Method 20 -

Determination of Nitrogen Oxides, Sulfur Dioxide, and Oxygen Emissions from

Stationary Gas Turbines

1. APPLICABILITY

AND PRINCIPLE

3. MEASUREMENT SYSTEM

PERFORMANCE SPECIFICATIONS

4.4 Diluent Calibration

Gases.

5. MEASUREMENT SYSTEM

PERFORMANCE TEST PROCEDURES

5.2 Measurement System

Preparation.

5.6 NO2 to NO

Conversion Efficiency.

6. EMISSION MEASUREMENT

TEST PROCEDURE

6.1.1 Selection of a

Sampling Site.

6.1.2.1 Minimum Number

of Points.

6.1.2.2 Cross-sectional

Layout and Location of Traverse Points.

6.1.2.3 Preliminary

Diluent Measurement.

6.1.2.4 Selection of

Emission Test Sampling Points.

6.2 NOx and Diluent

Measurement.

7.3 Correction of

Pollutant Concentrations to 15 percent O2.

7.4 Average Adjusted

NOx Concentration.

7.5 NOx and SO2

Emission Rate Calculations.

1. APPLICABILITY AND PRINCIPLE

1.1 Applicability.

This method is

applicable for the determination of nitrogen oxides (NOx), sulfur dioxide

(SO2), and oxygen (O2) emissions from stationary gas turbines. For the NOx and

O2 determinations, this method includes: (1) measurement system design

criteria, (2) analyzer performance specifications and performance test

procedures; and (3) procedures for emission testing.

1.2 Principle.

A gas sample

in continuously extracted from the exhaust stream of a stationary gas turbine;

a portion of the sample stream is conveyed to instrumental analyzers for

determination of NOx and O2 content. During each NOx and O2 determination, a

separate measurement of SO2 emissions is made, using Method

6, or its equivalent. The O2 determination is used to adjust the NOx and

SO2 concentrations to a reference condition.

2. DEFINITIONS

2.1 Measurement System.

The total

equipment required for the determination of a gas concentration or a gas

emission rate. The system consists of the following major subsystems:

2.1.1 Sample Interface.

That portion

of a system that is used for one or more of the following: sample acquisition,

sample transportation, sample conditioning, or protection of the analyzers from

the effects of the stack effluent.

2.1.2 NOx Analyzer.

That portion

of the system that senses NOx and

generates an output proportional to the gas concentration.

2.1.3 O2 Analyzer.

That portion

of the system that senses O2 and

generates an output proportional to the gas concentration.

2.2 Span Value.

The upper

limit of a gas concentration measurement range that is specified for affected source

categories in the applicable part of the regulations.

2.3 Calibration Gas.

A known

concentration of a gas in an appropriate diluent gas.

2.4 Calibration Error.

The difference

between the gas concentration indicated by the measurement system and the known

concentration of the calibration gas.

2.5 Zero Drift.

The difference

in the measurement system output readings from zero after a stated period of

operation during which no unscheduled maintenance, repair, or adjustment took

place and the input concentration at the time of the measurements was zero.

2.6 Calibration Drift.

The difference

in the measurement system output readings from the known concentration of the

calibration gas after a stated period of operation during which no unscheduled

maintenance, repair, or adjustment took place and the input at the time of the

measurements was a high-level value.

2.7 Response Time.

The amount of

time required for the continuous monitoring system to display on the data

output 95 percent of a step change in pollutant concentration.

2.8 Interference Response.

The output

response of the measurement system to

a component in

the sample gas other than the gas component being measured.

3. MEASUREMENT SYSTEM PERFORMANCE SPECIFICATIONS

3.1 NO2 to NO Converter. Greater than 90 percent conversion

efficiency of

NO2 to NO.

3.2

Interference Response. Less

than ±2 percent of span value.

3.3

Response Time. No

greater than 3 seconds.

3.4 Zero

Drift. Less than ±2

percent of span value over the period of each test run.

3.5

Calibration Drift. Less

than ±2 percent of span value over the period of each test run.

4. APPARATUS AND REAGENT

4.1 Measurement System.

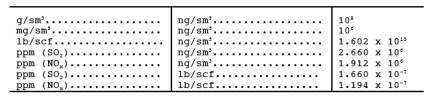

Use any

measurement system for NOx and O2 that is expected to meet the specifications

in this method. A schematic of an acceptable measurement system is shown in Figure 20-1. The essential components of the measurement

system are described below:

4.1.1

Sample Probe. Heated

stainless steel, or equivalent, open-ended, straight tube of sufficient length

to traverse the sample points.

4.1.2

Sample Line. Heated

(>95ūC) stainless steel or Teflon tubing to transport the sample gas to the

sample conditioners and analyzers.

4.1.3

Calibration Valve Assembly. A

three-way valve assembly to direct the zero and calibration gases to the sample

conditioners and to the analyzers. The calibration valve assembly shall be

capable of blocking the sample gas flow and of introducing calibration gases to

the measurement system when in the calibration mode.

4.1.4 NO2 to NO Converter. That portion of the system that converts

NO2 in the sample gas to NO. Some analyzers

are designed to measure NOx as NO2 on a wet basis and can be used without an

NO2 to NO converter or a moisture removal trap provided the sample line to the

analyzer is heated (>95ūC) to the inlet of the analyzer. In addition, an NO2

to NO converter is not necessary if the NO2 portion of the exhaust gas is less

than 5 percent of the total NOx concentration. As a guideline, an NO2 to NO

converter is not necessary if the gas turbine is operated at 90 percent or more

of peak load capacity. A converter is necessary under lower load conditions.

4.1.5

Moisture Removal Trap. A

refrigerator-type condenser or other type device designed to remove continuously

condensate from the sample gas while maintaining minimal contact between any

condensate and the sample gas. The moisture removal trap is not necessary for

analyzers that can measure NOx concentrations

on a wet basis; for these analyzers, (a) heat the sample line up to the inlet

of the analyzers, (b) determine the moisture content using methods subject to

the approval of the Administrator, and (c) correct the NOx and O2 concentration to a dry basis.

4.1.6

Particulate Filter. An

in-stack or an out-of-stack glass fiber filter, of the type specified in Method

5; however, an out-of-stack filter is recommended when the stack gas

temperature exceeds 250 to 300ūC.

4.1.7

Sample Pump. A

nonreactive leak-free sample pump to pull the sample gas through the system at

a flow rate sufficient to minimize transport delay. The pump shall be made from

stainless steel or coated with Teflon, or equivalent.

4.1.8

Sample Gas Manifold. A

sample gas manifold to divert portions of the sample gas stream to the

analyzers. The manifold may be constructed of glass, Teflon, stainless steel,

or equivalent.

4.1.9

Diluent Gas. An analyzer

to determine the percent O2 or CO2 concentration of the sample gas stream.

4.1.10

Nitrogen Oxides Analyzer. An

analyzer to determine the ppm NOx concentration

in the sample gas stream.

4.1.11 Data

Output. A strip-chart

recorder, analog computer, or digital recorder for recording measurement data.

4.2 SO2 Analysis.

Method 6

apparatus and reagents.

4.3 NOx Calibration Gases.

The

calibration gases for the NOx analyzer shall be NO in N2. Use four

calibration gas mixtures as specified below:

4.3.1

High-level Gas. A gas

concentration that is equivalent to 80 to 90 percent of the span value.

4.3.2

Mid-level Gas. A gas

concentration that is equivalent to 45 to 55 percent of the span value.

4.3.3

Low-level Gas. A gas

concentration that is equivalent to 20 to 30 percent of the span value.

4.3.4 Zero

Gas. A gas concentration

of less than 0.25 percent of the span value. Ambient air may be used for the

NOx zero gas.

4.4 Diluent Calibration Gases.

Use purified

air at 20.9 percent O2 as the high-level O gas. Use a gas concentration that is

equivalent to 11-14 percent O2 in N2 for the mid-level gas. Use purified N2 for

the zero gas.

5. MEASUREMENT SYSTEM PERFORMANCE TEST PROCEDURES

Perform the

following procedures before measurement of emissions (Section 6) and only once

for each test program, i.e., the series of all test runs for a given gas

turbine engine.

5.1 Calibration Gas Checks.

There are two

alternatives for checking gases. (a) The first is to use calibration gases that

are documented traceable to National Bureau of Standards Reference Materials.

Use "Traceability Protocol for Establishing True Concentrations of Gases

Used for Calibrations and Audits of Continuous Source Emission Monitors"

(Protocol Number 1) that is available from the Environmental Monitoring Support

Laboratory, Quality Assurance Branch, Mail Drop 77, Environmental Protection

Agency, Research Triangle Park, NC 27711. Obtain a certification from the gas

manufacturer that the protocol was followed. These calibration gases are not to

be analyzed with the Reference Methods. (b) The second alternative is to use

calibration gases not prepared according to the protocol. If this alternative

is chosen, within 1 month prior to the emission test, analyze each of the

calibration gas mixtures in triplicate using Method 7

or the procedure outlined in Citation 1 of the Bibliography for NOx and use Method 3 for O2 or CO2 . Record the results on a data

sheet (example is shown in Figure 20-2). For the

low-level, mid-level, or high-level gas mixtures, each of the individual NOx

analytical results must be within 10 percent (or 10 ppm, whichever is greater)

of the triplicate set average (O2 or CO2 test results must be within 0.5

percent O2 or CO2);otherwise, discard the entire set and repeat the triplicate

analyses. If the average of the triplicate reference method test results is

within 5 percent for NOx gas or 0.5 percent O2 or CO2 for the O2 or CO2 gas of

the calibration gas manufacturer's tag value, use the tag value; otherwise,

conduct at least three additional reference method test analyses until the

results of six individual NOx runs (the three original plus three additional)

agree within 10 percent (or 10 ppm, whichever is greater) of the average (O2 or

CO2 test results must be within 0.5 percent O2 or CO2 ). Then use this average

for the cylinder value.

5.2 Measurement System Preparation.

Before the

emission test, assemble the measurement system following the manufacturer's

written instructions in preparing and operating the NO2 to NO converter, the

NOx analyzer, the O2 analyzer, and other components.

5.3 Calibration Check.

Conduct the

calibration checks for both the NO2 and the diluent analyzers as follows:

5.3.1 After the measurement system has been

prepared for use (Section 5.2), introduce zero gases and the mid-level

calibration gases; set the analyzer output responses to the appropriate levels.

Then introduce each of the remainder of the calibration gases described in

Section 4.3 or 4.4, one at a time, to the measurement system. Record the

responses on a form similar to Figure 20-3.

5.3.2 If the linear curve determined from the

zero and mid-level calibration gas responses does not predict the actual

response of the low-level (not applicable for the diluent analyzer) and high-level

gases within ±2 percent of the span value, the calibration shall be considered

invalid. Take corrective measures on the measurement system before proceeding

with the test.

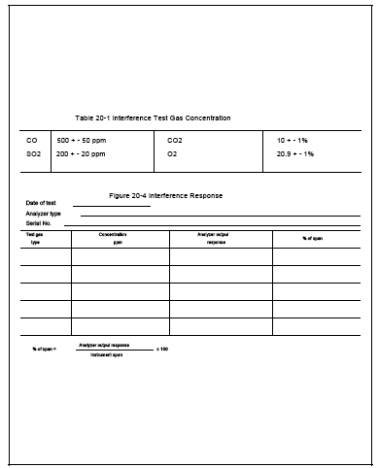

5.4 Interference Response.

5.4.1 Introduce the gaseous components listed

in Table 20-1 into the measurement system separately, or

as gas mixtures. Determine the total interference output response of the system

to these components in concentration units; record the values on a form similar

to Figure 20-4. If the sum of the interference responses

of the test gases for either the NOx or diluent analyzers is greater than 2

percent of the applicable span value, take corrective measures on the

measurement system.

5.4.2 Conduct an interference response test of

each analyzer before its initial use in the field. Thereafter, recheck the

measurement system if changes are made in the instrumentation that could alter

the interference response, e.g., changes in the type of gas detector.

5.4.3 In lieu of conducting the interference

response test, instrument vendor data, which demonstrate that for the test

gases of Table 20-1 the interference performance specification is not exceeded,

are acceptable.

5.5 Response Time.

To determine

response time, first introduce zero gas into the system at the calibration

valve until all readings are stable; then, switch to monitor the stack effluent

until a stable reading can be obtained. Record the upscale response time. Next,

introduce high-level calibration gas into the system. Once the system has

stabilized at the high-level calibration concentration, switch to monitor the

stack effluent and wait until a stable value is reached. Record the downscale

response time. Repeat the procedure three times. A stable value is equivalent

to a change of less than 1 percent of span value for 30 seconds or less than 5

percent of the measured average concentration for 2 minutes. Record the

response time data on a form similar to Figure 20-5, the

readings of the upscale or downscale response time, and report the greater time

as the "response time" for the analyzer. Conduct a response time test

before the initial field use of the measurement system, and repeat if changes

are made in the measurement system.

5.6 NO2

to NO Conversion Efficiency.

5.6.1 Add gas from the mid-level NO in N2

calibration gas cylinder to a clean, evacuated, leak-tight Tedlar bag. Dilute

this gas approximately 1:1 with 20.9 percent O2, purified air. Immediately

attach the bag outlet to the calibration valve assembly and begin operation of

the sampling system. Operate the sampling system, recording the NOx response,

for at least 30 minutes. If the NO2 to NO conversion is 100 percent, the

instrument response will be stable at the highest peak value observed. If the

response at the end of 30 minutes decreases more than 2.0 percent of the

highest peak value, the system is not acceptable and corrections must be made

before repeating the check.

5.6.2 Alternatively, the NO2 to NO converter

check described in title 40, Part 86: Certification and Test Procedures for

Heavy-duty Engines for 1979 and Later Model Years, may be used. Other

alternative procedures may be used with approval of the Administrator.

6. EMISSION MEASUREMENT TEST PROCEDURE

6.1 Preliminaries.

6.1.1 Selection of a Sampling Site.

Select a

sampling site as close as practical to the exhaust of the turbine. Turbine

geometry, stack configuration, internal baffling, and point of introduction of

dilution air will vary for different turbine designs. Thus, each of these

factors must be given special consideration in order to obtain a representative

sample. Whenever possible, the sampling site shall be located upstream of the

point of introduction of dilution air into the duct. Sample ports may be

located before or after the upturn elbow, in order to accommodate the

configuration of the turning vanes and baffles and to permit a complete,

unobstructed traverse of the stack. The sample ports shall not be located

within 5 feet or 2 diameters (whichever is less) of the gas discharge to

atmosphere. For supplementary-fired, combined-cycle plants, the sampling site

shall be located between the gas turbine and the boiler. The diameter of the

sample ports shall be sufficient to allow entry of the sample probe.

6.1.2 Preliminary O2 or CO2

A preliminary

O2 or CO2 traverse is made for the purpose of selecting sampling points of low

O2 values or high CO2 concentrations as appropriate for the measurement system.

Conduct this test at the turbine operating condition that is the lowest

percentage of peak load operation included in the program. Follow the procedure

below or alternative procedures subject to the approval of the Administrator.

6.1.2.1 Minimum Number of Points.

Select a minimum

number of points as follows: (1) Eight, for stacks having cross-sectional areas

less than 1.5 m2

(16.1 ft2); (2) eight plus one additional sample

point for each 0.2 m2

(2.2 ft2) of areas, for stacks of 1.5 m2 to 10.0 m2 (16.1

to 107.6 ft2) in cross-sectional area; and (3) 49

sample points (48 for circular stacks) for stacks greater than 10.0 m2 (107.6 ft2)

in cross-sectional area. Note that for circular ducts, the number of sample

points must be a multiple of 4, and for rectangular ducts, the number of points

must be one of those listed in Table 20-2; therefore,

round off the number of points (upward), when appropriate.

6.1.2.2 Cross-sectional Layout and Location of Traverse Points.

After the

number of traverse points for the preliminary diluent sampling has been

determined, use Method 1 to locate the traverse points.

6.1.2.3 Preliminary Diluent Measurement.

While the gas

turbine is operating at the lowest percent of peak load, conduct a preliminary

diluent measurement as follows: Position the probe at the first traverse point

and begin sampling. The minimum sampling time at each point shall be 1 minute

plus the average system response time. Determine the average steady-state

concentration of O2 at each point and record the data on Figure

20-6.

6.1.2.4 Selection of Emission Test Sampling Points.

Select the

eight sampling points at which the lowest O2 concentrations or highest CO2

concentrations were obtained. Sample at each of these selected points during

each run at the different load conditions. More than eight points may be used,

if desired, providing that the points selected as described above are included.

6.2 NOx and Diluent Measurement.

This test is

to be conducted at each of the specified load conditions. Three test runs at

each load condition constitute a complete test.

6.2.1 At the beginning of each NOx test run

and, as applicable, during the run, record turbine data as indicated in Figure 20-7. Also, record the location and number of the

traverse points on a diagram.

6.2.2 Position the probe at the first point

determined in the preceding section and begin sampling. The minimum sampling

time at each point shall be at least 1 minute plus the average system response

time. Determine the average steady-state concentration of diluent and NOx at

each point and record the data on Figure 20-8.

6.2.3 After sampling the last point, conclude

the test run by recording the final turbine operating parameters and by

determining the zero and calibration drift, as follows: Immediately following

the test run at each load condition, or if adjustments are necessary for the

measurement system during the tests, reintroduce the zero and mid-level

calibration gases as described in Sections 4.3 and 4.4, one at a time, to the

measurement system at the calibration valve assembly. (Make no adjustments to

the measurement system until after the drift checks are made). Record the

analyzers' responses on a form similar to Figure 20-3. If the drift values

exceed the specified limits, the test run preceding the check is considered

invalid and will be repeated following corrections to the measurement system.

Alternatively, recalibrate the measurement system and recalculate the

measurement data. Report the test results based on both the initial calibration

and the recalibration data.

6.3 SO2 Measurement.

6.3.1 This test is conducted only at the 100 percent

peak load condition. Determine SO2 using Method 6, or equivalent, during the

test. Select a minimum of six total points from those required for the NOx

measurements; use two points for each sample run. The sample time at each point

shall be at least 10 minutes. Average the O2 readings taken during the NOx test

runs at sample points corresponding to the SO2 traverse points (see Section

6.2.2) and use this average diluent concentration to correct the integrated SO2 concentration obtained by Method 6 to 15 percent O2 (see Equation 20-1).

6.3.2 If the applicable regulation allows fuel

sampling and analysis for fuel sulfur content to demonstrate compliance with

sulfur emission unit, emission sampling with Method 6 is not required, provided

the fuel sulfur content meets the limits of the regulation.

7. EMISSION CALCULATIONS

7.1 Moisture Correction.

Measurement

data used in most of these calculations must be on a dry basis. If measurements

must be corrected to dry conditions, use the following equation:

![]()

where:

C d = Pollutant or diluent concentration

adjusted to dry conditions, ppm or percent

C w = Pollutant or diluent concentration

measured under moist sample conditions, ppm or percent.

B ws = Moisture content of sample gas as

measured with Method 4, reference method, or other approved method,

percent/100.

7.2 CO2 Correction Factor.

If pollutant

concentrations are to be corrected to 15 percent O2 and CO2 concentration is

measured in lieu of O2 concentration measurement, a CO2 correction factor is

needed. Calculate the CO2 correction factor as follows:

7.2.1 Calculate the fuel-specific F0 value for the fuel burned during the

test using values obtained from Method 19, Section 5.2, and the following

equation.

Where:

F o = Fuel factor based on the ratio of

oxygen volume to the ultimate CO2 volume produced by the fuel at zero percent

excess air, dimensionless.

0.209 =

Fraction of air that is oxygen, percent/100.

F d = Ratio of the volume of dry effluent

gas to the gross calorific value of the fuel from Method 19, dsm3/J (dscf/106Btu).

F c = Ratio of the volume or carbon dioxide

produced to the gross calorific value of the fuel from Method 19, dsm3/J (dscf/106 Btu).

7.2.2 Calculate the CO2 correction factor for

correcting measurement data to 15 percent oxygen, as follows:

![]()

where:

X CO2 = CO2

Correction factor, percent.

5.9 = 20.9

percent O2 - 15 percent O2 , the defined O2 correction value, percent.

7.3 Correction of Pollutant Concentrations to 15 percent O2.

Calculate the

NOx and SO2 gas concentrations adjusted to 15 percent O2 using Equation 20-4 or

20-5, as appropriate. The correction to 15 percent O2 is very sensitive to the

accuracy of the O2 or CO2 concentration measurement. At the level of the

analyzer drift specified in Section 3, the O2 or CO2 correction can exceed 5

percent at the concentration levels expected in gas turbine exhaust gases.

Therefore, O2 or CO2 analyzer stability and careful calibration are necessary.

7.3.1 Correction of Pollutant Concentration

Using O2 Concentration. Calculate the O2 corrected pollutant concentration, as

follows:

![]()

where:

C adj = Pollutant concentration corrected to

15 percent O2 ppm.

C d = Pollutant concentration measured, dry

basis, ppm.

%O2 = Measured O2 concentration dry basis,

percent.

7.3.2 Correction of Pollutant Concentration

Using CO2 Concentration. Calculate the CO2 corrected pollutant concentration,

as follows:

![]()

where:

%CO2 = Measured CO2 concentration measured,

dry basis, percent.

7.4 Average Adjusted NOx Concentration.

Calculate the

average adjusted NOx

concentration by summing the

adjusted values for each sample point and dividing by the number of points for

each run.

7.5 NOx and SO2 Emission Rate Calculations.

The emission

rates for NOx

and SO2 in units of

pollutant mass per quantity of heat input can be calculated using the pollutant

and diluent concentrations and fuel-specific F-factors based on the fuel

combustion characteristics. The measured concentrations of pollutant in units

of parts per million by volume (ppm) must be converted to mass per unit volume

concentration units for these calculations. Use the following table for such

conversions:

CONVERSION

FACTORS FOR CONCENTRATION

![]()

7.5.1 Calculation of Emission Rate Using Oxygen

Correction. Both the O2

concentration and the

pollutant concentration must be on a dry basis. Calculate the pollutant

emission rate, as follows:

![]()

where:

E = Mass emission

rate of pollutant, ng/J (lb/106 Btu).

7.5.2 Calculation of Emission Rate Using Carbon

Dioxide Correction. The CO2

concentration and the

pollutant concentration may be on either a dry basis or a wet basis, but both

concentrations must be on the same basis for the calculations. Calculate the

pollutant emission rate using Equation 20-7 or 20-8:

where:

C w = Pollutant concentration measured on a

moist sample basis, ng/sm3

(lb/scf).

%CO2W = Measured CO2 concentration measured on

a moist sample basis, percent.

8. BIBLIOGRAPHY

1. Curtis, F. A Method for Analyzing NOx

Cylinder Gases--Specific Ion Electrode Procedure, Monograph available from

Emission Measurement Branch, ESED, Research Triangle Park, NC 27711. October

1978.

2. Sigsby, John E., F.M. Black, T.A. Bellar,

and D.L. Klosterman. Chemiluminescent Method for Analysis of Nitrogen Compounds

in Mobile Source Emissions (NO, NO2 , and NH3). Environmental Science and

Technology. 7:51-54. January 1973.

3. Shigehara, T.T., R.M Neulicht, and W.S.

Smith. Validating Orsat Analysis Data from Fossil Fuel-Fired Units. Emission

Measurement Branch, Emission Standards and Engineering Division, Office of Air

Quality Planning and Standards, U.S. Environmental Protection Agency, Research

Triangle Park, NC 27711. June 1975.

Figure

20-1 Measurement System Design

Figure 20-2 Analysis of Calibration Gases Date

Figure

20-3 Zero and Calibration Data

Table

20-1 Interference Test Gas Concentration

Figure

20-4 Interference Response

Table

20-2 Cross-Sectional Layout for Rectangular Stacks

Figure

20-6 Preliminary Diluent Traverse

Figure

20-7 Stationary Gas Turbine Data

Figure

20-8 Stationary Gas Turbine Sample Point Record