Method 9 - Visual Determination of the Opacity of Emissions from Stationary Sources

1. PRINCIPLE AND

APPLICABILITY

3.1 Certification

Requirements.

3.3 Smoke Generator

Specifications.

INTRODUCTION

(a) Many stationary sources discharge visible

emissions into the atmosphere; these emissions are usually in the shape of a

plume. This method involves the determination of plume opacity by qualified observers.

The method includes procedures for the training and certification of observers

and procedures to be used in the field for determination of plume opacity.

(b) The appearance of a plume as viewed by an

observer depends upon a number of variables, some of which may be controllable

in the field. Variables which can be controlled to an extent to which they no

longer exert a significant influence upon plume appearance include: angle of

the observer with respect to the plume; angle of the observer with respect to

the sun; point of observation of attached and detached steam plume; and angle

of the observer with respect to a plume emitted from a rectangular stack with a

large length to width ratio. The method includes specific criteria applicable

to these variables.

(c) Other variables, which may not be controllable

in the field, are luminescence and color contrast between the plume and the

background against which the plume is viewed. These variables exert an

influence upon the appearance of a plume as viewed by an observer and can

affect the ability of the observer to assign accurately opacity values to the

observed plume. Studies of the theory of plume opacity and field studies have

demonstrated that a plume is most visible and presents the greatest apparent

opacity when viewed against a contrasting background. Accordingly, the opacity

of a plume viewed under conditions where a contrasting background is present

can be assigned with the greatest degree of accuracy. However, the potential

for a positive error is also the greatest when a plume is viewed under such

contrasting conditions. Under conditions presenting a less contrasting

background, the apparent opacity of a plume is less and approaches zero as the

color and luminescence contrast decrease toward zero. As a result, significant

negative bias and negative errors can be made when a plume is viewed under less

contrasting conditions. A negative bias decreases rather than increases the

possibility that a plant operator will be incorrectly cited for a violation of

opacity standards as a result of observer error.

(d) Studies have been undertaken to determine the

magnitude of positive errors made by qualified observers while reading plumes

under contrasting conditions and using the procedures set forth in this method.

The results of these studies (field trials), which involve a total of 769 sets

of 25 readings each, are as follows:

(1) For black plumes

(133 sets at a smoke generator), 100 percent of the sets were read with a

positive error of less than 7.5 percent opacity; 99 percent were read with a

positive error of less than 5 percent opacity. (Note: For a set, positive error

= average opacity determined by observers' 25 observations -average opacity

determined from transmissometer's 25 recordings.)

(2) For white plumes

(170 sets at a smoke generator, 168 sets at a coal-fired power plant, 298 sets

at a sulfuric acid plant), 99 percent of the sets were read with a positive

error of less than 7.5 percent opacity; 95 percent were read with a positive

error of less than 5 percent opacity.

(e) The positive observational error associated with

an average of twenty-five readings is therefore established. The accuracy of

the method must be taken into account when determining possible violations of

applicable opacity standards.

1. PRINCIPLE AND APPLICABILITY

1.1 Principle.

The opacity of

emissions from stationary sources is determined visually by a qualified

observer.

1.2 Applicability.

This method is

applicable for the determination of the opacity of emissions from stationary

sources pursuant to ¤ 60.11(b) and for visually determining opacity of

emissions.

2. PROCEDURES

The observer

qualified in accordance with Section 3 of this method

shall use the following procedures for visually determining the opacity of

emissions.

2.1 Position.

The qualified

observer shall stand at a distance sufficient to provide a clear view of the

emissions with the sun oriented in the 140E sector to his back. Consistent with

maintaining the above requirement, the observer shall, as much as possible,

make his observations from a position such that his line of vision is

approximately perpendicular to the plume direction and, when observing opacity

of emissions from rectangular outlets (e.g., roof monitors, open baghouses,

noncircular stacks), approximately perpendicular to the longer axis of the

outlet. The observer's line of sight should not include more than one plume at

a time when multiple stacks are involved, and in any case the observer should

make his observations with his line of sight perpendicular to the longer axis

of such a set of multiple stacks (e.g., stub stacks on baghouses).

2.2 Field Records.

The observer shall

record the name of the plant, emission location, facility type, observer's name

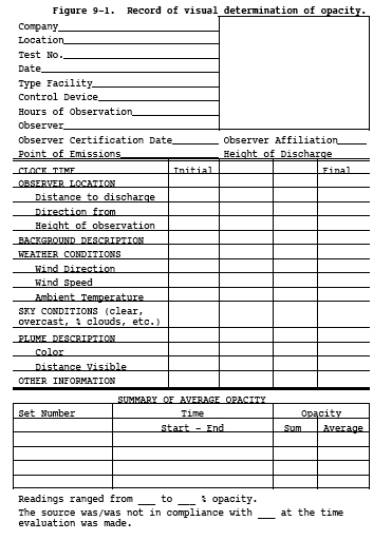

and affiliation, and the date on a field data sheet (Figure 9-1). The time,

estimated distance to the emission location, approximate wind direction,

estimated wind speed, description of the sky condition (presence and color of

clouds), and plume background are recorded on a field data sheet at the time

opacity readings are initiated and completed.

Figure

9-1. Record of visual determination of opacity.

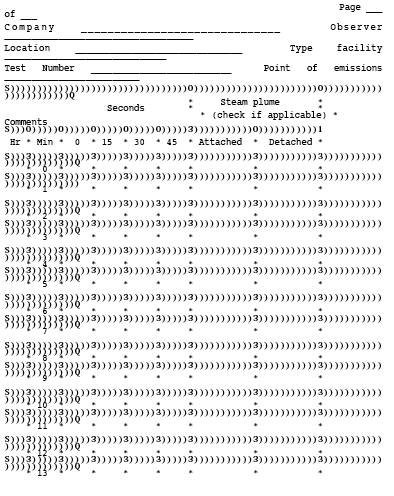

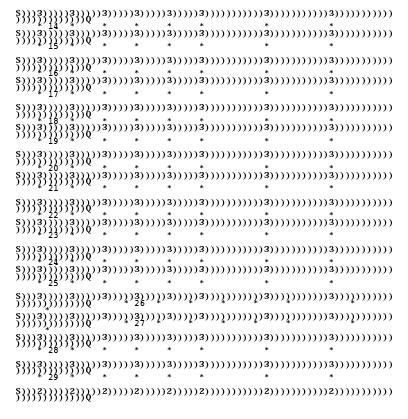

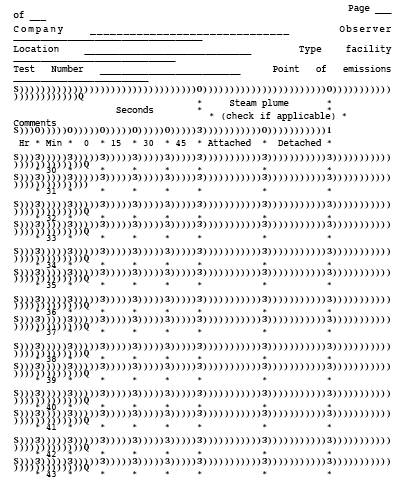

Figure

9-2. Observation record.

2.3 Observations.

Opacity observations

shall be made at the point of greatest opacity in that portion of the plume

where condensed water vapor is not present. The observer shall not look

continuously at the plume but instead shall observe the plume momentarily at

15-second intervals.

2.3.1 Attached Steam Plumes.

When condensed water

vapor is present within the plume as it emerges from the emission outlet,

opacity observations shall be made beyond the point in the plume at which

condensed water vapor is no longer visible. The observer shall record the

approximate distance from the emission outlet to the point in the plume at

which the observations are made.

2.3.2 Detached Steam Plume.

When water vapor in

the plume condenses and becomes visible at a distinct distance from the

emission outlet, the opacity of emissions should be evaluated at the emission

outlet prior to the condensation of water vapor and the formation of the steam

plume.

2.4 Recording Observations.

Opacity observations

shall be recorded to the nearest 5 percent at 15-second intervals on an

observational record sheet. (See Figure 9-2 for an

example.) A minimum of 24 observations shall be recorded. Each momentary

observation recorded shall be deemed to represent the average opacity of

emissions for a 15-second period.

2.5 Data Reduction.

Opacity shall be

determined as an average of 24 consecutive observations recorded at 15-second intervals.

Divide the observations recorded on the record sheet into sets of 24

consecutive observations. A set is composed of any 24 consecutive observations.

Sets need not be consecutive in time and in no case shall two sets overlap. For

each set of 24 observations, calculate the average by summing the opacity of

the 24 observations and dividing this sum by 24. If an applicable standard

specifies an averaging time requiring more than 24 observations, calculate the

average for all observations made during the specified time period. Record the

average opacity on a record sheet. (See Figure 9-1 for an

example.)

3. QUALIFICATION AND TESTING

3.1 Certification Requirements.

To receive

certification as a qualified observer, a candidate must be tested and

demonstrate the ability to assign opacity readings in 5 percent increments to

25 different black plumes and 25 different white plumes, with an error not to

exceed 15 percent opacity on any one reading and average error not to exceed

7.5 percent opacity in each category. Candidates shall be tested according to

the procedures described in Section 3.2. Smoke generators used pursuant to

Section 3.2 shall be equipped with a smoke meter which meets the requirements

of Section 3.3. The certification shall be valid for a period of 6 months, at

which time the qualification procedure must be repeated by any observer in

order to retain certification.

3.2 Certification Procedure.

The certification test

consists of showing the candidate a complete run of 50 plumes--25 black plumes

and 25 white plumes-generated by a smoke generator. Plumes within each set of

25 black and 25 white runs shall be presented in random order. The candidate

assigns an opacity value to each plume and records his observation on a

suitable form. At the completion of each run of 50 readings, the score of the

candidate is determined. If a candidate fails to qualify, the complete run of

50 readings must be repeated in any retest. The smoke test may be administered

as part of a smoke school or training program and may be preceded by training

or familiarization runs of the smoke generator during which candidates are

shown black and white plumes of known opacity.

3.3 Smoke Generator Specifications.

Any smoke generator

used for the purposes of Section 3.2 shall be equipped with a smoke meter

installed to measure opacity across the diameter of the smoke generator stack.

The smoke meter output shall display in-stack opacity based upon a path length

equal to the stack exit diameter, on a full 0 to 100 percent chart recorder

scale. The smoke meter optical design and performance shall meet the

specifications shown in Table 9-1. The smoke meter shall

be calibrated as prescribed in Section 3.3.1 prior to the conduct of each smoke

reading test. At the completion of each test, the zero and span drift shall be

checked and if the drift exceeds ±l percent opacity, the condition shall be

corrected prior to conducting any subsequent test runs. The smoke meter shall

be demonstrated, at the time of installation, to meet the specifications listed

in Table 9-1. This demonstration shall be repeated following any subsequent

repair or replacement of the photocell or associated electronic circuitry

including the chart recorder or output meter, or every 6 months, whichever

occurs first.

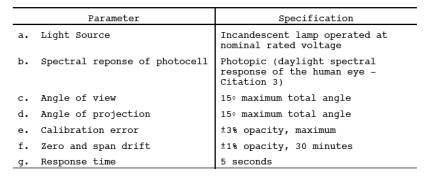

TABLE

9-1 - SMOKE METER DESIGN AND PERFORMANCE SPECIFICATIONS

3.3.1 Calibration.

The smoke meter is calibrated

after allowing a minimum of 30 minutes warm-up by alternately producing

simulated opacity of 0 percent and 100 percent. When stable response at 0

percent or 100 percent is noted, the smoke meter is adjusted to produce an

output of 0 percent or 100 percent, as appropriate. This calibration shall be

repeated until stable 0 percent and 100 percent opacity values may be produced

by alternately switching the power to the light source on and off while the

smoke generator is not producing smoke.

3.3.2 Smoke Meter

Evaluation. The smoke meter design

and performance are to be evaluated as follows:

3.3.2.1 Light

Source. Verify from

manufacturer's data and from voltage measurements made at the lamp, as

installed, that the lamp is operated within ±5 percent of the nominal rated

voltage.

3.3.2.2 Spectral

Response of Photocell. Verify

from manufacturer's data that the photocell has a photopic response; i.e., the

spectral sensitivity of the cell shall closely approximate the standard

spectral luminosity in (b) of Table 9-1.

3.3.2.3 Angle of

View. Check construction

geometry to ensure that the total angle of view of the smoke plume, as seen by

the photocell, does not exceed 15¡. The total angle of view may be calculated

from: ¥ = 2 tan -1 (d/2L), where ¥ = total angle of view; d = the sum of the

photocell diameter + the diameter of the limiting aperture; and L = the

distance from the photocell to the limiting aperture. The limiting aperture is

the point in the path between the photocell and the smoke plume where the angle

of view is most restricted. In smoke generator smoke meters this is normally an

orifice plate.

3.3.2.4 Angle of

Projection. Check construction

geometry to ensure that the total angle of projection of the lamp on the smoke

plume does not exceed 15¡. The total angle of projection may be calculated

from: ¥ = 2 tan-1 (d/2L), where ¥ = total angle of projection; d =

the sum of the length of the lamp filament + the diameter of the limiting

aperture; and L = the distance from the lamp to the limiting aperture.

3.3.2.5

Calibration Error. Using

neutral-density filters of known opacity, check the error between the actual

response and the theoretical linear response of the smoke meter. This check is

accomplished by first calibrating the smoke meter according to Section 3.3.1

and then inserting a series of three neutral-density filters of nominal opacity

of 20, 50, and 75 percent in the smoke meter path length. Filters calibrated

within 2 percent shall be used. Care should be taken when inserting the filters

to prevent stray light from affecting the meter. Make a total of five

nonconsecutive readings for each filter. The maximum error on any one reading

shall be 3 percent opacity.

3.3.2.6 Zero and

Span Drift. Determine the zero

and span drift by calibrating and operating the smoke generator in a normal

manner over a 1-hour period. The drift is measured by checking the zero and

span at the end of this period.

3.3.2.7 Response

Time. Determine the response

time by producing the series of five simulated 0 percent and 100 percent

opacity values and observing the time required to reach stable response.

Opacity values of 0 percent and 100 percent may be simulated by alternately

switching the power to the light source off and on while the smoke generator is

not operating.

4. BIBLIOGRAPHY

1. Air Pollution Control District Rules and

Regulations, Los Angeles County Air Pollution Control District, Regulation IV,

Prohibitions, Rule 50.

2. Weisburd, Melvin I., Field Operations and

Enforcement Manual for Air, U.S. Environmental Protection Agency, Research

Triangle Park, NC, APTD-1100, August 1972, pp. 4.1-4.36.

3. Condon. E.U., and Odishaw, H., Handbook of

Physics, McGraw-Hill

Co., New York, NY,

1958, Table 3.1, p. 6-52.