PERFORMANCE

SPECIFICATION 2 - SPECIFICATIONS AND TEST PROCEDURES FOR SO2 AND NOX CONTINUOUS

EMISSION MONITORING SYSTEMS IN STATIONARY SOURCES

2.0 Summary of

Performance Specification.

3.3 Continuous Emission

Monitoring System

6.1 CEMS Equipment

Specifications.

6.2 Other equipment and

supplies

8.0 Performance

Specification Test Procedure.

8.1 Installation and

Measurement Location Specifications.

8.1.2 CEMS Measurement

Location.

8.1.3 Reference Method

Measurement Location and Traverse Points.

8.3 Calibration Drift

Test Procedure.

8.4 Relative Accuracy

Test Procedure.

9.0 Quality Control.

[Reserved]

10.0 Calibration and

Standardization. [Reserved]

12.0 Calculations and

Data Analysis.

14.0 Pollution

Prevention. [Reserved]

15.0 Waste Management.

[Reserved]

18.0 Tables, Diagrams,

Flowcharts, and Validation Data.

1.0 Scope and Application.

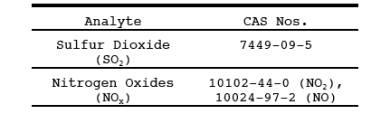

1.1 Analytes.

1.2 Applicability.

1.2.1 This specification

is for evaluating the acceptability of SO2 and NOx continuous emission monitoring systems (CEMS) at the time of

installation or soon after and whenever specified in the regulations. The CEMS

may include, for certain stationary sources, a diluent (O2 or CO2) monitor.

1.2.2 This

specification is not designed to evaluate the installed CEMS performance over

an extended period of time nor does it identify specific calibration techniques

and other auxiliary procedures to assess the CEMS performance. The source owner

or operator is responsible to calibrate, maintain, and operate the CEMS

properly. The Administrator may require, under Section 114 of the Act, the

operator to conduct CEMS performance evaluations at other times besides the

initial test to evaluate the CEMS performance. See 40 CFR Part 60, €60.13(c).

2.0 Summary of Performance Specification.

Procedures for

measuring CEMS relative accuracy and calibration drift are outlined. CEMS

installation and measurement location specifications, equipment specifications,

performance specifications, and data reduction procedures are included.

Conformance of the CEMS with the Performance Specification is determined.

3.0 Definitions.

3.1 Calibration Drift (CD)

Means the difference

in the CEMS output readings from the established reference value after a stated

period of operation during which no unscheduled maintenance, repair, or

adjustment took place.

3.2 Centroidal Area

Means a concentric

area that is geometrically similar to the stack or duct cross section and is no

greater than l percent of the stack or duct cross-sectional area.

3.3 Continuous Emission Monitoring System

Means the total

equipment required for the determination of a gas concentration or emission

rate. The sample interface, pollutant analyzer, diluent analyzer, and data

recorder are the major subsystems of the CEMS.

3.4 Data Recorder

Means that portion of

the CEMS that provides a permanent record of the analyzer output. The data

recorder may include automatic data reduction capabilities.

3.5 Diluent Analyzer

Means that portion of

the CEMS that senses the diluent gas (i.e., CO2 or O2) and

generates an output proportional to the gas concentration.

3.6 Path CEMS

Means a CEMS that

measures the gas concentration along a path greater than 10 percent of the

equivalent diameter of the stack or duct cross section.

3.7 Point CEMS

Means a CEMS that

measures the gas concentration either at a single point or along a path equal

to or less than 10 percent of the equivalent diameter of the stack or duct

cross section.

3.8 Pollutant Analyzer

Means that portion of

the CEMS that senses the pollutant gas and generates an output proportional to

the gas concentration.

3.9 Relative Accuracy (RA)

Means the absolute

mean difference between the gas concentration or emission rate determined by

the CEMS and the value determined by the reference method (RM), plus the 2.5

percent error confidence coefficient of a series of tests, divided by the mean

of the RM tests or the applicable emission limit.

3.10 Sample Interface

Means that portion of

the CEMS used for one or more of the following: sample acquisition, sample

delivery, sample conditioning, or protection of the monitor from the effects of

the stack effluent.

3.11 Span Value

Means the

concentration specified for the affected source category in an applicable

subpart of the regulations that is used to set the calibration gas

concentration and in determining calibration drift.

4.0 Interferences. [Reserved]

5.0 Safety.

The procedures

required under this performance specification may involve hazardous materials,

operations, and equipment. This performance specification may not address all

of the safety problems associated with these procedures. It is the

responsibility of the user to establish appropriate safety and health practices

and determine the applicable regulatory limitations prior to performing these

procedures. The CEMS user's manual and materials recommended by the reference

method should be consulted for specific precautions to be taken.

6.0 Equipment and Supplies.

6.1 CEMS Equipment Specifications.

6.1.1 Data Recorder

Scale. The CEMS data recorder output range must include zero and a high-level

value. The high-level value is chosen by the source owner or operator and is

defined as follows:

6.1.1.1 For a CEMS

intended to measure an uncontrolled emission (e.g., SO2 measurements

at the inlet of a flue gas desulfurization unit), the high-level value should

be between 1.25 and 2 times the maximum potential emission level over the

appropriate averaging time, unless otherwise specified in an applicable subpart

of the regulations.

6.1.1.2 For a CEMS

installed to measure controlled emissions or emissions that are in compliance

with an applicable regulation, the high-level value between 1.5 times the pollutant

concentration corresponding to the emission standard level and the span value

given in the applicable regulations is adequate.

6.1.1.3 Alternative

high-level values may be used, provided the source can measure emissions which

exceed the full-scale limit in accordance with the requirements of applicable

regulations.

6.1.1.4 If an analog

data recorder is used, the data recorder output must be established so that the

high-level value would read between 90 and 100 percent of the data recorder

full scale. (This scale requirement may not be applicable to digital data

recorders.) The zero and high level calibration gas, optical filter, or cell

values should be used to establish the data recorder scale.

6.1.2 The CEMS design

should also allow the determination of calibration drift at the zero and

high-level values. If this is not possible or practical, the design must allow

these determinations to be conducted at a low-level value (zero to 20 percent

of the high-level value) and at a value between 50 and 100 percent of the

high-level value. In special cases, the Administrator may approve a

single-point calibration-drift determination.

6.2 Other equipment and supplies

As needed by the

applicable reference method(s) (see Section 8.4.2 of this Performance Specification),

may be required.

7.0 Reagents and Standards.

7.1 Reference Gases,

Gas Cells, or Optical Filters. As specified by the CEMS manufacturer for

calibration of the CEMS (these need not be certified).

7.2 Reagents and Standards.

May be required as needed by the applicable reference method(s) (see Section

8.4.2 of this Performance Specification).

8.0 Performance Specification Test Procedure.

8.1 Installation and Measurement Location Specifications.

8.1.1 CEMS Installation.

Install the CEMS at

an accessible location where the pollutant concentration or emission rate

measurements are directly representative or can be corrected so as to be

representative of the total emissions from the affected facility or at the

measurement location cross section. Then select representative measurement

points or paths for monitoring in locations that the CEMS will pass the RA test

(see Section 8.4). If the cause of failure to meet the RA test is determined to

be the measurement location and a satisfactory correction technique cannot be

established, the Administrator may require the CEMS to be relocated. Suggested

measurement locations and points or paths that are most likely to provide data

that will meet the RA requirements are listed below.

8.1.2 CEMS Measurement Location.

It is suggested that

the measurement location be (1) at least two equivalent diameters downstream

from the nearest control device, the point of pollutant generation, or other

point at which a change in the pollutant concentration or emission rate may

occur and (2) at least a half equivalent diameter upstream from the effluent

exhaust or control device.

8.1.2.1 Point CEMS.

It is suggested that the measurement point be (1) no less than 1.0 meter (3.3

ft) 1542 from the stack or duct wall or (2) within or centrally located over

the centroidal area of the stack or duct cross section.

8.1.2.2 Path CEMS. It

is suggested that the effective measurement path (1) be totally within the

inner area bounded by a line 1.0 meter (3.3 ft) from the stack or duct wall, or

(2) have at least 70 percent of the path within the inner 50 percent of the

stack or duct cross-sectional area, or (3) be centrally located over any part

of the centroidal area.

8.1.3 Reference Method Measurement Location and Traverse Points.

8.1.3.1 Select, as

appropriate, an accessible RM measurement point at least two equivalent

diameters downstream from the nearest control device, the point of pollutant

generation, or other point at which a change in the pollutant concentration or

emission rate may occur, and at least a half equivalent diameter upstream from

the effluent exhaust or control device. When pollutant concentration changes

are due solely to diluent leakage (e.g., air heater leakages) and pollutants and diluents are

simultaneously measured at the same location, a half diameter may be used in

lieu of two equivalent diameters. The CEMS and RM locations need not be the

same.

8.1.3.2 Select

traverse points that assure acquisition of representative samples over the

stack or duct cross-section. The minimum requirements are as follows: Establish

a "measurement line" that passes through the centroidal area and in

the direction of any expected stratification. If this line interferes with the

CEMS measurements, displace the line up to 30 cm (12 in.) (or 5 percent of the

equivalent diameter of the cross section, whichever is less) from the

centroidal area. Locate three traverse points at 16.7, 50.0, and 83.3 percent

of the measurement line. If the measurement line is longer than 2.4 meters (7.8

ft) and pollutant stratification is not expected, the three traverse points may

be located on the line at 0.4, 1.2, and 2.0 meters from the stack or duct wall.

This option must not be used after wet scrubbers or at points where two streams

with different pollutant concentrations are combined. If stratification is

suspected, the following procedure is suggested. For rectangular ducts, locate

at least nine sample points in the cross section such that sample points are

the centroids of similarly-shaped, equal area divisions of the cross section.

Measure the pollutant concentration, and, if applicable, the diluent

concentration at each point using appropriate reference methods or other appropriate

instrument methods that give responses relative to pollutant concentrations.

Then calculate the mean value for all sample points. For circular ducts,

conduct a 12-point traverse (i.e., six points on each of the two perpendicular

diameters) locating the sample points as described in 40 CFR 60, Appendix A,

Method 1. Perform the measurements and calculations as described above.

Determine if the mean pollutant concentration is more than 10% different from

any single point. If so, the cross section is considered to be stratified, and

the tester may not use the alternative traverse point locations (...0.4, 1.2,

and 2.0 meters from the stack or duct wall.) but must use the three traverse

points at 16.7, 50.0, and 83.3 percent of the entire measurement line. Other

traverse points may be selected, provided that they can be shown to the

satisfaction of the Administrator to provide a representative sample over the

stack or duct cross section. Conduct all necessary RM tests within 3 cm (1.2

in.) of the traverse points, but no closer than 3 cm (1.2 in.) to the stack or

duct wall.

8.2 Pretest Preparation.

Install the CEMS,

prepare the RM test site according to the specifications in Section 8.1, and

prepare the CEMS for operation according to the manufacturer's written

instructions.

8.3 Calibration Drift Test Procedure.

8.3.1 CD Test Period.

While the affected facility is operating at more than 50 percent of normal

load, or as specified in an applicable subpart, determine the magnitude of the CD

once each day (at 24-hour intervals) for 7 consecutive days according to the

procedure given in Sections 8.3.2 through 8.3.4.

8.3.2 The purpose of

the CD measurement is to verify the ability of the CEMS to conform to the

established CEMS calibration used for determining the emission concentration or

emission rate. Therefore, if periodic automatic or manual adjustments are made

to the CEMS zero and calibration settings, conduct the CD test immediately

before these adjustments, or conduct it in such a way that the CD can be

determined.

8.3.3 Conduct the CD

test at the two points specified in Section 6.1.2. Introduce to the CEMS the

reference gases, gas cells, or optical filters (these need not be certified).

Record the CEMS response and subtract this value from the reference value (see

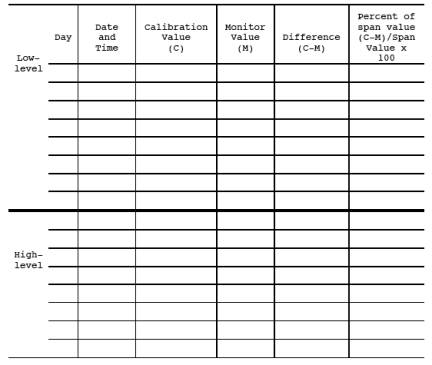

example data sheet in Figure 2-1).

8.4 Relative Accuracy Test Procedure.

8.4.1 RA Test Period.

Conduct the RA test according to the procedure given in Sections 8.4.2 through

8.4.6 while the affected facility is operating at more than 50 percent of

normal load, or as specified in an applicable subpart. The RA test may be

conducted during the CD test period.

8.4.2 Reference

Methods. Unless otherwise specified in an applicable subpart of the

regulations, Methods 3B, 4, 6, and 7, or their approved alternatives, are the

reference methods for diluent (O2 and CO2), moisture, SO2, and NOx, respectively.

8.4.3 Sampling

Strategy for RM Tests. Conduct the RM tests in such a way that they will yield

results representative of the emissions from the source and can be correlated

to the CEMS data. It is preferable to conduct the diluent (if applicable),

moisture (if needed), and pollutant measurements simultaneously. However,

diluent and moisture measurements that are taken within an hour of the

pollutant measurements may be used to calculate dry pollutant concentration and

emission rates. In order to correlate the CEMS and RM data properly, note the

beginning and end of each RM test period of each run (including the exact time

of day) on the CEMS chart recordings or other permanent record of output. Use

the following strategies for the RM tests:

8.4.3.1 For

integrated samples (e.g.,

Methods 6 and Method 4), make a sample traverse of at least 21 minutes,

sampling for an equal time at each traverse point (see Section 8.1.3.2 for

discussion of traverse points.

8.4.3.2 For grab

samples (e.g., Method 7),

take one sample at each traverse point, scheduling the grab samples so that

they are taken simultaneously (within a 3-minute period) or at an equal

interval of time apart over the span of time the CEM pollutant is measured. A

test run for grab samples must be made up of at least three separate

measurements.

NOTE: At times, CEMS RA tests are conducted during new

source performance standards performance tests. In these cases, RM results

obtained during CEMS RA tests may be used to determine compliance as long as

the source and test conditions are consistent with the applicable regulations.

8.4.4 Number of RM

Tests. Conduct a minimum of nine sets of all necessary RM test runs.

NOTE: More than nine sets of RM tests may be

performed. If this option is chosen, a maximum of three sets of the test

results may be rejected so long as the total number of test results used to

determine the RA is greater than or equal to nine. However, all data must be

reported, including the rejected data.

8.4.5 Correlation of

RM and CEMS Data. Correlate the CEMS and the RM test data as to the time and

duration by first determining from the CEMS final output (the one used for

reporting) the integrated average pollutant concentration or emission rate for

each pollutant RM test period. Consider system response time, if important, and

confirm that the pair of results are on a consistent moisture, temperature, and

diluent concentration basis. Then, compare each integrated CEMS value against

the corresponding average RM value. Use the following guidelines to make these

comparisons.

8.4.5.1 If the RM has

an integrated sampling technique, make a direct comparison of the RM results

and CEMS integrated average value.

8.4.5.2 If the RM has

a grab sampling technique, first average the results from all grab samples

taken during the test run, and then compare this average value against the

integrated value obtained from the CEMS chart recording or output during the

run. If the pollutant concentration is varying with time over the run, the

arithmetic average of the CEMS value recorded at the time of each grab sample

may be used.

8.4.6 Calculate the

mean difference between the RM and CEMS values in the units of the emission

standard, the standard deviation, the confidence coefficient, and the relative

accuracy according to the procedures in Section 12.0.

8.5 Reporting.

At a minimum (check

with the appropriate regional office, State, or Local agency for additional

requirements, if any), summarize in tabular form the results of the CD tests

and the RA tests or alternative RA procedure, as appropriate. Include all data

sheets, calculations, charts (records of CEMS responses), cylinder gas

concentration certifications, and calibration cell response certifications (if

applicable) necessary to confirm that the performance of the CEMS met the

performance specifications.

9.0 Quality Control. [Reserved]

10.0 Calibration and Standardization. [Reserved]

11.0 Analytical Procedure.

Sample collection and

analysis are concurrent for this Performance Specification (see Section 8.0).

Refer to the RM for specific analytical procedures.

12.0 Calculations and Data Analysis.

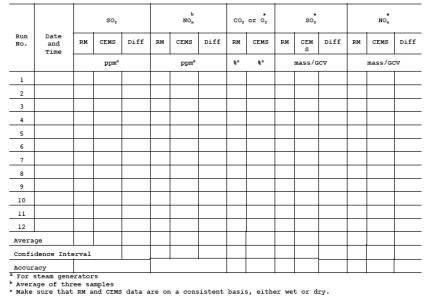

Summarize the results

on a data sheet similar to that shown in Figure 2-2 (in Section 18.0).

12.1 All data from

the RM and CEMS must be on a consistent dry basis and, as applicable, on a

consistent diluent basis and in the units of the emission standard. Correct the

RM and CEMS data for moisture and diluent as follows:

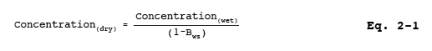

12.1.1 Moisture

Correction (as applicable). Correct each wet RM run for moisture with the

corresponding Method 4 data; correct each wet CEMS run using the corresponding

CEMS moisture monitor date using Equation 2-1.

12.1.2 Correction to

Units of Standard (as applicable). Correct each dry RM run to the units of the

emission standard with the corresponding Method 3B data; correct each dry CEMS

run using the corresponding CEMS diluent monitor data as follows:

12.1.2.1 Correct to

Diluent Basis. The following is an example of concentration (ppm) correction to

7% oxygen.

![]()

The following is an

example of mass/gross calorific value (lbs/million Btu) correction.

![]()

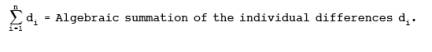

12.2 Arithmetic Mean.

Calculate the arithmetic mean of the difference, d, of a data set as follows:

![]()

where:

n = Number of

data points.

12.3 Standard

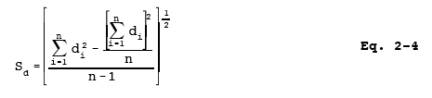

Deviation. Calculate the standard deviation, Sd, as

follows:

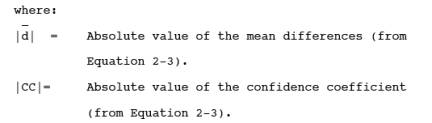

12.4 Confidence

Coefficient. Calculate the 2.5 percent error confidence coefficient

(one-tailed), CC, as follows:

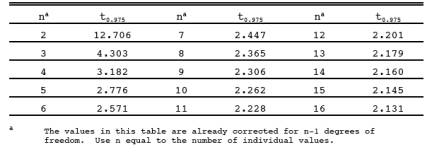

where: t0.975 = t-value (see Table 2-1).

12.5 Relative

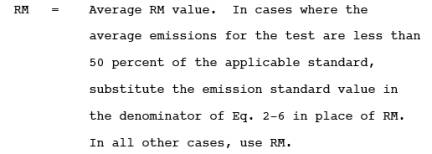

Accuracy. Calculate the RA of a set of data as follows:

13.0 Method Performance.

13.1 Calibration Drift

Performance Specification. The CEMS calibration must not drift or deviate from

the reference value of the gas cylinder, gas cell, or optical filter by more

than 2.5 percent of the span value. If the CEMS includes pollutant and diluent

monitors, the CD must be determined separately for each in terms of

concentrations (See Performance Specification 3 for the diluent

specifications), and none of the CDs may exceed the specification.

13.2 Relative

Accuracy Performance Specification. The RA of the CEMS must be no greater than

20 percent when RøMø is used in the denominator of Eq. 2-6 (average emissions

during test are greater than 50 percent of the emission standard) or 10 percent

when the applicable emission standard is used in the denominator of Eq. 2-6 (average

emissions during test are less than 50 percent of the emission standard).

13.3 For instruments

that use common components to measure more than one effluent gas constituent,

all channels must simultaneously pass the RA requirement, unless it can be

demonstrated that any adjustments made to one channel did not affect the

others.

14.0 Pollution Prevention. [Reserved]

15.0 Waste Management. [Reserved]

16.0 Alternative Procedures.

Paragraphs

60.13(j)(1) and (2) of 40 CFR part 60 contain criteria for which the reference

method procedure for determining relative accuracy (see Section 8.4 of this

Performance Specification) may be waived and the following procedure

substituted.

16.1 Conduct a

complete CEMS status check following the manufacturer's written instructions.

The check should include operation of the light source, signal receiver, timing

mechanism functions, data acquisition and data reduction functions, data

recorders, mechanically operated functions (mirror movements, zero pipe

operation, calibration gas valve operations, etc.), sample filters, sample line

heaters, moisture traps, and other related functions of the CEMS, as

applicable. All parts of the CEMS shall be functioning properly before

proceeding to the alternative RA procedure.

16.2 Alternative RA

Procedure.

16.2.1 Challenge each

monitor (both pollutant and diluent, if applicable) with cylinder gases of

known concentrations or calibration cells that produce known responses at two measurement

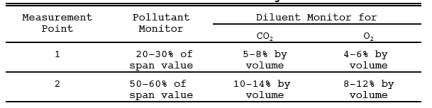

points within the ranges shown in Table 2-2 (Section 18).

16.2.2 Use a separate

cylinder gas (for point CEMS only) or calibration cell (for path CEMS or where

compressed gas cylinders can not be used) for measurement points 1 and 2.

Challenge the CEMS and record the responses three times at each measurement

point. The Administrator may allow dilution of cylinder gas using the

performance criteria in Test Method 205, 40 CFR Part 51, Appendix M. Use the

average of the three responses in determining relative accuracy.

16.2.3 Operate each

monitor in its normal sampling mode as nearly as possible. When using cylinder

gases, pass the cylinder gas through all filters, scrubbers, conditioners, and

other monitor components used during normal sampling and as much of the

sampling probe as practical. When using calibration cells, the CEMS components

used in the normal sampling mode should not be by-passed during the RA

determination. These include light sources, lenses, detectors, and reference

cells. The CEMS should be challenged at each measurement point for a sufficient

period of time to assure adsorption-desorption reactions on the CEMS surfaces

have stabilized.

16.2.4 Use cylinder

gases that have been certified by comparison to National Institute of Standards

and Technology (NIST) gaseous standard reference material (SRM) or NIST/EPA

approved gas manufacturer's certified reference material (CRM) (See Reference 2

in Section 17.0) following EPA Traceability Protocol Number 1 (See Reference 3

in Section 17.0). As an alternative to Protocol Number 1 gases, CRM's may be

used directly as alternative RA cylinder gases. A list of gas manufacturers

that have prepared approved CRM's is available from EPA at the address shown in

Reference 2. Procedures for preparation of CRM's are described in Reference 2.

16.2.5 Use

calibration cells certified by the manufacturer to produce a known response in

the CEMS. The cell certification procedure shall include determination of CEMS

response produced by the calibration cell in direct comparison with measurement

of gases of known concentration. This can be accomplished using SRM or CRM

gases in a laboratory source simulator or through extended tests using

reference methods at the CEMS location in the exhaust stack. These procedures

are discussed in Reference 4 in Section 17.0. The calibration cell

certification procedure is subject to approval of the Administrator.

16.3 The differences

between the known concentrations of the cylinder gases and the concentrations

indicated by the CEMS are used to assess the accuracy of the CEMS. The

calculations and limits of acceptable relative accuracy are as follows:

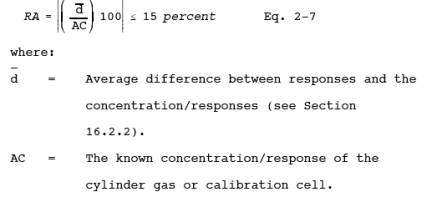

16.3.1 For pollutant

CEMS:

16.3.2 For diluent

CEMS:

![]()

NOTE: Waiver of the relative accuracy test in favor of

the alternative RA procedure does not preclude the requirements to complete the

CD tests nor any other requirements specified in an applicable subpart for

reporting CEMS data and performing CEMS drift checks or audits.

17.0 References.

1. Department of

Commerce. Experimental Statistics. Handbook 91. Washington, D.C. p. 3-31,

paragraphs 3-3.1.4.

2. "A Procedure

for Establishing Traceability of Gas Mixtures to Certain National Bureau of

Standards Standard Reference Materials." Joint publication by NBS and EPA.

EPA 600/7-81-010. Available from U.S. Environmental Protection Agency, Quality

Assurance Division (MD-77), Research Triangle Park, North Carolina 27711.

3. "Traceability

Protocol for Establishing True Concentrations of Gases Used for Calibration and

Audits of Continuous Source Emission Monitors. (Protocol Number 1)." June

1978. Protocol Number 1 is included in the Quality Assurance Handbook for

Air Pollution Measurement Systems, Volume III, Stationary Source Specific

Methods. EPA-600/4-77-027b.

August 1977.

4. "Gaseous

Continuous Emission Monitoring Systems - Performance Specification Guidelines

for SO2, NOx, CO2, O2, and TRS." EPA-450/3-82-026. Available

from the U.S. EPA, Emission Measurement Center, Emission Monitoring and Data

Analysis Division (MD-19), Research Triangle Park, North Carolina 27711.

18.0 Tables, Diagrams, Flowcharts, and Validation Data.

Figure 2-1.

Calibration Drift Determination.

Figure 2-2. Relative

Accuracy Determination.