The

EMRC Gas Flow Monitor is the most reliable system available.

The

EMRC Gas Flow Monitor is the most reliable system available.

- +99.99% uptime

- Low installation cost

- Low maintenance cost

- No utilities at the stack or duct (probe can operate in explosion hazard situations)

- Fully automated calibration and purge

- Onboard primary reference manual calibration capacity (no need to go back to the factory)

- In situ sensors are designed to meet extremely hostile conditions (corrosion, erosion, high temperatures, moisture, etc.)

- EMRC personnel are available to supply a stationary or portable unit and electronic interfacing system so that mass flow requirements can be met on a consistent and verifiable basis.

- All EMRC Gas Flow Monitors are custom-designed to match each gas flow stream condition. We can custom design employing site-standard electronic components. We will build to your standard component desires.

In order to design an EMRC Gas Flow Monitor to best "fit" each application, it is essential to carefully evaluate each gas stream. Click here for a data sheet to send to EMRC with your inquiry or order.

Physical Specifications

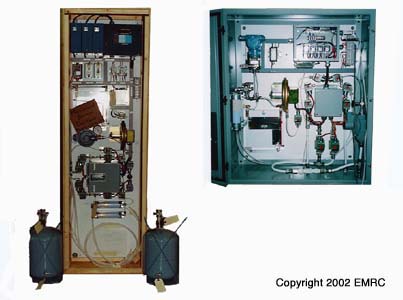

Size: EMRC will package to fit the needs of its customers

Weight: Stationary @ 100 - 250 lbs.

Power: 115v, 60hz Operating Cabinet

Temperature: 30° - 120°F (Some units have internal heaters)

Probe Temperature: -2000° F (melting point of probe material) or ceramics up to ~3000° F

Recorder Outputs: 4-20 ma standard, all others upon request

Performance Specifications Sensitivity: ~2fps

Response Time: ~1-2 seconds to 100% of final reading

Linearity: +/- 2% of full scale

Repeatability: < 1 % Zero Drift: ~2% of full scale Span Drift: ~2% of full scale

Accuracy: ~2% of full scale

The advantages of the EMRC Gas Flow Monitor are obvious for industry requiring simplicity of operation and regulatory compatibility.

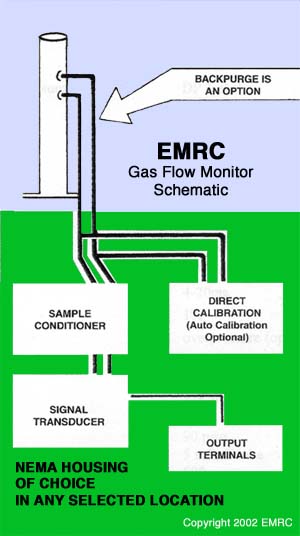

1.

The in situ sensor is a stack or duct-mounted heavy duty S-type

pitot. The pitot is manufactured of any desired material to withstand

corrosion, high temperatures, and other hostile conditions. Plugging is

avoided via backpurging, as necessary.

1.

The in situ sensor is a stack or duct-mounted heavy duty S-type

pitot. The pitot is manufactured of any desired material to withstand

corrosion, high temperatures, and other hostile conditions. Plugging is

avoided via backpurging, as necessary.

Advantages:

- Sensor replacement cost is minimal.

- Methodology is EPA method #2.

- Only the sensory unit is mounted on the stack or duct, therefore maintenance is minimized.

2. All instrumental equipment is located at convenient locations.

Advantages:

- Maintenance is minimized and is conducted under more ideal conditions.

- The Gas Flow Monitor can be located with other gas monitoring equipment.

- Operation and daily calibration is thus simplified.

3. The EMRC Gas Flow Monitor is calibrated dynamically (auto-cal and manual primary reference).

Advantages:

- The signal output is easily verified against standard EPA #2 methods via on onboard manometer.

- In addition, a dynamic (pressure) auto-calibration is routinely included.

4. The sample conditioning module allows for the accurate determination of gas flow above ~5 FPS.

Advantages:

- Sources with a high level of static variation can be monitored with a minimum of interference.

- Very hostile in situ conditions can be monitored without endangering the expensive instrument package.