Method 321 -

Measurement of Gaseous Hydrogen Chloride Emissions At

Portland Cement Kilns

by Fourier Transform Infrared (FTIR) Spectroscopy

1.3 Method Range and

Sensitivity.

4.1.1 Background

Interferences.

4.2 Sampling System

Interferences.

6.1 FTIR Spectrometer

and Detector.

6.3 Mass Flow

Meters/Controllers.

6.4

Polytetrafluoroethane tubing.

6.11

Calibration/Analyte Spike Assembly.

8.0 Sample Collection,

Preservation and Storage

8.4 Pre-Test

Calibration Transfer Standard (Direct Instrument Calibration).

8.5 Pre-Test System

Calibration.

8.6.3 Continuous Flow

Through Sampling.

8.8 Sampling QA, Data

Storage and Reporting.

10.0 Calibration and

Standardization

10.1 Calibration

transfer standards (CTS).

10.2 Signal-to-Noise

Ratio (S/N).

12.0 Data Analysis and

Calculations

1.0 Introduction

This method should be

performed by those persons familiar with the operation of Fourier Transform

Infrared (FTIR) instrumentation in the application to source sampling. This

document describes the sampling procedures for use in the application of FTIR

spectrometry for the determination of vapor phase hydrogen chloride (HCl)

concentrations both before and after particulate matter control devices

installed at portland cement kilns. A procedure for analyte spiking is included

for quality assurance. This method is considered to be self validating provided

that the requirements listed in section 9 of this method are followed. The

analytical procedures for interpreting infrared spectra from emission

measurements are described in the "Protocol For The Use of Extractive

Fourier Transform Infrared (FTIR) Spectrometry in Analyses of Gaseous Emissions

From Stationary Industrial Sources", included as an addendum to proposed

Method 320 of this appendix (hereafter referred to as the "FTIR

Protocol)". References 1 and 2 describe the use of FTIR spectrometry in field

measurements. Sample transport presents the principal difficulty in directly

measuring HCl emissions. This identical problem must be overcome by any

extractive measurement method. HCl is reactive and water soluble. The sampling

system must be adequately designed to prevent sample condensation in the

system.

1.1 Scope and Application

This method is

specifically designed for the application of FTIR Spectrometry in extractive

measurements of gaseous HCl concentrations in Portland cement kiln emissions.

1.2 Applicability.

This method applies to the

measurement of HCl [CAS No. 7647-01-0]. This method can be applied to the

determination of HCl concentrations both before and after particulate matter

control devices installed at Portland cement manufacturing facilities. This

method applies to either continuous flow through measurement (with isolated

sample analysis) or grab sampling (batch analysis). HCl is measured using the

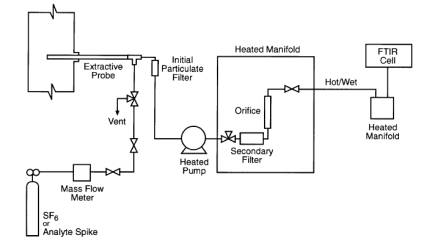

mid-infrared spectral region for analysis (about 400 to 4000 cm-1 or 25 to 2.5 µm). Table 1 lists the suggested analytical region for

quantification of HCl taking the interference from water vapor into

consideration.

TABLE 1. EXAMPLE

ANALYTICAL REGION FOR HCl.

1.3 Method Range and Sensitivity.

1.3.1 The analytical range

is determined by the instrumental design and the composition of the gas stream.

For practical purposes there is no upper limit to the range because the path length

may be reduced or the sample may be diluted. The lower detection range depends

on (1) the absorption coefficient of the compound in the analytical frequency

region, (2) the spectral resolution, (3) the interferometer sampling time, (4)

the detector sensitivity and response, and (5) the absorption path length.

1.3.2 The practical lower

quantification range is usually higher than the instrument sensitivity allows

and is dependent upon (1) the presence of interfering species in the exhaust

gas including H2O, CO2, and SO2, (2) analyte losses in the sampling system, (3) the optical alignment

of the gas cell and transfer optics, and (4) the quality of the reflective

surfaces in the cell (cell throughput). Under typical test conditions (moisture

content of up to 30% and CO2 concentrations from 1 to 15

percent), a 22 meter path length cell with a suitable sampling system may

achieve a lower quantification range of from 1 to 5 ppm for HCl.

1.4 Data Quality Objectives.

1.4.1 In designing or

configuring the analytical system, data quality is determined by measuring of

the root mean square deviation (RMSD) of the absorbance values within a chosen

spectral (analytical) region. The RMSD provides an indication of the

signal-to-noise ratio (S/N) of the spectral baseline. Appendix D of the FTIR

Protocol (the addendum to Method 320 of this appendix) presents a discussion of

the relationship between the RMSD, lower detection limit, DLi, and analytical uncertainty,

AUi. It is important to consider the target analyte

quantification limit when performing testing with FTIR instrumentation, and to

optimize the system to achieve the desired detection limit.

1.4.2 Data quality is

determined by measuring the root mean square (RMS) noise level in each

analytical spectral region (appendix C of the FTIR Protocol). The RMS noise is

defined as the root mean square deviation (RMSD) of the absorbance values in an

analytical region from the mean absorbance value in the same region. Appendix D

of the FTIR Protocol defines the minimum analyte uncertainty (MAU), and how the

RMSD is used to calculate the MAU. The MAUim is the minimum

concentration of the ith analyte in the mth analytical region for which the

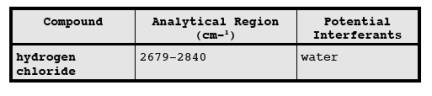

analytical uncertainty limit can be maintained. Table 2 presents example values

of AU and MAU using the analytical region presented in Table 1.

TABLE 2. EXAMPLE PRE-TEST PROTOCOL CALCULATIONS

FOR HYDROGEN CHLORIDE

2.0 Summary of Method

2.1 Principle.

See Method 320 of this

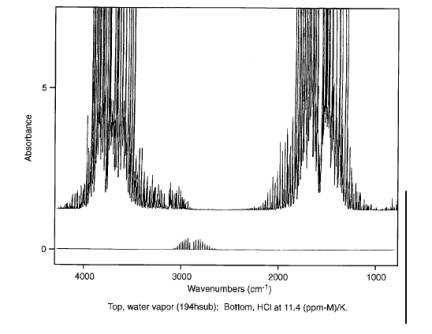

appendix. HCl can also undergo rotation transitions by absorbing energy in the

far-infrared spectral region. The rotational transitions are superimposed on

the vibrational fundamental to give a series of lines centered at the

fundamental vibrational frequency, 2885 cm-1. The frequencies

of absorbance and the pattern of rotational/vibrational lines are unique to

HCl. When this distinct pattern is observed in an infrared spectrum of an unknown

sample, it unequivocally identifies HCl as a component of the mixture. The

infrared spectrum of HCl is very distinctive and cannot be confused with the

spectrum of any other compound. See Reference 6.

2.2 Sampling and Analysis.

See Method 320 of this

appendix.

2.3 Operator Requirements.

The analyst must have

knowledge of spectral patterns to choose an appropriate absorption path length

or determine if sample dilution is necessary. The analyst should also

understand FTIR instrument operation well enough to choose instrument settings

that are consistent with the objectives of the analysis.

3.0 Definitions

See appendix A of the FTIR

Protocol.

4.0 Interferences

This method will not

measure HCl under conditions: (1) where the sample gas stream can condense in

the sampling system or the instrumentation, or (2) where a high moisture

content sample relative to the analyte concentrations imparts spectral

interference due to the water vapor absorbance bands. For measuring HCl the

first (sampling) consideration is more critical. Spectral interference from

water vapor is not a significant problem except at very high moisture levels

and low HCl concentrations.

4.1 Analytical Interferences.

See Method 320 of this

appendix.

4.1.1 Background Interferences.

See Method 320 of this

appendix.

4.1.2 Spectral interferences.

Water vapor can present

spectral interference for FTIR gas analysis of HCl. Therefore, the water vapor

in the spectra of kiln gas samples must be accounted for. This means preparing

at least one spectrum of a water vapor sample where the moisture concentration

is close to that in the kiln gas.

4.2 Sampling System Interferences.

The principal sampling

system interferant for measuring HCl is water vapor. Steps must be taken to

ensure that no condensation forms anywhere in the probe assembly, sample lines,

or analytical instrumentation. Cold spots anywhere in the sampling system must

be avoided. The extent of sampling system bias in the FTIR analysis of HCl

depends on concentrations of potential interferants, moisture content of the

gas stream, temperature of the gas stream, temperature of sampling system

components, sample flow rate, and reactivity of HCl with other species in the

gas stream (e.g., ammonia). For measuring HCl in a wet gas stream the

temperatures of the gas stream, sampling components, and the sample flow rate

are of primary importance. Analyte spiking with HCl is performed to demonstrate

the integrity of the sampling system for transporting HCl vapor in the flue gas

to the FTIR instrument. See section 9 of this method for a complete description

of analyte spiking.

5.0 Safety

5.1 Hydrogen chloride

vapor is corrosive and can cause irritation or severe damage to respiratory

system, eyes and skin. Exposure to this compound should be avoided.

5.2 This method may

involve sampling at locations having high positive or negative pressures, or

high concentrations of hazardous or toxic pollutants, and can not address all

safety problems encountered under these diverse sampling conditions. It is the

responsibility of the tester(s) to ensure proper safety and health practices,

and to determine the applicability of regulatory limitations before performing

this test method. Leak-check procedures are outlined in section 8.2 of Method

320 of this appendix.

6.0 Equipment and Supplies

Note: Mention of trade

names or specific products does not constitute endorsement by the Environmental

Protection Agency.

6.1 FTIR Spectrometer and Detector.

An FTIR Spectrometer

system (interferometer, transfer optics, gas cell and detector) having the

capability of measuring HCl to the predetermined minimum detectable level

required (see section 4.1.3 of the FTIR Protocol). The system must also include

an accurate means to control and/or measure the temperature of the FTIR gas

analysis cell, and a personal computer with compatible software that provides

real-time updates of the spectral profile during sample and spectral

collection.

6.2 Pump.

Capable of evacuating the

FTIR cell volume to 1 Torr (133.3 Pascals) within two minutes (for batch sample

analysis).

6.3 Mass Flow Meters/Controllers.

To accurately measure

analyte spike flow rate, having the appropriate calibrated range and a stated

accuracy of ± 2 percent of the absolute measurement value. This device must be

calibrated with the major component of the calibration/spike gas (e.g.,

nitrogen) using an NIST traceable bubble meter or equivalent. Single point

calibration checks should be performed daily in the field. When spiking HCl,

the mass flow meter/controller should be thoroughly purged before and after

introduction of the gas to prevent corrosion of the interior parts.

6.4 Polytetrafluoroethane tubing.

Diameter and length

suitable to connect cylinder regulators.

6.5 Stainless Steel tubing.

Type 316 of appropriate

length and diameter for heated connections.

6.6 Gas Regulators.

Purgeable HCl regulator.

6.7 Pressure Gauge.

Capable of measuring

pressure from 0 to 1000 Torr (133.3 Pa=1 Torr) within ± 5 percent.

6.8 Sampling Probe.

Glass, stainless steel or

other appropriate material of sufficient length and physical integrity to

sustain heating, prevent adsorption of analytes and capable of reaching gas

sampling point.

6.9 Sampling Line.

Heated 180 ¼C (360 ¼F) and

fabricated of either stainless steel, polytetrafluoroethane or other material

that prevents adsorption of HCl and transports effluent to analytical

instrumentation. The extractive sample line must have the capability to

transport sample gas to the analytical components as well as direct heated

calibration spike gas to the calibration assembly located at the sample probe.

It is important to minimize the length of heated sample line.

6.10 Particulate Filters.

A sintered stainless steel

filter rated at 20 microns or greater may be placed at the inlet of the probe

(for removal of large particulate matter). A heated filter (Balston¨ or equivalent) rated at 1 micron is necessary for primary particulate

matter removal, and shall be placed immediately after the heated probe. The

filter/filter holder temperature should be maintained at 180 ¼C (360 ¼F).

6.11 Calibration/Analyte Spike Assembly.

A heated three12 way valve

assembly (or equivalent) to introduce surrogate spikes into the sampling system

at the outlet of the probe before the primary particulate filter.

6.12 Sample Extraction Pump.

A leak-free heated head

pump (KNF¨ Neuberger or equivalent) capable of extracting sample

effluent through entire sampling system at a rate which prevents analyte losses

and minimizes analyzer response time. The pump should have a heated by-pass and

may be placed either before the FTIR instrument or after. If the sample pump is

located upstream of the FTIR instrument, it must be fabricated from materials

non-reactive to HCl. The sampling system and FTIR measurement system shall

allow the operator to obtain at least six sample spectra during a one-hour

period.

6.13 Barometer.

For measurement of

barometric pressure.

6.14 Gas Sample Manifold.

A distribution manifold

having the capabilities listed in sections 6.14.1 through 6.14.4;

6.14.1 Delivery of

calibration gas directly to the analytical instrumentation;

6.14.2 Delivery of

calibration gas to the sample probe (system calibration or analyte spike) via a

heated traced sample line;

6.14.3 Delivery of sample

gas (kiln gas, spiked kiln gas, or system calibrations) to the analytical

instrumentation;

6.14.4 Delivery (optional)

of a humidified nitrogen sample stream.

6.15 Flow Measurement Device.

Type S Pitot tube (or

equivalent) and Magnahelic¨

set for measurement of volumetric flow

rate.

7.0 Reagents and Standards

HCl can be purchased in a

standard compressed gas cylinder. The most stable HCl cylinder mixture

available has a concentration certified at ±5 percent. Such a cylinder is

suitable for performing analyte spiking because it will provide reproducible

samples. The stability of the cylinder can be monitored over time by

periodically performing direct FTIR analysis of cylinder samples. It is

recommended that a 10-50 ppm cylinder of HCl be prepared having from 2-5 ppm

SF6 as a tracer compound. (See sections 7.1 through 7.3 of Method 320 of this

appendix for a complete description of the use of existing HCl reference

spectra. See section 9.1 of Method 320 of this appendix for a complete

discussion of standard concentration selection.)

8.0 Sample Collection, Preservation and Storage

See also Method 320 of

this appendix.

8.1 Pretest.

A screening test is ideal

for obtaining proper data that can be used for preparing analytical program

files. Information from literature surveys and source personnel is also

acceptable. Information about the sampling location and gas stream composition

is required to determine the optimum sampling system configuration for

measuring HCl. Determine the percent moisture of the kiln gas by Method 4 of

appendix A to part 60 of this chapter or by performing a wet bulb/dry bulb

measurement. Perform a preliminary traverse of the sample duct or stack and

select the sampling point(s). Acquire an initial spectrum and determine the

optimum operational path length of the instrument.

8.2 Leak-Check.

See Method 320 of this

appendix, section 8.2 for direction on performing leak-checks.

8.3 Background Spectrum.

See Method 320 of this

appendix, section 8.5 for direction in background spectral acquisition.

8.4 Pre-Test Calibration Transfer Standard (Direct Instrument Calibration).

See Method 320 of this

appendix, section 8.3 for direction in CTS spectral acquisition.

8.5 Pre-Test System Calibration.

See Method 320 of this

appendix, sections 8.6.1 through 8.6.2 for direction in performing system

calibration.

8.6 Sampling.

8.6.1 Extractive System.

An extractive system

maintained at 180 ¼C (360 ¼F) or higher which is capable of directing a total

flow of at least 12 L/min to the sample cell is required (References 1 and 2).

Insert the probe into the duct or stack at a point representing the average

volumetric flow rate and 25

percent of the cross sectional area. Co-locate an appropriate flow monitoring

device with the sample probe so that the flow rate is recorded at specified

time intervals during emission testing (e.g., differential pressure

measurements taken every 10 minutes during each run).

8.6.2 Batch Samples.

Evacuate the absorbance

cell to 5 Torr (or less) absolute pressure before taking first sample. Fill the

cell with kiln gas to ambient pressure and record the infrared spectrum, then

evacuate the cell until there is no further evidence of infrared absorption.

Repeat this procedure, collecting a total of six separate sample spectra within

a 1-hour period.

8.6.3 Continuous Flow Through Sampling.

Purge the FTIR cell with

kiln gas for a time period sufficient to equilibrate the entire sampling system

and FTIR gas cell. The time required is a function of the mechanical response

time of the system (determined by performing the system calibration with the

CTS gas or equivalent), and by the chemical reactivity of the target analytes.

If the effluent target analyte concentration is not variable, observation of

the spectral up-date of the flowing gas sample should be performed until

equilibration of the sample is achieved. Isolate the gas cell from the sample

flow by directing the purge flow to vent. Record the spectrum and pressure of

the sample gas. After spectral acquisition, allow the sample gas to purge the

cell with at least three volumes of kiln gas. The time required to adequately

purge the cell with the required volume of gas is a function of 1) cell volume,

2) flow rate through the cell, and 3) cell design. It is important that the gas

introduction and vent for the FTIR cell provides a complete purge through the

cell.

8.6.4 Continuous Sampling.

In some cases it is

possible to collect spectra continuously while the FTIR cell is purged with

sample gas. The sample integration time, tss, the sample flow

rate through the gas cell, and the sample integration time must be chosen so

that the collected data consist of at least 10 spectra with each spectrum being

of a separate cell volume of flue gas. Sampling in this manner may only be

performed if the native source analyte concentrations do not affect the test

results.

8.7 Sample Conditioning

8.7.1 High Moisture Sampling.

Kiln gas emitted from wet

process cement kilns may contain 3- to 40 percent moisture. Zinc selenide

windows or the equivalent should be used when attempting to analyze hot/wet

kiln gas under these conditions to prevent dissolution of water soluble window

materials (e.g., KBr).

8.7.2 Sample Dilution.

The sample may be diluted

using an in-stack dilution probe, or an external dilution device provided that

the sample is not diluted below the instrument's quantification range. As an

alternative to using a dilution probe, nitrogen may be dynamically spiked into

the effluent stream in the same manner as analyte spiking. A constant dilution

rate shall be maintained throughout the measurement process. It is critical to

measure and verify the exact dilution ratio when using a dilution probe or the

nitrogen spiking approach. Calibrating the system with a calibration gas

containing an appropriate tracer compound will allow determination of the

dilution ratio for most measurement systems. The tester shall specify the

procedures used to determine the dilution ratio, and include these calibration

results in the report.

8.8 Sampling QA, Data Storage and Reporting.

See the FTIR Protocol.

Sample integration times shall be sufficient to achieve the required

signal-to-noise ratio, and all sample spectra should have unique file names.

Two copies of sample interferograms and processed spectra will be stored on

separate computer media. For each sample spectrum the analyst must document the

sampling conditions, the sampling time (while the cell was being filled), the

time the spectrum was recorded, the instrumental conditions (path length,

temperature, pressure, resolution, integration time), and the spectral file

name. A hard copy of these data must be maintained until the test results are

accepted.

8.9 Signal Transmittance.

Monitor the signal

transmittance through the instrumental system. If signal transmittance

(relative to the background) drops below 95 percent in any spectral region

where the sample does not absorb infrared energy, then a new background

spectrum must be obtained.

8.10 Post-test CTS.

After the sampling run

completion, record the CTS spectrum. Analysis of the spectral band area used

for quantification from pre- and post-test CTS spectra should agree to within

±5 percent or corrective action must be taken.

8.11 Post-test QA.

The sample spectra shall

be inspected immediately after the run to verify that the gas matrix

composition was close to the assumed gas matrix, (this is necessary to account

for the concentrations of the interferants for use in the analytical analysis

programs), and to confirm that the sampling and instrumental parameters were

appropriate for the conditions encountered.

9.0 Quality Control

Use analyte spiking to

verify the effectiveness of the sampling system for the target compounds in the

actual kiln gas matrix. QA spiking shall be performed before and after each

sample run. QA spiking shall be performed after the pre- and post-test CTS

direct and system calibrations. The system biases calculated from the pre- and

post-test dynamic analyte spiking shall be within ±30 percent for the spiked

surrogate analytes for the measurements to be considered valid. See sections

9.3.1 through 9.3.2 for the requisite calculations. Measurement of the

undiluted spike (direct-to-cell measurement) involves sending dry, spike gas to

the FTIR cell, filling the cell to 1 atmosphere and obtaining the spectrum of

this sample. The direct-to-cell measurement should be performed before each

analyte spike so that the recovery of the dynamically spiked analytes may be

calculated. Analyte spiking is only effective for assessing the integrity of

the sampling system when the concentration of HCl in the source does not vary

substantially. Any attempt to quantify an analyte recovery in a variable

concentration matrix will result in errors in the expected concentration of the

spiked sample. If the kiln gas target analyte concentrations vary by more than

±5 percent (or 5 ppm, whichever is greater) in the time required to acquire a

sample spectrum, it may be necessary to: 1) use a dual sample probe approach,

2) use two independent FTIR measurement systems, 3) use alternate QA/QC

procedures, or 4) postpone testing until stable emission concentrations are

achieved. (See section 9.2.3 of this method). It is recommended that a

laboratory evaluation be performed before attempting to employ this method under

actual field conditions. The laboratory evaluation shall include 1) performance

of all applicable calculations in section 4 of the FTIR Protocol; 2) simulated

analyte spiking experiments in dry (ambient) and humidified sample matrices

using HCl; and 3) performance of bias (recovery) calculations from analyte

spiking experiments. It is not necessary to perform a laboratory evaluation

before every field test. The purpose of the laboratory study is to demonstrate

that the actual instrument and sampling system configuration used in field

testing meets the requirements set forth in this method.

9.1 Spike Materials.

Perform analyte spiking

with an HCl standard to demonstrate the integrity of the sampling system.

9.1.1 An HCl standard of

approximately 50 ppm in a balance of ultra pure nitrogen is recommended. The SF6 (tracer) concentration shall be 2 to 5 ppm depending upon the

measurement path length. The spike ratio (spike flow/total flow) shall be no

greater than 1:10, and an ideal spike concentration should approximate the

native effluent concentration.

9.1.2 The ideal spike

concentration may not be achieved because the target concentration cannot be

accurately predicted prior to the field test, and limited calibration standards

will be available during testing. Therefore, practical constraints must be

applied that allow the tester to spike at an anticipated concentration. For

these tests, the analyte concentration contributed by the HCl standard spike

should be 1 to 5 ppm or should more closely approximate the native

concentration if it is greater.

9.2 Spike Procedure

9.2.1 A spiking/sampling

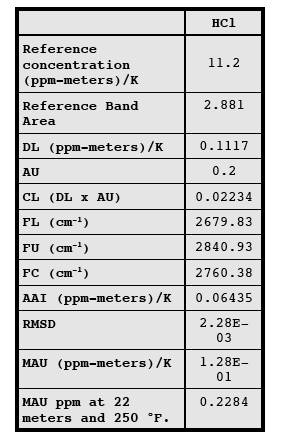

apparatus is shown in Figure 2. Introduce the spike/tracer gas mixture at a

constant flow (±2 percent) rate at approximately 10 percent of the total sample

flow. (For example, introduce the surrogate spike at 1 L/min ± 20 cc/min, into

a total sample flow rate of 10 L/min). The spike must be pre-heated before

introduction into the sample matrix to prevent a localized condensation of the

gas stream at the spike introduction point. A heated sample transport line(s)

containing multiple transport tubes within the heated bundle may be used to

spike gas up through the sampling system to the spike introduction point. Use a

calibrated flow device (e.g., mass flow meter/controller), to monitor the spike

flow as indicated by a calibrated flow meter or controller, or alternately, the

SF6 tracer ratio may be calculated from the direct

measurement and the diluted measurement. It is often desirable to use the

tracer approach in calculating the spike/total flow ratio because of the

difficulty in accurately measuring hot/wet total flow. The tracer technique has

been successfully used in past validation efforts (Reference 1).

9.2.2 Perform a

direct-to-cell measurement of the dry, undiluted spike gas. Introduce the spike

directly to the FTIR cell, bypassing the sampling system. Fill cell to 1

atmosphere and collect the spectrum of this sample. Ensure that the spike gas

has equilibrated to the temperature of the measurement cell before acquisition

of the spectra. Inspect the spectrum and verify that the gas is dry and

contains negligible CO2. Repeat the process to obtain a second

direct-to-cell measurement. Analysis of spectral band areas for HCl from these

duplicate measurements should agree to within ± 5 percent of the mean.

9.2.3 Analyte Spiking.

Determine whether the kiln gas contains native concentrations of HCl by

examination of preliminary spectra. Determine whether the concentration varies

significantly with time by observing a continuously up-dated spectrum of sample

gas in the flow-through sampling mode. If the concentration varies by more than

± 5 percent during the period of time required to acquire a spectra, then an

alternate approach should be used. One alternate approach uses two sampling

lines to convey sample to the gas distribution manifold. One of the sample

lines is used to continuously extract unspiked kiln gas from the source. The

other sample line serves as the analyte spike line. One FTIR system can be used

in this arrangement. Spiked or unspiked sample gas may be directed to the FTIR

system from the gas distribution manifold, with the need to purge only the

components between the manifold and the FTIR system. This approach minimizes

the time required to acquire an equilibrated sample of spiked or unspiked kiln

gas. If the source varies by more than ± 5 percent (or 5 ppm, whichever is

greater) in the time it takes to switch from the unspiked sample line to the

spiked sample line, then analyte spiking may not be a feasible means to

determine the effectiveness of the sampling system for the HCl in the sample

matrix. A second alternative is to use two completely independent FTIR

measurement systems. One system would measure unspiked samples while the other

system would measure the spiked samples. As a last option, (where no other

alternatives can be used) a humidified nitrogen stream may be generated in the

field which approximates the moisture content of the kiln gas. Analyte spiking

into this humidified stream can be employed to assure that the sampling system

is adequate for transporting the HCl to the FTIR instrumentation.

9.2.3.1 Adjust the spike

flow rate to approximately 10 percent of the total flow by metering spike gas

through a calibrated mass flowmeter or controller. Allow spike flow to

equilibrate within the sampling system before analyzing the first spiked kiln

gas samples. A minimum of two consecutive spikes are required. Analysis of the

spectral band area used for quantification should agree to within ± 5 percent

or corrective action must be taken.

9.2.3.2 After QA spiking

is completed, the sampling system components shall be purged with nitrogen or

dry air to eliminate traces of the HCl compound from the sampling system

components. Acquire a sample spectra of the nitrogen purge to verify the

absence of the calibration mixture.

9.2.3.3 Analyte spiking

procedures must be carefully executed to ensure that meaningful measurements

are achieved. The requirements of sections 9.2.3.3.1 through 9.2.3.3.4 shall be

met.

9.2.3.3.1 The spike must

be in the vapor phase, dry, and heated to (or above) the kiln gas temperature

before it is introduced to the kiln gas stream.

9.2.3.3.2 The spike flow

rate must be constant and accurately measured.

9.2.3.3.3 The total flow

must also be measured continuously and reliably or the dilution ratio must

otherwise be verified before and after a run by introducing a spike of a

non-reactive, stable compound (i.e., tracer).

9.2.3.3.4 The tracer must

be inert to the sampling system components, not contained in the effluent gas,

and readily detected by the analytical instrumentation. Sulfur hexafluoride (SF6) has been used successfully (References 1 and 2) for this purpose.

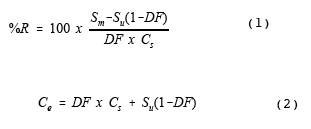

9.3 Calculations

9.3.1 Recovery.

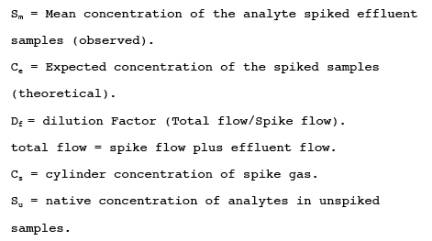

Calculate the percent

recovery of the spiked analytes using equations 1 and 2.

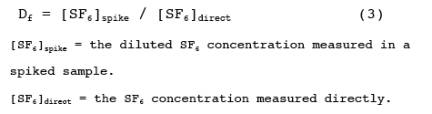

The spike dilution factor

may be confirmed by measuring the total flow and the spike flow directly.

Alternately, the spike dilution can be verified by comparing the concentration

of the tracer compound in the spiked samples (diluted) to the tracer

concentration in the direct (undiluted) measurement of the spike gas.

If SF6 is the tracer gas, then

9.3.2 Bias.

The bias may be determined

by the difference between the observed spike value and the expected response

(i.e., the equivalent concentration of the spiked material plus the analyte

concentration adjusted for spike dilution). Bias is defined by section 6.3.1 of

EPA Method 301 of this appendix (Reference 8) as,

![]()

where:

B = Bias at spike level.

Sm = Mean concentration of the analyte spiked samples.

Ce = Expected concentration of the analyte in spiked samples.

Acceptable recoveries for

analyte spiking are ± 30 percent. Application of correction factors to the data

based upon bias and recovery calculations is subject to the approval of the

Administrator.

10.0 Calibration and Standardization

10.1 Calibration transfer standards (CTS).

The EPA Traceability

Protocol gases or NIST traceable standards, with a minimum accuracy of ± 2

percent shall be used. For other requirements of the CTS, see the FTIR Protocol

section 4.5.

10.2 Signal-to-Noise Ratio (S/N).

The S/N shall be less than

the minimum acceptable measurement uncertainty in the analytical regions to be

used for measuring HCl.

10.3 Absorbance Path length.

Verify the absorbance path

length by comparing CTS spectra to reference spectra of the calibration

gas(es).

10.4 Instrument Resolution.

Measure the line width of

appropriate CTS band(s) to verify instrumental resolution.

10.5 Apodization Function.

Choose the appropriate

apodization function. Determine any appropriate mathematical transformations

that are required to correct instrumental errors by measuring the CTS. Any

mathematical transformations must be documented and reproducible. Reference 9

provides additional information about FTIR instrumentation.

11.0 Analytical Procedure

A full description of the

analytical procedures is given in sections 4.6 - 4.11, sections 5, 6, and 7,

and the appendices of the FTIR Protocol. Additional description of quantitative

spectral analysis is provided in References 10 and 11.

12.0 Data Analysis and Calculations

Data analysis is performed

using appropriate reference spectra whose concentrations can be verified using

CTS spectra. Various analytical programs (References 10 and 11) are available

to relate sample absorbance to a concentration standard. Calculated

concentrations should be verified by analyzing spectral baselines after

mathematically subtracting scaled reference spectra from the sample spectra. A

full description of the data analysis and calculations may be found in the FTIR

Protocol (sections 4.0, 5.0, 6.0 and appendices).

12.1 Calculated

concentrations in sample spectra are corrected for differences in absorption

path length between the reference and sample spectra by

![]()

where:

Ccorr = The path length corrected concentration.

Ccalc = The initial calculated concentration (output of the multicomponent

analysis program designed for the compound).

Lr = The path length associated with the reference spectra.

Ls = The path length associated with the sample spectra.

Ts = The absolute temperature (K) of the sample gas.

Tr = The absolute temperature (K) at which reference.

spectra were recorded.

12.2 The temperature

correction in equation 5 is a volumetric correction. It does not account for

temperature dependence of rotational-vibrational relative line intensities.

Whenever possible, the reference spectra used in the analysis should be

collected at a temperature near the temperature of the FTIR cell used in the

test to minimize the calculated error in the measurement (FTIR Protocol,

appendix D). Additionally, the analytical region chosen for the analysis should

be sufficiently broad to minimize errors caused by small differences in

relative line intensities between reference spectra and the sample spectra.

13.0 Method Performance

A description of the

method performance may be found in the FTIR Protocol. This method is self

validating provided the results meet the performance specification of the QA spike

in sections 9.0 through 9.3 of this method.

14.0 Pollution Prevention

This is a gas phase

measurement. Gas is extracted from the source, analyzed by the instrumentation,

and discharged through the instrument vent.

15.0 Waste Management

Gas standards of HCl are

handled according to the instructions enclosed with the material safety data

sheet.

16.0 References

1. "Laboratory and

Field Evaluation of a Methodology for Determination of Hydrogen Chloride

Emissions From Municipal and Hazardous Waste Incinerators," S. C.

Steinsberger and J. H. Margeson. Prepared for U.S. Environmental Protection

Agency, Research Triangle Park, NC. NTIS Report No. PB89-220586. (1989).

2. "Evaluation of HCl

Measurement Techniques at Municipal and Hazardous Waste Incinerators," S.

A. Shanklin, S. C. Steinsberger, and L. Cone, Entropy, Inc. Prepared for U.S.

Environmental Protection Agency, Research Triangle Park, NC. NTIS Report No.

PB90-221896. (1989).

3. "Fourier Transform

Infrared (FTIR) Method Validation at a Coal Fired-Boiler," Entropy, Inc.

Prepared for U.S. Environmental Protection Agency, Research Triangle Park, NC.

EPA Publication No. EPA-454/R95-004. NTIS Report No. PB95-193199. (1993).

4. "Field Validation

Test Using Fourier Transform Infrared (FTIR) Spectrometry To Measure

Formaldehyde, Phenol and Methanol at a Wool Fiberglass Production

Facility." Draft. U.S. Environmental Protection Agency Report, Entropy,

Inc., EPA Contract No. 68D20163, Work Assignment I-32.

5. Kinner, L.L., Geyer,

T.G., Plummer, G.W., Dunder, T.A., Entropy, Inc. "Application of FTIR as a

Continuous Emission Monitoring System." Presentation at 1994 International

Incineration Conference, Houston, Tx. May 10, 1994.

6. "Molecular

Vibrations; The Theory of Infrared and Raman Vibrational Spectra," E.

Bright Wilson, J. C. Decius, and P. C. Cross, Dover Publications, Inc., 1980.

For a less intensive treatment of molecular rotational-vibrational spectra see,

for example, "Physical Chemistry," G. M. Barrow, chapters 12, 13, and

14, McGraw Hill, Inc., 1979.

7. "Laboratory and

Field Evaluations of Ammonium Chloride Interference in Method 26," U.S.

Environmental Protection Agency Report, Entropy, Inc., EPA Contract No.

68D20163, Work Assignment No. I-45.

8. 40 CFR 63, appendix A.

Method 301 - Field Validation of Pollutant Measurement Methods from Various

Waste Media.

9. "Fourier Transform

Infrared Spectrometry," Peter R. Griffiths and James de Haseth, Chemical

Analysis, 83, 16-25,(1986), P. J. Elving, J. D. Winefordner and I. M. Kolthoff

(ed.), John Wiley and Sons.

10.

"Computer-Assisted Quantitative Infrared Spectroscopy," Gregory L.

McClure (ed.), ASTM Special Publication 934 (ASTM), 1987.

11. "Multivariate

Least-Squares Methods Applied to the Quantitative Spectral Analysis of

Multicomponent Mixtures," Applied Spectroscopy, 39(10), 73-84, 1985.

Figure 1. FTIR Spectra

of HCl and Water.

Figure 2. FTIR

Sampling/Spiking System.