Plain English Guide to the Part 75 Rule

U.S.

Environmental Protection Agency

Clear

Air Markets Division

1200

Pennsylvania Avenue, NW

Washington,

DC 20460

September,

2005

TABLE of CONTENTS

SECTION 1:

INTRODUCTION

1.1 What is the purpose of this guide?

1.2

What is Part 75 and who must comply with it?

1.3

What is a cap and trade program?

1.4 Why is continuous monitoring

necessary?

1.5 How is the Part 75 rule

structured?

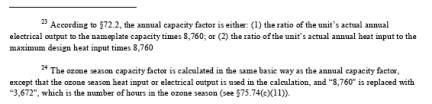

1.6 What other Federal regulations

interface with Part 75?

SECTION 2:

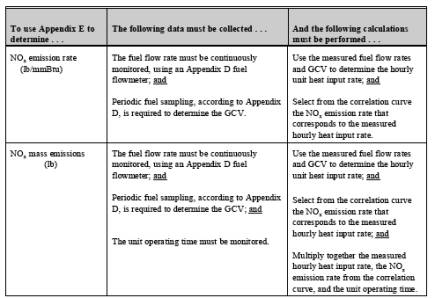

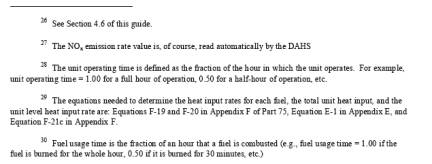

OVERVIEW OF PART 75 MONITORINGREQUIREMENTS

2.1

Register the Affected Unit(s) with EPA

2.2

Select a Monitoring Methodology

Oil-fired

and gas-fired peaking units

Certain

oil-fired and gas-fired units

Certain

Acid Rain Program units

Affected

coal-fired units under the CAMR rule

Certain

affected units under CAMR

Alternative

Monitoring Systems

2.3 Install and Certify Monitoring

Systems

2.4 Monitor and Record Emissions Data

2.5 Conduct Quality Assurance/Quality

Control Procedures

SECTION 3: BASIC CONTINUOUS EMISSION MONITORING REQUIREMENTS

3.1 What is a continuous emission

monitoring system (CEMS)?

3.2 What is a sorbent trap monitoring

system?

3.3 Primary and Backup Monitoring

Systems

3.4 How must a CEMS be operated?

3.5 How are emissions and heat input

rates determined from CEMS data?

3.6 When are corrections for stack

gas moisture content required?

3.7 What if a unit has multiple

stacks or shares a stack with other units?

3.8 What are the missing data

procedures for CEMS?

SECTION 4: APPENDIX D METHODOLOGY

FORGAS-FIRED

4.1 What is a “gas-fired” or

“oil-fired” unit?

4.2 What is the Appendix D

alternative monitoring method?

4.3 How is the fuel flow rate

measured?

4.4 What are the fuel sampling

requirements of Appendix D?

4.5 How is the SO2 mass emission rate calculated?

4.6 How is the unit heat input rate

calculated?

4.7 Which sulfur content, GCV and

density values are used in the calculations?

•

The results of the fuel

sampling and analysis are used directly in the calculations.

•

An “assumed value” is

used in the calculations.

4.8 What are the ongoing

quality-assurance requirements of Appendix D?

4.9 What are the missing data

procedures for an Appendix D unit?

SECTION 5: APPENDIX E METHODOLOGY FOR

GAS-FIRED AND OIL-FIRED PEAKING UNITS

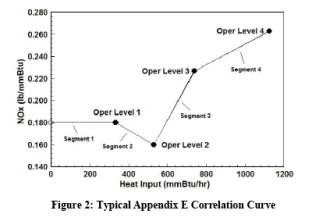

5.2 How is an Appendix E correlation

curve constructed?

5.3 How are hourly NOx emissions determined?

5.4 What are the fuel sampling

requirements of Appendix E?

5.5 What are the on-going

quality-assurance requirements of Appendix E?

5.6 What are the missing data

procedures for an Appendix E unit?

5.7 What happens if an Appendix E

unit loses its peaking unit status?

SECTION 6: LOW

MASS EMISSIONS METHODOLOGIES

6.1 Gas-Fired and

Oil-Fired Units

6.1.1 What is a low mass emissions

(LME) unit?

6.1.2 How does a unit qualify for LME

status?

6.1.3 How are emissions and heat input

calculated for an LME unit?

Generic

vs. Site-Specific Default Emission Rates

6.1.4 How are site-specific default NOx emission rates determined

6.1.5 Which site-specific default

emission rates are used for reporting?

6.1.6 What are the recordkeeping and

reporting requirements for LME units?

6.1.7 What are the on-going QA/QC

requirements for LME units?

6.1.8 What happens if a low mass

emissions unit loses its LME status?

SECTION 7: PART 75

MONITORING SYSTEM CERTIFICATION

PROCEDURES

7.1 How are Part 75 monitoring

systems certified?

7.2 Step 1 - Submit an Initial

Monitoring Plan

7.3 Step 2 - Submit Certification

Test Notices

7.4 Step 3 - Conduct Certification

Testing

7.5 Step 4 - Submit Certification

Application

7.6 Step 5 - Receive Agency Approval

or Disapproval

7.7 What reference test methods and

standards are used for certification testing?

Fuel

Flowmeter Accuracy standards

7.8 What performance specifications

must be met for certification?

7.9 What is meant by the “span

value”, and why is it important?

7.10 Recertification

and Diagnostic Testing

SECTION 8: QUALITY

ASSURANCE AND QUALITY

8.1 Does Part 75 require periodic

quality QA/QC testing after a monitoring

system is certified ? If so, where are these test requirements found?

8.2 What are the on-going QA test

requirements in Part 75 for units reporting

8.3 Are there any exceptions to these

basic QA test requirements?

8.4 Are there any special

considerations when performing these basic QA tests?

8.5 What are the on-going QA test

requirements for ozone season-only reporters?

8.6 What performance

specifications must be met for the routine QA tests required by Part 75?

8.7 Are there any notification

requirements for the periodic QA tests?

8.8 What are the essential elements

of a Part 75 QA/QC program?

SECTION 9: MISSING

DATA SUBSTITUTION PROCEDURES

9.1 Does Part 75 require emissions to

be reported for every unit

operating hour?

9.2 How are emissions data reported

when a monitoring system

9.3 What are the Part 75 missing data

procedures for CEMS?

9.4 What are the missing data

procedures for Appendices D, E, and G?

9.5 What is conditional data

validation?

SECTION 10: PART

75 REPORTING REQUIREMENTS

10.1 What are the basic reporting

requirements of Part 75?

10.2 How does EPA evaluate the electronic

quarterly reports?

10.4 Electronic Reporting—Update

APPENDIX I: Regulatory Update (CAIR and CAMR Rules)

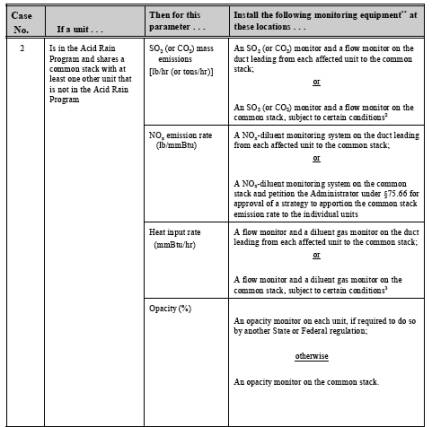

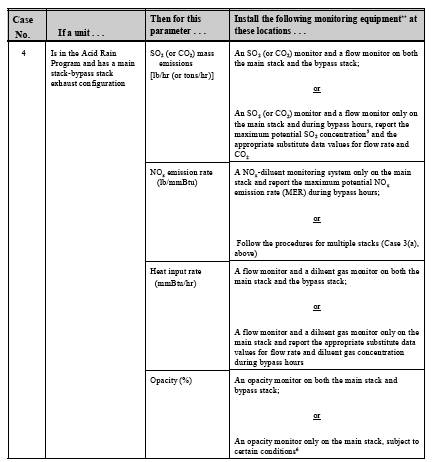

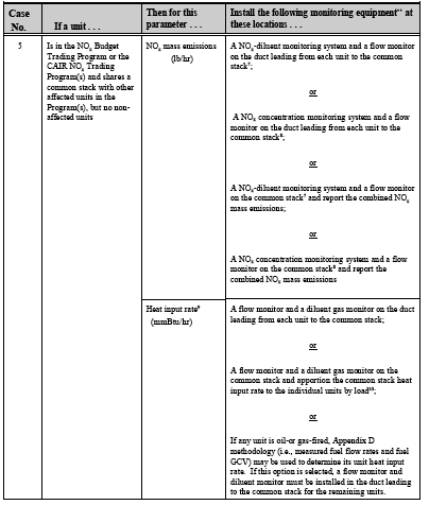

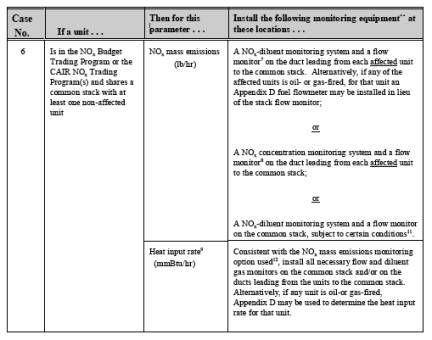

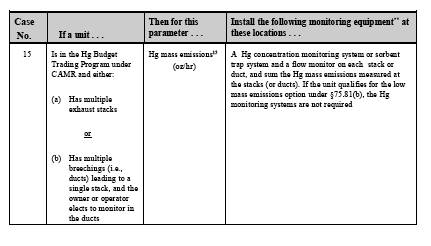

APPENDIX II: Summary of Part 75 Monitoring Requirements for Common

and Multiple Stack

Configurations

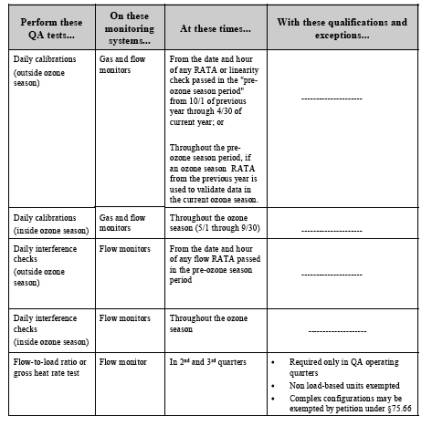

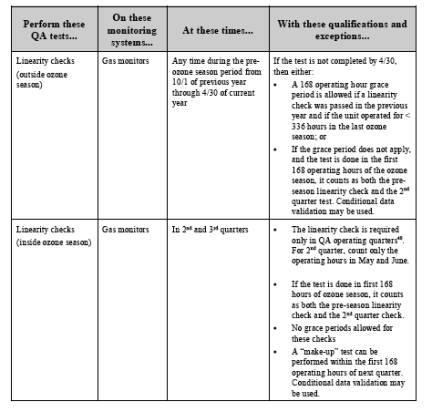

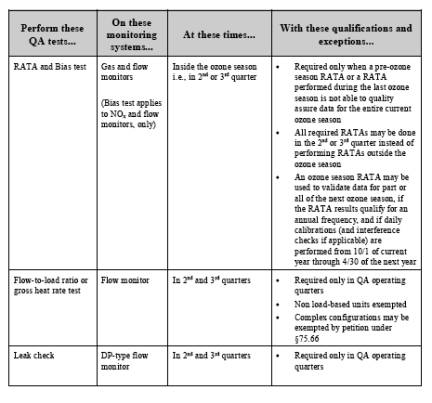

APPENDIX III: On-Going QA Test Requirements for

ACRONYMS and UNITS of

MEASURE

AAR - Authorized Account

Representative

AGA - American Gas

Association

API - American Petroleum

Institute

ARP - Acid Rain Program

ASME - American Society of

Mechanical Engineers

ASTM - American Society of

Testing and Materials

BAF - Bias Adjustment

Factor

CAIR - Clean Air

Interstate Regulation

CAMD - Clean Air Markets

Division

CAMR - Clean Air Mercury

Regulation

CDV - Conditional Data

Validation

CEM - Continuous Emission

Monitoring

CEMS - Continuous Emission

Monitoring System

CFR - Code of Federal

Regulations

CO2 - Carbon Dioxide

DAHS - Data Acquisition

and Handling System

DP - Differential Pressure

DR - Designated Representative

EDR - Electronic Data

Reporting

EGU - Electric Generating

Unit

EPA - Environmental

Protection Agency

ETS - Emissions Tracking

System

GCV - Gross Calorific

Value

GHR - Gross heat Rate

GPA - Gas Processors

Association

Hg - Mercury

ISO - International Organization

for Standardization

LME - Low Mass Emissions

MDC - Monitoring Data

Checking

MER - Maximum Potential

Emission Rate (MER)

NBP - NOx Budget Trading Program

NIST - National Institute

of Standards and Technology

NSPS - New Source

Performance Standards

NOx - Nitrogen Oxides

O2 - Oxygen

OOC - Out-of-Control

PLC - Programmable Logic

Controller

PMA - Percent Monitor Data

Availability

PNG - Pipeline Natural Gas

QA/QC - Quality

Assurance/Quality Control

RA - Relative Accuracy

RATA - Relative Accuracy

Test Audit

RM - Reference method

SIP - State Implementation

Plan

SO2 - Sulfur Dioxide

TTFA - Targeting Tool for

Field Audits

WAF - Wall Effects

Adjustment Factor

Btu - British thermal unit

dscfh - Dry standard cubic

feet per hour

dscf/mmBtu - Dry standard cubic

feet per million Btu

lb/hr - Pounds per hour

lb/mmBtu - Pounds per

million Btu

lb/scf - Pounds per

standard cubic foot

mmBtu/hr - Million Btu per

hour

ppmv - Parts per million

by volume

scfh - Standard cubic feet

per hour

scf CO2/mmBtu - Standard cubic feet of CO2 per million Btu

tons/hr - Tons per hour

tons/scf - Tons per

standard cubic foot

:g/scm - Micrograms per

standard cubic meter

1.1 What is the purpose

of this guide?

EPA

has developed this plain-English guide as a “road map” to help interested

parties navigate through the complex Part 75 continuous emission monitoring

rule. This guide may be useful to people responsible for complying with the

rule, regulatory agencies assessing compliance with the rule, and others who

want a general understanding of the emissions monitoring approach used in EPA’s

emissions trading programs. This guide, although quite comprehensive, does not

replace the Part 75 rule. Rather, it provides a general overview of Part 75 and

is intended to clarify the regulation. To gain a more complete understanding of

the rule, it is necessary to carefully read and study Part 75, as well as the

associated guidance documents issued by EPA, such as the “Part 75 Emissions

Monitoring Policy Manual” and the “Electronic Data Reporting Instructions”).

For further information on EPA’s emissions trading programs, continuous

emissions monitoring, Part 75, and related topics, see the EPA Clean Air

Markets Division (CAMD) website at: www.epa.gov/airmarkets

1.2 What is Part 75 and

who must comply with it ?

The

Part 75 continuous emission monitoring rule, which is found in Volume 40 of the

Code of Federal Regulations (CFR), was originally published in January, 1993.

The purpose of the regulation was to establish continuous emission monitoring

(CEM) and reporting requirements under EPA’s Acid Rain Program (ARP), which was

instituted in 1990 under Title IV of the Clean Air Act. The ARP regulates

electric generating units (EGUs) that burn fossil fuels such as coal, oil and

natural gas and that serve a generator > 25 megawatts. For these units, Part

75 requires continuous monitoring and reporting of sulfur dioxide (SO2) mass emissions, carbon dioxide (CO2) mass emissions,

nitrogen oxides (NOx) emission rate, and heat input. The SO2 component of the ARP is a “cap and trade” program, designed to reduce

acid deposition by limiting SO2 emission levels in the “lower

48" states of the U.S.

In

October, 1998, EPA added Subpart H to Part 75, which provides a blueprint for

the monitoring and reporting of NOx mass emissions and

heat input under a State or Federal NOx emissions reduction

program. The Agency anticipated that such programs were likely to come into

existence, due to growing concern over health hazards associated with NOx emissions from power plants and large industrial sources. NOx is a precursor to ozone and fine particulate matter formation. Subpart H

has since been adopted as the required monitoring methodology for NOx mass emissions and heat input under the NOx Budget

Trading Program (NBP).

The

NBP is a NOx cap and trade program, designed to limit ground-level

ozone formation during the ozone season (from May 1st through September 30th) in 22 states in the Eastern U.S.

The state regulations for the NBP apply mainly to large EGUs and industrial

boilers, although certain states have included other categories of NOx-emitting sources, such as cement kilns and

On May 12 and May 18,

2005, EPA published two new air regulations, the Clean Air Interstate Rule

(CAIR) and the Clean Air Mercury Rule (CAMR). These regulations provide model

rules for cap and trade programs that can be adopted by the states. The CAIR

rule seeks to reduce fine particulate and ozone emissions by imposing tight

emission caps on SO2 and NOx mass emissions from EGUs in 28

states. CAIR includes annual SO2 and NOx emissions caps for 23 of the 28 affected states and an ozone season cap

on NOx emissions in 25 of the states. The AMR rule seeks to

achieve substantial reductions in mercury (Hg) mass emissions from coal-fired

EGUs in all 50 states.

Both CAIR and CAMR require

Part 75 monitoring. Under CAIR, monitoring systems for NOx mass emissions and heat input must be installed and certified by 2008,

and monitoring systems for SO2 mass emissions and heat input

must be certified by 2009. Under CAMR, Part 75-compliant monitoring systems for

Hg mass emissions and, if required, heat input must be installed and certified

by January 1, 2009. For a further discussion of these new rules, see Appendix I of this guide.

Part 75 specifies the

types of continuous monitoring systems that may be used for each parameter (SO2, NOx, Hg, etc.) and sets forth the operation, maintenance

and quality assurance/quality control (QA/QC) requirements for each system. In

most cases, continuous emission monitoring systems (CEMS) are required, although

in some instances, other monitoring methodologies are allowed.

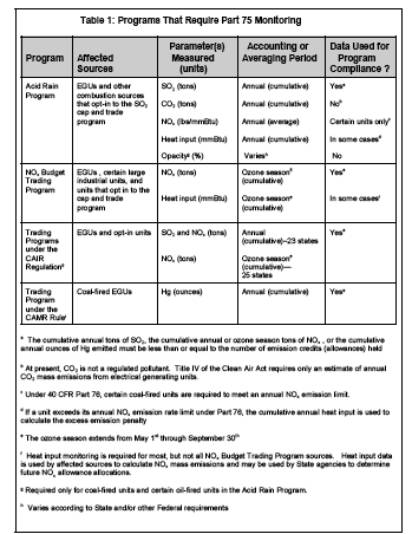

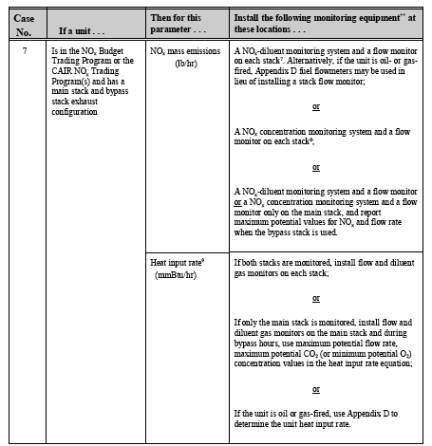

Table 1 summarizes

the various programs that require (or will require) Part 75 monitoring. Each of

these programs requires certain parameters to be monitored over specified time

periods. For each affected unit, the specific parameters that must be

monitored, the units of measure, and the averaging (or accounting) periods

depend on which program(s) apply.

Table 1 also shows

that when the same pollutant is regulated under two different programs, the

Part 75 monitoring and reporting requirements for the pollutant are not

necessarily consistent between the two programs. For example, the ARP and NBP

assess NOx compliance differently. The ARP requires the NOx emission rate to be monitored and reported in pounds per million Btu

(lb/mmBtu) and specifies annual NOx emission rate

limits for certain coal-fired EGUs, under 40 CFR Part 76. But the ARP does not

have an emissions trading component for NOx, and therefore does

not require NOx mass emissions to be reported1. Conversely, the NBP, which is a NOx cap and trade

program, does require NOx

mass emissions to be monitored and

reported for allowance accounting purposes, but does not require compliance

with NOx emission limits in lb/mmBtu. For sources subject to

both the ARP and the NBP, the requirements of both programs must be met --

therefore, NOx mass emissions and NOx emission rate

must both be monitored and reported.

___________________

1.3 What is a cap and

trade program?

A cap and trade

program is a market-based approach to reducing emissions. The concept is

simple: EPA caps, or limits, the total annual or seasonal mass emissions of a

pollutant such as SO2, NOx or Hg. The cap is divided into

emission allowances that are allocated to each affected source. Each emission

allowance represents an authorization to emit one ton of SO2 or NOx, or one ounce of Hg over a specified time period

(i.e., calendar year or ozone season). To demonstrate compliance, a source is

required to hold a number of allowances greater than or equal to its emissions

in the regulated time period. Since the total number of allowances allocated to

the affected sources is less than the pre-program (“baseline”) mass emissions

from those sources, the program reduces the mass emissions of the regulated

pollutant.

A cap and trade program does not specify traditional numerical emission limits (e.g. ppm, lb/mmBtu, etc.) for the regulated pollutant(s) Instead, compliance is demonstrated by holding enough allowances to cover the total mass emissions from the affected unit(s) during a specified time period. However, numerical emission limits imposed by other programs or by the operating permit still apply.

At the end of each

compliance period, a reconciliation process takes place to verify that each

affected source has enough allowances to cover its emissions. Automatic

penalties for noncompliance are part of the U.S. cap and trade programs. For

example, if an ARP unit does not have enough allowances to cover its annual SO2 emissions, the owner or operator of the unit must pay an excess

emissions penalty and must surrender future year allowances to cover the

shortfall. For a NBP unit, if its ozone season NOx emissions

exceed its allowance holdings, the owner or operator of the unit must surrender

at least 3 future-year allowances and, if required by state rules, pay

additional penalties.

This market-based

approach allows sources to determine the most cost-effective way to comply.

Sources may reduce emissions by using pollution control technologies, employing

energy conservation measures, reducing utilization, switching fuels, or other

strategies. Sources also are allowed to buy and sell allowances from each other

to ensure that each unit has enough allowance credits in its account to cover

its emissions. In this manner, a cap and trade program reduces emissions at a

lower cost than traditional pollution control regulations and policies, by setting

a goal and allowing market forces to determine how the goal is met.

1.4 Why is continuous

monitoring necessary?

Emissions monitoring

and accounting are the backbone of cap and trade programs. Because the emission

allowances are based on the total mass of a pollutant emitted over a certain

time period, emissions must be monitored continuously during the compliance

period. It is, therefore, essential to have a reliable measurement method for

the commodity being regulated and traded---in this case, emissions--- to ensure

that the goal of achieving actual, measurable emissions reductions in a

cost-effective manner is met. Part 75 provides the necessary measurement

method, and gives value to the traded commodity by:

•

Ensuring that the

emissions from all sources are consistently and accurately measured and

reported. In other words, a ton of emissions2 from one source is

equal to a ton of emissions2 from any other source;

•

Ensuring that a

complete record of emission data is produced for each unit in the program

(i.e., data are obtained for every hour of unit operation);

•

Verifying that emission

caps are not exceeded, thereby ensuring that emissions are not underestimated

and that emission reduction goals are being met.

1.5 How is the Part 75

Rule Structured ?

Part 75 consists of

nine Subparts, A through I, followed by a series of eleven Appendices, A

through K3. A brief description of each Subpart and Appendix

follows.

Subparts

Defines the purpose of the regulation and the extent of its

applicability. Subpart A also includes general Acid Rain Program provisions,

compliance dates, prohibitions, and lists various methodologies (e.g., ASTM,

ASME, etc.) that are incorporated into the rule by reference.

Presents the general emission monitoring requirements for each pollutant

(SO2 , NOx , etc.). Special instructions

are given for monitoring at common stack and multiple stack exhaust

configurations.

___________________

Presents the process for certification and recertification of the

required continuous monitoring systems, provides the quality assurance and

quality control (QA/QC) requirements for the systems, defines “out-of-control”

periods, and requires bias adjustment of data from SO2 , NOx , and flow monitors.

Describes the missing data procedures that are used to determine the

appropriate substitute data values, for unit operating hours in which the

monitoring systems fail to provide quality-assured data.

Describes the requirements that must be met for approval of an

alternative monitoring system.

Contains the recordkeeping requirements

Contains the reporting requirements. Instructions are provided for

submitting notifications, monitoring plans, certification applications,

emissions reports, and special petitions to the Administrator.

Describes the NOx

mass emission monitoring requirements

for sources in a NOx mass emissions reduction program that adopts Part 75,

such as the NOx Budget Program or a NOx trading

program under the CAIR rule. Special instructions are provided for sources that

report data only during the ozone season.

Describes the Hg mass emission monitoring requirements for sources in a

Hg mass emissions reduction program that adopts Part 75, such as a national Hg

trading program under the CAMR rule.

Appendices

Describes CEMS installation and certification test procedures, and

provides performance specifications for the CEMS and explains how to set the

span and range of CEMS;

Describes the required on-going CEMS quality assurance tests and

procedures for CEMS, and includes rules for data validation;

Provides guidelines for parametric and load-based missing data

substitution;

Provides an optional protocol for estimating SO2 mass emissions and heat input for gas-fired and oil-fired units;

Provides an optional protocol for estimating NOx emissions from gas-fired and oil-fired peaking units;

Provides equations for converting raw monitoring data into the

appropriate units of measure;

Gives procedures for monitoring and calculating CO2 mass emissions, for ARP units;

Are currently reserved; and

Provides special operating instructions and quality-assurance

requirements for sorbent trap monitoring systems, which are used to monitor Hg

emissions.

1.6 What other Federal

regulations interface with Part 75?

Part 75 is one of the

Acid Rain Program core rules, which, collectively, are found in Volume 40 of

the CFR, Parts 72 through 78. Part 75 is referenced in several of the other

core rules. First, in §72.2, there are numerous important definitions that

apply to Part 75. Second, Part 76, which specifies annual NOx emission limits for certain coal-fired boilers, requires Part 75

monitoring to be used to demonstrate compliance with these emission limits.

Third, Part 74 requires units that opt-in to the Acid Rain Program to monitor

and report SO2 emissions according to Part 75.

Part 75 also

interfaces with some of the New Source Performance Standards (NSPS) regulations

in 40 CFR Part 60. Many units that are currently in the Acid Rain Program or

the NOx Budget Program are also subject to one of the NSPS

boiler regulations (Subparts D, Da, Db and Dc) or to the NSPS rule for

combustion turbines (Subpart GG). The Part 60 boiler regulations require

continuous emission monitoring for SO2 and/or NOx , and Subpart GG allows a NOx CEMS to be used to

monitor and report “excess emissions”. Subparts Da and Db allow a certified

Part 75 NOx monitoring system to be used to meet the Part 60 NOx monitoring requirements. Subpart GG allows a certified Part 75 NOx CEMS to be used for excess emission monitoring.

2.0

OVERVIEW OF PART 75 MONITORING REQUIREMENTS

Part 75 requires an

hourly accounting of the emissions from each affected unit. Continuous emission

monitoring systems (CEMS) are used to provide the emissions data unless the

unit qualifies to use one of the alternative monitoring methodologies specified

in the rule. With few exceptions, the alternative methodologies apply to

oil-fired and gas-fired units.

The selected

monitoring methodology for each unit must be approved by EPA through a

certification process. Once the methodology has been approved and the required

monitoring systems are certified, the recording and reporting of emissions data

begins. Part 75 also requires on-going quality assurance and quality control

(QA/QC) procedures, to ensure that the data collected by the monitoring systems

continue to be accurate.

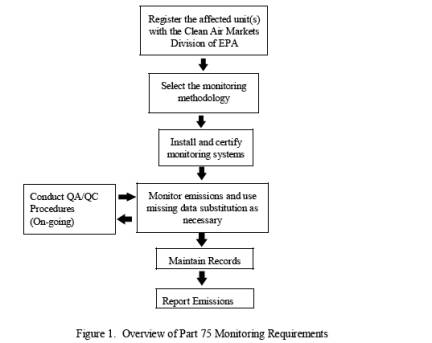

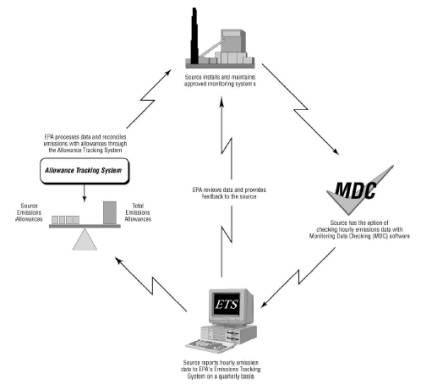

This section provides

an overview and general description of the Part 75 monitoring and reporting

requirements (see Figure 1). More specific information is provided in the

subsequent sections of this guide.

2.1 Register the

Affected Unit(s) with EPA.

Each affected unit

must be registered with EPA’s Clean Air Markets Division (CAMD) before any data

is reported for the unit. As part of the registration process, a Designated

Representative, or “DR” (for the Acid Rain and CAIR Programs), a “Hg Designated

Representative” (for the CAMR Program), or an Authorized Account

Representative, or “AAR” (for the NOx Budget Program),

must be assigned for each unit. The Designated Representative or AAR takes the

responsibility for ensuring that each affected unit complies with all of the

applicable program requirements, and that the emissions data reported to EPA

are true and accurate. For units subject to both the Acid Rain Program and to

one or more of the SO2 and NOx trading programs under CAIR,

the Designated Representative for all of these trading programs must be the

same person.

2.2 Select a Monitoring

Methodology

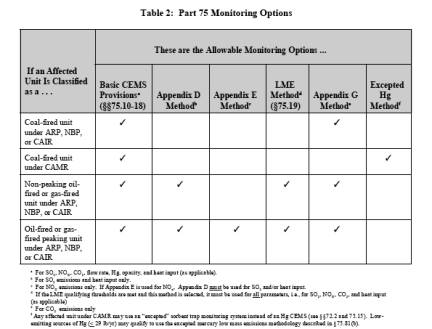

Part 75 provides

several monitoring options. The options that are available for a unit depend on

how the unit is classified (see Table 2 in Section 2.4, below). In general, if

a unit is coal-fired or combusts any type of solid fuel, the basic continuous

monitoring provisions in §§75.10-75.18 require the use of CEMS for all

monitored parameters. However, there are a few exceptions to this. If a unit is

classified as an oil- or gas-fired unit, it may qualify for an alternative

monitoring approach instead of CEMS for some or all parameters. In

some cases, the unit may

even qualify for a monitoring exemption.

The Part 75 rule generally requires

the use of CEMS for units that combust coal or other solid fuel(s). Alternative

monitoring approaches, referred to in the rule as “excepted methods” or

“excepted monitoring systems” , may be used for qualifying oil-fired and

gas-fired units, and for certain coal-fired units under the CAMR rule.

The monitoring

alternatives or exemptions that apply to a unit depend mainly on how often the

unit operates each year, how much it emits, and the type(s) of fuel(s) it

combusts. These alternatives and exemptions are:

•

Monitoring

Options

May use the alternative, or “excepted” methodology in Appendix D of Part

75 to determine SO2 mass emissions and/or unit heat input. The Appendix D

method requires continuous monitoring of the fuel flow rate with a certified fuel

flowmeter and periodic fuel sampling and analysis to determine one or more of

the following quantities: (1) the gross calorific value (GCV) of the fuel; (2)

the fuel sulfur content; and (3) the density of the fuel. The Appendix D

methodology is discussed in greater detail in Section 4 of this guide.

•

Oil-fired and

gas-fired peaking units

May use the alternative method in Appendix E of Part 75 to estimate the

hourly NOx emission rate in lb/mmBtu. Appendix E requires hourly

determination of the heat input rate to the unit, using the fuel flow rate

measured by a certified Appendix D fuel flowmeter, in conjunction with the GCV

of the fuel. A correlation curve of NOx emission rate

versus heat input rate (derived from emission testing) is then used to estimate

the hourly NOx emission rates. The Appendix E methodology is

discussed in greater detail in Section 5 of this guide.

•

Certain oil-fired

and gas-fired units

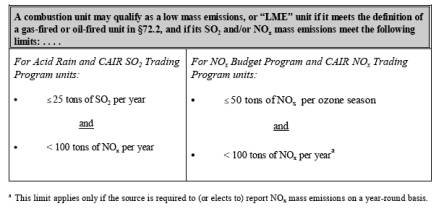

May qualify to use the low mass emissions (LME) methodology in §75.19 to

estimate SO2, CO2, and/or NOx emissions and heat input. To qualify for LME status, a unit’s annual SO2 and NOx mass emissions, and in some cases, its ozone season

NOx mass emissions, must be demonstrated to be below

certain threshold values.

The LME methodology requires

that records be kept of the hours in which the unit operates, the type(s) of

fuel(s) combusted, the electrical or steam load during each of those hours,

and, in some cases, the operational status of the NOx emission controls. Default emission rates and estimates of heat input

are used to quantify the unit’s mass emissions. The LME methodology is

discussed in greater detail in Section 6 of this guide.

May use the alternative procedures in Appendix G of Part 75 to estimate

CO2 mass emissions, in lieu of installing CEMS. Appendix

G allows CO2 emissions to be estimated, either by using: (1) fuel

feed rates and the results of periodic fuel sampling and analysis (to determine

the % carbon in the fuel); or (2) hourly heat input rate measurements from a

certified Appendix D fuel flowmeter and a fuel-specific, carbon-based

“F-factor”.

Appendix G is the most frequently used method for estimating CO2 mass emissions from oil and gas-fired units. Part 75 allows the fuel

feed rate methodology (option (1), above) to be used for coal-fired units also,

but it is not currently being used by any of them.

•

Certain Acid Rain

Program units

Are exempted from opacity monitoring requirements. Coal-fired units with

wet scrubbers may be exempted if the presence of condensed water in the

effluent gas stream interferes with the opacity readings. Also, any unit that

meets the definition of gas-fired or diesel-fired in §72.2, or that qualifies

as a dual-fuel reciprocating engine is exempted from opacity monitoring.

However, note that these Part 75 exemptions do not supersede the provisions of

any other program, regulation, or permit that may require an opacity monitor to

be installed.

•

Affected

coal-fired units under the CAMR rule

May use an alternative (“excepted”) type of continuous Hg monitoring

system, known as a “sorbent trap monitoring system”. A sorbent trap system

continuously samples the stack gas for an extended period of time (e.g., up to

a week or more) and collects Hg on a sorbent medium such as activated carbon.

The total volume of stack gas sampled during the collection period is measured,

and the Hg concentration is determined by taking the ratio of the collected Hg

mass to the sample volume.

•

Certain affected

units under CAMR

May qualify to use a low mass emissions methodology to estimate the

annual Hg mass emissions, in lieu of continuously monitoring the Hg

concentration. This alternative methodology applies mainly to small units with

very low (< 29 lb/yr) annual Hg mass emissions. It requires periodic

Hg emission testing, and conservatively high default Hg concentrations must be

used for emissions reporting.

Sections 3 through 6 of this guide provide more information on the various Part 75 emission monitoring methodologies. Section 3 describes the basic CEM provisions, and Sections 4, 5, and 6, respectively, discuss the alternative Appendix D, Appendix E, and low mass emission methodologies.

Under §75.66, EPA has

established a petition process through which affected sources can request

relief or variances from certain provisions of Part 75. Each petition must

contain sufficient information for the Agency to evaluate the request. At a

minimum, the petition must: (1) identify the affected facility and unit(s); (2)

explain why the proposed alternative is being suggested instead of the

regulatory requirement; (3) provide a description of any equipment or

procedures used in the proposed alternative; (4) demonstrate that the proposed

alternative is consistent with the purposes of Part 75 and the Clean Air Act;

and (5) explain why approving it will not have any significant adverse effects.

The regulatory

flexibility provided by the petition process reduces the cost of compliance for

many sources and facilitates program implementation. EPA strives for

consistency in its petition responses. When a petition is approved (or denied),

petitions of a similar nature will also be approved (or denied). The Agency

also seeks to avoid setting precedents by answering petitions in a way that

will weaken or undermine the Part 75 rule. Finally, when EPA approves a large

number of petitions of the same type, this often indicates the need for a rule

change. The Agency has revised Part 75 a number of times on this basis.

Alternative Monitoring

Systems

Subpart E of Part 75

allows sources to petition EPA for approval of an alternative monitoring

system. To obtain approval, the petition must demonstrate that the alternative

system has the same precision, reliability, accessibility, and timeliness as a

certified Part 75 CEMS. The performance of any alternative system must be

demonstrated by simultaneous testing against a fully certified CEMS or an EPA

reference test method. The petition must also propose quality assurance

procedures and missing data substitution procedures for the alternative

monitoring system that are consistent with the corresponding Part 75 procedures

for CEMS. The criteria and procedures for approval of alternative systems are

specified in Subpart E and are not discussed further in this guide.

On the one hand, EPA has received

and approved only a few Subpart E petitions to use alternative monitoring

systems, partly due to the rigorous requirements of Subpart E and partly

because the Appendix D, Appendix E and LME “excepted” methods in Part 75

provide substantial flexibility in choosing a monitoring methodology. On the

other hand, the Agency has approved many minor variations to the monitoring

provisions of Part 75

2.3 Install and Certify

Monitoring Systems

Before any monitoring

methodology or monitoring system is used, it must be approved through a

certification process. This process is described in detail in Section 7 of this

guide. Except for LME units4, the general steps for

obtaining certification are:

•

Step 1---Prepare and

submit an initial monitoring plan

•

Step 2---Submit

certification test notices

•

Step 3---Conduct

certification testing

•

Step 4---Submit a

certification application

•

Step 5---Receive

approval or disapproval

2.4 Monitor and Record

Emissions Data

With the exception of

LME units5, monitoring and reporting of emissions begins as

soon as certification testing is successfully completed, provided that the

tests are completed by the certification deadline specified in the regulations6. Part 75 monitoring systems are considered to be “provisionally

certified” in the period extending from the date of successful completion of

the

![]()

____________________

certification tests7 through the end of a 120-day review period8, provided

that the systems are operated in accordance with all Part 75 requirements and

the permitting authority does not disapprove the systems in the meantime.

Emissions data may be reported as quality-assured during this period of

provisional certification.

Part 75 requires

emissions data to be reported for every hour that an affected unit is

operating, including periods of start-up, shutdown, and malfunction. If one of

the required monitoring systems is not working or is out-of-control (e.g., if

it fails one of its required quality assurance tests), data from an approved

backup monitor or from an EPA reference method9 may be

reported. If quality-assured data from a back-up monitor or reference method

are not available, the Part 75 missing data substitution procedures must be

used to estimate emissions.

The Part 75 missing

data routines for CEMS are found in §§75.31 through 75.38 and the routines for

sorbent trap monitoring systems are found in §75.39. These routines consist of

mathematical algorithms that are used to determine an appropriate substitute

value for any unit operating hour in which quality-assured data are not

obtained for a monitored parameter (i.e., for SO2 , NOx, Hg, CO2, O2 , flow rate, or moisture).

Generally speaking, historical, quality-assured monitoring data are used to

determine the substitute data values. The exact substitute data values that are

applied in a given situation depends on:

•

The historical

availability of quality-assured data from the monitor(s)10;

•

The length of the missing

data period; and

•

For certain parameters

(NOx and flow rate), the hourly unit loads during the

missing data period.

The missing data

procedures are designed to be conservative. This provides an incentive to

reduce periods of monitor downtime, by rewarding high percent monitor data

availability (PMA)10. The procedures will produce conservatively high

emissions estimates for units with lower PMA values. The monitoring

methodologies in Appendices D, E, and G of Part 75 also have missing data

procedures. The missing data algorithms under these appendices are considerably

less complex than the CEMS and sorbent trap system algorithms. The Part 75

missing data substitution procedures are discussed in greater detail in Section

9 of this guide.

__________________

2.5 Conduct Quality

Assurance/Quality Control Procedures

After certification,

the following periodic performance evaluations of all monitoring systems must

be conducted, to ensure the continued accuracy of the emissions data:

•

The quality-assurance

tests for CEMS include daily assessments (e.g., calibration error tests),

weekly assessments (system integrity checks of Hg CEMS equipped with

converters), quarterly assessments (e.g., linearity checks), and semi-annual

(or annual in some cases) relative accuracy test audits (RATAs);

•

For sorbent trap

monitoring systems, annual RATAs and the quality assurance procedures of Part

75, Appendix K are required;

•

For CAMR units that

qualify to use the Hg low mass emissions option, either semiannual or annual Hg

emission testing is required, depending on the annual mass emission level;

•

For Appendix D fuel

flowmeters, annual accuracy tests are required; and

•

For Appendix E units

and LME units using site-specific emission rates, re-testing is required once every

5 years.

Note that for

linearity checks, RATAs, and fuel flowmeter accuracy tests, test exemptions and

test deadline extensions are permitted by Part 75 in certain circumstances. The

required QA tests for Part 75 monitoring systems are discussed in greater

detail in section 8 of this guide.

For all required

continuous monitoring systems, a written quality assurance (QA) plan must be

developed and followed. The quality control plan includes step-by-step

procedures for each of the required QA tests, as well as procedures for

calibration adjustments, preventive maintenance, audits, recordkeeping and

reporting.

The basic record

keeping provisions of Part 75 are found in Subpart F (§75.53 and §§75.57

through 75.59). Most of the required records are kept electronically, for a

minimum of three years, using a data acquisition and handling system (DAHS),

although some monitoring plan information and quality assurance (QA) test

support data is kept in hard copy. The DAHS records all data from the

monitoring systems, translates it into the required units of measure, and

stores the data. When emissions data are missing, the DAHS automatically

performs missing data substitution. The DAHS also electronically records and

stores operating data for the combustion unit, emission control device data,

monitoring plan data, and the results of QA checks and tests.

Parallel

recordkeeping sections, that frequently cite the basic Subpart F provisions,

are found in §75.73 of Subpart H (for NOx mass trading

programs such as the NBP) and in §75.84 of Subpart I (for mercury mass trading

programs such as the CAMR). The NBP, CAIR and CAMR rules also include

recordkeeping sections, but in general, these sections contain no new or unique

requirements. Rather, they serve as “road signs”, pointing back to the

recordkeeping provisions in Subparts F, H, and I.

The electronic

records that must be maintained are quite detailed and are not discussed

further in this guide. Typically, DAHS vendors can provide software that meets

the Part 75 recordkeeping requirements.

The basic Part 75

reporting provisions (originally written for the ARP) are found in Subpart G

(§§75.60 through 75.64). Subpart G includes requirements to provide various

types of notifications and to submit monitoring plans, certification

applications, and electronic emissions reports at specified times. Parallel

notification and reporting sections, which reference sections of Subpart G, are

found in §§75.73 and 75.74 of Subpart H (for NOx trading

programs such as the NBP), and in §75.84 of Subpart I (for mercury trading

programs such as the CAMR).

The NBP, CAIR and

CAMR rules also include notification and reporting sections, but these sections

simply reference the notification and reporting provisions in Subparts G, H,

and I of Part 75. The CAIR SO2 rule refers to Subpart G; the

NBP and CAIR NOx rules refer to Subparts G and H; and the CAMR rule

refers to Subpart I.

For units under the

Acid Rain Program and/or the CAIR annual SO2 and NOx trading programs, emissions reports must be submitted four times a year,

i.e., one report for each calendar quarter. Units that are subject to the NOx Budget Program or to the CAIR ozone season NOx trading program, but are not in either the Acid Rain Program or the CAIR

annual SO2 and NOx programs, have the option of

reporting emissions data either year-round or only for the ozone season (May 1st through September 30th).

The quarterly reports

allow EPA to track the quality of the emissions data throughout the year (or

ozone season) as well as the status of emissions compared to the allowances

held. The data and information to be reported include the following:

•

Facility information;

•

The hourly emissions data,

operating data, the results of the required QA tests, and other information

specified in the monitoring plan and recordkeeping sections of Part 75;

•

Unit operating hours

for the quarter and cumulative operating hours for the calendar year and/or

ozone season;

•

Tons of SO2 emitted during the quarter and cumulative SO2 mass emissions for the calendar year (ARP units and units in the CAIR SO2 Trading Program, only);

•

Average NOx emission rates (lb/mmBtu) for the quarter and for the year-to-date (ARP

units, and certain units in the NBP and CAIR NOx Trading

Programs);

•

Tons of CO2 emitted during the quarter and cumulative CO2 mass emissions for the calendar year (ARP units, only);

•

Tons of NOx emitted during the quarter and cumulative NOx mass emissions for the calendar year and/or ozone season, as applicable

(for units in the NBP and CAIR NOx Trading Programs);

•

Ounces of Hg emitted

during the quarter and cumulative Hg mass emissions for the calendar year (CAMR

units, only); and

•

Total heat input

(mmBtu) for quarter and cumulative heat input for calendar year (or ozone

season)—unless exempted from heat input reporting by regulation.

EPA requires the data

be submitted electronically, because of the large volume of information that

must be reported. The Agency provides a standard electronic data reporting

(EDR) format that must be used and provides monitoring data checking (MDC)

software that can be used to perform quality control checks on the data prior

to data submittal. While use of the MDC software is optional, EPA encourages it

because using the MDC will cut down on the number of re-submissions and save

time and money. EPA processes each quarterly report through rigorous quality

control checks to verify data accuracy and conformance to the required format.

After the review, the Agency sends notifications to the affected sources,

indicating whether the quarterly data are acceptable or unacceptable. The Part

75 reporting requirements are discussed in more detail in Section 10 of this

guide.

3.0

BASIC CONTINUOUS EMISSION MONITORING REQUIREMENTS

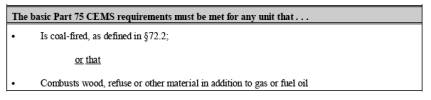

The basic Part 75

continuous monitoring approach is to install CEMS and a DAHS on each affected

unit and record emissions and heat input data. This general approach must be

followed for combustion units that burn coal or any other solid fuel11 (see Table 3). Oil-fired and gas-fired units may either comply with

these basic requirements or may use alternative monitoring methods for some or

all parameters (see Sections 4, 5, and 6 of this guide for further discussion

of the alternative methods).

Table 3: Units that Must Comply with the Basic Part 75

CEMS

Requirements

3.1 What is a

continuous emission monitoring system (CEMS)?

A continuous emission

monitoring system, or CEMS, consists of all the equipment needed to measure and

provide a permanent record of the emissions from an affected unit. Examples of

CEMS components include:

•

Pollutant concentration

monitors (e.g., SO2 , NOx, or Hg monitors).

•

Diluent gas monitors,

to measure %O2 or %CO2

•

Volumetric flow

monitors

•

Sample probes

•

Sample (“umbilical”)

lines

•

Sample pumps

•

Sample conditioning

equipment (e.g., heaters, condensers, gas dilution equipment)

•

Data loggers or

programmable logic controllers (PLCs)

•

DAHS components that

electronically record all measurements and automatically calculate and record

emissions and heat input in the units of measure required by the rule.

____________________

The specific

components of a CEMS depend upon the parameter being monitored, the measurement

principle of the CEMS, and the required units of measure. Some components are

common to all systems, while others are specific to a particular monitoring

technology. To illustrate:

•

The key components of

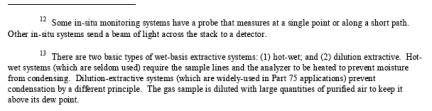

every Part 75 CEMS are the analyzer(s) and the DAHS (see Table 4). Table 4

shows that all Part 75 CEM systems, except for one, have only one component

monitor. The exception is the NOx emission rate, or “NOx diluent” monitoring system, which measures NOx in lb/mmBtu. This system includes both a NOx monitor and a diluent gas monitor (either CO2 or O2).

•

PLCs and data loggers

are common to all types of CEMS

•

Probes, sample lines,

vacuum pumps and sample conditioning equipment are associated with “extractive”

CEMS, which continuously withdraw a sample of the effluent gas from the stack

and send it to an analyzer located in a climate controlled environment (i.e., a

“CEMS shelter”).

•

“In-situ” CEMS, which

analyze the effluent gas at stack conditions, sometimes have probes12, but unlike extractive systems, do not require sample lines, sample conditioning

equipment, etc.

•

Extractive CEMS that

measure on a dry basis require moisture removal systems, whereas wet basis

extractive systems13 do not.

The number of

required monitors can sometimes be minimized by sharing certain components

among two or more monitoring systems. For example, data from a single diluent

gas monitor could be used to calculate NOx emission rate and

CO2 mass emissions.

____________________

3.2 What is a sorbent

trap monitoring system?

As previously noted

in Section 2.2, above, a sorbent trap monitoring system is an alternative type

of continuous Hg monitoring system that may be used instead of an Hg CEMS, for

any affected unit under the CAMR rule. A sorbent trap system continuously samples

the stack gas for an extended period of time (anywhere from several hours to

several days, depending on the Hg concentration in the stack). Mercury is

collected inside a tube (“trap”) that is filled with a sorbent medium such as

activated carbon, and a dry gas meter is used to measure the total volume of

dry stack gas sampled during the data collection period.

The sorbent trap

system is similar to an extractive-type CEMS, in that it continuously samples

the stack gas and uses a moisture removal system. However, the similarity ends

there, as the sorbent trap system differs from a CEMS in many ways. First, it

does not measure the real-time Hg concentration every hour. Rather, it gives

only an average Hg concentration over the data collection period, and this

average concentration cannot be known until the sorbent traps have been

analyzed in the lab. Second, unlike a CEMS, which samples at a constant rate,

the sample flow rate through a sorbent trap is varied during the collection

period, in proportion to the stack gas volumetric flow rate. Third, paired

sorbent trap systems must be run simultaneously during each data collection

period, and the Hg concentrations obtained from the two systems must agree to

within a specified tolerance to validate the data. Finally, the certification

and ongoing quality-assurance test requirements for sorbent trap systems are

considerably different from those for an Hg CEMS. The only QA test common to

both types of systems is the RATA. The certification and QA test requirements

for Hg monitoring systems are discussed further in Sections 7 and 8 of this

guide.

3.3 Primary and Backup

Monitoring Systems

For each monitored

pollutant or parameter, Part 75 requires that a primary monitoring system be

designated. Data from the primary system must be reported if it is in-service.

However, when the primary system is not able to provide quality-assured data,

data from one of the following types of backup monitors or monitoring systems

may be reported:

•

Redundant backups. A redundant backup monitoring system is a fully

certified, stack- or duct-mounted system that continuously records data and is

kept on “hot stand-by” in case of a primary system outage. A redundant backup

monitoring system is operated, maintained and quality-assured in the same

manner as the primary system.

•

Non-redundant

backups. A non-redundant backup

monitoring system is a certified system that does not operate continuously.

Rather, it is kept on “cold stand-by”, and must pass a substantive quality-assurance

test each time it is brought into service. For example, before a non-redundant

backup gas monitoring system can be used for Part 75 reporting, it must pass a

linearity check. The use of a non-redundant backup system is restricted to 720

hours per year at a given unit or stack location.

•

Like-kind

replacement analyzers. A

like-kind replacement analyzer is a gas analyzer of the same type as the

primary (i.e., it monitors the same parameter by the same measurement

principle). A like-kind replacement analyzer may be used for short periods of

time when the primary analyzer malfunctions or needs maintenance. The

replacement analyzer does not require certification, provided that it is

connected to the same probe and sample interface as the primary analyzer, and

that it is not used for more than 720 hours per year at a particular unit or

stack location. A linearity check of the analyzer is required each time it is

brought into service.

•

Reference method

backups. EPA reference test

methods (e.g., Method 6C for SO2 or Method 7E for NOx) may be used to provide quality-assured data during CEMS outages.

Although it might

save money initially, failure to have backup or redundant monitoring equipment

could result in over-reporting of emissions in the long run. For example,

suppose that the same CO2

monitor is used to determine both CO2 mass emissions and NOx emission rate. When the CO2 monitor malfunctions, the missing data procedures for both NOx and CO2 must be applied, since the systems for NOx and CO2 are considered to be out-of-control. As previously

noted, the Part 75 missing data procedures tend to produce increasingly more

conservative (i.e., conservatively high) emissions estimates as the PMA

decreases. Therefore, long missing data periods may result in significant

over-reporting of emissions and loss of allowance credits.

3.4 How must a CEMS be

operated?

The minimum operating

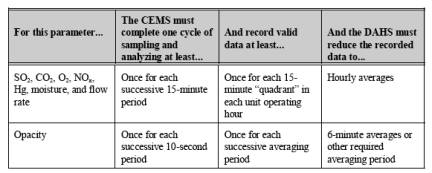

and data capture requirements for Part 75 CEM systems are summarized in Table

5. In general, the CEMS must be operated at all times when the unit is

combusting fuel, except when the monitors are being calibrated, maintained, or

repaired. As previously noted, each CEMS must be equipped with an automated

DAHS, to record the emissions data and to reduce it to hourly averages14. To make an hourly average, at least one valid data point (generally,

this means a valid one-minute average) is required in each 15-minute quadrant

of the hour in which the unit operates.15 A single DAHS is

usually sufficient to manage data for all the parameters that must be

monitored.

___________________

Table

5: Minimum Operating and Data Capture Requirements

for

Part 75 CEMS

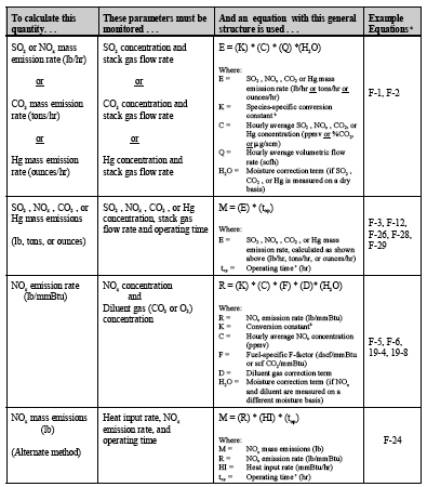

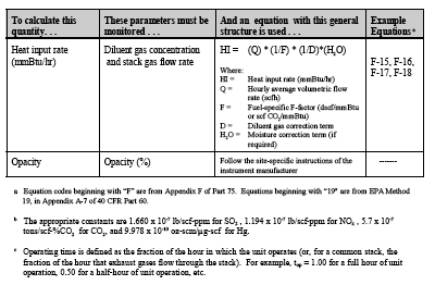

3.5 How are emissions

and heat input rates determined from CEMS data?

The methods for determining

emissions and heat input rates are shown in Table 6. This table presents the

general equations used to convert monitoring data into the units of measure

required by Part 75. The equations are somewhat different for each parameter

monitored, but are based on the same principles. These principles are explained

below.

The gas monitors

required by Part 75 (i.e., SO2 , NOx , CO2 and O2) measure concentration in parts

per million by volume (ppmv)16, with one exception---Hg

monitors measure concentration in micrograms per standard cubic meter (Ķg/scm).

However, concentration data alone are not sufficient to characterize emissions

under Part 75---the concentrations must be converted into emission rates. The

rule specifies the appropriate conversion factors to use.

The units of the

emission rates are pounds per standard cubic foot (lb/scf) for SO2 and NOx, tons per standard cubic foot (tons/scf) for CO2, and ounces per standard cubic foot (oz/scf) for Hg. These emission

rates are then used to determine the emissions in the units of measure required

by Part 75, i.e., either mass per unit of time (lb/hr, tons/hr, or oz/hr), mass

per unit of heat input (e.g., lb/mmBtu), or simply mass (pounds, tons, ounces).

____________________

Table

6: Calculating Emissions and Heat Input Rate

from

Part 75 CEMS Data

Determining

lb/mmBtu emission rates

To obtain emission

rates in terms of mass per unit of heat input (e.g., NOx emission rate in lb/mmBtu), the emission rate in lb/scf is multiplied by

a fuel-specific “F-factor.” The F-factor relates the volume of stack gas or CO2 produced by combustion to the caloric heat content of the fuel

combusted. For example, typical units for an F-factor are dry standard cubic

feet of stack gas per million Btu heat input (dscf/mmBtu), or standard cubic

feet of CO2 per million Btu (scf CO2 /mmBtu). The

F-factors, which are listed in Appendix F of the rule, are derived for each

type of fuel based on the thermodynamic principles of combustion. Since

F-factors are derived assuming that fuel and air are mixed in an exact

stoichiometric ratio and that combustion is complete, corrections for excess

air are needed.

Determining

mass emission rates

To obtain emission rates

in terms of mass per unit time (lb/hr, tons/hr, or oz/hr), the emission rate

(lb/scf, tons/scf, or oz/scf) is multiplied by the stack gas flow rate, in

standard cubic feet per hour (scfh). For NOx, the mass emission

rate in lb/hr may also be calculated by multiplying the NOx emission rate (lb/mmBtu) by the heat input rate (mmBtu/hr).

Determining

heat input rate, in mmBtu/hr

To determine heat

input rate (mmBtu/hr), the monitored stack gas flow rate (scfh) is divided by the

F-factor (scf/mmBtu) and a correction for excess air is applied.

Converting mass

emission rates and heat input rates

To convert an hourly

pollutant mass emission rate (e.g., lb/hr) to mass (e.g., lb), or to convert an

hourly heat input rate (mmBtu/hr) to heat input (mmBtu), multiply the emission

(or heat input) rate by the operating time. The operating time, top, is defined as the fraction of the hour in which the unit combusts

fuel. For units sharing a common stack, if the CEMS are installed on the stack,

the operating time is the fraction of the hour that exhaust gases flow through

the stack. For example, top

= 1.00 for a full hour of unit

operation, 0.50 for a half-hour of unit operation, etc.

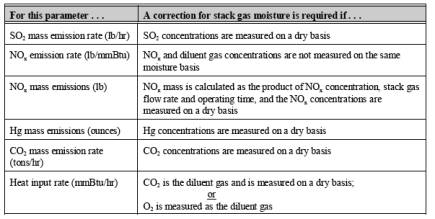

3.6 When are

corrections for stack gas moisture content required?

Determination of the

stack gas moisture content is required only in certain situations where CEMS

are used to satisfy the Part 75 monitoring requirements. Table 7 summarizes

when correction for the stack gas moisture content is required. Generally

speaking, the stack gas moisture content must be monitored when two parameters

in the emission or heat input rate equation (e.g., gas concentration and stack

gas flow rate) are not measured on the same moisture basis (i.e., one is

measured on a wet basis and the other on a dry basis).

For example, flow

rate monitors always measure stack gas flow on a wet basis. This means that the

volume of gas measured includes the contribution from the moisture content of

the stack gas. Therefore, when a gaseous pollutant such as SO2 is measured on a dry basis, in order to obtain the correct mass emission

rate in lb/hr, the dry-basis SO2 concentration is multiplied by

the wet-basis stack gas flow rate, and a moisture correction is applied. As a

second example, when NOx

emisssion rate in lb/mmBtu is measured,

a moisture correction is needed if the NOx concentration and

diluent gas monitors measure on different moisture bases.

If a correction for

the stack gas moisture content is required, one of the following moisture measurement

methods must be used:

•

An O2 analyzer (or analyzers) capable of measuring on both a wet and dry

basis.

•

A continuous moisture

sensor.

•

A stack temperature

sensor and a moisture look-up table (for saturated gas streams only).

•

A fuel-specific default

moisture value defined in Part 75 (for coal and wood, only).

•

A site-specific default

moisture value approved by petition under §75.66.

Table

7: Correction for Stack Gas Moisture Content

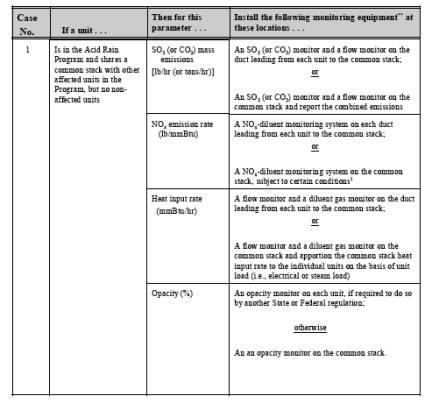

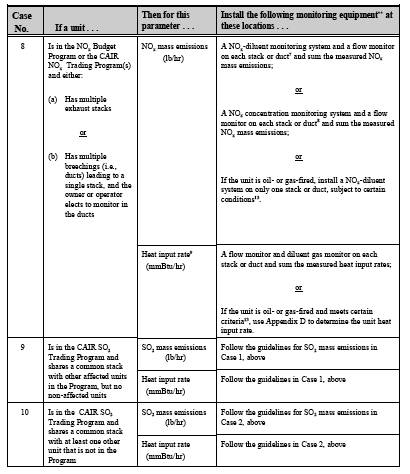

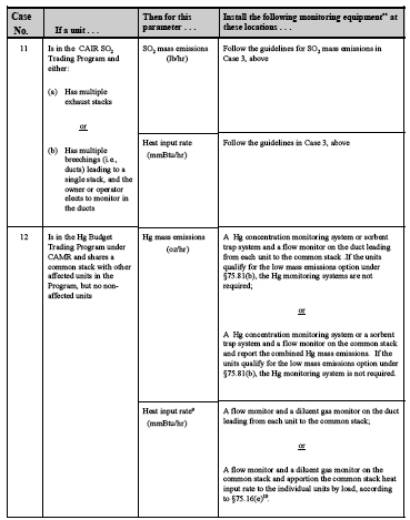

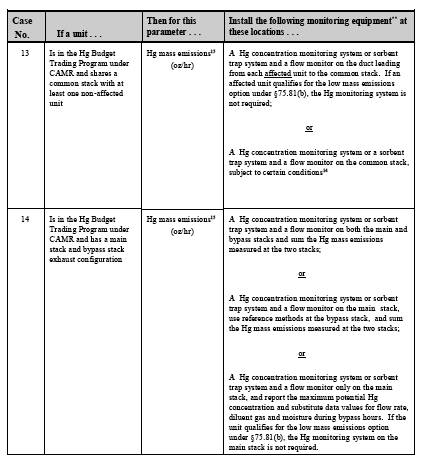

3.7 What if a unit has multiple

stacks or shares a stack with other units?

If a unit shares a

common stack with other units or emits through multiple stacks, Part 75

requires procedures to be implemented that ensure complete emissions and heat

input accounting. In some cases, the procedures will require monitoring systems

to be installed at more than one stack or duct location. The configuration of

ductwork and stacks, the program(s) that the unit is subject to, and the

regulatory status of the units (i.e., affected or non-affected) determine the

number of monitors needed and the required locations.

Common and multiple

stack configurations for the various trading programs are addressed in several

different places within Part 75. For Acid Rain Program units, the rule

provisions pertaining to common and multiple stacks are found in §§ 75.16

through 75.18. For CAIR SO2

Trading Program units, the provisions

are in §75.16. For NOx Budget Trading Program units and CAIR NOx Trading Program units, the applicable provisions are in §75.72. For Hg

Budget units under CAMR, the common and multiple stack provisions are found in

§75.82.

These rule provisions

are summarized in Table II-A of Appendix II of this guide. For configurations

that are not covered in Table II-A, sources should contact EPA for additional

guidance.

3.8 What are the

missing data procedures for CEMS?

For each unit

operating hour in which quality-assured CEMS data are not obtained (i.e., are

missing), Part 75 requires substitute data to be reported. The rather complex

CEMS missing data procedures are discussed in detail in Section 9 of this

guide.

4.0

APPENDIX D METHODOLOGY FOR GAS-FIRED AND OIL-FIRED UNITS

If an affected unit meets

the definition of gas-fired or oil-fired, the alternative methodology in

Appendix D of Part 75 may be used instead of CEMS, for certain parameters.

Appendix D applies only to the measurement of the SO2 mass emission rate and the unit heat input rate.

The alternative methodology in

Appendix D of Part 75 for gas-fired and oil-fired units pertains

to the monitoring of the SO2 mass

emission rate and the unit heat input rate.

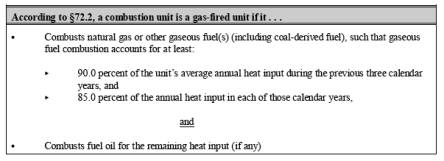

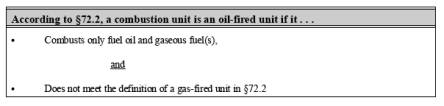

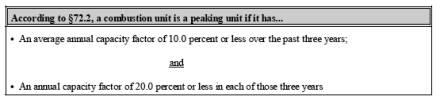

4.1 What is a gas-fired

or oil-fired unit?

Gas-fired and oil-fired

units are defined17 in Tables 8 and 9.

____________________

4.2 What is the

Appendix D alternative monitoring

method?

The alternative

monitoring methodology in Appendix D requires continuous monitoring of the fuel

flow rate and periodic sampling of the fuel characteristics, such as sulfur content,

gross calorific value (GCV), and density. The measured fuel flow rates are used

together with the results of the fuel sampling and analysis to determine the SO2 mass emission rate and/or the unit heat input rate, depending on the

requirements of the applicable program(s). The Appendix D methodology is

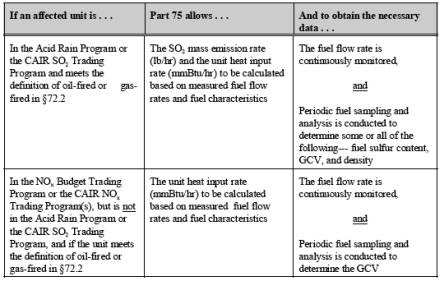

summarized in Table 10.

Table

10: Appendix D Monitoring Methodology

for

Gas-Fired and Oil-Fired Units

4.3 How is the fuel

flow rate measured?

Appendix D requires the

fuel flow rate to be continuously monitored and the data to be reduced to

hourly averages. To achieve this a certified fuel flowmeter or a commercial

billing meter may be used. To certify a fuel flowmeter, its accuracy must be

established using one of the methods18 specified in

section 2.1.5.1 of Appendix D.

•

In most cases, the

certification test procedure consists of calibrating the meter with a flowing

fluid, at three flow rates covering its normal operating range. Generally, this requirement is met by calibrating the

flowmeter in a laboratory, although the flowmeter may be calibrated at the

affected facility, by comparison against an in-line “master meter” which has

been tested for accuracy within the past 365 days using one of the methods in

section 2.1.5.1 of Appendix D.

•

Alternatively, an

orifice-, nozzle- or venturi-type flowmeter may be certified if its primary

element (for example, the orifice plate) meets the design criteria specified in

American Gas Association Report No. 3, and if its pressure, temperature, and

differential pressure transmitters are calibrated with standards traceable to

the National Institute of Standards and Technology (NIST).

•

A commercial billing

meter may be used for Appendix D applications without certification, if the meter

can provide hourly average fuel flow rates, and if the regulated source is not

affiliated with the billing company.

![]()

____________________

4.4 What are the fuel

sampling requirements of Appendix D ?

For both gaseous fuels

and fuel oil, Appendix D requires periodic sampling of fuel characteristics

(sulfur content and/or GCV and/or density). The required samples may be taken

either by the owner/operator, the fuel supplier, or by an independent

laboratory.

Appendix D divides

gaseous fuels into three categories: (1) pipeline natural gas (PNG); (2)

natural gas; and (3) other gaseous fuels. The distinction between PNG and

natural gas is in the fuel sulfur content. Natural gas may have as much as 20

grains of total sulfur per 100 standard cubic feet (i.e., 20 gr/100 scf), but

to qualify as PNG, the total sulfur content of the gas must not exceed 0.5

gr/100 scf. The Appendix D fuel sampling and analysis requirements for gaseous

fuels are as follows:

•

For PNG and natural

gas, annual sampling of the total sulfur content19 is required,

unless a valid fuel contract is in place documenting that the fuel meets the

definition of PNG or natural gas. If such a contract exists, the owner or

operator may choose not to perform the annual sampling—however, the maximum

total sulfur content specified in the contract (often 20 gr/100 scf) must then

be used to calculate the SO2 emissions.

•

The GCV of PNG or

natural gas must be determined monthly, with certain exceptions for units that

operate infrequently.

•

For other gaseous fuels

transmitted by pipeline, the required frequency of total sulfur sampling19 is hourly, unless the results of a 720-hour demonstration20 show that the fuel qualifies for less frequent (i.e., daily or annual)

sampling.

•

The GCV of other

gaseous fuels transmitted by pipeline must be determined daily, or hourly

unless the fuel is demonstrated 20 to have a low GCV variability,

in which case monthly sampling is sufficient.

•

For other gaseous fuels

delivered in shipments or lots, each shipment or lot must be sampled for sulfur

content19 and GCV.

Acceptable ASTM and

GPA sampling and analysis methods for gaseous fuels are referenced in sections

2.3.3.1.2 (for fuel sulfur content) and 2.3.4 (for fuel GCV) of Appendix D.

For oil, Appendix D

provides several fuel sampling and analysis options. The required sampling of

the sulfur content19, GCV and, if applicable, density of the oil may be

done using any of the following methods:

•

Daily sampling; or

•

Composite sampling for

up to 168 hours, using hourly flow-proportional sampling or continuous drip

sampling; or

•

Sampling after each

addition of oil to the storage tank; or

•

Sampling each delivery

or “lot” of fuel (i.e., each ship load, barge load, group of trucks, etc). The

sample may be taken from either the supplier’s storage tank or from the

shipment tank (container) upon receipt.

Acceptable ASTM

sampling and analysis methods for fuel oil are given in sections 2.2.5 (for

fuel sulfur content) and 2.2.7 (for fuel GCV) of Appendix D.

![]()

![]()

________________

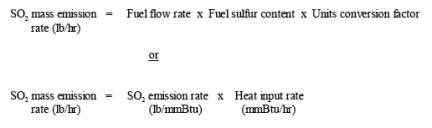

4.5 How is the SO2 mass emission rate calculated?

For an Acid Rain

Program unit using the Appendix D methodology, the hourly SO2 mass emission rate is calculated using an equation that has one of the

following basic structures:

An example of an

equation with the first basic structure is Equation D-2 in section 3 of

Appendix D, and an equation with the second basic structure is Equation D-5. In

the first general equation above, the fuel flow rate is the hourly average

reading from the fuel flowmeter, and the fuel sulfur content is based on the

results of periodic fuel sampling and analysis (see Section 4.7, below). In the

second general equation, the heat input rate is derived from the hourly average

fuel flowmeter reading and the fuel GCV (see Section 4.6, below), and the SO2 emission rate is either:

•

A generic default value

for the type of fuel combusted (e.g., 0.0006 lb/mmBtu for PNG); or

•

A site-specific default

value, determined by substituting the GCV and total sulfur content of the fuel

into Equation D-1h in Appendix D.

Note that for oil,

when the fuel flow rate is measured on a volumetric basis (e.g., gal/hr), it must

be converted to a mass basis using the oil density. Therefore, for Acid Rain

sources using volumetric oil flowmeters, periodic sampling of the density of

the oil is also required.

4.6 How is the unit

heat input rate calculated?

For an Acid Rain, NOx Budget, or CAIR unit using Appendix D to determine the hourly unit heat

input rate, an equation with the following basic structure is used:

Heat input rate =

Fuel flow rate x Fuel GCV x Units conversion factor

(mmBtu/hr)

Examples of equations

having this basic structure are Equations D-6 and D-8 in section 3 of Appendix

D. In the general equation above, the fuel flow rate is the hourly average

reading from the fuel flowmeter, and the GCV is based on the results of

periodic fuel sampling and analysis. The units of measure for the fuel flow

rate and the GCV must be consistent. For example, if the fuel flowmeter

measures in gallons per hour, the GCV is expressed in units of Btu per gallon.

4.7 Which sulfur

content, GCV, and density values are used in the calculations?

Appendix D provides

the source owner or operator with considerable flexibility in selecting the

values of fuel sulfur content, GCV and density that are used in the emission

and heat input calculations. Generally speaking, the values used in the

calculations are determined in one of two ways:

(1) The results

of the fuel sampling and analysis are used directly in the calculations.

Example 1: The GCV from the most recent monthly sample of

pipeline natural gas is used in the heat input rate calculations.

Example 2: For a process gas, hourly samples are taken of the

sulfur content and GCV, and the hourly values are used to calculate the SO2

emissions and unit

heat input rate; or

(2) An “assumed

value” is used in the calculations. The assumed value may be:

•

A default SO2 emission rate of 0.0006 lb/mmBtu, for a fuel that qualifies as pipeline

natural gas; or

•

The highest value from

any required sample taken in the previous calendar year; or

•

The highest value from

any sample taken in a specified “look-back” period; or

•

The highest value

specified in a valid, active fuel contract or tariff sheet; or

•

The value obtained from

a 720-hour characterization of the fuel’s sulfur content or GCV21

This calculation

method is subject to the following conditions:

•

If the results of any

required fuel sampling and analysis exceed the assumed value, then that sample

result becomes the new assumed value; and

•

If the assumed value is

from a fuel contract or tariff sheet, and if the contract or tariff sheet is

superseded by a new one, then the assumed value may have to be adjusted, or, in

some instances, the fuel may have to be reclassified. Consider the following

examples:

Example 1: A maximum GCV

of 105,000 Btu/100 scf is specified in a valid, active natural gas contract.

This GCV value may continue to be used in the heat input rate calculations,

provided that it is not exceeded, either by the results of a required monthly

GCV sample, or by the maximum GCV value in a new contract.

Example 2: In 2004, the

highest percent sulfur (%S) value obtained from the required samples of

distillate oil was 0.15 %S, by weight. This %S value may be used in the SO2 emission calculations throughout 2005, provided that it is not exceeded

by the results of any required fuel sample.

Example 3: Daily manual

sampling of fuel oil is performed, and on each successive unit operating day,

the highest sulfur content, GCV, and density values from the previous 30 daily

samples are used in the calculations.

Example 4: The results of

a 720-hour demonstration under section 2.3.6 of Appendix D show that a process

gas has a low sulfur variability. A default SO2 emission rate

of 0.025 lb/mmBtu is calculated by substituting the 90th percentile value of the fuel’s sulfur content from the demonstration

into Equation D-1h. This default emission rate may continue to be used unless

it is exceeded when Equation D-1h is applied to the results of a required

annual sample of the fuel’s sulfur content.

Example 5: A fuel

initially qualifies as pipeline natural gas, based on historical fuel sampling

data. In this year’s required annual fuel sampling and analysis, 3 samples are

taken and the total sulfur content of all samples is between 1.0 and 1.5 gr/

100 scf. The fuel is therefore re-classified as “natural gas” and the average

total sulfur value from the 3 samples is used in Equation D-1h, to calculate a

site-specific default SO2

emission rate.

For a complete listing of all of the available calculation options for fuel oil and gaseous fuels, see Tables D-4 and D-5 in Appendix D. Also note that for each of these options, instructions are given in section 2.3.7 of Appendix D, explaining when and how to apply the fuel sampling results. This helps to ensure national consistency in the reporting of Appendix D data.

![]()

_________________

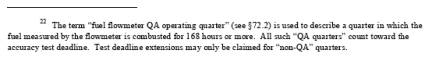

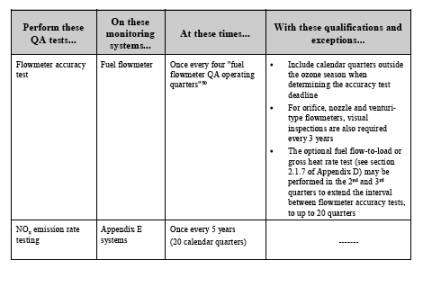

4.8 What are the

on-going quality-assurance requirements of Appendix D?

Following initial

certification, each Appendix D fuel flowmeter (except for qualifying fuel

billing meters) must undergo periodic accuracy testing, using the same general

approach that was used for initial certification (see Section 4.3, above). Fuel

flowmeter accuracy testing must be performed once every 4 calendar quarters,

unless the flowmeter qualifies for an extension of the test deadline. A

one-quarter extension of the test deadline may be claimed for any calendar

quarter in which:

•

The fuel measured by

the flowmeter is burned for less than 168 hours22 . This type

of extension is most advantageous for fuels that are seldom combusted and for

units that operate infrequently; or

•

The optional fuel

flow-to-load ratio test described in section 2.1.7 of Appendix D is performed

and passed. This option is most useful for fuels that are routinely combusted

for more than 168 hours per quarter.

Note that fuel

flowmeter accuracy test deadlines may not be extended indefinitely. The limits

to these extensions are as follows:

•

If the deadline extension

is based on infrequent combustion of a fuel or infrequent unit operation, a

flowmeter accuracy test must be performed no later than 4 “QA” quarters22 or 20 calendar quarters—whichever comes first—after the quarter in which

the previous test was done; or

•

If the deadline is

being extended by performing the fuel flow-to-load ratio test, the maximum

allowable extension is 20 calendar quarters from the quarter of the previous

test.

___________________

In addition to

performing periodic fuel flowmeter accuracy testing, section 1.3 in Appendix B

of Part 75 requires the owner or operator of an Appendix D unit to develop and

implement a quality-assurance plan. The essential elements of the QA plan

include the following:

•

A written record of the