METHOD

3B - GAS ANALYSIS FOR THE DETERMINATION OF EMISSION RATE CORRECTION FACTOR OR

EXCESS AIR

NOTE: This method does not include all of the

specifications (e.g.,

equipment and supplies) and procedures (e.g., sampling) essential to its performance. Some

material is incorporated by reference from other methods in this part.

Therefore, to obtain reliable results, persons using this method should have a

thorough knowledge of at least the following additional test methods: Method 1 and 3.

1.3 Other methods, as

well as modifications

6.1 Grab Sampling and

Integrated Sampling.

6.2 Analysis. An Orsat

analyzer only.

8.0 Sample Collection,

Preservation, Storage, and Transport.

8.1 Single-Point, Grab

Sampling and Analytical Procedure.

8.2 Single-Point,

Integrated Sampling and Analytical Procedure.

8.3 Multi-Point,

Integrated Sampling and Analytical Procedure.

10.0 Calibration and

Standardization.

11.3 Integrated Sample

Analysis.

12.0 Calculations and

Data Analysis.

13.0 Method

Performance. [Reserved]

14.0 Pollution

Prevention. [Reserved]

15.0 Waste Management.

[Reserved]

17.0 Tables, Diagrams,

Flowcharts, and Validation Data.

1.0 Scope and Application.

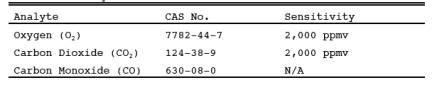

1.1 Analytes.

1.2 Applicability.

This method is

applicable for the determination of O2, CO2, and CO concentrations in the effluent from fossil-fuel combustion

processes for use in excess air or emission rate correction factor

calculations. Where compounds other than CO2, O2, CO, and nitrogen (N2) are

present in concentrations sufficient to affect the results, the calculation

procedures presented in this method must be modified, subject to the approval

of the Administrator.

1.3 Other methods, as well as modifications

Other methods, as

well as modifications to the procedure described herein, are also applicable

for all of the above determinations. Examples of specific methods and

modifications include: (1) a multi-point sampling method using an Orsat

analyzer to analyze individual grab samples obtained at each point, and (2) a method

using CO2 or O2 and

stoichiometric calculations to determine excess air. These methods and

modifications may be used, but are subject to the approval of the

Administrator.

1.4 Data Quality Objectives.

Adherence to the

requirements of this method will enhance the quality of the data obtained from

air pollutant sampling methods.

2.0 Summary of Method.

2.1 A gas sample is

extracted from a stack by one of the following methods: (1) single-point, grab

sampling; (2) single-point, integrated sampling; or (3) multi-point, integrated

sampling. The gas sample is analyzed for percent CO2, percent O2, and, if necessary, percent CO using an Orsat

combustion gas analyzer.

3.0 Definitions. [Reserved]

4.0 Interferences.

4.1 Several compounds

can interfere, to varying degrees, with the results of Orsat analyses.

Compounds that interfere with CO2 concentration

measurement include acid gases (e.g., sulfur dioxide, hydrogen chloride); compounds that interfere with

O2 concentration measurement include unsaturated

hydrocarbons (e.g., acetone,

acetylene), nitrous oxide, and ammonia. Ammonia reacts chemically with the O2 absorbing solution, and when present in the effluent gas stream

must be removed before analysis.

5.0 Safety.

5.1 Disclaimer.

This method may

involve hazardous materials, operations, and equipment. This test method may

not address all of the safety problems associated with its use. It is the

responsibility of the user of this test method to establish appropriate safety

and health practices and determine the applicability of regulatory limitations

prior to performing this test method.

5.2 Corrosive Reagents.

A typical Orsat

analyzer requires four reagents: a gas-confining solution, CO2 absorbent, O2

absorbent, and CO absorbent. These

reagents may contain potassium hydroxide, sodium hydroxide, cuprous chloride,

cuprous sulfate, alkaline pyrogallic acid, and/or chromous chloride. Follow

manufacturer's operating instructions and observe all warning labels for

reagent use.

6.0 Equipment and Supplies.

NOTE: As an alternative to the sampling apparatus and

systems described herein, other sampling systems (e.g., liquid displacement) may be used, provided

such systems are capable of obtaining a representative sample and maintaining a

constant sampling rate, and are, otherwise, capable of yielding acceptable

results. Use of such systems is subject to the approval of the Administrator.

6.1 Grab Sampling and Integrated Sampling.

Same as in Sections 6.1 and 6.2,

respectively for Method 3.

6.2 Analysis. An Orsat analyzer only.

For low CO2 (less than 4.0 percent) or high O2 (greater

than 15.0 percent) concentrations, the measuring burette of the Orsat must have

at least 0.1 percent subdivisions. For Orsat maintenance and operation

procedures, follow the instructions recommended by the manufacturer, unless

otherwise specified herein.

7.0 Reagents and Standards.

7.1 Reagents.

Same as in Method 3, Section 7.1.

7.2 Standards.

Same as in Method 3, Section 7.2.

8.0 Sample Collection, Preservation, Storage, and Transport.

NOTE: Each of the three procedures below shall be used

only when specified in an applicable subpart of the standards. The use of these

procedures for other purposes must have specific prior approval of the

Administrator. A Fyrite-type combustion gas analyzer is not acceptable for

excess air or emission rate correction factor determinations, unless approved

by the Administrator. If both percent CO2 and

percent O2 are measured, the analytical results of any of

the three procedures given below may also be used for calculating the dry

molecular weight (see Method 3).

8.1 Single-Point, Grab Sampling and Analytical Procedure.

8.1.1 The sampling

point in the duct shall either be at the centroid of the cross section or at a

point no closer to the walls than 1.0 m (3.3 ft), unless otherwise specified by

the Administrator.

8.1.2 Set up the

equipment as shown in Figure 3-1 of Method 3,

making sure all connections ahead of the analyzer are tight. Leak-check the

Orsat analyzer according to the procedure described in Section 11.5 of Method 3. This leak-check is

mandatory.

8.1.3 Place the probe

in the stack, with the tip of the probe positioned at the sampling point; purge

the sampling line long enough to allow at least five exchanges. Draw a sample

into the analyzer. For emission rate correction factor determinations,

immediately analyze the sample for percent CO2 or

percent O2, as outlined in Section 11.2. For excess air

determination, immediately analyze the sample for percent CO2, O2, and CO, as outlined in Section

11.2, and calculate excess air as outlined in Section

12.2.

8.1.4 After the

analysis is completed, leak-check (mandatory) the Orsat analyzer once again, as

described in Section 11.5 of Method 3. For the results of the analysis to be

valid, the Orsat analyzer must pass this leak-test before and after the

analysis.

8.2 Single-Point, Integrated Sampling and Analytical Procedure.

8.2.1 The sampling

point in the duct shall be located as specified in Section 8.1.1.

8.2.2 Leak-check (mandatory)

the flexible bag as in Section 6.2.6 of Method 3. Set up the equipment as shown

in Figure 3-2 of Method 3. Just before sampling,

leak-check (mandatory) the train by placing a vacuum gauge at the condenser inlet,

pulling a vacuum of at least 250 mm Hg (10 in. Hg), plugging the outlet at the

quick disconnect, and then turning off the pump. The vacuum should remain

stable for at least 0.5 minute. Evacuate the flexible bag. Connect the probe,

and place it in the stack, with the tip of the probe positioned at the sampling

point; purge the sampling line. Next, connect the bag, and make sure that all

connections are tight.

8.2.3 Sample at a

constant rate, or as specified by the Administrator. The sampling run must be

simultaneous with, and for the same total length of time as, the pollutant

emission rate determination. Collect at least 28 liters (1.0 ft3) of sample gas. Smaller volumes may be collected, subject to

approval of the Administrator.

8.2.4 Obtain one integrated

flue gas sample during each pollutant emission rate determination. For emission

rate correction factor determination, analyze the sample within 4 hours after

it is taken for percent CO2

or percent O2 (as outlined in Section 11.2).

8.3 Multi-Point, Integrated Sampling and Analytical Procedure.

8.3.1 Unless

otherwise specified in an applicable regulation, or by the Administrator, a

minimum of eight traverse points shall be used for circular stacks having

diameters less than 0.61 m (24 in.), a minimum of nine shall be used for

rectangular stacks having equivalent diameters less than 0.61 m (24 in.), and a

minimum of 12 traverse points shall be used for all other cases. The traverse

points shall be located according to Method 1.

8.3.2 Follow the procedures

outlined in Sections 8.2.2 through 8.2.4, except for the following: Traverse

all sampling points, and sample at each point for an equal length of time.

Record sampling data as shown in Figure 3-3 of

Method 3.

9.0 Quality Control.

9.1 Data Validation

Using Fuel Factor. Although in most instances, only CO2 or O2 measurement is required, it is recommended that

both CO2 and O2 be

measured to provide a check on the quality of the data. The data validation

procedure of Section 12.3 is suggested.

NOTE: Since this method for validating the CO2 and O2 analyses is based on combustion of organic and

fossil fuels and dilution of the gas stream with air, this method does not

apply to sources that (1) remove CO2 or O2 through processes other than combustion, (2) add O2 (e.g., oxygen

enrichment) and N2 in proportions different from that of air, (3)

add CO2 (e.g., cement or lime kilns), or (4) have no fuel factor, Fo, values obtainable (e.g., extremely variable waste mixtures). This method validates the

measured proportions of CO2

and O2 for

fuel type, but the method does not detect sample dilution resulting from leaks

during or after sample collection. The method is applicable for samples

collected downstream of most lime or limestone flue-gas desulfurization units

as the CO2 added or removed from the gas stream is not

significant in relation to the total CO2 concentration.

The CO2 concentrations from other types of scrubbers using

only water or basic slurry can be significantly affected and would render the

fuel factor check minimally useful.

10.0 Calibration and Standardization.

10.1 Analyzer.

The analyzer and

analyzer operator technique should be audited periodically as follows: take a

sample from a manifold containing a known mixture of CO2 and O2, and analyze according to the procedure in

Section 11.3. Repeat this procedure until the measured concentration of three

consecutive samples agrees with the stated value ±0.5 percent. If necessary,

take corrective action, as specified in the analyzer users manual.

10.2 Rotameter.

The rotameter need

not be calibrated, but should be cleaned and maintained according to the

manufacturer's instruction.

11.0 Analytical Procedure.

11.1 Maintenance.

The Orsat analyzer

should be maintained according to the manufacturers specifications.

11.2 Grab Sample Analysis.

To ensure complete

absorption of the CO2, O2, or if

applicable, CO, make repeated passes through each absorbing solution until two

consecutive readings are the same. Several passes (three or four) should be

made between readings. (If constant readings cannot be obtained after three

consecutive readings, replace the absorbing solution.) Although in most cases,

only CO2 or O2 concentration

is required, it is recommended that both CO2 and O2 be measured, and that the procedure in Section 12.3 be used to

validate the analytical data.

NOTE: Since this single-point, grab sampling and

analytical procedure is normally conducted in conjunction with a single-point,

grab sampling and analytical procedure for a pollutant, only one analysis is

ordinarily conducted. Therefore, great care must be taken to obtain a valid

sample and analysis.

11.3 Integrated Sample Analysis.

The Orsat analyzer

must be leak-checked (see Section 11.5 of Method 3) before the analysis. If

excess air is desired, proceed as follows: (1) within 4 hours after the sample

is taken, analyze it (as in Sections 11.3.1 through 11.3.3) for percent CO2, O2, and CO; (2) determine the percentage of the

gas that is N2 by subtracting the sum of the percent CO2, percent O2, and percent CO from 100 percent; and (3)

calculate percent excess air, as outlined in Section 12.2.

11.3.1 To ensure

complete absorption of the CO2, O2, or if applicable, CO, follow the procedure described in Section

11.2.

NOTE: Although in most instances only CO2 or O2 is required, it is recommended that both CO2 and O2 be measured, and that the procedures in Section

12.3 be used to validate the analytical data.

11.3.2 Repeat the

analysis until the following criteria are met:

11.3.2.1 For percent

CO2, repeat the analytical procedure until the

results of any three analyses differ by no more than (a) 0.3 percent by volume

when CO2 is greater than 4.0 percent or (b) 0.2 percent

by volume when CO2 is less than or equal to 4.0 percent. Average

three acceptable values of percent CO2, and

report the results to the nearest 0.2 percent.

11.3.2.2 For percent

O2, repeat the analytical procedure until the

results of any three analyses differ by no more than (a) 0.3 percent by volume

when O2 is less than 15.0 percent or (b) 0.2 percent by

volume when O2 is greater than or equal to 15.0 percent.

Average the three acceptable values of percent O2,

and report the results to the nearest 0.1 percent.

11.3.2.3 For percent

CO, repeat the analytical procedure until the results of any three analyses

differ by no more than 0.3 percent. Average the three acceptable values of

percent CO, and report the results to the nearest 0.1 percent.

11.3.3 After the

analysis is completed, leak-check (mandatory) the Orsat analyzer once again, as

described in Section 11.5 of Method 3. For the results of the analysis to be

valid, the Orsat analyzer must pass this leak-test before and after the analysis.

11.4 Standardization.

A periodic check of

the reagents and of operator technique should be conducted at least once every

three series of test runs as indicated in

Section 10.1.

12.0 Calculations and Data Analysis.

12.1 Nomenclature.

Same as Section 12.1 of Method 3 with the

addition of the following:

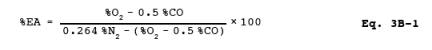

%EA = Percent excess

air.

0.264 = Ratio of O2 to N2 in air, v/v.

12.2

Percent Excess Air. Determine the percentage of the gas that is N2 by subtracting the sum of the percent CO2, percent CO, and percent O2 from 100

percent. Calculate the percent excess air (if applicable) by substituting the

appropriate values of percent O2, CO, and N2 into Equation 3B-1.

NOTE: The equation above assumes that ambient air is

used as the source of O2

and that the fuel does not contain

appreciable amounts of N2

(as do coke oven or blast furnace

gases). For those cases when appreciable amounts of N2 are present (coal, oil, and natural gas do not contain appreciable

amounts of N2) or when oxygen enrichment is used, alternative

methods, subject to approval of the Administrator, are required.

12.3 Data Validation

When Both CO2 and O2 Are

Measured.

12.3.1 Fuel Factor, Fo. Calculate the fuel factor (if applicable) using Equation 3B-2:

where:

%O2 = Percent O2

by volume, dry basis.

%CO2 = Percent CO2

by volume, dry basis.

20.9 = Percent O2 by volume in ambient air.

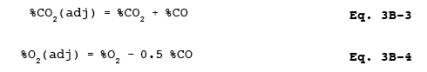

If CO is present in

quantities measurable by this method, adjust the O2 and CO2

values using Equations 3B-3 and

3B-4 before performing the calculation for Fo:

where:

%CO = Percent CO by

volume, dry basis.

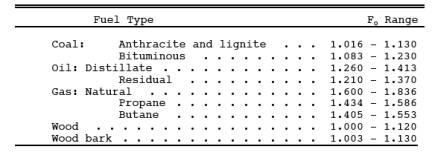

12.3.2 Compare the

calculated Fo factor with the expected Fo values. Table 3B-1 in Section 17.0 may be

used in establishing acceptable ranges for the expected Fo if the fuel being burned is known. When fuels are burned in

combinations, calculate the combined fuel Fd and Fc factors (as defined in Method 19,

Section 12.2) according to the procedure in Method 19, Sections 12.2 and 12.3.

Then calculate the Fo

factor according to Equation 3B-5.

12.3.3 Calculated Fo values, beyond the acceptable ranges shown in this table, should be

investigated before accepting the test results. For example, the strength of

the solutions in the gas analyzer and the analyzing technique should be checked

by sampling and analyzing a known concentration, such as air; the fuel factor

should be reviewed and verified. An acceptability range of ±12 percent is

appropriate for the Fo

factor of mixed fuels with variable

fuel ratios. The level of the emission rate relative to the compliance level

should be considered in determining if a retest is appropriate; i.e., if the measured emissions are much lower or

much greater than the compliance limit, repetition of the test would not

significantly change the compliance status of the source and would be

unnecessarily time consuming and costly.

13.0 Method Performance. [Reserved]

14.0 Pollution Prevention. [Reserved]

15.0 Waste Management. [Reserved]

16.0 References.

Same as Method 3, Section 16.0.

17.0 Tables, Diagrams, Flowcharts, and Validation Data.

TABLE

3B-1. Fo FACTORS FOR SELECTED FUELS