Method

2H-Determination of Stack Gas Velocity Taking Into Account Velocity Decay Near

the Stack Wall

3.1 Complete wall

effects traverse

3.4 ‘‘May,’’ ‘‘Must,’’

‘‘Shall,’’ ‘‘Should,’’ and the imperative form of verbs.

3.4.2 ‘‘Must,’’

‘‘Shall,’’ and the imperative form of verbs

(such as ‘‘record’’ or ‘‘enter’’)

3.6 Method 1 exterior

equal-area sector and Method 1 equal-area sector closest to the wall

3.7 Method 1 interior

equal-area sector

3.8 Method 1 traverse

point and Method 1 equal-area traverse point

3.12 1-in. incremented

wall effects traverse point

3.13 Partial wall

effects traverse

3.14 Relative accuracy

test audit (RATA)

3.15 Wall

effects-unadjusted average velocity

3.16 Wall

effects-adjusted average velocity

3.17 Wall effects

traverse point

7.0 Reagents and

Standards. [Reserved]

8.0 Sample Collection

and Analysis

8.1 Default Wall

Effects Adjustment Factors.

8.2.1 Method 1

equal-area traverse point locations.

8.2.2 Partial wall

effects traverse.

8.2.3 Complete wall

effects traverse.

8.3 Traverse Point

Sampling Order and Probe Selection.

8.4 Measurements at

Method 1 and Wall Effects Traverse Points.

8.4.1 Probe residence

time at wall effects traverse points.

8.4.2 Temperature

measurement for wall effects traverse points.

8.4.3 Non-detectable

velocity pressure at wall effects traverse points.

8.6 Point Velocity

Calculation.

8.7 Tabulating Calculated

Point Velocity Values for Wall Effects Traverse Points.

8.7.1 Point velocity

values at wall effects traverse points other than dlast.

8.7.2 Point velocity

value at dlast.

8.7.3 Point velocity

value (vdrem) at drem.

9.1 Particulate Matter

Build-up in Horizontal Ducts.

9.2 Verifying Traverse

Point Distances.

9.2.2 Automated probe

systems.

12.0 Data Analysis and

Calculations

13.0 Method

Performance. [Reserved]

14.0 Pollution

Prevention. [Reserved]

15.0 Waste Management.

[Reserved]

16.1.1 Description of

the source and site.

16.1.4 Quality

assurance and control.

16.2 Reporting a

Default Wall Effects Adjustment Factor.

1.0 Scope and Application

1.1 This

method is applicable in conjunction with Methods 2,

2F, and 2G (40 CFR

Part 60, Appendix A) to account for velocity decay near the wall in circular

stacks and ducts.

1.2 This

method is not applicable for testing stacks and ducts less than 3.3 ft (1.0 m)

in diameter.

1.3 Data Quality

Objectives. Adherence to the requirements of this method will enhance the

quality of the data obtained from air pollutant sampling methods.

2.0 Summary of Method

2.1 A wall

effects adjustment factor is determined. It is used to adjust the average stack

gas velocity obtained under Method 2, 2F, or 2G of this appendix to take into

account velocity decay near the stack or duct wall.

2.2 The method

contains two possible procedures: a calculational approach which derives an

adjustment factor from velocity measurements and a default procedure which

assigns a generic adjustment factor based on the construction of the stack or

duct.

2.2.1 The

calculational procedure derives a wall effects adjustment factor from velocity

measurements taken using Method 2, 2F, or 2G at 16 (or more) traverse points

specified under Method 1 of this appendix and a total of eight (or more) wall

effects traverse points specified under this method. The calculational

procedure based on velocity measurements is not applicable for horizontal

circular ducts where build-up of particulate matter or other material in the

bottom of the duct is present.

2.2.2 A

default wall effects adjustment factor of 0.9900 for brick and mortar stacks

and 0.9950 for all other types of stacks and ducts may be used without taking

wall effects measurements in a stack or duct.

2.3 When the

calculational procedure is conducted as part of a relative accuracy test audit

(RATA) or other multiple-run test procedure, the wall effects adjustment factor

derived from a single traverse (i.e., single RATA run) may be applied to all

runs of the same RATA without repeating the wall effects measurements.

Alternatively, wall effects adjustment factors may be derived for several

traverses and an average wall effects adjustment factor applied to all runs of

the same RATA.

3.0 Definitions.

3.1 Complete wall effects traverse

A traverse in

which measurements are taken at drem (see section 3.3) and at 1-in. intervals in each of the four

Method 1 equal-area sectors closest to the wall,

beginning not farther than 4 in. (10.2 cm) from the wall and extending either

(1) across the entire width of the Method 1 equal-area sector or (2) for stacks

or ducts where this width exceeds 12 in. (30.5 cm) (i.e., stacks or ducts

greater than or equal to 15.6 ft [4.8 m] in diameter), to a distance of not

less than 12 in. (30.5 cm) from the wall. Note: Because this method specifies

that measurements must be taken at whole number multiples of 1 in. from a stack

or duct wall, for clarity numerical quantities in this method are expressed in

English units followed by metric units in parentheses. To enhance readability,

hyphenated terms such as ‘‘1-in. intervals’’ or ‘‘1-in. incremented,’’ are

expressed in English units only.

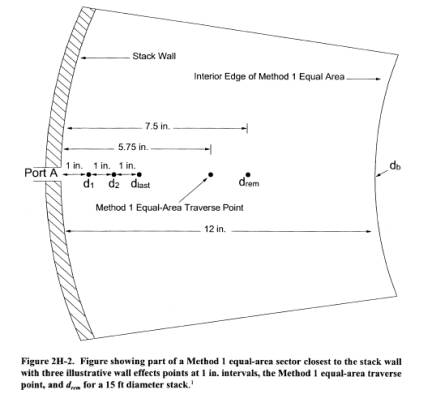

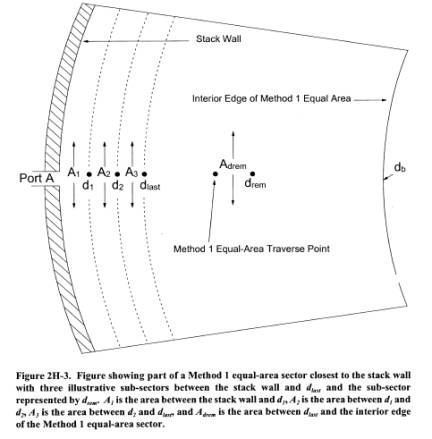

3.2 dlast.

Depending on

context, dlast means

either (1) the distance from the wall of the last 1-in. incremented wall

effects traverse point or (2) the traverse point located at that distance (see Figure 2H-2).

3.3 drem.

Depending on

context, drem means

either (1) the distance from the wall of the centroid of the area between dlast

and the interior edge of

the Method 1 equal-area sector closest to the wall or (2) the traverse point

located at that distance (see Figure 2H-2).

3.4 ‘‘May,’’ ‘‘Must,’’ ‘‘Shall,’’ ‘‘Should,’’ and the imperative form of

verbs.

3.4.1 ‘‘May’’

Used to

indicate that a provision of this method is optional.

3.4.2 ‘‘Must,’’ ‘‘Shall,’’ and the imperative form of verbs (such as ‘‘record’’ or ‘‘enter’’)

Used to

indicate that a provision of this method is mandatory.

3.4.3 ‘‘Should’’

Used to

indicate that a provision of this method is not mandatory but is highly

recommended as good practice.

3.5 Method 1

Refers to 40

CFR part 60, appendix A, ‘‘Method 1 - Sample and velocity traverses for

stationary sources.’’

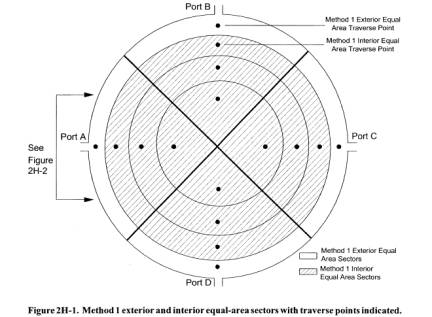

3.6 Method 1 exterior equal-area sector and Method 1 equal-area sector closest to the wall

Any one of the

four equal-area sectors that are closest to the wall for a circular stack or

duct laid out in accordance with section 2.3.1 of Method 1 (see Figure 2H-1).

3.7 Method 1 interior equal-area sector

Any of the

equal-area sectors other than the Method 1 exterior equal-area sectors (as

defined in section 3.6) for a circular stack or duct laid out in accordance

with section 2.3.1 of Method 1 (see Figure 2H-1).

3.8 Method 1 traverse point and Method 1 equal-area traverse point

A traverse

point located at the centroid of an equal-area sector of a circular stack laid

out in accordance with section 2.3.1 of Method 1.

3.9 Method 2

Refers to 40

CFR part 60, appendix A, ‘‘Method 2 - Determination of stack gas velocity and

volumetric flow rate (Type S pitot tube).’’

3.10 Method 2F

Refers to 40

CFR part 60, appendix A, ‘‘Method 2F - Determination of stack gas velocity and

volumetric flow rate with three-dimensional probes.’’

3.11 Method 2G

Refers to 40

CFR part 60, appendix A, ‘‘Method 2G - Determination of stack gas velocity and

volumetric flow rate with two-dimensional probes.’’

3.12 1-in. incremented wall effects traverse point

Any of the

wall effects traverse points that are located at 1-in. intervals, i.e.,

traverse points d1 through dlast (see

Figure 2H-2).

3.13 Partial wall effects traverse

A traverse in

which measurements are taken at fewer than the number of traverse points

required for a ‘‘complete wall effects traverse’’ (as defined in section 3.1),

but are taken at a minimum of two traverse points in each Method 1 equal-area

sector closest to the wall, as specified in section 8.2.2.

3.14 Relative accuracy test audit (RATA)

A field test

procedure performed in a stack or duct in which a series of concurrent

measurements of the same stack gas stream is taken by a reference method and an

installed monitoring system. A RATA usually consists of series of 9 to 12 sets

of such concurrent measurements, each of which is referred to as a RATA run. In

a volumetric flow RATA, each reference method run consists of a complete

traverse of the stack or duct.

3.15 Wall effects-unadjusted average velocity

The average

stack gas velocity, not accounting for velocity decay near the wall, as

determined in accordance with Method 2, 2F, or 2G for a Method 1 traverse

consisting of 16 or more points.

3.16 Wall effects-adjusted average velocity

The average

stack gas velocity, taking into account velocity decay near the wall, as

calculated from measurements at 16 or more Method 1 traverse points and at the

additional wall effects traverse points specified in this method.

3.17 Wall effects traverse point

A traverse

point located in accordance with sections 8.2.2 or 8.2.3 of this method.

4.0 Interferences. [Reserved]

5.0 Safety

5.1 This method

may involve hazardous materials, operations, and equipment. This method does

not purport to address all of the health and safety considerations associated

with its use. It is the responsibility of the user of this method to establish

appropriate health and safety practices and to determine the applicability of

occupational health and safety regulatory requirements prior to performing this

method.

6.0 Equipment and Supplies

6.1 The

provisions pertaining to equipment and supplies in the method that is used to

take the traverse point measurements (i.e., Method 2, 2F, or 2G) are applicable

under this method.

7.0 Reagents and Standards. [Reserved]

8.0 Sample Collection and Analysis

8.1 Default Wall Effects Adjustment Factors.

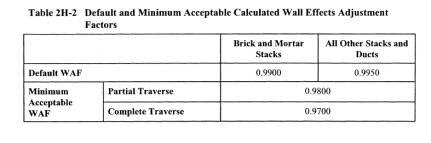

A default wall

effects adjustment factor of 0.9900 for brick and mortar stacks and 0.9950 for

all other types of stacks and ducts may be used without conducting the

following procedures.

8.2 Traverse Point Locations.

Determine the

location of the Method 1 traverse points in accordance with section 8.2.1 and

the location of the traverse points for either a partial wall effects traverse

in accordance with section 8.2.2 or a complete wall effects traverse in

accordance with section 8.2.3.

8.2.1 Method 1 equal-area traverse point locations.

Determine the

location of the Method 1 equal-area traverse points for a traverse consisting

of 16 or more points using Table 1-2 (Location of Traverse Points in Circular

Stacks) of Method 1.

8.2.2 Partial wall effects traverse.

For a partial

wall effects traverse, measurements must be taken at a minimum of the following

two wall effects traverse point locations in all four Method 1 equal-area

sectors closest to the wall: (1) 1 in. (2.5 cm) from the wall (except as

provided in section 8.2.2.1) and (2) drem, as determined using Equation 2H-1 or 2H-2 (see section

8.2.2.2).

8.2.2.1 If the

probe cannot be positioned at 1 in. (2.5 cm) from the wall (e.g., because of

insufficient room to withdraw the probe shaft) or if velocity pressure cannot

be detected at 1 in. (2.5 cm) from the wall (for any reason other than build-up

of particulate matter in the bottom of a duct), take measurements at the 1-in.

incremented wall effects traverse point closest to the wall where the probe can

be positioned and velocity pressure can be detected.

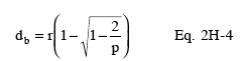

8.2.2.2

Calculate the distance of drem

from the wall to within ±1⁄4 in. (6.4 mm) using Equation 2H-1 or Equation 2H-2

(for a 16-point traverse).

![]()

Where:

r = the stack or duct radius determined from

direct measurement of the stack or duct diameter in accordance with section 8.6

of Method 2F or Method 2G, in. (cm);

p = the number of Method 1 equal-area

traverse points on a diameter, p 3

8 (e.g., for a 16-point traverse, p = 8); For a

16-point Method 1 traverse, Equation 2H-1 becomes:

8.2.2.3

Measurements may be taken at any number of additional wall effects traverse

points, with the following provisions.

(a) dlast must not be closer to the center of the

stack or duct than the distance of the interior edge (boundary), db, of the Method 1 equal-area sector

closest to the wall (see Figure 2H-2 or 2H-3). That is,

Where:

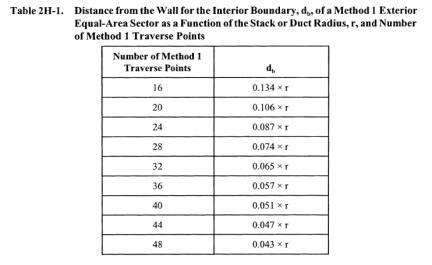

Table 2H-1

shows db as a

function of the stack or duct radius, r, for traverses ranging from 16 to 48 points (i.e., for

values of p ranging

from 8 to 24).

(b) Each point

must be located at a distance that is a whole number (e.g., 1, 2, 3) multiple

of 1 in. (2.5 cm).

(c) Points do

not have to be located at consecutive 1-in. intervals. That is, one or more

1-in. incremented points may be skipped. For example, it would be acceptable

for points to be located at 1 in. (2.5 cm), 3 in. (7.6 cm), 5 in. (12.7 cm), dlast, and drem; or at 1 in. (2.5 cm), 2 in. (5.1 cm), 4

in. (10.2 cm), 7 in. (17.8 cm), dlast, and drem.

Follow the instructions in section 8.7.1.2 of this method for recording results

for wall effects traverse points that are skipped. It should be noted that the

full extent of velocity decay may not be accounted for if measurements are not

taken at all 1-in. incremented points close to the wall.

8.2.3 Complete wall effects traverse.

For a complete

wall effects traverse, measurements must be taken at the following points in

all four Method 1 equal-area sectors closest to the wall.

(a) The 1-in. incremented

wall effects traverse point closest to the wall where the probe can be

positioned and velocity can be detected, but no farther than 4 in. (10.2 cm)

from the wall.

(b) Every

subsequent 1-in. incremented wall effects traverse point out to the interior

edge of the Method 1 equal-area sector or to 12 in. (30.5 cm) from the wall,

whichever comes first. Note: In stacks or ducts with diameters greater than

15.6 ft (4.8 m) the interior edge of the Method 1 equal-area sector is farther

from the wall than 12 in. (30.5 cm).

(c) drem, as determined using Equation 2H-1 or

2H-2 (as applicable). Note: For a complete traverse of a stack or duct with a

diameter less than 16.5 ft (5.0 m), the distance between drem and dlast is less than or equal to 1⁄2 in.

(12.7 mm). As discussed in section 8.2.4.2, when the distance between drem and dlast is less than or equal to 1⁄2 in.

(12.7 mm), the velocity measured at dlast may be used for drem. Thus, it is not necessary to calculate the distance of drem or to take measurements at drem when conducting a complete traverse

of a stack or duct with a diameter less than 16.5 ft (5.0 m).

8.2.4 Special considerations.

The following

special considerations apply when the distance between traverse points is less

than or equal to 1⁄2 in. (12.7 mm).

8.2.4.1 A wall

effects traverse point and the Method 1 traverse point. If the distance between

a wall effects traverse point and the Method 1 traverse point is less than or

equal to 1⁄2 in. (12.7 mm), taking measurements at both points is allowed but

not required or recommended; if measurements are taken at only one point, take

the measurements at the point that is farther from the wall and use the

velocity obtained at that point as the value for both points (see sections

8.2.3 and 9.2 for related requirements).

8.2.4.2 drem and dlast. If the distance between drem and dlast is less than or equal to 1⁄2 in.

(12.7 mm), taking measurements at drem

is allowed but not required or recommended; if measurements are not taken at drem, the measured velocity value at dlast must be used as the value for both dlast and drem.

8.3 Traverse Point Sampling Order and Probe Selection.

Determine the

sampling order of the Method 1 and wall effects traverse points and select the

appropriate probe for the measurements, taking into account the following

considerations.

8.3.1 Traverse

points on any radius may be sampled in either direction (i.e., from the wall

toward the center of the stack or duct, or vice versa).

8.3.2 To

reduce the likelihood of velocity variations during the time of the traverse

and the attendant potential impact on the wall effects-adjusted and unadjusted

average velocities, the following provisions of this method shall be met.

8.3.2.1 Each complete

set of Method 1 and wall effects traverse points accessed from the same port

shall be sampled without interruption. Unless traverses are performed

simultaneously in all ports using separate probes at each port, this provision

disallows first sampling all Method 1 points at all ports and then sampling all

the wall effects points.

8.3.2.2 The

entire integrated Method 1 and wall effects traverse across all test ports

shall be as short as practicable, consistent with the measurement system

response time (see section 8.4.1.1) and sampling (see section 8.4.1.2)

provisions of this method.

8.3.3 It is

recommended but not required that in each Method 1 equal-area sector closest to

the wall, the Method 1 equal-area traverse point should be sampled in sequence

between the adjacent wall effects traverse points. For example, for the

traverse point configuration shown in Figure 2H-2, it is recommended that the

Method 1 equal-area traverse point be sampled between dlast and drem. In this example, if the traverse is

conducted from the wall toward the center of the stack or duct, it is

recommended that measurements be taken at points in the following order: d1, d2, dlast,

the Method 1 traverse point, drem,

and then at the traverse points in the three Method 1 interior equal area

sectors.

8.3.4 The same

type of probe must be used to take measurements at all Method 1 and wall

effects traverse points. However, different copies of the same type of probe

may be used at different ports (e.g., Type S probe 1 at port A, Type S probe 2

at port B) or at different traverse points accessed from a particular port

(e.g., Type S probe 1 for Method 1 interior traverse points accessed from port

A, Type S probe 2 for wall effects traverse points and the Method 1 exterior

traverse point accessed from port A). The identification number of the probe

used to obtain measurements at each traverse point must be recorded.

8.4 Measurements at Method 1 and Wall Effects Traverse Points.

Conduct

measurements at Method 1 and wall effects traverse points in accordance with

Method 2, 2F, or 2G and in accordance with the provisions of the following

subsections (some of which are included in Methods 2F and 2G but not in Method

2), which are particularly important for wall effects testing.

8.4.1 Probe residence time at wall effects traverse points.

Due to the

steep temperature and pressure gradients that can occur close to the wall, it

is very important for the probe residence time (i.e., the total time spent at a

traverse point) to be long enough to ensure collection of representative

temperature and pressure measurements. The provisions of Methods 2F and 2G in

the following subsections shall be observed.

8.4.1.1 System

response time. Determine the response time of each probe measurement system by

inserting and positioning the ‘‘cold’’ probe (at ambient temperature and

pressure) at any Method 1 traverse point. Read and record the probe

differential pressure, temperature, and elapsed time at 15-second intervals

until stable readings for both pressure and temperature are achieved. The

response time is the longer of these two elapsed times. Record the response

time.

8.4.1.2

Sampling. At the start of testing in each port (i.e., after a probe has been

inserted into the stack gas stream), allow at least the response time to elapse

before beginning to take measurements at the first traverse point accessed from

that port. Provided that the probe is not removed from the stack gas stream,

measurements may be taken at subsequent traverse points accessed from the same

test port without waiting again for the response time to elapse.

8.4.2 Temperature measurement for wall effects traverse points.

Either (1)

take temperature measurements at each wall effects traverse point in accordance

with the applicable provisions of Method 2, 2F, or 2G; or (2) use the

temperature measurement at the Method 1 traverse point closest to the wall as

the temperature measurement for all the wall effects traverse points in the

corresponding equal-area sector.

8.4.3 Non-detectable velocity pressure at wall effects traverse points.

If the probe

cannot be positioned at a wall effects traverse point or if no velocity

pressure can be detected at a wall effects point, measurements shall be taken

at the first subsequent wall effects traverse point farther from the wall where

velocity can be detected. Follow the instructions in section 8.7.1.2 of this

method for recording results for wall effects traverse points where velocity

pressure cannot be detected. It should be noted that the full extent of

velocity decay may not be accounted for if measurements are not taken at the

1-in. incremented wall effects traverse points closest to the wall.

8.5 Data Recording.

For each wall

effects and Method 1 traverse point where measurements are taken, record all

pressure, temperature, and attendant measurements prescribed in section 3 of

Method 2 or section 8.0 of Method 2F or 2G, as applicable.

8.6 Point Velocity Calculation.

For each wall

effects and Method 1 traverse point, calculate the point velocity value (vi) in accordance with sections 12.1 and

12.2 of Method 2F for tests using Method 2F and in accordance with sections

12.1 and 12.2 of Method 2G for tests using Method 2 and Method 2G. (Note that

the term (vi) in this

method corresponds to the term (va(i)) in Methods 2F and 2G.) When the

equations in the indicated sections of Method 2G are used in deriving point

velocity values for Method 2 tests, set the value of the yaw angles appearing

in the equations to 0°.

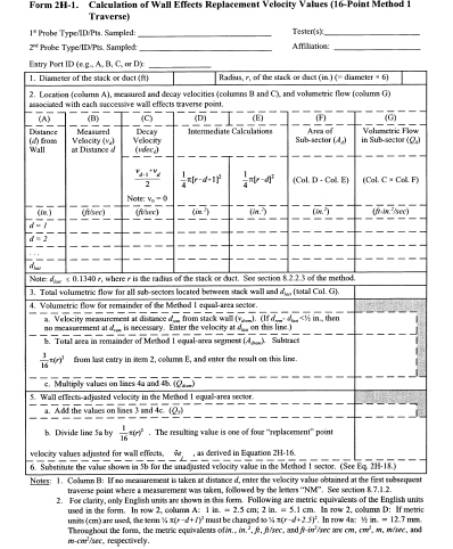

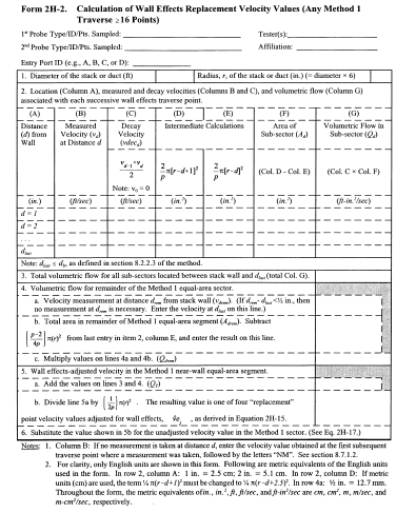

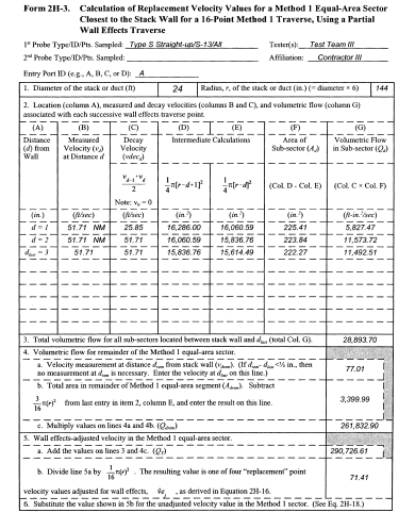

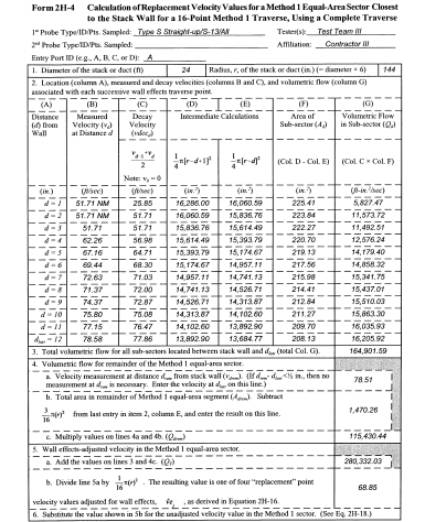

8.7 Tabulating Calculated Point Velocity Values for Wall Effects Traverse Points.

Enter the

following values in a hardcopy or electronic form similar to Form

2H-1 (for 16-point Method 1 traverses) or Form 2H-2

(for Method 1 traverses consisting of more than 16 points). A separate form

must be completed for each of the four Method 1 equal-area sectors that are

closest to the wall.

(a) Port ID

(e.g., A, B, C, or D)

(b) Probe type

(c) Probe ID

(d) Stack or

duct diameter in ft (m) (determined in accordance with section 8.6 of Method 2F

or Method 2G)

(e) Stack or

duct radius in in. (cm)

(f) Distance

from the wall of wall effects traverse points at 1-in. intervals, in ascending

order starting with 1 in. (2.5 cm) (column A of Form 2H-1 or 2H-2)

(g) Point

velocity values (vd)

for 1-in. incremented traverse points (see section 8.7.1), including dlast (see section 8.7.2)

(h) Point

velocity value (vdrem)

at drem (see section

8.7.3).

8.7.1 Point velocity values at wall effects traverse points other than dlast.

For every

1-in. incremented wall effects traverse point other than dlast, enter in column B of Form 2H-1 or 2H-2

either the velocity measured at the point (see section 8.7.1.1) or the velocity

measured at the first subsequent traverse point farther from the wall (see

section 8.7.1.2). A velocity value must be entered in column B of Form 2H-1 or

2H-2 for every 1-in. incremented traverse point from d1 (representing the wall effects traverse

point 1 in. [2.5 cm] from the wall) to dlast.

8.7.1.1 For

wall effects traverse points where the probe can be positioned and velocity

pressure can be detected, enter the value obtained in accordance with section

8.6.

8.7.1.2 For

wall effects traverse points that were skipped [see section 8.2.2.3(c)] and for

points where the probe cannot be positioned or where no velocity pressure can

be detected, enter the value obtained at the first subsequent traverse point

farther from the wall where velocity pressure was detected and measured and

follow the entered value with a ‘‘flag,’’ such as the notation ‘‘NM,’’ to

indicate that ‘‘no measurements’’ were actually taken at this point.

8.7.2 Point velocity value at dlast.

For dlast, enter in column B of Form 2H-1 or 2H-2

the measured value obtained in accordance with section 8.6.

8.7.3 Point velocity value (vdrem) at drem.

Enter the

point velocity value obtained at drem in column G of row 4a in Form 2H-1 or 2H-2. If the distance

between drem and dlast

is less than or equal to

1⁄2 in. (12.7 mm), the measured velocity value at dlast may be used as the value at drem (see section 8.2.4.2).

9.0 Quality Control.

9.1 Particulate Matter Build-up in Horizontal Ducts.

Wall effects

testing of horizontal circular ducts should be conducted only if build-up of

particulate matter or other material in the bottom of the duct is not present.

9.2 Verifying Traverse Point Distances.

In taking

measurements at wall effects traverse points, it is very important for the

probe impact pressure port to be positioned as close as practicable to the

traverse point locations in the gas stream. For this reason, before beginning

wall effects testing, it is important to calculate and record the traverse

point positions that will be marked on each probe for each port, taking into

account the distance that each port nipple (or probe mounting flange for

automated probes) extends out of the stack and any extension of the port nipple

(or mounting flange) into the gas stream. To ensure that traverse point

positions are properly identified, the following procedures should be performed

on each probe used.

9.2.1 Manual probes.

Mark the probe

insertion distance of the wall effects and Method 1 traverse points on the

probe sheath so that when a mark is aligned with the outside face of the stack

port, the probe impact port is located at the calculated distance of the

traverse point from the stack inside wall. The use of different colored marks

is recommended for designating the wall effects and Method 1 traverse points.

Before the first use of each probe, check to ensure that the distance of each

mark from the center of the probe impact pressure port agrees with the

previously calculated traverse point positions to within ±1⁄4 in. (6.4 mm).

9.2.2 Automated probe systems.

For automated

probe systems that mechanically position the probe head at prescribed traverse

point positions, activate the system with the probe assemblies removed from the

test ports and sequentially extend the probes to the programmed location of

each wall effects traverse point and the Method 1 traverse points. Measure the

distance between the center of the probe impact pressure port and the inside of

the probe assembly mounting flange for each traverse point. The measured

distances must agree with the previously calculated traverse point positions to

within ±1⁄4 in. (6.4 mm).

9.3 Probe Installation.

Properly

sealing the port area is particularly important in taking measurements at wall

effects traverse points. For testing involving manual probes, the area between

the probe sheath and the port should be sealed with a tightly fitting flexible

seal made of an appropriate material such as heavy cloth so that leakage is

minimized. For automated probe systems, the probe assembly mounting flange area

should be checked to verify that there is no leakage.

9.4 Velocity Stability.

This method

should be performed only when the average gas velocity in the stack or duct is

relatively constant over the duration of the test. If the average gas velocity

changes significantly during the course of a wall effects test, the test

results should be discarded.

10.0 Calibration

10.1 The

calibration coefficient(s) or curves obtained under Method 2, 2F, or 2G and

used to perform the Method 1 traverse are applicable under this method.

11.0 Analytical Procedure

11.1 Sample

collection and analysis are concurrent for this method (see section 8).

12.0 Data Analysis and Calculations

12.1 The

following calculations shall be performed to obtain a wall effects adjustment

factor (WAF) from (1)

the wall effects unadjusted average velocity (vavg), (2) the replacement velocity (vˆej) for each of the four Method 1 sectors

closest to the wall, and (3) the average stack gas velocity that accounts for velocity

decay near the wall (vˆ avg).

12.2

Nomenclature. The following terms are listed in the order in which they appear

in Equations 2H-5 through 2H-21.

vavg=the average stack gas velocity,

unadjusted for wall effects, actual ft/sec(m/sec);

vii=stack gas point velocity value at Method

1 interior equal-area sectors, actual ft/sec (m/sec);

vej=stack gas point velocity value,

unadjusted for wall effects, at Method 1 exterior equal area sectors, actual

ft/sec (m/sec);

i=index of Method 1 interior equal-area

traverse points;

j=index of Method 1 exterior equal-area

traverse points;

n=total number of traverse points in the

Method 1 traverse;

vdecd=the wall effects decay velocity for a

sub-sector located between the traverse points at distances d- 1 (in metric units, d- 2.5)

and d from the wall,

actual ft/sec (m/sec);

vd=the measured stack gas velocity at

distance d from the

wall, actual ft/sec (m/sec); Note: v0=0;

d=the distance of a 1-in. incremented wall

effects traverse point from the wall, for traverse points d1 through dlast, in. (cm);

Ad=the cross-sectional area of a sub-sector

located between the traverse points at distances d- 1 (in metric units, d- 2.5)

and d from the wall,

in.2 (cm 2) ( e.g., sub-sector A2 shown in Figures 2H-3

and 2H-4);

r=the stack or duct radius, in. (cm);

Qd=the stack gas volumetric flow rate for a

sub-sector located between the traverse points at distances d- 1 (in metric units, d- 2.5)

and d from the wall,

actual ft-in.2/sec (m-cm 2/sec);

![]() dlast =the total stack gas volumetric flow rate

for all sub-sectors located between the wall and dlast, actual ft-in.2/sec (m-cm 2/sec);

dlast=the distance

from the wall of the last 1-in. incremented wall effects traverse point, in.

(cm);

dlast =the total stack gas volumetric flow rate

for all sub-sectors located between the wall and dlast, actual ft-in.2/sec (m-cm 2/sec);

dlast=the distance

from the wall of the last 1-in. incremented wall effects traverse point, in.

(cm);

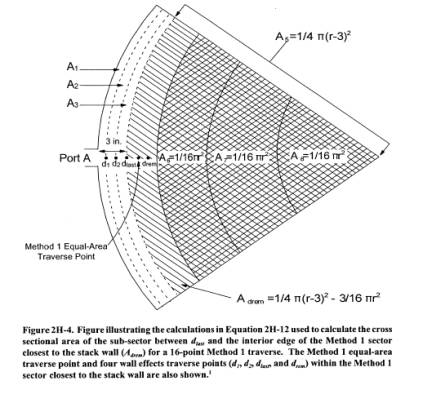

Adrem=the cross-sectional area of the

sub-sector located between dlast and

the interior edge of the Method 1 equal-area sector closest to the wall, in.2

(cm 2) (see Figure 2H-4);

p=the number of Method 1 traverse points

per diameter, p ≥8

(e.g., for a 16-point traverse, p=8);

drem=the distance from the wall of the

centroid of the area between dlast and

the interior edge of the Method 1 equal-area sector closest to the wall, in.

(cm);

Qdrem=the total stack gas volumetric flow rate

for the sub-sector located between dlast and the interior edge of the Method 1 equal area sector

closest to the wall, actual ftin. 2/sec (m-cm 2/sec);

vdrem=the measured stack gas velocity at

distance drem from

the wall, actual ft/sec (m/sec);

QT=the total stack gas volumetric flow rate

for the Method 1 equal-area sector closest to the wall, actual ft-in.2/sec

(m-cm 2/sec);

vˆ ej=the replacement stack gas velocity for

the Method 1 equal-area sector closest to the wall, i.e., the stack gas point

velocity value, adjusted for wall effects, for the jth Method

1 equal-area

sector closest to the wall, actual ft/sec (m/sec);

vˆ avg=the average stack gas velocity that

accounts for velocity decay near the wall, actual ft/sec (m/sec);

WAF=the wall effects adjustment factor

derived from vavg and

vˆ avg for a single

traverse, dimensionless;

vˆ final=the final wall effects-adjusted average

stack gas velocity that replaces the unadjusted average stack gas velocity

obtained using Method 2, 2F, or 2G for a field test consisting of a single

traverse, actual ft/sec (m/sec);

WAF=the wall effects adjustment factor that

is applied to the average velocity, unadjusted for wall effects, in order to

obtain the final wall effects-adjusted stack gas velocity, vˆ final or, vˆ final(k), dimensionless;

vˆ final(k)=the final wall effects-adjusted average stack gas velocity

that replaces the unadjusted average stack gas velocity obtained using Method

2, 2F, or 2G on run k of

a RATA or other multiple-run field test procedure, actual ft/sec (m/sec);

vˆ avg(k)=the average stack gas velocity, obtained on run k of a RATA or other multiple-run

procedure, unadjusted for velocity decay near the wall, actual ft/sec (m/sec);

k=index of runs in a RATA or other

multiple-run procedure.

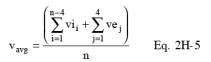

12.3 Calculate

the average stack gas velocity that does not account for velocity decay near

the wall (vavg) using

Equation 2H-5.

(Note that vavg in Equation 2H-5 is the same as v(a)avg in

Equations 2F-9 and 2G-8 in Methods 2F and 2G, respectively.) For a 16-point traverse,

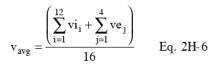

Equation 2H-5 may be written as follows:

12.4 Calculate

the replacement velocity, vˆ ej,

for each of the four Method 1 equal-area sectors closest to the wall using the

procedures described in sections 12.4.1 through 12.4.8. Forms 2H-1 and 2H-2 provide

sample tables that may be used in either hardcopy or spreadsheet format to

perform the calculations described in sections 12.4.1 through 12.4.8. Forms 2H-3 and 2H-4 provide examples of

Form 2H-1 filled in for partial and complete wall effects traverses.

12.4.1

Calculate the average velocity (designated the ‘‘decay velocity,’’ vdecd) for

each sub-sector located between the wall and dlast (see Figure 2H-3) using Equation

2H-7.

![]()

For each line

in column A of Form 2H-1 or 2H-2 that contains a value of d, enter the

corresponding calculated value of vdecd in column C.

12.4.2

Calculate the cross-sectional area between the wall and the first 1-in.

incremented wall effects traverse point and between successive 1-in.

incremented wall effects traverse points, from the wall to dlast (see Figure 2H-3),

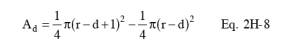

using Equation 2H-8.

For each line

in column A of Form 2H-1 or 2H-2 that contains a value of d, enter the value of

the expression 1⁄4 π(r-

d+1)2 in

column D, the value of the expression 1⁄4 π(r- d)2 in column E, and the value of Ad in column F. Note that Equation 2H-8 is

designed for use only with English units (in.). If metric units (cm) are used,

the first term, 1⁄4 π(r-

d+1)2,

must be changed to 1⁄4 π(r-

d+2.5)2.

This change must also be made in column D of Form 2H-1 or 2H-2.

12.4.3

Calculate the volumetric flow through each cross-sectional area derived in

section 12.4.2 by multiplying the values of vdecd, derived according to section 12.4.1, by

the cross-sectional areas derived in section 12.4.2 using Equation 2H-9.

![]()

For each line

in column A of Form 2H-1 or 2H-2 that contains a value of d, enter the

corresponding calculated value of Qd in

column G.

12.4.4

Calculate the total volumetric flow through all sub-sectors located between the

wall and dlast, using

Equation 2H-10.

Enter the

calculated value of Qd1 Õdlast in line 3 of column G of Form 2H-1 or

2H-2.

12.4.5

Calculate the cross-sectional area of the sub-sector located between dlast and the interior edge of the Method 1

equal-area sector (e.g., sub-sector Adrem shown in Figures 2H-3 and 2H-4) using Equation 2H-11.

![]()

For a 16-point

traverse (eight points per diameter), Equation 2H-11 may be written as follows:

![]()

Enter the

calculated value of Adrem

in line 4b of column G of Form 2H-1 or 2H-2.

12.4.6

Calculate the volumetric flow for the sub-sector located between dlast and the interior edge of the Method

1 equal-area sector, using Equation 2H-13.

![]()

In Equation

2H-13, µdrem is either (1) the measured velocity value at drem or (2) the measured velocity at dlast, if the distance between ddrem and dlast is less than or equal to 1⁄2 in.

(12.7 mm) and no velocity measurement is taken at drem (see section 8.2.4.2). Enter the

calculated value of Qdrem

in line 4c of column G of Form 2H-1 or 2H-2.

12.4.7

Calculate the total volumetric flow for the Method 1 equal-area sector closest

to the wall, using Equation 2H-14.

![]()

Enter the

calculated value of QT

in line 5a of column G of Form 2H-1 or 2H-2.

12.4.8

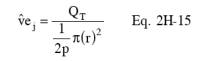

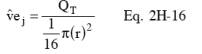

Calculate the wall effects-adjusted replacement velocity value for the Method 1

equal-area sector closest to the wall, using Equation 2H-15.

For a 16-point

traverse (eight points per diameter), Equation 2H-15 may be written as follows:

Enter the

calculated value of vˆej in

line 5b of column G of Form 2H-1 or 2H-2.

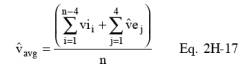

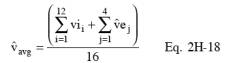

12.5 Calculate

the wall effects-adjusted average velocity,, by replacing the four values of õ avg shown in Equation 2H-5 with the four

wall effects-adjusted replacement velocity values, Ã µe, calculated according to section 12.4.8, using Equation

2H-17.

For a 16-point

traverse, Equation 2H-17 may be written as follows:

12.6 Calculate

the wall effects adjustment factor, WAF, using Equation 2H-19.

![]()

12.6.1 Partial

wall effects traverse. If a partial wall effects traverse (see section 8.2.2)

is conducted, the value obtained from Equation 2H-19 is acceptable and may be

reported as the wall effects adjustment factor provided that the value is

greater than or equal to 0.9800. If the value is less than 0.9800, it shall not

be used and a wall effects adjustment factor of 0.9800 may be used instead.

12.6.2

Complete wall effects traverse. If a complete wall effects traverse (see

section 8.2.3) is conducted, the value obtained from Equation 2H-19 is

acceptable and may be reported as the wall effects adjustment factor provided

that the value is greater than or equal to 0.9700. If the value is less than

0.9700, it shall not be used and a wall effects adjustment factor of 0.9700 may

be used instead. If the wall effects adjustment factor for a particular stack

or duct is less than 0.9700, the tester may (1) repeat the wall effects test,

taking measurements at more Method 1 traverse points and (2) recalculate the

wall effects adjustment factor from these measurements, in an attempt to obtain

a wall effects adjustment factor that meets the 0.9700 specification and

completely characterizes the wall effects.

12.7 Applying

a Wall Effects Adjustment Factor. A default wall effects adjustment factor, as

specified in section 8.1, or a calculated wall effects adjustment factor

meeting the requirements of section 12.6.1 or 12.6.2 may be used to adjust the

average stack gas velocity obtained using Methods 2, 2F, or 2G to take into

account velocity decay near the wall of circular stacks or ducts. Default wall

effects adjustment factors specified in section 8.1 and calculated wall effects

adjustment factors that meet the requirements of section 12.6.1 and 12.6.2 are

summarized in Table 2H-2.

12.7.1

Single-run tests. Calculate the final wall effects-adjusted average stack gas

velocity for field tests consisting of a single traverse using Equation 2H-20.

![]()

The wall effects

adjustment factor, WAF, shown in Equation 2H-20, may be (1) a default wall

effects adjustment factor, as specified in section 8.1, or (2) a calculated

adjustment factor that meets the specifications in sections 12.6.1 or 12.6.2.

If a calculated adjustment factor is used in Equation 2H-20, the factor must

have been obtained during the same traverse in which µavg was obtained.

12.7.2 RATA or

other multiple run test procedure. Calculate the final wall effects adjusted

average stack gas velocity for any run k of a RATA or other multiple-run procedure using Equation

2H–21.

![]()

The wall

effects adjustment factor, WAF, shown in Equation 2H-21 may be (1) a default

wall effects adjustment factor, as specified in section 8.1; (2) a calculated adjustment

factor (meeting the specifications in sections 12.6.1 or 12.6.2) obtained from

any single run of the RATA that includes run k; or (3) the arithmetic average of more

than one WAF (each meeting the specifications in sections 12.6.1 or 12.6.2)

obtained through wall effects testing conducted during several runs of the RATA

that includes run k.

If wall effects adjustment factors (meeting the specifications in sections

12.6.1 or 12.6.2) are determined for more than one RATA run, the arithmetic

average of all of the resulting calculated wall effects adjustment factors must

be used as the value of WAF and

applied to all runs of that RATA. If a calculated, not a default, wall effects

adjustment factor is used in Equation 2H-21, the average velocity unadjusted

for wall effects, µavg(k), must be obtained from runs in which the number of

Method 1 traverse points sampled does not exceed the number of Method 1

traverse points in the runs used to derive the wall effects adjustment factor,

WAF, shown in Equation 2H-21.

12.8

Calculating Volumetric Flow Using Final Wall Effects-Adjusted Average Velocity

Value. To obtain a stack gas flow rate that accounts for velocity decay near

the wall of circular stacks or ducts, replace µs in Equation 2-10 in Method 2, or µa(avg) a in Equations 2F-10 and 2F-11 in Method 2F, or µa(avg) in Equations 2G-9 and 2G-10 in Method 2G with one of the

following.

12.8.1 For

single-run test procedures, use the final wall effects-adjusted average stack

gas velocity, µfinal, calculated

according to Equation 2H-20.

12.8.2 For

RATA and other multiple run test procedures, use the final wall effects

adjusted average stack gas velocity, µfinal(k), calculated

according to Equation 2H-21.

13.0 Method Performance. [Reserved]

14.0 Pollution Prevention. [Reserved]

15.0 Waste Management. [Reserved]

16.0 Reporting

16.1 Field Test Reports.

Field test

reports shall be submitted to the Agency according to the applicable regulatory

requirements. When Method 2H is performed in conjunction with Method 2, 2F, or

2G to derive a wall effects adjustment factor, a single consolidated Method

2H/2F (or 2H/2G) field test report should be prepared. At a minimum, the

consolidated field test report should contain (1) all of the general

information, and data for Method 1 points, specified in section 16.0 of Method

2F (when Method 2H is used in conjunction with Method 2F) or section 16.0 of

Method 2G (when Method 2H is used in conjunction with Method 2 or 2G) and (2)

the additional general information, and data for Method 1 points and wall

effects points, specified in this section (some of which are included in

section 16.0 of Methods 2F and 2G and are repeated in this section to ensure

complete reporting for wall effects testing).

16.1.1 Description of the source and site.

The field test

report should include the descriptive information specified in section 16.1.1

of Method 2F (when using Method 2F) or 2G (when using either Method 2 or 2G).

It should also include a description of the stack or duct’s construction

material along with the diagram showing the dimensions of the stack or duct at

the test port elevation prescribed in Methods 2F and 2G. The diagram should

indicate the location of all wall effects traverse points where measurements

were taken as well as the Method 1 traverse points. The diagram should provide

a unique identification number for each wall effects and Method 1 traverse

point, its distance from the wall, and its location relative to the probe entry

ports.

16.1.2 Field test forms.

The field test

report should include a copy of Form 2H-1, 2H-2, or an equivalent for each

Method 1 exterior equal-area sector.

16.1.3 Field test data.

The field test

report should include the following data for the Method 1 and wall effects

traverse.

16.1.3.1 Data

for each traverse point. The field test report should include the values

specified in section 16.1.3.2 of Method 2F (when using Method 2F) or 2G (when

using either Method 2 or 2G) for each Method 1 and wall effects traverse point.

The provisions of section 8.4.2 of Method 2H apply to the temperature

measurements reported for wall effects traverse points. For each wall effects

and Method 1 traverse point, the following values should also be included in

the field test report.

(a) Traverse

point identification number for each Method 1 and wall effects traverse point.

(b) Probe

type.

(c) Probe

identification number.

(d) Probe

velocity calibration coefficient (i.e., Cp when Method 2 or 2G is used; F2 when Method 2F is used). For each Method

1 traverse point in an exterior equal-area sector, the following additional

value should be included.

(e) Calculated

replacement velocity, vˆej,

accounting for wall effects.

16.1.3.2 Data

for each run. The values specified in section 16.1.3.3 of Method 2F (when using

Method 2F) or 2G (when using either Method 2 or 2G) should be included in the

field test report once for each run. The provisions of section 12.8 of Method

2H apply for calculating the reported gas volumetric flow rate. In addition,

the following Method 2H run values should also be included in the field test

report.

(a) Average

velocity for run, accounting for wall effects, vˆ avg.

(b) Wall

effects adjustment factor derived from a test run, WAF.

16.1.3.3 Data for

a complete set of runs. The values specified in section 16.1.3.4 of Method 2F

(when using Method 2F) or 2G (when using either Method 2 or 2G) should be

included in the field test report once for each complete set of runs. In

addition, the field test report should include the wall effects adjustment

factor, WAF, that is

applied in accordance with section 12.7.1 or 12.7.2 to obtain the final wall

effects-adjusted average stack gas velocity vˆ final or vˆ final(k).

16.1.4 Quality assurance and control.

Quality

assurance and control procedures, specifically tailored to wall effects

testing, should be described.

16.2 Reporting a Default Wall Effects Adjustment Factor.

When a default

wall effects adjustment factor is used in accordance with section 8.1 of this

method, its value and a description of the stack or duct’s construction

material should be reported in lieu of submitting a test report.

17.0 References.

(1) 40 CFR

Part 60, Appendix A, Method 1’Sample and velocity traverses for stationary

sources.

(2) 40 CFR

Part 60, Appendix A, Method 2’Determination of stack gas velocity and

volumetric flow rate (Type S pitot tube).

(3) 40 CFR

Part 60, Appendix A, Method 2F’Determination of stack gas velocity and

volumetric flow rate with three-dimensional probes.

(4) 40 CFR

Part 60, Appendix A, Method 2G’Determination of stack gas velocity and

volumetric flow rate with two-dimensional probes.

(5) 40 CFR

Part 60, Appendix A, Method 3’Gas analysis for carbon dioxide, oxygen, excess

air, and dry molecular weight.

(6) 40 CFR

Part 60, Appendix A, Method 3A - Determination of oxygen and carbon dioxide

concentrations in emissions from stationary sources (instrumental analyzer

procedure).

(7) 40 CFR

Part 60, Appendix A, Method 4 - Determination of moisture content in stack

gases.

(8) Emission

Measurement Center (EMC) Approved Alternative Method (ALT-011) ‘‘Alternative

Method 2 Thermocouple Calibration Procedure.’’

(9) The Cadmus

Group, Inc., 1998, ‘‘EPA Flow Reference Method Testing and Analysis: Data Report,

Texas Utilities, DeCordova Steam Electric Station, Volume I: Test Description

and Appendix A (Data Distribution Package),’’ EPA/430-R-98-015a.

(10) The

Cadmus Group, Inc., 1998, ‘‘EPA Flow Reference Method Testing and Analysis:

Data Report, Texas Utilities, Lake Hubbard Steam Electric Station, Volume I:

Test Description and Appendix A (Data Distribution Package),’’

EPA/430-R-98-017a.

(11) The

Cadmus Group, Inc., 1998, ‘‘EPA Flow Reference Method Testing and Analysis:

Data Report, Pennsylvania Electric Co., G.P.U. Genco Homer City Station: Unit

1, Volume I: Test Description and Appendix A (Data Distribution Package),’’

EPA/430-R-98-018a.

(12) The

Cadmus Group, Inc., May 1999, ‘‘EPA Flow Reference Method Testing and Analysis:

Findings Report,’’ EPA/430-R-99-009.

(13) The

Cadmus Group, Inc., 1997, ‘‘EPA Flow Reference Method Testing and Analysis:

Wind Tunnel Experimental Results,’’ EPA/430-R-97-013.

(14) National

Institute of Standards and Technology, 1998, ‘‘Report of Special Test of Air

Speed Instrumentation, Four Prandtl Probes, Four S-Type Probes, Four French

Probes, Four Modified Kiel Probes,’’ Prepared for the U.S. Environmental

Protection Agency under IAG No. DW13938432-01-0.

(15) National

Institute of Standards and Technology, 1998, ‘‘Report of Special Test of Air

Speed Instrumentation, Five Autoprobes,’’ Prepared for the U.S. Environmental

Protection Agency under IAG No. DW13938432-01-0.

(16) National

Institute of Standards and Technology, 1998, ‘‘Report of Special Test of Air

Speed Instrumentation, Eight Spherical Probes,’’ Prepared for the U.S.

Environmental Protection Agency under IAG No. DW13938432-01-0.

(17) National

Institute of Standards and Technology, 1998, ‘‘Report of Special Test of Air

Speed Instrumentation, Four DAT Probes,’’ Prepared for the U.S. Environmental

Protection Agency under IAG No. DW13938432-01-0.

(18)

Massachusetts Institute of Technology (MIT), 1998, ‘‘Calibration of Eight Wind

Speed Probes Over a Reynolds Number Range of 46,000 to 725,000 per Foot, Text

and Summary Plots,’’ Plus Appendices, WBWT-TR-1317, Prepared for The Cadmus

Group, Inc., under EPA Contract 68-W6-0050, Work Assignment 0007AA-3.

(19) Fossil

Energy Research Corporation, Final Report, ‘‘Velocity Probe Tests in Nonaxial

Flow Fields,’’ November 1998, Prepared for the U.S. Environmental Protection

Agency.

(20) Fossil

Energy Research Corporation, ‘‘Additional Swirl Tunnel Tests: E-DAT

and T-DAT

Probes,’’ February 24, 1999, Technical Memorandum Prepared for U.S.

Environmental Protection Agency, P.O. No. 7W-1193-NALX.