METHOD

7 - DETERMINATION OF NITROGEN OXIDE EMISSIONS FROM STATIONARY SOURCES.

NOTE: This method does not include all of the

specifications (e.g.,

equipment and supplies) and procedures (e.g., sampling and analytical) essential to its

performance. Some material is incorporated by reference from other methods in

this part. Therefore, to obtain reliable results, persons using this method

should have a thorough knowledge of at least the following additional test

methods: Method 1 and Method

5.

5.2.1 Hydrogen Peroxide

(H2O2).

5.2.3 Sodium Hydroxide

(NaOH).

6.1.9 Volumetric

Pipette. 25-ml.

6.1.10 Stopcock and

Ground Joint Grease.

6.2.5 Test Paper for

Indicating pH.

6.3.2 Porcelain

Evaporating Dishes.

6.3.4 Dropping Pipette

or Dropper.

6.3.10 Test Paper for

Indicating pH.

7.3.5 Potassium Nitrate

(KNO3).

7.3.7 Working Standard

KNO3 Solution.

7.3.8 Phenoldisulfonic

Acid Solution.

7.3.9 Concentrated

Ammonium Hydroxide.

7.3.10 Quality

Assurance Audit Samples.

8.0 Sample Collection,

Preservation, Storage and Transport.

10.0 Calibration and

Standardization.

12.0 Data Analysis and

Calculations.

12.2 Spectrophotometer

Calibration Factor.

12.3 Sample Volume, Dry

Basis, Corrected to Standard Conditions.

12.5 Sample

Concentration, Dry Basis, Corrected to Standard Conditions.

12.6 Relative Error for

QA Audit Samples.

14.0 Pollution

Prevention. [Reserved]

15.0 Waste Management.

[Reserved]

17.0 Tables, Diagrams,

Flowcharts, and Validation Data.

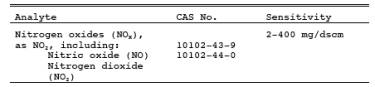

1.0 Scope and Application.

1.1 Analytes.

1.2 Applicability.

This method is

applicable for the measurement of nitrogen oxides (NOx) emitted from stationary sources.

1.3 Data Quality Objectives.

Adherence to the

requirements of this method will enhance the quality of the data obtained from

air pollutant sample methods.

2.0 Summary of Method.

A grab sample is

collected in an evacuated flask containing a dilute sulfuric acid-hydrogen

peroxide absorbing solution, and the nitrogen oxides, except nitrous oxide, are

measured colorimetrically using the phenoldisulfonic acid (PDS) procedure.

3.0 Definitions. [Reserved]

4.0 Interferences.

Biased results have been

observed when sampling under conditions of high sulfur dioxide concentrations

(above 2000 ppm).

5.0 Safety.

5.1 Disclaimer.

This method may

involve hazardous materials, operations, and equipment. This test method may

not address all of the safety problems associated with its use. It is the

responsibility of the user to establish appropriate safety and health practices

and to determine the applicability of regulatory limitations prior to

performing this test method.

5.2 Corrosive Reagents.

The following

reagents are hazardous. Personal protective equipment and safe procedures are

useful in preventing chemical splashes. If contact occurs, immediately flush

with copious amounts of water for at least 15 minutes. Remove clothing under

shower and decontaminate. Treat residual chemical burns as thermal burns.

5.2.1 Hydrogen Peroxide (H2O2).

Irritating to eyes,

skin, nose, and lungs.

5.2.2 Phenoldisulfonic Acid.

Irritating to eyes

and skin.

5.2.3 Sodium Hydroxide (NaOH).

Causes severe damage

to eyes and skin. Inhalation causes irritation to nose, throat, and lungs.

Reacts exothermically with limited amounts of water.

5.2.4 Sulfuric Acid (H2SO4).

Rapidly destructive

to body tissue. Will cause third degree burns. Eye damage may result in

blindness. Inhalation may be fatal from spasm of the larynx, usually within 30

minutes. May cause lung tissue damage with edema. 1 mg/m3 for 8 hours will cause lung damage or, in higher concentrations,

death. Provide ventilation to limit inhalation. Reacts violently with metals

and organics.

5.2.5 Phenol.

Poisonous and

caustic. Do not handle with bare hands as it is absorbed through the skin.

6.0 Equipment and Supplies.

6.1 Sample Collection.

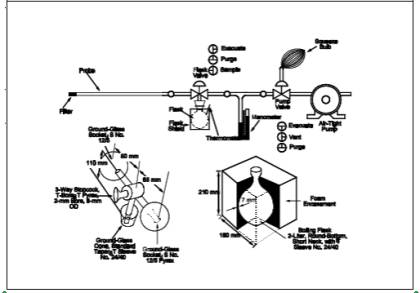

A schematic of the sampling

train used in performing this method is shown in Figure

7-1. Other grab sampling systems or equipment, capable of measuring sample

volume to within 2.0 percent and collecting a sufficient sample volume to allow

analytical reproducibility to within 5 percent, will be considered acceptable

alternatives, subject to the approval of the Administrator. The following items

are required for sample

collection:

6.1.1 Probe.

Borosilicate glass

tubing, sufficiently heated to prevent water condensation and equipped with an

in-stack or heated out-of-stack filter to remove particulate matter (a plug of

glass wool is satisfactory for this purpose). Stainless steel or Teflon tubing

may also be used for the probe. Heating is not necessary if the probe remains

dry during the purging period.

6.1.2 Collection Flask.

Two-liter

borosilicate, round bottom flask, with short neck and 24/40 standard taper

opening, protected against implosion or breakage.

6.1.3 Flask Valve.

T-bore stopcock

connected to a 24/40 standard taper joint.

6.1.4 Temperature Gauge.

Dial-type

thermometer, or other temperature gauge, capable of measuring 1 ¡C (2 ¡F)

intervals from -5 to 50 ¡C (23 to 122 ¡F).

6.1.5 Vacuum Line.

Tubing capable of withstanding

a vacuum of 75 mm (3 in.) Hg absolute pressure, with "T" connection

and T-bore stopcock.

6.1.6 Vacuum Gauge.

U-tube manometer, 1

meter (39 in.), with 1 mm (0.04 in.) divisions, or other gauge capable of

measuring pressure to within 2.5 mm (0.10 in.) Hg.

6.1.7 Pump.

Capable of evacuating

the collection flask to a pressure equal to or less than 75 mm (3 in.) Hg

absolute.

6.1.8 Squeeze Bulb.

One-way.

6.1.9 Volumetric Pipette. 25-ml.

6.1.10 Stopcock and Ground Joint Grease.

A highvacuum, high-temperature

chlorofluorocarbon grease is required. Halocarbon 25-5S has been found to be

effective.

6.1.11 Barometer.

Mercury, aneroid, or

other barometer capable of measuring atmospheric pressure to within 2.5 mm (0.1

in.) Hg. See NOTE in Method 5, Section 6.1.2.

6.2 Sample Recovery.

The following items

are required for sample recovery:

6.2.1 Graduated Cylinder.

50-ml with 1 ml

divisions.

6.2.2 Storage Containers.

Leak-free

polyethylene bottles.

6.2.3 Wash Bottle.

Polyethylene or

glass.

6.2.4 Glass Stirring Rod.

6.2.5 Test Paper for Indicating pH.

To cover the pH range

of 7 to 14.

6.3 Analysis.

The following items

are required for analysis:

6.3.1 Volumetric Pipettes.

Two 1-ml, two 2-ml,

one 3-ml, one 4-ml, two 10-ml, and one 25-ml for each sample and standard.

6.3.2 Porcelain Evaporating Dishes.

175- to 250-ml

capacity with lip for pouring, one for each sample and each standard. The Coors

No. 45006 (shallowform, 195-ml) has been found to be satisfactory.

Alternatively, polymethyl pentene beakers (Nalge No. 1203, 150-ml), or glass

beakers (150-ml) may be used. When glass beakers are used, etching of the

beakers may cause solid matter to be present in the analytical step; the solids

should be removed by filtration.

6.3.3 Steam Bath.

Low-temperature ovens

or thermostatically controlled hot plates kept below 70 ¡C (160 ¡F) are

acceptable alternatives.

6.3.4 Dropping Pipette or Dropper.

Three required.

6.3.5 Polyethylene Policeman.

One for each sample

and each standard.

6.3.6 Graduated Cylinder.

100-ml with 1-ml

divisions.

6.3.7 Volumetric Flasks.

50-ml (one for each

sample and each standard), 100-ml (one for each sample and each standard, and

one for the working standard KNO3 solution), and

1000-ml (one).

6.3.8 Spectrophotometer.

To measure at 410 nm.

6.3.9 Graduated Pipette.

10-ml with 0.1-ml

divisions.

6.3.10 Test Paper for Indicating pH.

To cover the pH range

of 7 to 14.

6.3.11 Analytical Balance.

To measure to within

0.1 mg.

7.0 Reagents and Standards.

Unless otherwise

indicated, it is intended that all reagents conform to the specifications

established by the Committee on Analytical Reagents of the American Chemical

Society, where such specifications are available; otherwise, use the best

available grade.

7.1 Sample Collection.

The following

reagents are required for sampling:

7.1.1 Water.

Deionized distilled

to conform to ASTM D 1193-77 or 91 Type 3 (incorporated by reference - see

¤60.17). The KMnO4 test for oxidizable organic matter may be

omitted when high concentrations of organic matter are not expected to be

present.

7.1.2 Absorbing Solution.

Cautiously add 2.8 ml

concentrated H2SO4 to a

1-liter flask partially filled with water. Mix well, and add 6 ml of 3 percent

hydrogen peroxide, freshly prepared from 30 percent hydrogen peroxide solution.

Dilute to 1 liter of water and mix well. The absorbing solution should be used

within 1 week of its preparation. Do not expose to extreme heat or direct sunlight.

7.2 Sample Recovery.

The following

reagents are required for sample recovery:

7.2.1 Water.

Same as in 7.1.1.

7.2.2 Sodium Hydroxide

1 N. Dissolve 40 g

NaOH in water, and dilute to 1 liter.

7.3 Analysis.

The following

reagents and standards are required for analysis:

7.3.1 Water.

Same as in 7.1.1.

7.3.2 Fuming Sulfuric Acid.

15 to 18 percent by

weight free sulfur trioxide. HANDLE WITH CAUTION.

7.3.3 Phenol.

White solid.

7.3.4 Sulfuric Acid.

Concentrated, 95

percent minimum assay.

7.3.5 Potassium Nitrate (KNO3).

Dried at 105 to 110

¡C (221 to 230 ¡F) for a minimum of 2 hours just prior to preparation of

standard solution.

7.3.6 Standard KNO3 Solution.

Dissolve exactly

2.198 g of dried KNO3

in water, and dilute to 1 liter

with water in a 1000-ml volumetric flask.

7.3.7 Working Standard KNO3 Solution.

Dilute 10 ml of the

standard solution to 100 ml with water. One ml of the working standard solution

is equivalent to 100 µg nitrogen dioxide (NO2).

7.3.8 Phenoldisulfonic Acid Solution.

Dissolve 25 g of pure

white phenol solid in 150 ml concentrated sulfuric acid on a steam bath. Cool,

add 75 ml fuming sulfuric acid (15 to 18 percent by weight free sulfur trioxide

- HANDLE WITH CAUTION), and heat at 100 ¡C (212 ¡F) for 2 hours. Store in a

dark, stoppered bottle.

7.3.9 Concentrated Ammonium Hydroxide.

7.3.10 Quality Assurance Audit Samples.

When making

compliance determinations, and upon availability, audit samples may be obtained

from the appropriate EPA Regional Office or from the responsible enforcement

authority. NOTE: The responsible enforcement authority should be

notified at least 30 days prior to the test date to allow sufficient time for

sample delivery.

8.0 Sample Collection, Preservation, Storage and Transport.

8.1 Sample Collection.

8.1.1 Flask Volume.

The volume of the

collection flask and flask valve combination must be known prior to sampling.

Assemble the flask and flask valve, and fill with water to the stopcock.

Measure the volume of water to ± 10 ml. Record this volume on the flask.

8.1.2 Pipette 25 ml

of absorbing solution into a sample flask, retaining a sufficient quantity for

use in preparing the calibration standards. Insert the flask valve stopper into

the flask with the valve in the "purge" position. Assemble the

sampling train as shown in Figure 7-1, and place the

probe at the sampling point. Make sure that all fittings are tight and

leak-free, and that all ground glass joints have been greased properly with a

high-vacuum, high- temperature chlorofluorocarbon-based stopcock grease. Turn

the flask valve and the pump valve to their "evacuate" positions.

Evacuate the flask to 75 mm (3 in.) Hg absolute pressure, or less. Evacuation

to a pressure approaching the vapor pressure of water at the existing

temperature is desirable. Turn the pump valve to its "vent" position,

and turn off the pump. Check for leakage by observing the manometer for any

pressure fluctuation. (Any variation greater than 10 mm (0.4 in.) Hg over a

period of 1 minute is not acceptable, and the flask is not to be used until the

leakage problem is corrected. Pressure in the flask is not to exceed 75 mm (3

in.) Hg absolute at the time sampling is commenced.) Record the volume of the

flask and valve (Vf), the flask temperature (Ti), and the barometric pressure. Turn the flask valve

counterclockwise to its "purge" position, and do the same with the

pump valve. Purge the probe and

the vacuum tube using the squeeze bulb. If condensation occurs in the probe and

the flask valve area, heat the probe, and purge until the condensation

disappears. Next, turn the pump valve to its "vent" position. Turn

the flask valve clockwise to its "evacuate" position, and record the

difference in the mercury levels in the manometer. The absolute internal

pressure in the flask (Pi) is equal to the barometric pressure less the

manometer reading. Immediately turn the flask valve to the "sample"

position, and permit the gas to enter the flask until pressures in the flask

and sample line (i.e., duct,

stack) are equal. This will usually require about 15 seconds; a longer period

indicates a plug in the probe, which must be corrected before sampling is

continued. After collecting the sample, turn the flask valve to its

"purge" position, and disconnect the flask from the sampling train.

8.1.3 Shake the flask

for at least 5 minutes.

8.1.4 If the gas

being sampled contains insufficient oxygen for the conversion of NO to NO2 (e.g., an

applicable subpart of the standards may require taking a sample of a

calibration gas mixture of NO in N2), then

introduce oxygen into the flask to permit this conversion. Oxygen may be

introduced into the flask by one of three methods: (1) Before evacuating the

sampling flask, flush with pure cylinder oxygen, then evacuate flask to 75 mm

(3 in.) Hg absolute pressure or less; or (2) inject oxygen into the flask after

sampling; or (3) terminate sampling with a minimum of 50 mm (2 in.) Hg vacuum

remaining in the flask, record this final pressure, and then vent the flask to

the atmosphere until the flask pressure is almost equal to atmospheric

pressure.

8.2 Sample Recovery.

Let the flask sit for

a minimum of 16 hours, and then shake the contents for 2 minutes.

8.2.1 Connect the

flask to a mercury filled U-tube manometer. Open the valve from the flask to

the manometer, and record the flask temperature (Tf), the barometric pressure, and the difference between the mercury

levels in the manometer. The absolute internal pressure in the flask (Pf) is the barometric pressure less the manometer reading. Transfer

the contents of the flask to a leak-free polyethylene bottle. Rinse the flask

twice with 5 ml portions of water, and add the rinse water to the bottle. Adjust the pH to between 9 and 12 by

adding 1 N NaOH, dropwise (about 25 to 35 drops). Check the pH by dipping a

stirring rod into the solution and then touching the rod to the pH test paper.

Remove as little material as possible during this step. Mark the height of the

liquid level so that the container can be checked for leakage after transport.

Label the container to identify clearly its contents. Seal the container for

shipping.

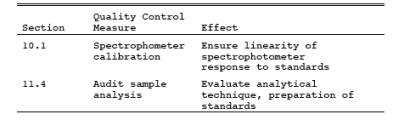

9.0 Quality Control.

10.0 Calibration and Standardization.

10.1 Spectrophotometer.

10.1.1 Optimum

Wavelength Determination.

10.1.1.1 Calibrate

the wavelength scale of the spectrophotometer every 6 months. The calibration

may be accomplished by using an energy source with an intense line emission

such as a mercury lamp, or by using a series of glass filters spanning the measuring

range of the spectrophotometer. Calibration materials are available

commercially and from the National Institute of Standards and Technology.

Specific details on the use of such materials should be supplied by the vendor;

general information about calibration techniques can be obtained from general

reference books on analytical chemistry. The wavelength scale of the

spectrophotometer must read correctly within 5 nm at all calibration points;

otherwise, repair and recalibrate the spectrophotometer. Once the wavelength

scale of the spectrophotometer is in proper calibration, use 410 nm as the

optimum wavelength for the measurement of the absorbance of the standards and

samples.

10.1.1.2

Alternatively, a scanning procedure may be employed to determine the proper

measuring wavelength. If the instrument is a double-beam spectrophotometer,

scan the spectrum between 400 and 415 nm using a 200 µg NO2 standard solution in the sample cell and a blank solution in the

reference cell. If a peak does not occur, the spectrophotometer is probably

malfunctioning and should be repaired. When a peak is obtained within the 400

to 415 nm range, the wavelength at which this peak occurs shall be the optimum

wavelength for the measurement of absorbance of both the standards and the

samples. For a single-beam spectrophotometer, follow the scanning procedure

described above, except scan separately the blank and standard solutions. The

optimum wavelength shall be the wavelength at which the maximum difference in

absorbance between the standard and the blank occurs.

10.1.2 Determination

of Spectrophotometer Calibration Factor Kc. Add 0

ml, 2.0 ml, 4.0 ml, 6.0 ml, and 8.0 ml of the KNO3 working

standard solution (1 ml = 100 µg NO2) to a

series of five 50-ml volumetric flasks. To each flask, add 25 ml of absorbing

solution and 10 ml water. Add 1 N NaOH to each flask until the pH is between 9

and 12 (about 25 to 35 drops). Dilute to the mark with water. Mix thoroughly,

and pipette a 25-ml aliquot of each solution into a separate porcelain-evaporating

dish. Beginning with the evaporation step, follow the analysis procedure of

Section 11.2 until the solution has been transferred to the 100-ml volumetric

flask and diluted to the mark. Measure the absorbance of each solution at the

optimum wavelength as determined in Section 10.2.1. This calibration procedure

must be repeated on each day that samples are analyzed. Calculate the

spectrophotometer calibration factor as shown in Section 12.2.

10.1.3

Spectrophotometer Calibration Quality Control. Multiply the absorbance value

obtained for each standard by the Kc factor

(reciprocal of the least squares slope) to determine the distance each

calibration point lies from the theoretical calibration line. The difference

between the calculated concentration values and the actual concentrations (i.e., 100, 200, 300, and 400 µg NO2) should be less than 7 percent for all standards.

10.2 Barometer.

Calibrate against a

mercury barometer.

10.3 Temperature Gauge.

Calibrate dial

thermometers against mercury-in-glass thermometers.

10.4 Vacuum Gauge.

Calibrate mechanical

gauges, if used, against a mercury manometer such as that specified in Section

6.1.6.

10.5 Analytical Balance.

Calibrate against

standard weights.

11.0 Analytical Procedures.

11.1 Sample Loss Check.

Note the level of the

liquid in the container, and confirm whether any sample was lost during

shipment. Note this on the analytical data sheet. If a noticeable amount of leakage has occurred, either void

the sample or use methods, subject to the approval of the Administrator, to

correct the final results.

11.2 Sample Preparation.

Immediately prior to

analysis, transfer the contents of the shipping container to a 50 ml volumetric

flask, and rinse the container twice with 5 ml portions of water. Add the rinse

water to the flask, and dilute to mark with water; mix thoroughly. Pipette a

25-ml aliquot into the porcelain evaporating dish. Return any unused portion of

the sample to the polyethylene storage bottle. Evaporate the 25-ml aliquot to

dryness on a steam bath, and allow to cool. Add 2 ml phenoldisulfonic acid

solution to the dried residue, and triturate thoroughly with a polyethylene

policeman. Make sure the solution contacts all the residue. Add 1 ml water and

4 drops of concentrated sulfuric acid. Heat the solution on a steam bath for 3

minutes with occasional stirring. Allow the solution to cool, add 20 ml water,

mix well by stirring, and add concentrated ammonium hydroxide, dropwise, with

constant stirring, until the pH is 10 (as determined by pH paper). If the

sample contains solids, these must be removed by filtration (centrifugation is

an acceptable alternative, subject to the approval of the Administrator) as

follows: Filter through Whatman No. 41 filter paper into a 100-ml volumetric flask.

Rinse the evaporating dish with three 5- ml portions of water. Filter these

three rinses. Wash the filter with at least three 15-ml portions of water. Add

the filter washings to the contents of the volumetric flask, and dilute to the

mark with water. If solids are absent, the solution can be transferred directly

to the 100-ml volumetric flask and diluted to the mark with water.

11.3 Sample Analysis.

Mix the contents of

the flask thoroughly, and measure the absorbance at the optimum wavelength used

for the standards (Section 10.2.1), using the blank solution as a zero

reference. Dilute the sample and the blank with equal volumes of water if the

absorbance exceeds A4, the absorbance of the 400-µg NO2 standard (see Section 10.2.2).

11.4 Audit Sample Analysis.

11.4.1 When the

method is used to analyze samples to demonstrate compliance with a source

emission regulation, an audit sample must be analyzed, subject to availability.

11.4.2 Concurrently analyze

the audit sample and the compliance samples in the same manner to evaluate the

technique of the analyst and the standards preparation.

11.4.3 The same

analyst, analytical reagents, and analytical system must be used for the

compliance samples and the audit sample. If this condition is met, duplicate

auditing of subsequent compliance analyses for the same enforcement agency

within a 30-day period is waived. An audit sample set may not be used to

validate different sets of compliance samples under the jurisdiction of

separate enforcement agencies, unless prior arrangements have been made with

both enforcement agencies.

11.5 Audit Sample Results.

11.5.1 Calculate the

audit sample concentrations and submit results using the instructions provided

with the audit samples.

11.5.2 Report the

results of the audit samples and the compliance determination samples along

with their identification numbers, and the analyst's name to the responsible

enforcement authority. Include this information with reports of any subsequent

compliance analyses for the same enforcement authority during the 30-day

period.

11.5.3 The

concentrations of the audit samples obtained by the analyst must agree within 5

percent of the actual concentration. If the 5 percent specification is not met,

reanalyze the compliance and audit samples, and include initial and reanalysis

values in the test report.

11.5.4 Failure to

meet the 5-percent specification may require retests until the audit problems

are resolved. However, if the audit results do not affect the compliance or

noncompliance status of the affected facility, the Administrator may waive the

reanalysis requirement, further audits, or retests and accept the results of

the compliance test. While steps are being taken to resolve audit analysis

problems, the Administrator may also choose to use the data to determine the

compliance or noncompliance status of the affected facility.

12.0 Data Analysis and Calculations.

Carry out the

calculations, retaining at least one extra significant figure beyond that of

the acquired data. Round off figures after final calculations.

12.1 Nomenclature.

A = Absorbance of

sample.

A1 = Absorbance of the 100-µg NO2 standard.

A2 = Absorbance of the 200-µg NO2 standard.

A3 = Absorbance of the 300-µg NO2 standard.

A4 = Absorbance of the 400-µg NO2 standard.

C = Concentration of

NOx as NO2, dry

basis, corrected to standard conditions, mg/dsm3 (lb/dscf).

Cd = Determined audit sample concentration, mg/dscm.

Ca = Actual audit sample concentration, mg/dscm.

F = Dilution factor (i.e., 25/5, 25/10, etc., required only if sample dilution was needed to

reduce the absorbance into the range of the calibration).

Kc = Spectrophotometer calibration factor.

m = Mass of NOx as NO2 in gas sample, µg.

Pf = Final absolute pressure of flask, mm Hg (in. Hg).

Pi = Initial absolute pressure of flask, mm Hg (in. Hg).

Pstd = Standard absolute pressure, 760 mm Hg (29.92

in. Hg).

RE = Relative error

for QA audit samples, percent.

Tf = Final absolute temperature of flask, ¡K (¡R).

Ti = Initial absolute temperature of flask, ¡K (¡R).

Tstd = Standard absolute temperature, 293 ¡K (528

¡R).

Vsc = Sample volume at standard conditions (dry

basis), ml.

Vf = Volume of flask and valve, ml.

Va = Volume of absorbing solution, 25 ml.

12.2 Spectrophotometer Calibration Factor.

![]()

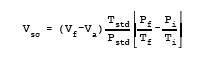

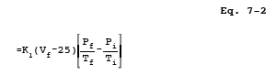

12.3 Sample Volume, Dry Basis, Corrected to Standard

Conditions.

where:

K1 = 0.3858 ¡K/mm Hg for metric units,

= 17.65 ¡R/in. Hg for

English units.

12.4 Total µg NO2 per sample.

m = 2 Kc

A F Eq.

7-3

where:

2 = 50/25, the

aliquot factor.

NOTE: If other than a 25-ml aliquot is used for

analysis, the factor 2 must be replaced by a corresponding factor.

12.5 Sample Concentration, Dry Basis, Corrected to Standard Conditions.

C = K2 (m/Vsc) Eq.

7-4

where:

K2 = 103 (mg/m3)/(µg/ml)

for metric units,

= 6.242 x 10-5 (lb/scf)/(µg/ml) for English units.

12.6 Relative Error for QA Audit Samples.

RE = 100 (Cd

- Ca)/Ca Eq. 7-5

13.0 Method Performance.

13.1 Range. The analytical

range of the method has been determined to be 2 to 400 milligrams NOx (as NO2) per dry standard cubic meter, without having

to dilute the sample.

14.0 Pollution Prevention. [Reserved]

15.0 Waste Management. [Reserved]

16.0 References.

1. Standard Methods

of Chemical Analysis. 6th ed. New York, D. Van Nostrand Co., Inc. 1962. Vol. 1,

pp. 329-330.

2. Standard Method of

Test for Oxides of Nitrogen in Gaseous Combustion Products (Phenoldisulfonic

Acid Procedure). In: 1968 Book of ASTM Standards, Part 26. Philadelphia, PA.

1968. ASTM Designation D 1608-60, pp. 725-729.

3. Jacob, M.B. The

Chemical Analysis of Air Pollutants. New York. Interscience Publishers, Inc.

1960. Vol. 10, pp. 351-356.

4. Beatty, R.L., L.B.

Berger, and H.H. Schrenk. Determination of Oxides of Nitrogen by the

Phenoldisulfonic Acid Method. Bureau of Mines, U.S. Dept. of Interior. R.I.

3687. February 1943.

5. Hamil, H.F. and

D.E. Camann. Collaborative Study of Method for the Determination of Nitrogen

Oxide Emissions from Stationary Sources (Fossil Fuel-Fired Steam Generators).

Southwest Research Institute Report for Environmental Protection Agency.

Research Triangle Park, NC. October 5, 1973.

6. Hamil, H.F. and

R.E. Thomas. Collaborative Study of Method for the Determination of Nitrogen

Oxide Emissions from Stationary Sources (Nitric Acid Plants). Southwest

Research Institute Report for Environmental Protection Agency. Research

Triangle Park, NC. May 8, 1974.

7. Stack Sampling

Safety Manual (Draft). U.S. Environmental Protection Agency, Office of Air

Quality Planning and Standards, Research Triangle Park, NC. September 1978.

17.0 Tables, Diagrams, Flowcharts, and Validation Data.

Figure

7-1. Sampling Train, Flask Valve, and Flask.