen

for the compounds of interest.

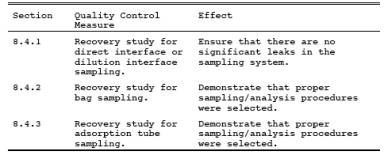

8.4.1 Recovery Study for Direct Interface or Dilution Interface Sampling.

If the procedures in

Section 8.2.2 or 8.2.3 are to be used to analyze the stack gas, conduct the

calibration procedure as stated in Section 8.2.2.2 or 8.2.3.2, as appropriate.

Upon successful completion of the appropriate calibration procedure, attach the

mid-level calibration gas for at least one target compound to the inlet of the

probe or as close as possible to the inlet of the probe, but before the filter.

Repeat the calibration procedure by sampling and analyzing the mid-level

calibration gas through the entire sampling and analytical system in

triplicate. The mean of the calibration gas response sampled through the probe

shall be within 10 percent of the analyzer response. If the difference in the

two means is greater than 10 percent, check for leaks throughout the sampling

system and repeat the analysis of the standard through the sampling system

until this criterion is met.

8.4.2 Recovery Study for Bag Sampling.

8.4.2.1 Follow the procedures

for the bag sampling and analysis in Section 8.2.1. After analyzing all three

bag samples, choose one of the bag samples and tag this bag as the spiked bag.

Spike the chosen bag sample with a known mixture (gaseous or liquid) of all of

the target pollutants. The theoretical concentration, in ppm, of each spiked

compound in the bag shall be 40 to 60 percent of the average concentration

measured in the three bag samples. If a target compound was not detected in the

bag samples, the concentration of that compound to be spiked shall be 5 times

the limit of detection for that compound. Store the spiked bag for the same

period of time as the bag samples collected in the field. After the appropriate

storage time has passed, analyze the spiked bag three times. Calculate the

average fraction recovered (R) of each spiked target compound with the equation

in Section 12.7.

8.4.2.2 For the bag

sampling technique to be considered valid for a compound, 0.70 ²R ²1.30. If the

R value does not meet this criterion for a target compound, the sampling

technique is not acceptable for that compound, and therefore another sampling

technique shall be evaluated for acceptance (by repeating the recovery study

with another sampling technique). Report the R value in the test report and

correct all field measurements with the calculated R value for that compound by

using the equation in Section 12.8.

8.4.3 Recovery Study for Adsorption Tube Sampling.

If following the

adsorption tube procedure in Section 8.2.4, conduct a recovery study of the

compounds of interest during the actual field test. Set up two identical

sampling trains. Collocate the two sampling probes in the stack. The probes

shall be placed in the same horizontal plane, where the first probe tip is 2.5

cm from the outside edge of the other. One of the sampling trains shall be

designated the spiked train and the other the unspiked train. Spike all of the

compounds of interest (in gaseous or liquid form) onto the adsorbent tube(s) in

the spiked train before sampling. The mass of each spiked compound shall be 40

to 60 percent of the mass expected to be collected with the unspiked train.

Sample the stack gas into the two trains simultaneously. Analyze the adsorbents

from the two trains utilizing identical analytical procedures and

instrumentation. Determine the fraction of spiked compound recovered (R) using

the equations in Section 12.9.

8.4.3.1 Repeat the

procedure in Section 8.4.3 twice more, for a total of three runs. In order for

the adsorbent tube sampling and analytical procedure to be acceptable for a

compound, 0.70 ²R ²1.30 (R in this case is the average of three runs). If the

average R value does not meet this criterion for a target compound, the sampling

technique is not acceptable for that compound, and therefore another sampling

technique shall be evaluated for acceptance (by repeating the recovery study

with another sampling technique). Report the R value in the test report and

correct all field measurements with the calculated R value for that compound by

using the equation in Section 12.8.

9.0 Quality Control.

9.1 Miscellaneous Quality Control Measures

9.2 Quality Assurance for Laboratory Procedures.

Immediately after the

preparation of the calibration curves, the analysis audit described in 40 CFR

Part 61, Appendix C, Procedure 2: "Procedure for Field Auditing GC

Analysis," should be performed if audit materials are available. The

information required to document the analysis of the audit samples has been

included on the example data sheets shown in Figures 18-3 and 18-7. The audit

analyses should agree with the certified audit concentrations within 10

percent. Audit sample results shall be submitted according to directions

provided with the audit samples.

10.0 Calibration and Standardization.

10.1 Calibration Standards.

Obtain calibration

gas standards for each target compound to be analyzed. Commercial cylinder

gases certified by the manufacturer to be accurate to within 1 percent of the

certified label value are preferable, although cylinder gases certified by the

manufacturer to 2 percent accuracy are allowed. Another option allowed by this

method is for the tester to obtain high concentration certified cylinder gases

and then use a dilution system meeting the requirements of Test Method 205, 40

CFR Part 51, Appendix M to make multi-level calibration gas standards. Prepare

or obtain enough calibration standards so that there are three different

concentrations of each organic compound expected to be measured in the source

sample. For each organic compound, select those concentrations that bracket the

concentrations expected in the source samples. A calibration standard may

contain more than one organic compound. If samples are collected in adsorbent

tubes and extracted using solvent extraction, prepare or obtain standards in

the same solvent used for the sample extraction procedure. Verify the stability

of all standards for the time periods they are used.

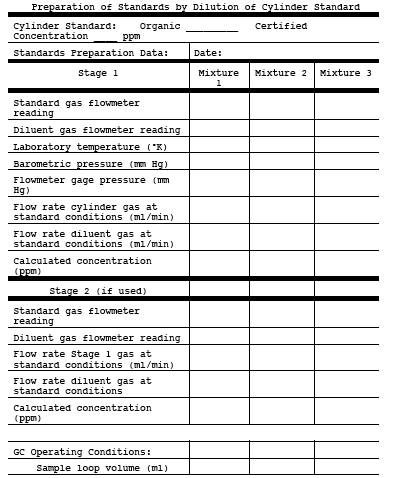

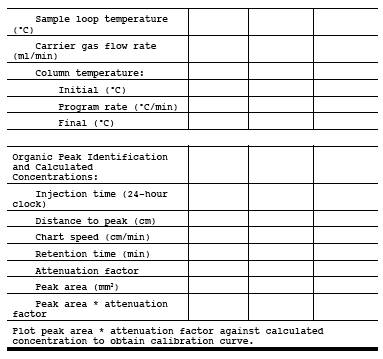

10.2 Preparation of Calibration Curves.

10.2.1 Establish

proper GC conditions, then flush the sampling loop for 30 seconds. Allow the

sample loop pressure to equilibrate to atmospheric pressure, and activate the

injection valve. Record the standard concentration, attenuator factor, injection

time, chart speed, retention time, peak area, sample loop temperature, column

temperature, and carrier gas flow rate. Analyze each standard in triplicate.

10.2.2 Repeat this

procedure for each standard. Prepare a graphical plot of concentration (Cs) versus the calibration area values. Perform a regression

analysis, and draw the least square line.

11.0 Analytical Procedures.

11.1 Analysis

Development.

11.1.1 Selection of

GC Parameters.

11.1.1.1 Column Choice.

Based on the initial contact with plant personnel concerning the plant process

and the anticipated emissions, choose a column that provides good resolution

and rapid analysis time. The choice of an appropriate column can be aided by a

literature search, contact with manufacturers of GC columns, and discussion

with personnel at the emission source.

NOTE: Most column manufacturers keep excellent records

on their products. Their technical service departments may be able to recommend

appropriate columns and detector type for separating the anticipated compounds,

and they may be able to provide information on interferences, optimum operating

conditions, and column limitations. Plants with analytical laboratories may be

able to provide information on their analytical procedures.

11.1.1.2 Preliminary

GC Adjustment. Using the standards and column obtained in Section 11.1.1.1,

perform initial tests to determine appropriate GC conditions that provide good

resolution and minimum analysis time for the compounds of interest.

11.1.1.3 Preparation

of Presurvey Samples. If the samples were collected on an adsorbent, extract

the sample as recommended by the manufacturer for removal of the compounds with

a solvent suitable to the type of GC analysis. Prepare other samples in an

appropriate manner.

11.1.1.4 Presurvey

Sample Analysis.

11.1.1.4.1 Before

analysis, heat the presurvey sample to the duct temperature to vaporize any

condensed material. Analyze the samples by the GC procedure, and compare the

retention times against those of the calibration samples that contain the

components expected to be in the stream. If any compounds cannot be identified

with certainty by this procedure, identify them by other means such as GC/mass

spectroscopy (GC/MS) or GC/infrared techniques. A GC/MS system is recommended.

11.1.1.4.2 Use the GC

conditions determined by the procedure of Section 11.1.1.2 for the first

injection. Vary the GC parameters during subsequent injections to determine the

optimum settings. Once the optimum settings have been determined, perform

repeat injections of the sample to determine the retention time of each

compound. To inject a sample, draw sample through the loop at a constant rate

(100 ml/min for 30 seconds). Be careful not to pressurize the gas in the loop.

Turn off the pump and allow the gas in the sample loop to come to ambient

pressure. Activate the sample valve, and record injection time, loop

temperature, column temperature, carrier flow rate, chart speed, and attenuator

setting. Calculate the retention time of each peak using the distance from

injection to the peak maximum divided by the chart speed. Retention times

should be repeatable within O.5 seconds.

11.1.1.4.3 If the

concentrations are too high for appropriate detector response, a smaller sample

loop or dilutions may be used for gas samples, and, for liquid samples,

dilution with solvent is appropriate. Use the standard curves (Section 10.2) to

obtain an estimate of the concentrations.

11.1.1.4.4 Identify

all peaks by comparing the known retention times of compounds expected to be in

the retention times of peaks in the sample. Identify any remaining unidentified

peaks which have areas larger than 5 percent of the total using a GC/MS, or

estimation of possible compounds by their retention times compared to known

compounds, with confirmation by further GC analysis.

12.0 Data Analysis and Calculations.

12.1 Nomenclature.

Bws = Water vapor content of the bag sample or stack

gas, proportion by volume.

Cs = Concentration of the organic from the calibration curve, ppm.

Gv = Gas volume or organic compound injected, ml.

Lv = Liquid volume of organic injected,µl.

M = Molecular weight

of organic, g/g-mole.

ms = Total mass of compound measured on adsorbent with spiked train

(µg).

mu = Total mass of compound measured on adsorbent with unspiked train

(µg).

mv = Mass per volume of spiked compound measured (µg/L).

Pi = Barometric or absolute sample loop pressure at time of sample

analysis, mm Hg.

Pm = Absolute pressure of dry gas meter, mm Hg.

Pr = Reference pressure, the barometric pressure or absolute sample

loop pressure recorded during calibration, mm Hg.

Ps = Absolute pressure of syringe before injection, mm Hg.

qc = Flow rate of the calibration gas to be diluted.

qc1 = Flow rate of the calibration gas to be diluted

in stage 1.

qc2 = Flow rate of the calibration gas to be diluted

in stage 2.

qd = Diluent gas flow rate.

qd1 = Flow rate of diluent gas in stage 1.

qd2 = Flow rate of diluent gas in stage 2.

s = Theoretical

concentration (ppm) of spiked target compound in the bag.

S = Theoretical mass

of compound spiked onto adsorbent in spiked train (µg).

t = Measured average

concentration (ppm) of target compound and source sample (analysis results

subsequent to bag spiking)

Ti = Sample loop temperature at the time of sample analysis, ¡K.

Tm = Absolute temperature of dry gas meter, ¡K.

Ts = Absolute temperature of syringe before injection, ¡K.

u = Source sample

average concentration (ppm) of target compound in the bag (analysis results

before bag spiking).

Vm = Gas volume indicated by dry gas meter, liters.

vs = volume of stack gas sampled with spiked train (L).

vu = volume of stack gas sampled with unspiked train (L).

X = Mole or volume fraction

of the organic in the calibration gas to be diluted.

Y = Dry gas meter

calibration factor, dimensionless.

µl = Liquid organic

density as determined, g/ml.

24.055 = Ideal gas

molar volume at 293 ¡K and 760 mm Hg, liters/g-mole.

1000 = Conversion factor,

ml/liter.

106 = Conversion to ppm.

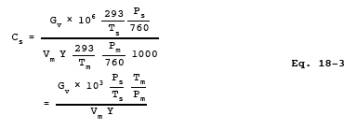

12.2 Calculate the

concentration, Cs, in ppm using the following equation:

![]()

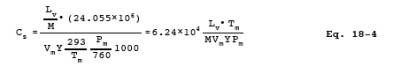

12.3 Calculate the

concentration, Cs, in ppm of the organic in the final gas mixture

using the following equation:

![]()

12.4 Calculate each

organic standard concentration, Cs, in ppm

using the following equation:

12.5 Calculate each

organic standard concentration, Cs, in ppm

using the following equation:

12.6

Calculate the concentration, Cc, in ppm, dry basis,

of each organic is the sample using the following equation:

12.7 Calculate the

average fraction recovered (R) of each spiked target compound using the

following equation:

![]()

12.8

Correct all field measurements with the calculated R value for that compound

using the following equation:

![]()

12.9

Determine the mass per volume of spiked compound measured using the following

equation:

![]()

12.10 Calculate the

fraction of spiked compound recovered, R, using the following equation:

![]()

13.0 Method Performance.

13.1 Since a

potential sample may contain a variety of compounds from various sources, a

specific precision limit for the analysis of field samples is impractical. Precision

in the range of 5 to 10 percent relative standard deviation (RSD) is typical

for gas chromatographic techniques, but an experienced GC operator with a

reliable instrument can readily achieve 5 percent RSD. For this method, the

following combined GC/operator values are required.

(a) Precision.

Triplicate analyses of calibration standards fall within 5 percent of their

mean value. (b) Accuracy. Analysis results of prepared audit samples are within

10 percent of preparation values. (c) Recovery. After developing an appropriate

sampling and analytical system for the pollutants of interest, conduct the

procedure in Section 8.4. Conduct the appropriate

recovery study in Section 8.4 at each sampling point where the method is being

applied. Submit the data and results of the recovery procedure with the

reporting of results under Section 8.3.

14.0 Pollution Prevention. [Reserved]

15.0 Waste Management. [Reserved]

16.0 Alternative Procedures.

16.1 Optional Presurvey and Presurvey Sampling.

NOTE: Presurvey screening is optional. Presurvey

sampling should be conducted for sources where the target pollutants are not

known from previous tests and/or process knowledge. Perform a presurvey for

each source to be tested. Refer to Figure 18-1. Some of

the information can be collected from literature surveys and source personnel.

Collect gas samples that can be analyzed to confirm the identities and

approximate concentrations of the organic emissions.

16.1.1 Apparatus.

This apparatus list

also applies to Sections 8.2 and 11.

16.1.1.1 Teflon

Tubing. (Mention of trade names or specific products does not constitute

endorsement by the U.S. Environmental Protection Agency.) Diameter and length

determined by connection requirements of cylinder regulators and the GC.

Additional tubing is necessary to connect the GC sample loop to the sample.

16.1.1.2 Gas

Chromatograph. GC with suitable detector, columns, temperature-controlled

sample loop and valve assembly, and temperature programmable oven, if

necessary. The GC shall achieve sensitivity requirements for the compounds

under study.

16.1.1.3 Pump.

Capable of pumping 100 ml/min. For flushing sample loop.

16.1.1.4 Flow Meter.

To measure flow rates.

16.1.1.5 Regulators.

Used on gas cylinders for GC and for cylinder standards.

16.1.1.6 Recorder.

Recorder with linear strip chart is minimum acceptable. Integrator (optional)

is recommended.

16.1.1.7 Syringes.

0.5-ml, 1.O- and 10-microliter size, calibrated, maximum accuracy (gas tight)

for preparing calibration standards. Other appropriate sizes can be used.

16.1.1.8 Tubing

Fittings. To plumb GC and gas cylinders.

16.1.1.9 Septa. For

syringe injections.

16.1.1.10 Glass Jars.

If necessary, clean, colored glass jars with Teflon-lined lids for condensate

sample collection. Size depends on volume of condensate.

16.1.1.11 Soap Film

Flowmeter. To determine flow rates.

16.1.1.12 Tedlar

Bags. 10- and 50-liter capacity, for preparation of standards.

16.1.1.13 Dry Gas

Meter with Temperature and Pressure Gauges. Accurate to ± 2 percent, for

preparation of gas standards.

16.1.1.14 Midget

Impinger/Hot Plate Assembly. For preparation of gas standards.

16.1.1.15 Sample

Flasks. For presurvey samples, must have gas-tight seals.

16.1.1.16 Adsorption

Tubes. If necessary, blank tubes filled with necessary adsorbent (charcoal,

Tenax, XAD-2, etc.) for presurvey samples.

16.1.1.17 Personnel

Sampling Pump. Calibrated, for collecting adsorbent tube presurvey samples.

16.1.1.18 Dilution

System. Calibrated, the dilution system is to be constructed following the

specifications of an acceptable method.

16.1.1.19 Sample

Probes. Pyrex or stainless steel, of sufficient length to reach centroid of

stack, or a point no closer to the walls than 1 m.

16.1.1.20 Barometer.

To measure barometric pressure.

16.1.2 Reagents.

16.1.2.1 Water.

Deionized distilled.

16.1.2.2 Methylene

chloride.

16.1.2.3 Calibration

Gases. A series of standards prepared for every compound of interest.

16.1.2.4 Organic

Compound Solutions. Pure (99.9 percent), or as pure as can reasonably be

obtained, liquid samples of all the organic compounds needed to prepare calibration

standards.

16.1.2.5 Extraction

Solvents. For extraction of adsorbent tube samples in preparation for analysis.

16.1.2.6 Fuel. As

recommended by the manufacturer for operation of the GC.

16.1.2.7 Carrier Gas.

Hydrocarbon free, as recommended by the manufacturer for operation of the

detector and compatibility with the column.

16.1.2.8 Zero Gas.

Hydrocarbon free air or nitrogen, to be used for dilutions, blank preparation,

and standard preparation.

16.1.3 Sampling.

16.1.3.1 Collection

of Samples with Glass Sampling Flasks. Presurvey samples may be collected in

precleaned 250-ml double-ended glass sampling flasks. Teflon stopcocks, without

grease, are preferred. Flasks should be cleaned as follows: Remove the

stopcocks from both ends of the flasks, and wipe the parts to remove any

grease. Clean the stopcocks, barrels, and receivers with methylene chloride (or

other non-target pollutant solvent, or heat and humidified air). Clean all

glass ports with a soap solution, then rinse with tap and deionized distilled

water. Place the flask in a cool glass annealing furnace, and apply heat up to

500¡C. Maintain at this temperature for 1 hours. After this time period, shut

off and open the furnace to allow the flask to cool. Return the stopcocks to

the flask receivers. Purge the assembly with high-purity nitrogen for 2 to 5

minutes. Close off the stopcocks after purging to maintain a slight positive

nitrogen pressure. Secure the stopcocks with tape. Presurvey samples can be

obtained either by drawing the gases into the previously evacuated flask or by

drawing the gases into and purging the flask with a rubber suction bulb.

16.1.3.1.1 Evacuated

Flask Procedure. Use a high-vacuum pump to evacuate the flask to the capacity

of the pump; then close off the stopcock leading to the pump. Attach a 6-mm

outside diameter (OD) glass tee to the flask inlet with a short piece of Teflon

tubing. Select a 6-mm OD borosilicate sampling probe, enlarged at one end to a

12-mm OD and of sufficient length to reach the centroid of the duct to be

sampled. Insert a glass wool plug in the enlarged end of the probe to remove

particulate matter. Attach the other end of the probe to the tee with a short

piece of Teflon tubing. Connect a rubber suction bulb to the third leg of the

tee. Place the filter end of the probe at the centroid of the duct, and purge

the probe with the rubber suction bulb. After the probe is completely purged

and filled with duct gases, open the stopcock to the grab flask until the

pressure in the flask reaches duct pressure. Close off the stopcock, and remove

the probe from the duct. Remove the tee from the flask and tape the stopcocks

to prevent leaks during shipment. Measure and record the duct temperature and

pressure.

16.1.3.1.2 Purged

Flask Procedure. Attach one end of the sampling flask to a rubber suction bulb.

Attach the other end to a 6-mm OD glass probe as described in Section

8.3.3.1.1. Place the filter end of the probe at the centroid of the duct, or at

a point no closer to the walls than 1 m, and apply suction with the bulb to

completely purge the probe and flask. After the flask has been purged, close

off the stopcock near the suction bulb, and then close off the stopcock near

the probe. Remove the probe from the duct, and disconnect both the probe and suction

bulb. Tape the stopcocks to prevent leakage during shipment. Measure and record

the duct temperature and pressure.

16.1.3.2 Flexible Bag

Procedure. Tedlar or aluminized Mylar bags can also be used to obtain the

presurvey sample. Use new bags, and leak-check them before field use. In

addition, check the bag before use for contamination by filling it with

nitrogen or air, and analyzing the gas by GC at high sensitivity. Experience

indicates that it is desirable to allow the inert gas to remain in the bag

about 24 hours or longer to check for desorption of organics from the bag.

Follow the leak-check and sample collection procedures given in Section 8.2.1.

16.1.3.3

Determination of Moisture Content. For combustion or water- controlled processes,

obtain the moisture content from plant personnel or by measurement during the

presurvey. If the source is below 59¡C, measure the wet bulb and dry bulb

temperatures, and calculate the moisture content using a psychrometric chart.

At higher temperatures, use Method 4 to determine the moisture content.

16.1.4 Determination of Static Pressure.

Obtain the static

pressure from the plant personnel or measurement. If a type S pitot tube and an

inclined manometer are used, take care to align the pitot tube 90¡ from the

direction of the flow. Disconnect one of the tubes to the manometer, and read

the static pressure; note whether the reading is positive or negative.

16.1.5 Collection of Presurvey Samples with Adsorption Tube.

Follow Section 8.2.4 for presurvey sampling.

17.0 References.

1. American Society

for Testing and Materials. C1 Through C5 Hydrocarbons in the Atmosphere by Gas

Chromatography. ASTM D 2820-72, Part 23. Philadelphia, Pa. 23:950-958. 1973.

2. Corazon, V.V.

Methodology for Collecting and Analyzing Organic Air Pollutants. U.S.

Environmental Protection Agency. Research Triangle Park, N.C. Publication No.

EPA-600/2-79-042. February 1979.

3. Dravnieks, A.,

B.K. Krotoszynski, J. Whitfield, A. O'Donnell, and T. Burgwald. Environmental

Science and Technology. 5(12):1200-1222. 1971.

4. Eggertsen, F.T.,

and F.M. Nelsen. Gas Chromatographic Analysis of Engine Exhaust and Atmosphere.

Analytical Chemistry. 30(6): 1040-1043. 1958.

5. Feairheller, W.R.,

P.J. Marn, D.H. Harris, and D.L. Harris. Technical Manual for Process Sampling

Strategies for Organic Materials. U.S. Environmental Protection Agency.

Research Triangle Park, N.C. Publication No. EPA 600/2-76-122. April 1976. 172

p.

6. Federal Register,

39 FR 9319-9323. 1974.

7. Federal Register,

39 FR 32857-32860. 1974.

8. Federal Register,

23069-23072 and 23076-23090. 1976.

9. Federal Register,

46569-46571. 1976.

10. Federal Register,

41771-41776. 1977.

11. Fishbein, L.

Chromatography of Environmental Hazards, Volume II. Elesevier Scientific

Publishing Company. New York, N.Y. 1973.

12. Hamersma, J.W.,

S.L. Reynolds, and R.F. Maddalone. EPA/IERL-RTP Procedures Manual: Level 1

Environmental Assessment. U.S. Environmental Protection Agency. Research

Triangle Park, N.C. Publication No. EPA 600/276-160a. June 1976. 130 p.

13. Harris, J.C.,

M.J. Hayes, P.L. Levins, and D.B. Lindsay. EPA/IERL-RTP Procedures for Level 2

Sampling and Analysis of Organic Materials. U.S. Environmental Protection

Agency. Research Triangle Park, N.C. Publication No. EPA 600/7-79-033. February

1979. 154 p.

14. Harris, W.E.,

H.W. Habgood. Programmed Temperature Gas Chromatography. John Wiley and Sons,

Inc. New York. 1966.

15. Intersociety

Committee. Methods of Air Sampling and Analysis. American Health Association.

Washington, D.C. 1972.

16. Jones, P.W., R.D.

Grammer, P.E. Strup, and T.B. Stanford. Environmental Science and Technology.

10:806-810. 1976.

17. McNair Han

Bunelli, E.J. Basic Gas Chromatography. Consolidated Printers. Berkeley. 1969.

18. Nelson, G.O.

Controlled Test Atmospheres, Principles and Techniques. Ann Arbor. Ann Arbor

Science Publishers. 1971. 247 p.

19. NIOSH Manual of

Analytical Methods, Volumes 1, 2, 3, 4, 5, 6, 7. U.S. Department of Health and

Human Services, National Institute for Occupational Safety and Health. Center

for Disease Control. 4676 Columbia Parkway, Cincinnati, Ohio 45226. April 1977

- August 1981. May be available from the Superintendent of Documents,

Government Printing Office, Washington, D.C. 20402. Stock Number/Price:

Volume 1 -

O17-033-00267-3/$13

Volume 2 -

O17-033-00260-6/$11

Volume 3 -

O17-033-00261-4/$14

Volume 4 -

O17-033-00317-3/$7.25

Volume 5 -

O17-033-00349-1/$10,

Volume 6 -

O17-033-00369-6/$9,

Volume 7 -

O17-033-00396-5/$7.

Prices subject to

change. Foreign orders add 25 percent.

20. Schuetzle, D.,

T.J. Prater, and S.R. Ruddell. Sampling and Analysis of Emissions from

Stationary Sources; I. Odor and Total Hydrocarbons. Journal of the Air

Pollution Control Association. 25(9): 925-932. 1975.

21. Snyder, A.D., F.N.

Hodgson, M.A. Kemmer and J.R. McKendree. Utility of Solid Sorbents for Sampling

Organic Emissions from Stationary Sources. U.S. Environmental Protection

Agency. Research Triangle Park, N.C. Publication No. EPA 600/2-76-201. July

1976. 71 p.

22. Tentative Method

for Continuous Analysis of Total Hydrocarbons in the Atmosphere. Intersociety

Committee, American Public Health Association. Washington, D.C. 1972. p.

184-186.

23. Zwerg, G. CRC

Handbook of Chromatography, Volumes I and II. Sherma, Joseph (ed.). CRC Press.

Cleveland. 1972.

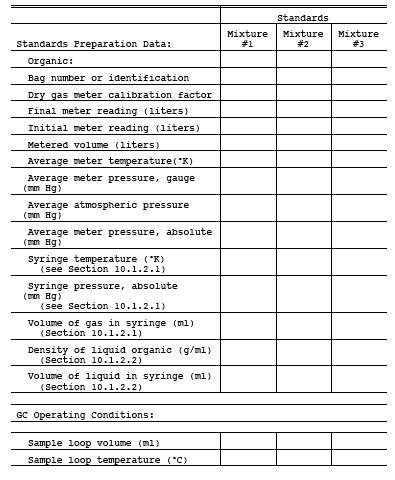

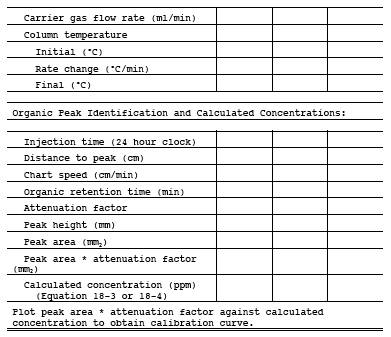

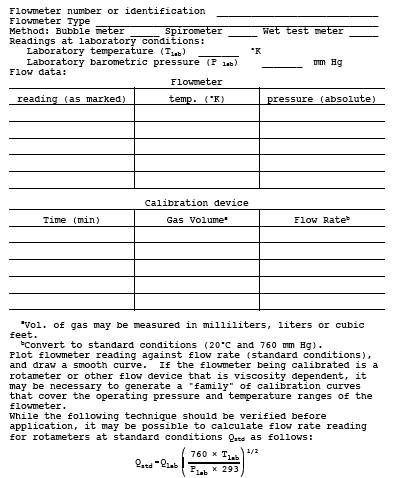

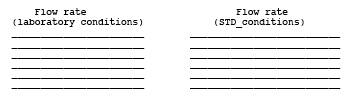

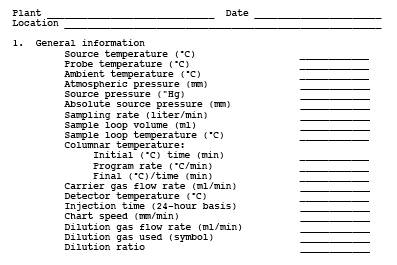

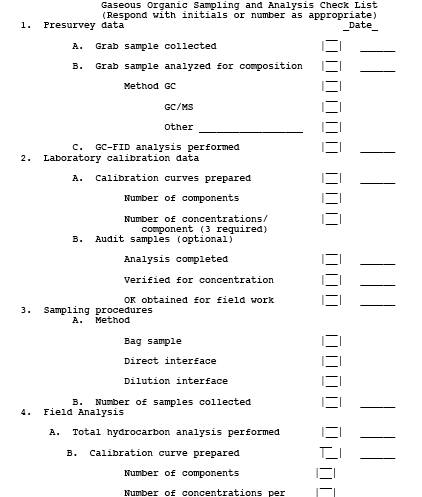

18.0 Tables, Diagrams, Flowcharts, and Validation Data.

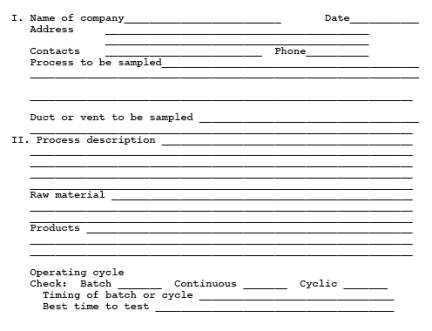

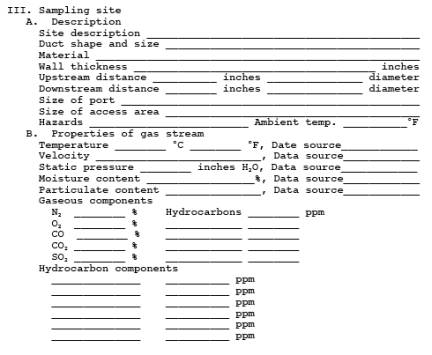

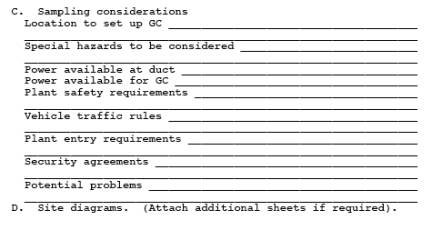

Figure

18-1. Preliminary survey data sheet.

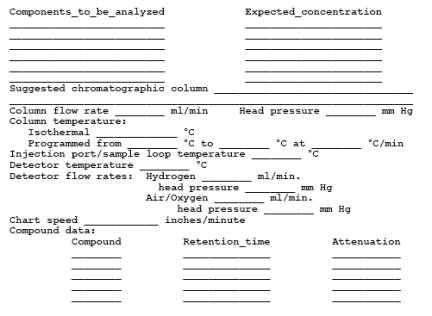

Figure

18-2. Chromatographic conditions data sheet.

Figure

18-3. Preparation of Standards in Tedlar Bags and Calibration Curve.

Figure

18-4. Flowmeter Calibration.

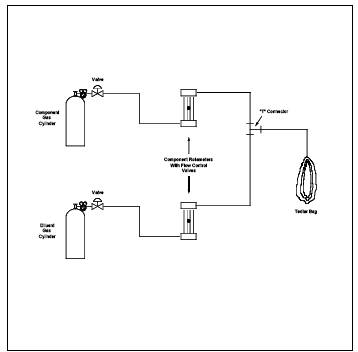

Figure 18-5. Single-Stage Calibration Gas Dilution System.

Figure

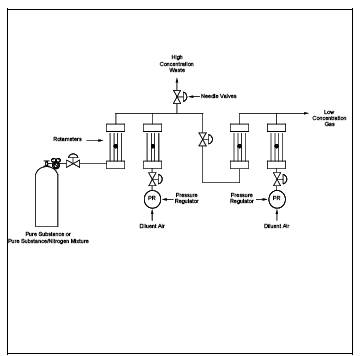

18-6. Two-Stage Dilution Apparatus.

Figure

18-7. Standards prepared by dilution of cylinder standard.

Figure

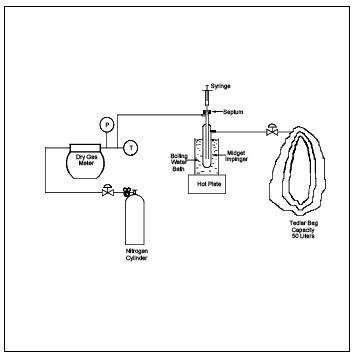

18-8. Apparatus for Preparation of Liquid Materials.

Figure

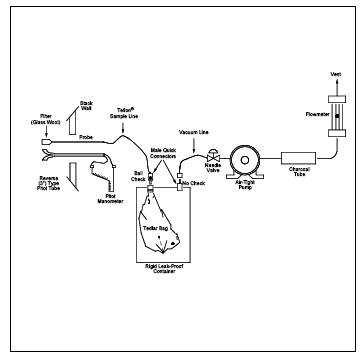

18-9. Integrated Bag Sampling Train.

Figure

18-9a. Explosion Risk Gas Sampling Method.

Figure

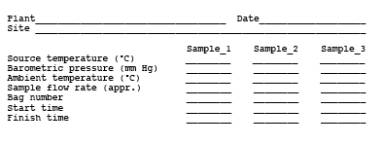

18-10. Field sample data sheet - Tedlar bag collection method.

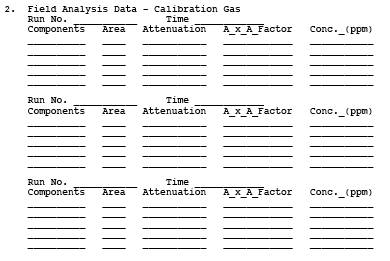

Figure

18-11. Field analysis data sheets.

Figure

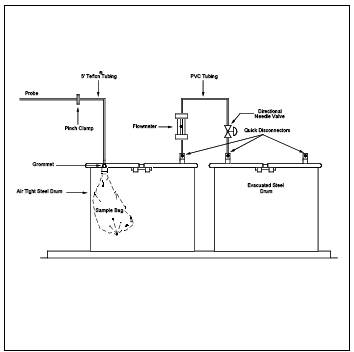

18-12. Direct Interface Sampling System.

Figure

18-13. Schematic Diagram of the Heated Box Required for Dilution of Sample Gas.

Figure

18-14. Sampling and analysis sheet.

component (3 required)