METHOD 320

MEASUREMENT OF VAPOR PHASE ORGANIC AND INORGANIC EMISSIONS BY EXTRACTIVE

FOURIER TRANSFORM INFRARED (FTIR) SPECTROSCOPY

Appendix A of part 63 is

amended by adding, in numerical order, Methods 320 and 321 to read as follows:

Appendix A to Part 63-Test Methods

1.2 Method Range and

Sensitivity.

2.3 Reference Spectra

Availability.

4.1.1 Background

Interference.

4.2 Sampling System

Interferences.

6.3 Sampling

Line/Heating System.

6.4 Gas Distribution

Manifold.

6.6 Calibration/Analyte

Spike Assembly.

6.9

Polytetrafluoroethane Tubing.

7.1 Analyte(s) and

Tracer Gas.

7.2 Calibration

Transfer Standard(s).

8.0 Sampling and

Analysis Procedure.

8.1 Pretest

Preparations and Evaluations.

8.1.4. Fractional

Reproducibility Uncertainty (FRUi).

8.1.6 Calculate the

Minimum Analyte Uncertainty, MAU

8.4 Data Storage

Requirements.

8.6.1 Calibration

Transfer Standard.

8.8 Sampling QA and

Reporting.

10.0 Calibration and

Standardization.

10.1 Signal-to-Noise

Ratio (S/N).

11.0 Data Analysis and

Calculations.

13.0 Method Validation

Procedure.

13.3 Simultaneous

Measurements With Two FTIR Systems.

2.0 APPLICABILITY AND

ANALYTICAL PRINCIPLE

3.0 GENERAL PRINCIPLES

OF PROTOCOL REQUIREMENTS

3.1 Verifiability and

Reproducibility of Results.

3.2 Transfer of

Reference Spectra.

3.3 Evaluation of FTIR

Analyses.

3.3.1

Sample-Independent Factors.

3.3.2 Sample-Dependent

Factors.

4.0 PRE-TEST

PREPARATIONS AND EVALUATIONS

4.1 Identify Test

Requirements.

4.2 Identify Potential

Interferants.

4.3 Select and Evaluate

the Sampling System.

4.4 Select

Spectroscopic System.

4.5 Select Calibration

Transfer Standards (CTS's).

4.6 Prepare Reference

Spectra.

4.7 Select Analytical

Regions.

4.8 Determine

Fractional Reproducibility Uncertainties.

4.9 Identify Known

Interferants.

4.10 Prepare

Computerized Analytical Programs.

4.11 Determine the

Fractional Calibration Uncertainty.

4.12 Verify System

Configuration Suitability.

5.0 SAMPLING AND

ANALYSIS PROCEDURE

5.1 Analysis System

Assembly and Leak-Test.

5.2 Verify Instrumental

Performance.

5.3 Determine the

Sample Absorption Pathlength.

5.5 Quantify Analyte

Concentrations.

5.6 Determine

Fractional Analysis Uncertainty.

6.1 Qualitatively

Confirm the Assumed Matrix.

6.2 Quantitatively

Evaluate Fractional Model Uncertainty (FMU).

6.3 Estimate Overall

Concentration Uncertainty (OCU).

APPENDIX A TO ADDENDUM TO METHOD 320

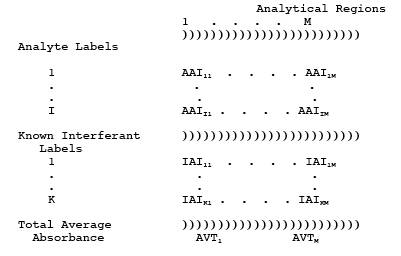

A.2 Definitions of

Mathematical Symbols.

APPENDIX B TO ADDENDUM

TO METHOD 320

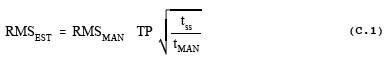

APPENDIX C TO ADDENDUM

TO METHOD 320

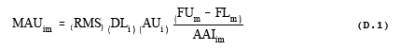

APPENDIX D TO ADDENDUM

TO METHOD 320

APPENDIX E TO ADDENDUM

TO METHOD 320

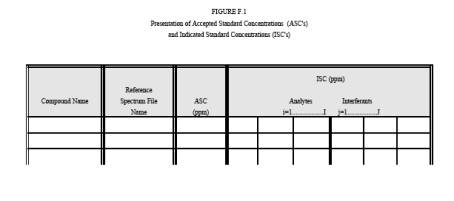

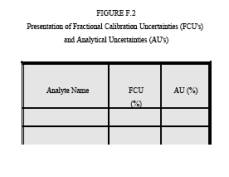

APPENDIX F OF ADDENDUM

TO METHOD 320

APPENDIX G TO ADDENDUM

TO METHOD 320

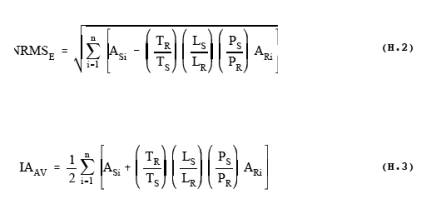

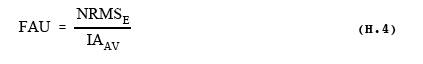

APPENDIX H OF ADDENDUM

TO METHOD 320

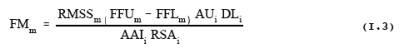

APPENDIX I TO ADDENDUM

TO METHOD 320

APPENDIX J OF ADDENDUM

TO METHOD 320

1.0 Introduction.

Persons unfamiliar with

basic elements of FTIR spectroscopy should not attempt to use this method. This

method describes sampling and analytical procedures for extractive emission

measurements using Fourier transform infrared (FTIR) spectroscopy. Detailed

analytical procedures for interpreting infrared spectra are described in the

"Protocol for the Use of Extractive Fourier Transform Infrared (FTIR) Spectrometry

in Analyses of Gaseous Emissions from Stationary Sources," hereafter

referred to as the "Protocol." Definitions not given in this method

are given in appendix A of the Protocol. References to specific sections in the

Protocol are made throughout this Method. For additional information refer to

references 1 and 2, and other EPA reports, which describe the use of FTIR

spectrometry in specific field measurement applications and validation tests.

The sampling procedure described here is extractive. Flue gas is extracted

through a heated gas transport and handling system. For some sources, sample

conditioning systems may be applicable. Some examples are given in this method.

Note: sample conditioning systems may be used providing the method validation

requirements in Sections 9.2 and 13.0 of this method are met.

1.1 Scope and Applicability.

1.1.1 Analytes. Analytes

include hazardous air pollutants (HAPs) for which EPA reference spectra have

been developed. Other compounds can also be measured with this method if

reference spectra are prepared according to section 4.6 of the protocol.

1.1.2 Applicability. This

method applies to the analysis of vapor phase organic or inorganic compounds

which absorb energy in the mid-infrared spectral region, about 400 to 4000 cm-1 (25 to 2.5 µm). This method is used to determine compound-specific

concentrations in a multi-component vapor phase sample, which is contained in a

closed-path gas cell. Spectra of samples are collected using double beam

infrared absorption spectroscopy. A computer program is used to analyze spectra

and report compound concentrations.

1.2 Method Range and Sensitivity.

Analytical range and

sensitivity depend on the frequency-dependent analyte absorptivity, instrument

configuration, data collection parameters, and gas stream composition.

Instrument factors include: (a) spectral resolution, (b) interferometer signal

averaging time, (c) detector sensitivity and response, and (d) absorption path

length.

1.2.1 For any optical

configuration the analytical range is between the absorbance values of about

.01 (infrared transmittance relative to the background = 0.98) and 1.0 (T =

0.1). (For absorbance > 1.0 the relation between absorbance and

concentration may not be linear.)

1.2.2 The concentrations

associated with this absorbance range depend primarily on the cell path length

and the sample temperature. An analyte absorbance greater than 1.0, can be

lowered by decreasing the optical path length. Analyte absorbance increases

with a longer path length. Analyte detection also depends on the presence of

other species exhibiting absorbance in the same analytical region.

Additionally, the estimated lower absorbance (A) limit (A = 0.01) depends on

the root mean square deviation (RMSD) noise in the analytical region.

1.2.3 The concentration

range of this method is determined by the choice of optical configuration.

1.2.3.1 The absorbance for

a given concentration can be decreased by decreasing the path length or by

diluting the sample. There is no practical upper limit to the measurement

range.

1.2.3.2 The analyte

absorbance for a given concentration may be increased by increasing the cell

path length or (to some extent) using a higher resolution. Both modifications

also cause a corresponding increased absorbance for all compounds in the

sample, and a decrease in the signal throughput. For this reason the practical

lower detection range (quantitation limit) usually depends on sample

characteristics such as moisture content of the gas, the presence of other

interferants, and losses in the sampling system.

1.3 Sensitivity.

The limit of sensitivity

for an optical configuration and integration time is determined using appendix

D of the Protocol: Minimum Analyte Uncertainty, (MAU). The MAU depends on the

RMSD noise in an analytical region, and on the absorptivity of the analyte in

the same region.

1.4 Data Quality.

Data quality shall be

determined by executing Protocol pre-test procedures in appendices B to H of

the protocol and post-test procedures in appendices I and J of the protocol.

1.4.1 Measurement

objectives shall be established by the choice of detection limit (DLi) and analytical uncertainty (AUi) for each analyte.

1.4.2 An instrumental

configuration shall be selected. An estimate of gas composition shall be made

based on previous test data, data from a similar source or information gathered

in a pre-test site survey. Spectral interferants shall be identified using the

selected DLi and AUi and band areas from reference

spectra and interferant spectra. The baseline noise of the system shall be

measured in each analytical region to determine the MAU of the instrument

configuration for each analyte and interferant (MIUi).

1.4.3 Data quality for the

application shall be determined, in part, by measuring the RMS (root mean

square) noise level in each analytical spectral region (appendix C of the

Protocol). The RMS noise is defined as the RMSD of the absorbance values in an

analytical region from the mean absorbance value in the region.

1.4.4 The MAU is the

minimum analyte concentration for which the AUi can be

maintained; if the measured analyte concentration is less than MAUi, then data quality are unacceptable.

2.0 Summary of Method.

2.1 Principle.

References 4 through 7

provide background material on infrared spectroscopy and quantitative analysis.

A summary is given in this section.

2.1.1 Infrared absorption

spectroscopy is performed by directing an infrared beam through a sample to a

detector. The frequency-dependent infrared absorbance of the sample is measured

by comparing this detector signal (single beam spectrum) to a signal obtained

without a sample in the beam path (background).

2.1.2 Most molecules

absorb infrared radiation and the absorbance occurs in a characteristic and

reproducible pattern. The infrared spectrum measures fundamental molecular

properties and a compound can be identified from its infrared spectrum alone.

2.1.3 Within constraints,

there is a linear relationship between infrared absorption and compound

concentration. If this frequency dependent relationship (absorptivity) is known

(measured), it can be used to determine compound concentration in a sample

mixture.

2.1.4 Absorptivity is

measured by preparing, in the laboratory, standard samples of compounds at

known concentrations and measuring the FTIR "reference spectra" of

these standard samples. These "reference spectra" are then used in

sample analysis: (1) compounds are detected by matching sample absorbance bands

with bands in reference spectra, and (2) concentrations are measured by

comparing sample band intensities with reference band intensities.

2.1.5 This method is

self-validating provided that the results meet the performance requirement of

the QA spike in sections 8.6.2 and 9.0 of this method, and results from a

previous method validation study support the use of this method in the

application.

2.2 Sampling and Analysis.

In extractive sampling a

probe assembly and pump are used to extract gas from the exhaust of the

affected source and transport the sample to the FTIR gas cell. Typically, the

sampling apparatus is similar to that used for single-component continuous

emission monitor (CEM) measurements.

2.2.1 The digitized

infrared spectrum of the sample in the FTIR gas cell is measured and stored on

a computer. Absorbance band intensities in the spectrum are related to sample

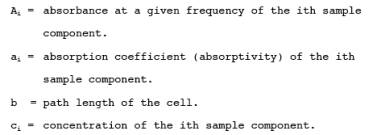

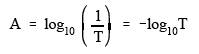

concentrations by what is commonly referred to as Beer's Law.

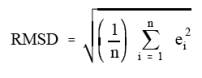

![]()

where:

2.2.2 Analyte spiking is

used for quality assurance (QA). In this procedure (section 8.6.2 of this

method) an analyte is spiked into the gas stream at the back end of the sample

probe. Analyte concentrations in the spiked samples are compared to analyte

concentrations in unspiked samples. Since the concentration of the spike is

known, this procedure can be used to determine if the sampling system is

removing the spiked analyte(s) from the sample stream.

2.3 Reference Spectra Availability.

Reference spectra of over

100 HAPs are available in the EPA FTIR spectral library on the EMTIC (Emission

Measurement Technical Information Center) computer bulletin board service and

at internet address https://info.arnold.af.mil/epa/welcome.htm.

Reference spectra for HAPs, or other analytes, may also be prepared according

to section 4.6 of the Protocol.

2.4 Operator Requirements.

The FTIR analyst shall be

trained in setting up the instrumentation, verifying the instrument is

functioning properly, and performing routine maintenance. The analyst must

evaluate the initial sample spectra to determine if the sample matrix is

consistent with pre-test assumptions and if the instrument configuration is

suitable. The analyst must be able to modify the instrument configuration, if

necessary.

2.4.1 The spectral

analysis shall be supervised by someone familiar with EPA FTIR Protocol

procedures.

2.4.2 A technician trained

in instrumental test methods is qualified to install and operate the sampling

system. This includes installing the probe and heated line assembly, operating

the analyte spike system, and performing moisture and flow measurements.

3.0 Definitions.

See appendix A of the

Protocol for definitions relating to infrared spectroscopy. Additional

definitions are given in sections 3.1 through 3.29.

3.1 Analyte.

A compound that this

method is used to measure. The term "target analyte" is also used.

This method is multi-component and a number of analytes can be targeted for a

test.

3.2 Reference Spectrum.

Infrared spectrum of an

analyte prepared under controlled, documented, and reproducible laboratory

conditions according to procedures in section 4.6 of the Protocol. A library of

reference spectra is used to measure analytes in gas samples.

3.3 Standard Spectrum.

A spectrum that has been

prepared from a reference spectrum through a (documented) mathematical

operation. A common example is de-resolving of reference spectra to

lower-resolution standard spectra (Protocol, appendix K to the addendum of this

method). Standard spectra, prepared by approved, and documented, procedures can

be used as reference spectra for analysis.

3.4 Concentration.

In this method

concentration is expressed as a molar concentration, in ppm-meters, or in

(ppm-meters)/K, where K is the absolute temperature (Kelvin). The latter units

allow the direct comparison of concentrations from systems using different

optical configurations or sampling temperatures.

3.5 Interferant.

A compound in the sample

matrix whose infrared spectrum overlaps with part of an analyte spectrum. The

most accurate analyte measurements are achieved when reference spectra of

interferants are used in the quantitative analysis with the analyte reference

spectra. The presence of an interferant can increase the analytical uncertainty

in the measured analyte concentration.

3.6 Gas Cell.

A gas containment cell

that can be evacuated. It is equipped with the optical components to pass the

infrared beam through the sample to the detector. Important cell features

include: path length (or range if variable), temperature range, materials of

construction, and total gas volume.

3.7 Sampling System.

Equipment used to extract

the sample from the test location and transport the sample gas to the FTIR

analyzer. This includes sample conditioning systems.

3.8 Sample Analysis.

The process of interpreting

the infrared spectra to obtain sample analyte concentrations. This process is

usually automated using a software routine employing a classical least squares

(cls), partial least squares (pls), or K- or P- matrix method.

3.9 One hundred percent line.

A double beam

transmittance spectrum obtained by combining two background single beam

spectra. Ideally, this line is equal to 100 percent transmittance (or zero

absorbance) at every frequency in the spectrum. Practically, a zero absorbance

line is used to measure the baseline noise in the spectrum.

3.10 Background Deviation.

A deviation from 100

percent transmittance in any region of the 100 percent line. Deviations greater

than ± 5 percent in an analytical region are unacceptable (absorbance of 0.021

to -0.022). Such deviations indicate a change in the instrument throughput

relative to the background single beam.

3.11 Batch Sampling.

A procedure where spectra

of discreet, static samples are collected. The gas cell is filled with sample

and the cell is isolated. The spectrum is collected. Finally, the cell is

evacuated to prepare for the next sample.

3.12 Continuous Sampling.

A procedure where spectra

are collected while sample gas is flowing through the cell at a measured rate.

3.13 Sampling resolution.

The spectral resolution

used to collect sample spectra.

3.14 Truncation.

Limiting the number of

interferogram data points by deleting points farthest from the center burst

(zero path difference, ZPD).

3.15 Zero filling.

The addition of points to

the interferogram. The position of each added point is interpolated from

neighboring real data points. Zero filling adds no information to the

interferogram, but affects line shapes in the absorbance spectrum (and possibly

analytical results).

3.16 Reference CTS.

Calibration Transfer

Standard spectra that were collected with reference spectra.

3.17 CTS Standard.

CTS spectrum produced by

applying a deresolution procedure to a reference CTS.

3.18 Test CTS.

CTS spectra collected at

the sampling resolution using the same optical configuration as for sample

spectra. Test spectra help verify the resolution, temperature and path length

of the FTIR system.

3.19 RMSD.

Root Mean Square

Difference, defined in EPA FTIR Protocol, appendix A.

3.20 Sensitivity.

The noise-limited

compound-dependent detection limit for the FTIR system configuration. This is

estimated by the MAU. It depends on the RMSD in an analytical region of a zero

absorbance line.

3.21 Quantitation Limit.

The lower limit of

detection for the FTIR system configuration in the sample spectra. This is

estimated by mathematically subtracting scaled reference spectra of analytes

and interferences from sample spectra, then measuring the RMSD in an analytical

region of the subtracted spectrum. Since the noise in subtracted sample spectra

may be much greater than in a zero absorbance spectrum, the quantitation limit

is generally much higher than the sensitivity. Removing spectral interferences

from the sample or improving the spectral subtraction can lower the

quantitation limit toward (but not below) the sensitivity.

3.22 Independent Sample.

A unique volume of sample

gas; there is no mixing of gas between two consecutive independent samples. In

continuous sampling two independent samples are separated by at least 5 cell

volumes. The interval between independent measurements depends on the cell

volume and the sample flow rate (through the cell).

3.23 Measurement.

A single spectrum of flue

gas contained in the FTIR cell.

3.24 Run.

A run consists of a series

of measurements. At a minimum a run includes 8 independent measurements spaced

over 1 hour.

3.25 Validation.

Validation of FTIR

measurements is described in sections 13.0 through 13.4 of this method.

Validation is used to verify the test procedures for measuring specific

analytes at a source. Validation provides proof that the method works under

certain test conditions.

3.26 Validation Run.

A validation run consists

of at least 24 measurements of independent samples. Half of the samples are

spiked and half are not spiked. The length of the run is determined by the

interval between independent samples.

3.27 Screening. Screening

is used when there is

little or no available information about a source. The purpose of screening is

to determine what analytes are emitted and to obtain information about

important sample characteristics such as moisture, temperature, and

interferences. Screening results are semi-quantitative (estimated

concentrations) or qualitative (identification only). Various optical and

sampling configurations may be used. Sample conditioning systems may be

evaluated for their effectiveness in removing interferences. It is unnecessary

to perform a complete run under any set of sampling conditions. Spiking is not

necessary, but spiking can be a useful screening tool for evaluating the

sampling system, especially if a reactive or soluble analyte is used for the

spike.

3.28 Emissions Test.

An FTIR emissions test is

performed according specific sampling and analytical procedures. These procedures,

for the target analytes and the source, are based on previous screening and

validation results. Emission results are quantitative. A QA spike (sections

8.6.2 and 9.2 of this method) is performed under each set of sampling

conditions using a representative analyte. Flow, gas temperature and diluent

data are recorded concurrently with the FTIR measurements to provide mass

emission rates for detected compounds.

3.29 Surrogate.

A surrogate is a compound

that is used in a QA spike procedure (section 8.6.2 of this method) to

represent other compounds. The chemical and physical properties of a surrogate

shall be similar to the compounds it is chosen to represent. Under given

sampling conditions, usually a single sampling factor is of primary concern for

measuring the target analytes: for example, the surrogate spike results can be

representative for analytes that are more reactive, more soluble, have a lower

absorptivity, or have a lower vapor pressure than the surrogate itself.

4.0 Interferences.

Interferences are divided

into two classifications: analytical and sampling.

4.1 Analytical Interferences.

An analytical interference

is a spectral feature that complicates (in extreme cases may prevent) the

analysis of an analyte. Analytical interferences are classified as background

or spectral interference.

4.1.1 Background Interference.

This results from a change

in throughput relative to the single beam background. It is corrected by

collecting a new background and proceeding with the test. In severe instances

the cause must be identified and corrected. Potential causes include: (1)

deposits on reflective surfaces or transmitting windows, (2) changes in

detector sensitivity, (3) a change in the infrared source output, or (4)

failure in the instrument electronics. In routine sampling throughput may

degrade over several hours. Periodically a new background must be collected,

but no other corrective action will be required.

4.1.2 Spectral Interference.

This results from the

presence of interfering compound(s) (interferant) in the sample. Interferant

spectral features overlap analyte spectral features. Any compound with an

infrared spectrum, including analytes, can potentially be an interferant. The

Protocol measures absorbance band overlap in each analytical region to

determine if potential interferants shall be classified as known interferants

(FTIR Protocol, section 4.9 and appendix B). Water vapor and CO2 are common spectral interferants. Both of these compounds have strong

infrared spectra and are present in many sample matrices at high concentrations

relative to analytes. The extent of interference depends on the (1) interferant

concentration, (2) analyte concentration, and (3) the degree of band overlap.

Choosing an alternate analytical region can minimize or avoid the spectral

interference. For example, CO2 interferes with the analysis of

the 670 cm-1 benzene band. However, benzene can also be measured

near 3000 cm-1 (with less sensitivity).

4.2 Sampling System Interferences.

These prevent analytes from

reaching the instrument. The analyte spike procedure is designed to measure

sampling system interference, if any.

4.2.1 Temperature. A

temperature that is too low causes condensation of analytes or water vapor. The

materials of the sampling system and the FTIR gas cell usually set the upper

limit of temperature.

4.2.2 Reactive Species.

Anything that reacts with analytes. Some analytes, like formaldehyde,

polymerize at lower temperatures.

4.2.3 Materials. Poor

choice of material for probe, or sampling line may remove some analytes. For

example, HF reacts with glass components.

4.2.4 Moisture. In

addition to being a spectral interferant, condensed moisture removes soluble

compounds.

5.0 Safety.

The hazards of performing

this method are those associated with any stack sampling method and the same

precautions shall be followed. Many HAPs are suspected carcinogens or present

other serious health risks. Exposure to these compounds should be avoided in

all circumstances. For instructions on the safe handling of any particular

compound, refer to its material safety data sheet. When using analyte

standards, always ensure that gases are properly vented and that the gas

handling system is leak free. (Always perform a leak check with the system

under maximum vacuum and, again, with the system at greater than ambient

pressure.) Refer to section 8.2 of this method for leak check procedures. This

method does not address all of the potential safety risks associated with its

use. Anyone performing this method must follow safety and health practices

consistent with applicable legal requirements and with prudent practice for

each application.

6.0 Equipment and Supplies.

Note: Mention of trade names or specific products does not

constitute endorsement by the Environmental Protection Agency.

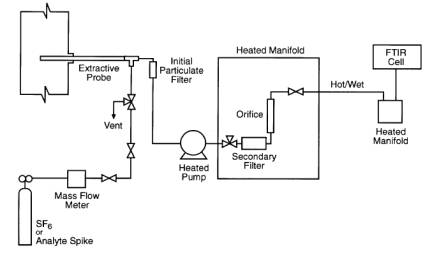

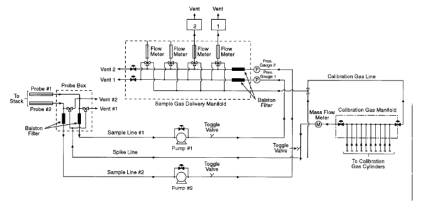

The equipment and supplies

are based on the schematic of a sampling system shown in Figure 1. Either the

batch or continuous sampling procedures may be used with this sampling system.

Alternative sampling configurations may also be used, provided that the data

quality objectives are met as determined in the post-analysis evaluation. Other

equipment or supplies may be necessary, depending on the design of the sampling

system or the specific target analytes.

6.1 Sampling Probe.

Glass, stainless steel, or

other appropriate material of sufficient length and physical integrity to

sustain heating, prevent adsorption of analytes, and to transport analytes to

the infrared gas cell. Special materials or configurations may be required in

some applications. For instance, high stack sample temperatures may require

special steel or cooling the probe. For very high moisture sources it may be

desirable to use a dilution probe.

6.2 Particulate Filters.

A glass wool plug

(optional) inserted at the probe tip (for large particulate removal) and a

filter (required) rated for 99 percent removal efficiency at 1-micron (e.g.,

Balstonª) connected at the outlet of the heated probe.

6.3 Sampling Line/Heating System.

Heated (sufficient to

prevent condensation) stainless steel, polytetrafluoroethane, or other material

inert to the analytes.

6.4 Gas Distribution Manifold.

A heated manifold allowing

the operator to control flows of gas standards and samples directly to the FTIR

system or through sample conditioning systems. Usually includes heated flow

meter, heated valve for selecting and sending sample to the analyzer, and a

bypass vent. This is typically constructed of stainless steel tubing and

fittings, and high-temperature valves.

6.5 Stainless Steel Tubing.

Type 316, appropriate

diameter (e.g., 3/8 in.) and length for heated connections. Higher grade

stainless may be desirable in some applications.

6.6 Calibration/Analyte Spike Assembly.

A three way valve assembly

(or equivalent) to introduce analyte or surrogate spikes into the sampling

system at the outlet of the probe upstream of the out-of-stack particulate

filter and the FTIR analytical system.

6.7 Mass Flow Meter (MFM).

These are used for

measuring analyte spike flow. The MFM shall be calibrated in the range of 0 to

5 L/min and be accurate to ± 2 percent (or better) of the flow meter span.

6.8 Gas Regulators.

Appropriate for individual

gas standards.

6.9 Polytetrafluoroethane Tubing.

Diameter (e.g., 3/8 in.)

and length suitable to connect cylinder regulators to gas standard manifold.

6.10 Sample Pump.

A leak-free pump (e.g.,

KNFª), with bypass valve, capable of producing a sample

flow rate of at least 10 L/min through 100 ft of sample line. If the pump is

positioned upstream of the distribution manifold and FTIR system, use a heated

pump that is constructed from materials non-reactive to the analytes. If the

pump is located downstream of the FTIR system, the gas cell sample pressure

will be lower than ambient pressure and it must be recorded at regular

intervals.

6.11 Gas Sample Manifold.

Secondary manifold to

control sample flow at the inlet to the FTIR manifold. This is optional, but

includes a by-pass vent and heated rotameter.

6.12 Rotameter.

A 0 to 20 L/min rotameter.

This meter need not be calibrated.

6.13 FTIR Analytical System.

Spectrometer and detector,

capable of measuring the analytes to the chosen detection limit. The system

shall include a personal computer with compatible software allowing automated

collection of spectra.

6.14 FTIR Cell Pump.

Required for the batch

sampling technique, capable of evacuating the FTIR cell volume within 2

minutes. The pumping speed shall allow the operator to obtain 8 sample spectra

in 1 hour.

6.15 Absolute Pressure Gauge.

Capable of measuring

pressure from 0 to 1000 mmHg to within ± 2.5 mmHg (e.g., Baratronª).

6.16 Temperature Gauge.

Capable of measuring the

cell temperature to within ± 2¡C.

6.17 Sample Conditioning.

One option is a condenser

system, which is used for moisture removal. This can be helpful in the

measurement of some analytes. Other sample conditioning procedures may be

devised for the removal of moisture or other interfering species.

6.17.1 The analyte spike

procedure of section 9.2 of this method, the QA spike procedure of section

8.6.2 of this method, and the validation procedure of section 13 of this method

demonstrate whether the sample conditioning affects analyte concentrations.

Alternatively, measurements can be made with two parallel FTIR systems; one

measuring conditioned sample, the other measuring unconditioned sample.

6.17.2 Another option is

sample dilution. The dilution factor measurement must be documented and

accounted for in the reported concentrations. An alternative to dilution is to

lower the sensitivity of the FTIR system by decreasing the cell path length, or

to use a short-path cell in conjunction with a long path cell to measure more

than one concentration range.

7.0 Reagents and Standards.

7.1 Analyte(s) and Tracer Gas.

Obtain a certified gas

cylinder mixture containing all of the analyte(s) at concentrations within ± 2

percent of the emission source levels (expressed in ppm-meter/K). If practical,

the analyte standard cylinder shall also contain the tracer gas at a

concentration which gives a measurable absorbance at a dilution factor of at

least 10:1. Two ppm SF6 is sufficient for a path length of 22 meters at 250

¡F.

7.2 Calibration Transfer Standard(s).

Select the calibration

transfer standards (CTS) according to section 4.5 of the FTIR Protocol. Obtain

a National Institute of Standards and Technology (NIST) traceable gravimetric

standard of the CTS (± 2 percent).

7.3 Reference Spectra.

Obtain reference spectra

for each analyte, interferant, surrogate, CTS, and tracer. If EPA reference

spectra are not available, use reference spectra prepared according to procedures

in section 4.6 of the EPA FTIR Protocol.

8.0 Sampling and Analysis Procedure.

Three types of testing can

be performed: (1) screening, (2) emissions test, and (3) validation. Each is

defined in section 3 of this method. Determine the purpose(s) of the FTIR test.

Test requirements include: (a) AUi, DLi, overall fractional uncertainty, OFUi, maximum expected

concentration (CMAXi), and tAN for each, (b)

potential interferants, (c) sampling system factors, e.g., minimum absolute

cell pressure, (Pmin), FTIR cell volume (VSS), estimated

sample absorption pathlength, LS', estimated sample pressure, PS', TS', signal integration time (tSS), minimum instrumental line-width, MIL, fractional error, and (d)

analytical regions, e.g., m = 1 to M, lower wavenumber position, FLm, center wavenumber position, FCm, and upper

wavenumber position, FUm, plus interferants, upper wavenumber position of the

CTS absorption band, FFUm, lower wavenumber position of the CTS absorption

band, FFLm, wavenumber range FNU to FNL. If necessary, sample

and acquire an initial spectrum. From analysis of this preliminary spectrum

determine a suitable operational path length. Set up the sampling train as

shown in Figure 1 or use an appropriate alternative configuration. Sections 8.1

through 8.11 of this method provide guidance on pre-test calculations in the

EPA protocol, sampling and analytical procedures, and post-test protocol

calculations.

8.1 Pretest Preparations and Evaluations.

Using the procedure in

section 4.0 of the FTIR Protocol, determine the optimum sampling system

configuration for measuring the target analytes. Use available information to

make reasonable assumptions about moisture content and other interferences.

8.1.1 Analytes.

Select the required

detection limit (DLi) and the maximum permissible analytical uncertainty

(AUi) for each analyte (labeled from 1 to i). Estimate,

if possible, the maximum expected concentration for each analyte, CMAXi. The expected measurement range is fixed by DLi and CMAXi for each analyte (i).

8.1.2 Potential Interferants.

List the potential

interferants. This usually includes water vapor and CO2, but may also include some analytes and other compounds.

8.1.3. Optical Configuration.

Choose an optical

configuration that can measure all of the analytes within the absorbance range

of .01 to 1.0 (this may require more than one path length). Use Protocol

sections 4.3 to 4.8 for guidance in choosing a configuration and measuring CTS.

8.1.4. Fractional Reproducibility Uncertainty (FRUi).

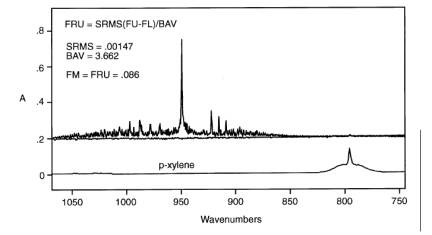

The FRU is determined for

each analyte by comparing CTS spectra taken before and after the reference

spectra were measured. The EPA para-xylene reference spectra were collected on

10/31/91 and 11/01/91 with corresponding CTS spectra "cts1031a," and "cts1101b."

The CTS spectra are used to estimate the reproducibility (FRU) in the system

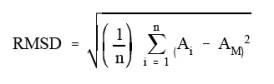

that was used to collect the references. The FRU must be < AU. Appendix E of

the protocol is used to calculate the FRU from CTS spectra. Figure 2 plots

results for 0.25 cm-1 CTS spectra in EPA reference library: S3 (cts1101b - cts1031a), and S4 [(cts1101b +

cts1031a)/2]. The RMSD (SRMS) is calculated in the subtracted baseline, S3, in the corresponding CTS region from 850 to 1065 cm-1. The area (BAV) is calculated in the same region of the averaged CTS

spectrum, S4.

8.1.5 Known Interferants.

Use appendix B of the EPA

FTIR Protocol.

8.1.6 Calculate the Minimum Analyte Uncertainty, MAU

(Section 1.3 of this

method discusses MAU and protocol appendix D gives the MAU procedure). The MAU for

each analyte, i, and each analytical region, m, depends on the RMS noise.

8.1.7 Analytical Program.

See FTIR Protocol, section

4.10. Prepare computer program based on the chosen analytical technique. Use as

input reference spectra of all target analytes and expected interferants.

Reference spectra of additional compounds shall also be included in the program

if their presence (even if transient) in the samples is considered possible.

The program output shall be in ppm (or ppb) and shall be corrected for

differences between the reference path length, LR, temperature,

TR, and pressure, PR, and the conditions

used for collecting the sample spectra. If sampling is performed at ambient

pressure, then any pressure correction is usually small relative to corrections

for path length and temperature, and may be neglected.

8.2 Leak-check.

8.2.1 Sampling System. A

typical FTIR extractive sampling train is shown in Figure 1. Leak check from

the probe tip to pump outlet as follows: Connect a 0Ð to 250-mL/min rate meter

(rotameter or bubble meter) to the outlet of the pump. Close off the inlet to

the probe, and record the leak rate. The leak rate shall be < 200

mL/min.

8.2.2 Analytical System

Leak check. Leak check the FTIR cell under vacuum and under pressure (greater

than ambient). Leak check connecting tubing and inlet manifold under

pressure.

8.2.2.1 For the evacuated

sample technique, close the valve to the FTIR cell, and evacuate the absorption

cell to the minimum absolute pressure Pmin. Close the valve

to the pump, and determine the change in pressure ¥Pv after 2 minutes.

8.2.2.2 For both the

evacuated sample and purging techniques, pressurize the system to about 100

mmHg above atmospheric pressure.

Isolate the pump and determine the change in pressure ¥Pp after 2 minutes.

8.2.2.3 Measure the

barometric pressure, Pb in mmHg.

8.2.2.4 Determine the

percent leak volume %VL for the signal integration time tSS and for ¥Pmax, i.e., the larger of ¥Pv or ¥Pp, as follows:

where:

50 = 100% divided by the

leak-check time of 2 minutes.

8.2.2.5 Leak volumes in

excess of 4 percent of the FTIR system volume VSS are

unacceptable.

8.3 Detector Linearity.

Once an optical

configuration is chosen, use one of the procedures of sections 8.3.1 through

8.3.3 to verify that the detector response is linear. If the detector response

is not linear, decrease the aperture, or attenuate the infrared beam. After a

change in the instrument configuration perform a linearity check until it is

demonstrated that the detector response is linear.

8.3.1 Vary the power

incident on the detector by modifying the aperture setting. Measure the

background and CTS at three instrument aperture settings: (1) at the aperture

setting to be used in the testing, (2) at one half this aperture and (3) at

twice the proposed testing aperture. Compare the three CTS spectra. CTS band

areas shall agree to within the uncertainty of the cylinder standard and the

RMSD noise in the system. If test aperture is the maximum aperture, collect CTS

spectrum at maximum aperture, then close the aperture to reduce the IR

throughput by half. Collect a second background and CTS at the smaller aperture

setting and compare the spectra again.

8.3.2 Use neutral density

filters to attenuate the infrared beam. Set up the FTIR system as it will be

used in the test measurements. Collect a CTS spectrum. Use a neutral density

filter to attenuate the infrared beam (either immediately after the source or

the interferometer) to approximately 1/2 its original intensity. Collect a

second CTS spectrum. Use another filter to attenuate the infrared beam to

approximately 1/4 its original intensity. Collect a third background and CTS

spectrum. Compare the CTS spectra. CTS band areas shall agree to within the

uncertainty of the cylinder standard and the RMSD noise in the system.

8.3.3 Observe the single

beam instrument response in a frequency region where the detector response is

known to be zero. Verify that the detector response is "flat" and

equal to zero in these regions.

8.4 Data Storage Requirements.

All field test spectra

shall be stored on a computer disk and a second backup copy must be stored on a

separate disk. The stored information includes sample interferograms, processed

absorbance spectra, background interferograms, CTS sample interferograms and

CTS absorbance spectra. Additionally, documentation of all sample conditions,

instrument settings, and test records must be recorded on hard copy or on

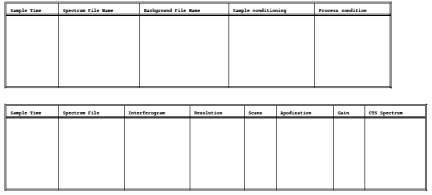

computer medium. Table 1 gives a sample presentation of documentation.

8.5 Background Spectrum.

Evacuate the gas cell to <

5 mmHg, and fill with dry nitrogen gas to ambient pressure (or purge the cell

with 10 volumes of dry nitrogen). Verify that no significant amounts of

absorbing species (for example water vapor and CO2) are present.

Collect a background spectrum, using a signal averaging period equal to or

greater than the averaging period for the sample spectra. Assign a unique file

name to the background spectrum. Store two copies of the background

interferogram and processed single-beam spectrum on separate computer disks

(one copy is the back-up).

8.5.1 Interference

Spectra. If possible, collect spectra of known and suspected major

interferences using the same optical system that will be used in the field

measurements. This can be done on-site or earlier. A number of gases, e.g. CO2, SO2, CO, NH3, are readily

available from cylinder gas suppliers.

8.5.2 Water vapor spectra

can be prepared by the following procedure. Fill a sample tube with distilled

water. Evacuate above the sample and remove dissolved gasses by alternately

freezing and thawing the water while evacuating. Allow water vapor into the

FTIR cell, then dilute to atmospheric pressure with nitrogen or dry air. If

quantitative water spectra are required, follow the reference spectrum

procedure for neat samples (protocol, section 4.6). Often, interference spectra

need not be quantitative, but for best results the absorbance must be

comparable to the interference absorbance in the sample spectra.

8.6 Pre-Test Calibrations

8.6.1 Calibration Transfer Standard.

Evacuate the gas cell to <

5 mmHg absolute pressure, and fill the FTIR cell to atmospheric pressure

with the CTS gas. Alternatively, purge the cell with 10 cell volumes of CTS

gas. (If purge is used, verify that the CTS concentration in the cell is stable

by collecting two spectra 2 minutes apart as the CTS gas continues to flow. If

the absorbance in the second spectrum is no greater than in the first, within

the uncertainty of the gas standard, then this can be used as the CTS

spectrum.) Record the spectrum.

8.6.2 QA Spike.

This procedure assumes

that the method has been validated for at least some of the target analytes at

the source. For emissions testing perform a QA spike. Use a certified standard,

if possible, of an analyte, which has been validated at the source. One analyte

standard can serve as a QA surrogate for other analytes which are less reactive

or less soluble than the standard. Perform the spike procedure of section 9.2

of this method. Record spectra of at least three independent (section 3.22 of

this method) spiked samples. Calculate the spiked component of the analyte

concentration. If the average spiked concentration is within 0.7 to 1.3 times

the expected concentration, then proceed with the testing. If applicable, apply

the correction factor from the Method 301 of this appendix validation test (not

the result from the QA spike).

8.7 Sampling.

If analyte concentrations

vary rapidly with time, continuous sampling is preferable using the smallest

cell volume, fastest sampling rate and fastest spectra collection rate

possible. Continuous sampling requires the least operator intervention even

without an automated sampling system. For continuous monitoring at one location

over long periods, Continuous sampling is preferred. Batch sampling and

continuous static sampling are used for screening and performing test runs of

finite duration. Either technique is preferred for sampling several locations

in a matter of days. Batch sampling gives reasonably good time resolution and

ensures that each spectrum measures a discreet (and unique) sample volume.

Continuous static (and continuous) sampling provides a very stable background

over long periods. Like batch sampling, continuous static sampling also ensures

that each spectrum measures a unique sample volume. It is essential that the

leak check procedure under vacuum (section 8.2 of this method) is passed if the

batch sampling procedure is used. It is essential that the leak check procedure

under positive pressure is passed if the continuous static or continuous

sampling procedures are used. The sampling techniques are described in sections

8.7.1 through 8.7.2 of this method.

8.7.1 Batch Sampling.

Evacuate the absorbance cell to < 5 mmHg absolute pressure. Fill the

cell with exhaust gas to ambient pressure, isolate the cell, and record the

spectrum. Before taking the next sample, evacuate the cell until no spectral

evidence of sample absorption remains. Repeat this procedure to collect eight

spectra of separate samples in 1 hour.

8.7.2 Continuous Static

Sampling. Purge the FTIR cell with 10 cell volumes of sample gas. Isolate the

cell, collect the spectrum of the static sample and record the pressure. Before

measuring the next sample, purge the cell with 10 more cell volumes of sample

gas.

8.8 Sampling QA and Reporting.

8.8.1 Sample integration

times shall be sufficient to achieve the required signal-to-noise ratio. Obtain

an absorbance spectrum by filling the cell with N2. Measure the

RMSD in each analytical region in this absorbance spectrum. Verify that the

number of scans used is sufficient to achieve the target MAU.

8.8.2 Assign a unique file

name to each spectrum.

8.8.3 Store two copies of

sample interferograms and processed spectra on separate computer disks.

8.8.4 For each sample

spectrum, document the sampling conditions, the sampling time (while the cell

was being filled), the time the spectrum was recorded, the instrumental

conditions (path length, temperature, pressure, resolution, signal integration

time), and the spectral file name. Keep a hard copy of these data sheets.

8.9 Signal Transmittance.

While sampling, monitor

the signal transmittance. If signal transmittance (relative to the background)

changes by 5 percent or more (absorbance =

-.02 to .02) in any analytical spectral region, obtain a new background

spectrum.

8.10 Post-test CTS.

After the sampling run,

record another CTS spectrum.

8.11 Post-test QA.

8.11.1 Inspect the sample

spectra immediately after the run to verify that the gas matrix composition was

close to the expected (assumed) gas matrix.

8.11.2 Verify that the

sampling and instrumental parameters were appropriate for the conditions

encountered. For example, if the moisture is much greater than anticipated, it

may be necessary to use a shorter path length or dilute the sample.

8.11.3 Compare the pre-

and post-test CTS spectra. The peak absorbance in pre- and post-test CTS must

be ± 5 percent of the mean value. See appendix E of the FTIR Protocol.

9.0 Quality Control.

Use analyte spiking

(sections 8.6.2, 9.2 and 13.0 of this method) to verify that the sampling

system can transport the analytes from the probe to the FTIR system.

9.1 Spike Materials.

Use a certified standard

(accurate to ± 2 percent) of the target analyte, if one can be obtained. If a

certified standard cannot be obtained, follow the procedures in section 4.6.2.2

of the FTIR Protocol.

9.2 Spiking Procedure.

QA spiking (section 8.6.2

of this method) is a calibration procedure used before testing. QA spiking involves

following the spike procedure of sections 9.2.1 through 9.2.3 of this method to

obtain at least three spiked samples. The analyte concentrations in the spiked

samples shall be compared to the expected spike concentration to verify that

the sampling/analytical system is working properly. Usually, when QA spiking is

used, the method has already been validated at a similar source for the analyte

in question. The QA spike demonstrates that the validated sampling/analytical

conditions are being duplicated. If the QA spike fails then the

sampling/analytical system shall be repaired before testing proceeds. The

method validation procedure (section 13.0 of this method) involves a more

extensive use of the analyte spike procedure of sections 9.2.1 through 9.2.3 of

this method. Spectra of at least 12 independent spiked and 12 independent

unspiked samples are recorded. The concentration results are analyzed

statistically to determine if there is a systematic bias in the method for

measuring a particular analyte. If there is a systematic bias, within the

limits allowed by Method 301 of this appendix, then a correction factor shall

be applied to the analytical results. If the systematic bias is greater than

the allowed limits, this method is not valid and cannot be used.

9.2.1 Introduce the

spike/tracer gas at a constant flow rate of < 10 percent of the total

sample flow, when possible. (Note: Use the rotameter at the end of the sampling

train to estimate the required spike/tracer gas flow rate.) Use a flow device,

e.g., mass flow meter (± 2 percent), to monitor the spike flow rate. Record the

spike flow rate every 10 minutes.

9.2.2 Determine the

response time (RT) of the system by continuously collecting spectra of the

spiked effluent until the spectrum of the spiked component is constant for 5

minutes. The RT is the interval from the first measurement until the spike

becomes constant. Wait for twice the duration of the RT, then collect spectra

of two independent spiked gas samples. Duplicate analyses of the spiked concentration

shall be within 5 percent of the mean of the two measurements.

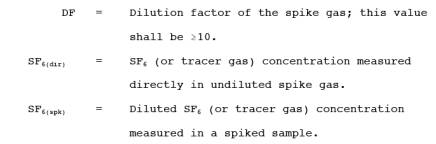

9.2.3 Calculate the

dilution ratio using the tracer gas as follows:

where:

![]()

10.0 Calibration and Standardization.

10.1 Signal-to-Noise Ratio (S/N).

The RMSD in the noise must

be less than one tenth of the minimum analyte peak absorbance in each

analytical region. For example if the minimum peak absorbance is 0.01 at the

required DL, then RMSD measured over the entire analytical region must be <

0.001.

10.2 Absorbance Path length.

Verify the absorbance path

length by comparing reference CTS spectra to test CTS spectra. See appendix E

of the FTIR Protocol.

10.3 Instrument Resolution.

Measure the line width of

appropriate test CTS band(s) to verify instrument resolution. Alternatively,

compare CTS spectra to a reference CTS spectrum, if available, measured at the

nominal resolution.

10.4 Apodization Function.

In transforming the sample

interferograms to absorbance spectra use the same apodization function that was

used in transforming the reference spectra.

10.5 FTIR Cell Volume.

Evacuate the cell to <

5 mmHg. Measure the initial absolute temperature (Ti) and absolute pressure (Pi). Connect a wet

test meter (or a calibrated dry gas meter), and slowly draw room air into the

cell. Measure the meter volume (Vm), meter absolute

temperature (Tm), and meter absolute pressure (Pm); and the cell final absolute temperature (Tf) and absolute pressure (Pf). Calculate the

FTIR cell volume VSS, including that of the connecting tubing, as

follows:

11.0 Data Analysis and Calculations.

Analyte concentrations

shall be measured using reference spectra from the EPA FTIR spectral library.

When EPA library spectra are not available, the procedures in section 4.6 of

the Protocol shall be followed to prepare reference spectra of all the target

analytes.

11.1 Spectral De-resolution.

Reference spectra can be

converted to lower resolution standard spectra (section 3.3 of this method) by

truncating the original reference sample and background interferograms.

Appendix K of the FTIR Protocol gives specific deresolution procedures.

Deresolved spectra shall be transformed using the same apodization function and

level of zero filling as the sample spectra. Additionally, pre-test FTIR protocol

calculations (e.g., FRU, MAU, FCU) shall be performed using the de-resolved

standard spectra.

11.2 Data Analysis.

Various analytical

programs are available for relating sample absorbance to a concentration

standard. Calculated concentrations shall be verified by analyzing residual

baselines after mathematically subtracting scaled reference spectra from the

sample spectra. A full description of the data analysis and calculations is

contained in the FTIR Protocol (sections 4.0, 5.0, 6.0 and appendices). Correct

the calculated concentrations in the sample spectra for differences in

absorption path length and temperature between the reference and sample spectra

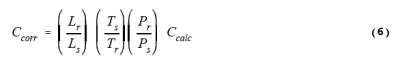

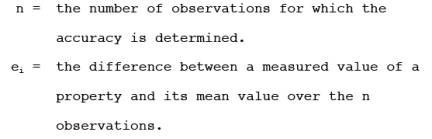

using equation 6,

where:

12.0 Method Performance.

12.1 Spectral Quality.

Refer to the FTIR Protocol

appendices for analytical requirements, evaluation of data quality, and

analysis of uncertainty.

12.2 Sampling QA/QC.

The analyte spike

procedure of section 9 of this method, the QA spike of section 8.6.2 of this

method, and the validation procedure of section 13 of this method are used to

evaluate the performance of the sampling system and to quantify sampling system

effects, if any, on the measured concentrations. This method is self-validating

provided that the results meet the performance requirement of the QA spike in

sections 9.0 and 8.6.2 of this method and results from a previous method

validation study support the use of this method in the application. Several

factors can contribute to uncertainty in the measurement of spiked samples.

Factors which can be controlled to provide better accuracy in the spiking

procedure are listed in sections 12.2.1 through 12.2.4 of this method.

12.2.1 Flow meter. An

accurate mass flow meter is accurate to ± 1 percent of its span. If a flow of 1

L/min is monitored with such a MFM, which is calibrated in the range of 0-5

L/min, the flow measurement has an uncertainty of 5 percent. This may be

improved by re-calibrating the meter at the specific flow rate to be used.

12.2.2 Calibration gas.

Usually the calibration standard is certified to within ± 2 percent. With

reactive analytes, such as HCl, the certified accuracy in a commercially

available standard may be no better than ± 5 percent.

12.2.3 Temperature.

Temperature measurements of the cell shall be quite accurate. If practical, it

is preferable to measure sample temperature directly, by inserting a

thermocouple into the cell chamber instead of monitoring the cell outer wall

temperature.

12.2.4 Pressure. Accuracy

depends on the accuracy of the barometer, but fluctuations in pressure

throughout a day may be as much as 2.5 percent due to weather variations.

13.0 Method Validation Procedure.

This validation procedure,

which is based on EPA Method 301 (40 CFR part 63, appendix A), may be used to

validate this method for the analytes in a gas matrix. Validation at one source

may also apply to another type of source, if it can be shown that the exhaust

gas characteristics are similar at both sources.

13.1 Analyte Spike procedure

Section 5.3 of Method 301

(40 CFR part 63, appendix A), the Analyte Spike procedure, is used with these

modifications. The statistical analysis of the results follows section 6.3 of

EPA Method 301. Section 3 of this method defines terms that are not defined in

Method 301.

13.1.1 The analyte spike

is performed dynamically. This means the spike flow is continuous and constant

as spiked samples are measured.

13.1.2 The spike gas is

introduced at the back of the sample probe.

13.1.3 Spiked effluent is

carried through all sampling components downstream of the probe.

13.1.4 A single FTIR

system (or more) may be used to collect and analyze spectra (not quadruplicate

integrated sampling trains).

13.1.5 All of the

validation measurements are performed sequentially in a single "run"

(section 3.26 of this method).

13.1.6 The measurements

analyzed statistically are each independent (section 3.22 of this method).

13.1.7 A validation data

set can consist of more than 12 spiked and 12 unspiked measurements.

13.2 Batch Sampling.

The procedure in sections

13.2.1 through 13.2.2 may be used for stable processes. If process emissions

are highly variable, the procedure in section

13.2.3 shall be used.

13.2.1 With a single FTIR

instrument and sampling system, begin by collecting spectra of two unspiked

samples. Introduce the spike flow into the sampling system and allow 10 cell

volumes to purge the sampling system and FTIR cell. Collect spectra of two

spiked samples. Turn off the spike and allow 10 cell volumes of unspiked sample

to purge the FTIR cell. Repeat this procedure until the 24 (or more) samples

are collected.

13.2.2 In batch sampling,

collect spectra of 24 distinct samples. (Each distinct sample consists of

filling the cell to ambient pressure after the cell has been evacuated.)

13.2.3 Alternatively, a

separate probe assembly, line, and sample pump can be used for spiked sample.

Verify and document that sampling conditions are the same in both the spiked

and the unspiked sampling systems. This can be done by wrapping both sample

lines in the same heated bundle. Keep the same flow rate in both sample lines.

Measure samples in sequence in pairs. After two spiked samples are measured,

evacuate the FTIR cell, and turn the manifold valve so that spiked sample flows

to the FTIR cell. Allow the connecting line from the manifold to the FTIR cell

to purge thoroughly (the time depends on the line length and flow rate).

Collect a pair of spiked samples. Repeat the procedure until at least 24

measurements are completed.

13.3 Simultaneous Measurements With Two FTIR Systems.

If unspiked effluent

concentrations of the target analyte(s) vary significantly with time, it may be

desirable to perform synchronized measurements of spiked and unspiked sample.

Use two FTIR systems, each with its own cell and sampling system to perform

simultaneous spiked and unspiked measurements. The optical configurations shall

be similar, if possible. The sampling configurations shall be the same. One

sampling system and FTIR analyzer shall be used to measure spiked effluent. The

other sampling system and FTIR analyzer shall be used to measure unspiked flue

gas. Both systems shall use the same sampling procedure (i.e., batch or

continuous).

13.3.1 If batch sampling

is used, synchronize the cell evacuation, cell filling, and collection of

spectra. Fill both cells at the same rate (in cell volumes per unit time).

13.3.2 If continuous

sampling is used, adjust the sample flow through each gas cell so that the same

number of cell volumes pass through each cell in a given time (i.e. TC1 = TC2).

13.4 Statistical Treatment.

The statistical procedure

of EPA Method 301 of this appendix, section 6.3 is used to evaluate the bias

and precision. For FTIR testing a validation "run" is defined as

spectra of 24 independent samples, 12 of which are spiked with the analyte(s)

and 12 of which are not spiked.

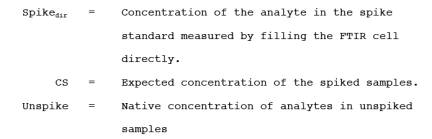

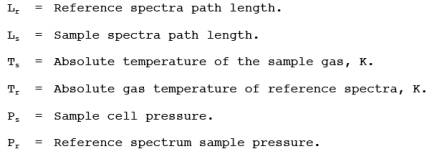

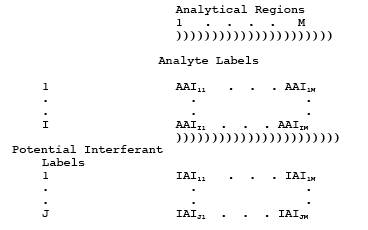

13.4.1 Bias. Determine the

bias (defined by EPA Method 301 of this appendix, section 6.3.2) using equation

7:

![]()

where:

13.4.2 Correction Factor.

Use section 6.3.2.2 of Method 301 of this appendix to evaluate the statistical

significance of the bias. If it is determined that the bias is significant,

then use section 6.3.3 of Method 301 to calculate a correction factor (CF).

Analytical results of the test method are multiplied by the correction factor,

if 0.7 < CF < 1.3. If is determined that the bias is

significant and CF > ± 30 percent, then the test method is considered to

"not valid."

13.4.3 If measurements do

not pass validation, evaluate the sampling system, instrument configuration,

and analytical system to determine if improper set-up or a malfunction was the

cause. If so, repair the system and repeat the validation.

14.0 Pollution Prevention.

The extracted sample gas

is vented outside the enclosure containing the FTIR system and gas manifold

after the analysis. In typical method applications the vented sample volume is

a small fraction of the source volumetric flow and its composition is identical

to that emitted from the source. When analyte spiking is used, spiked

pollutants are vented with the extracted sample gas. Approximately 1.6 x 10-4 to 3.2 x 10-4 lbs of a single HAP may be vented to the atmosphere

in a typical validation run of 3 hours. (This assumes a molar mass of 50 to 100

g, spike rate of 1.0 L/min, and a standard concentration of 100 ppm). Minimize

emissions by keeping the spike flow off when not in use.

15.0 Waste Management.

Small volumes of

laboratory gas standards can be vented through a laboratory hood. Neat samples

must be packed and disposed according to applicable regulations. Surplus

materials may be returned to supplier for disposal.

16.0 References.

1. "Field Validation

Test Using Fourier Transform Infrared (FTIR) Spectrometry To Measure

Formaldehyde, Phenol and Methanol at a Wool Fiberglass Production

Facility." Draft. U.S. Environmental Protection Agency Report, EPA

Contract No. 68D20163, Work Assignment I-32, September 1994.

2. "FTIR Method

Validation at a Coal-Fired Boiler". Prepared for U.S. Environmental

Protection Agency, Research Triangle Park, NC. Publication No.:

EPA-454/R95-004, NTIS No.: PB95-193199. July, 1993.

3. "Method 301 -

Field Validation of Pollutant Measurement Methods from Various Waste

Media," 40 CFR part 63, appendix A.

4. "Molecular

Vibrations; The Theory of Infrared and Raman Vibrational Spectra," E.

Bright Wilson, J. C. Decius, and P. C. Cross, Dover Publications, Inc., 1980.

For a less intensive treatment of molecular rotational-vibrational spectra see,

for example, "Physical Chemistry," G. M. Barrow, chapters 12, 13, and

14, McGraw Hill, Inc., 1979.

5. "Fourier Transform

Infrared Spectrometry," Peter R. Griffiths and James de Haseth, Chemical

Analysis, 83, 16-25,(1986), P. J. Elving, J. D. Winefordner and

I. M. Kolthoff (ed.), John Wiley and Sons.

6. "Computer-Assisted

Quantitative Infrared Spectroscopy," Gregory L. McClure (ed.), ASTM

Special Publication 934 (ASTM),

1987.

7. "Multivariate

Least-Squares Methods Applied to the Quantitative Spectral Analysis of

Multicomponent Mixtures," Applied Spectroscopy, 39(10),

73-84, 1985.

Table 1. EXAMPLE

PRESENTATION OF SAMPLING DOCUMENTATION.

Figure 1. Extractive

FTIR sampling system.

Figure 2. Fractional Reproducibility. Top: average of cts1031a and cts1101b. Bottom: Reference spectrum of p-xylene.

ADDENDUM TO TEST METHOD

320 PROTOCOL FOR THE USE OF EXTRACTIVE FOURIER TRANSFORM INFRARED (FTIR)

SPECTROMETRY FOR THE ANALYSES OF GASEOUS EMISSIONS FROM STATIONARY SOURCES

1.0 INTRODUCTION

The purpose of this

addendum is to set general guidelines for the use of modern FTIR spectroscopic

methods for the analysis of gas samples extracted from the effluent of

stationary emission sources. This addendum outlines techniques for developing

and evaluating such methods and sets basic requirements for reporting and

quality assurance procedures.

1.1 NOMENCLATURE

1.1.1 Appendix A to this

addendum lists definitions of the symbols and terms used in this Protocol, many

of which have been taken directly from American Society for Testing and

Materials (ASTM) publication E 131-90a, entitled "Terminology Relating to

Molecular Spectroscopy."

1.1.2 Except in the case

of background spectra or where otherwise noted, the term "spectrum"

refers to a double-beam spectrum in units of absorbance vs. wavenumber (cm-1).

1.1.3 The term

"Study" in this addendum refers to a publication that has been

subjected to EPA- or peer-review.

2.0 APPLICABILITY AND ANALYTICAL PRINCIPLE

2.1 Applicability.

This Protocol applies to

the determination of compound-specific concentrations in single and

multiple-component gas phase samples using double-beam absorption spectroscopy

in the mid-infrared band. It does not specifically address other FTIR

applications, such as single-beam spectroscopy, analysis of open-path

(non-enclosed) samples, and continuous measurement techniques. If multiple

spectrometers, absorption cells, or instrumental linewidths are used in such

analyses, each distinct operational configuration of the system must be

evaluated separately according to this Protocol.

2.2 Analytical Principle.

2.2.1 In the mid-infrared

band, most molecules exhibit characteristic gas phase absorption spectra that

may be recorded by FTIR systems. Such systems consist of a source of

mid-infrared radiation, an interferometer, an enclosed sample cell of known

absorption pathlength, an infrared detector, optical elements for the transfer

of infrared radiation between components, and gas flow control and measurement

components. Adjunct and integral computer systems are used for controlling the

instrument, processing the signal, and for performing both Fourier transforms

and quantitative analyses of spectral data.

2.2.2 The absorption

spectra of pure gases and of mixtures of gases are described by a linear

absorbance theory referred to as Beer's Law. Using this law, modern FTIR

systems use computerized analytical programs to quantify compounds by comparing

the absorption spectra of known (reference) gas samples to the absorption

spectrum of the sample gas. Some standard mathematical techniques used for

comparisons are classical least squares, inverse least squares,

cross-correlation, factor analysis, and partial least squares. Reference A

describes several of these techniques, as well as additional techniques, such

as differentiation methods, linear baseline corrections, and

non-linear absorbance

corrections.

3.0 GENERAL PRINCIPLES OF PROTOCOL REQUIREMENTS

The characteristics that

distinguish FTIR systems from gas analyzers used in instrumental gas analysis

methods (e.g., Methods 6C and 7E of appendix A to part 60 of this chapter) are:

(1) Computers are necessary to obtain and analyze data; (2) chemical

concentrations can be quantified using previously recorded infrared reference

spectra; and (3) analytical assumptions and results, including possible effects

of interfering compounds, can be evaluated after the quantitative analysis. The

following general principles and requirements of this Protocol are based on

these characteristics.

3.1 Verifiability and Reproducibility of Results.

Store all data and

document data analysis techniques sufficient to allow an independent agent to

reproduce the analytical results from the raw interferometric data.

3.2 Transfer of Reference Spectra.

To determine whether

reference spectra recorded under one set of conditions (e.g., optical bench, instrumental

line-width, absorption pathlength, detector performance, pressure, and

temperature) can be used to analyze sample spectra taken under a different set

of conditions, quantitatively compare "calibration transfer

standards" (CTS) and reference spectra as described in this Protocol.

(Note: The CTS may, but need not, include analytes of interest). To effect

this, record the absorption spectra of the CTS (a) immediately before and

immediately after recording reference spectra and (b) immediately after

recording sample spectra.

3.3 Evaluation of FTIR Analyses.

The applicability,

accuracy, and precision of FTIR measurements are influenced by a number of

interrelated factors, which may be divided into two classes:

3.3.1 Sample-Independent Factors.

Examples are system

configuration and performance (e.g., detector sensitivity and infrared source

output), quality and applicability of reference absorption spectra, and type of

mathematical analyses of the spectra. These factors define the fundamental limitations

of FTIR measurements for a given system configuration. These limitations may be

estimated from evaluations of the system before samples are available. For

example, the detection limit for the absorbing compound under a given set of

conditions may be estimated from the system noise level and the strength of a

particular absorption band. Similarly, the accuracy of measurements may be

estimated from the analysis of the reference spectra.

3.3.2 Sample-Dependent Factors.

Examples are spectral

interferants (e.g., water vapor and CO2) or the overlap of

spectral features of different compounds and contamination deposits on

reflective surfaces or transmitting windows. To maximize the effectiveness of

the mathematical techniques used in spectral analysis, identification of

interferants (a standard initial step) and analysis of samples (includes effect

of other analytical errors) are necessary. Thus, the Protocol requires

post-analysis calculation of measurement concentration uncertainties for the

detection of these potential sources of measurement error.

4.0 PRE-TEST PREPARATIONS AND EVALUATIONS

Before testing,

demonstrate the suitability of FTIR spectrometry for the desired application

according to the procedures of this section.

4.1 Identify Test Requirements.

Identify and record the

test requirements described in sections 4.1.1 through 4.1.4 of this addendum.

These values set the desired or required goals of the proposed analysis; the

description of methods for determining whether these goals are actually met

during the analysis comprises the majority of this Protocol.

4.1.1 Analytes (specific

chemical species) of interest. Label the analytes from i = 1 to I.

4.1.2 Analytical

uncertainty limit (AUi). The AUi is the maximum

permissible fractional uncertainty of analysis for the ith analyte concentration, expressed as a fraction of the analyte

concentration in the sample.

4.1.3 Required detection

limit for each analyte (DLi, ppm). The detection limit is the lowest

concentration of an analyte for which its overall fractional uncertainty (OFUi) is required to be less than its analytical uncertainty limit (AUi).

4.1.4 Maximum expected

concentration of each analyte (CMAXi, ppm).

4.2 Identify Potential Interferants.

Considering the chemistry

of the process or results of previous studies, identify potential interferants,

i.e., the major effluent constituents and any relatively minor effluent

constituents that possess either strong absorption characteristics or strong

structural similarities to any analyte of interest. Label them 1 through Nj, where the subscript "j" pertains to potential interferants.

Estimate the concentrations of these compounds in the effluent (CPOTj, ppm).

4.3 Select and Evaluate the Sampling System.

Considering the source,

e.g., temperature and pressure profiles, moisture content, analyte

characteristics, and particulate concentration), select the equipment for

extracting gas samples. Recommended are a particulate filter, heating system to

maintain sample temperature above the dew point for all sample constituents at

all points within the sampling system (including the filter), and sample

conditioning system (e.g., coolers, water-permeable membranes that remove water

or other compounds from the sample, and dilution devices) to remove spectral

interferants or to protect the sampling and analytical components. Determine

the minimum absolute sample system pressure (Pmin, mmHg) and

the infrared absorption cell volume (VSS, liter). Select

the techniques and/or equipment for the measurement of sample pressures and

temperatures.

4.4 Select Spectroscopic System.

Select a spectroscopic

configuration for the application. Approximate the absorption pathlength (LS', meter), sample pressure (PS', kPa), absolute

sample temperature TS', and signal integration period (tSS, seconds) for the analysis. Specify the nominal minimum instrumental

linewidth (MIL) of the system. Verify that the fractional error at the

approximate values PS' and TS' is less than one

half the smallest value AUi

(see section 4.1.2 of this addendum).

4.5 Select Calibration Transfer Standards (CTS's).

Select CTS's that meet the

criteria listed in sections 4.5.1, 4.5.2, and 4.5.3 of this addendum.

Note: It may be necessary

to choose preliminary analytical regions (see section 4.7 of this addendum),

identify the minimum analyte line-widths, or estimate the system noise level

(see section 4.12 of this addendum) before selecting the CTS. More than one

compound may be needed to meet the criteria; if so, obtain separate cylinders

for each compound.

4.5.1 The central

wavenumber position of each analytical region shall lie within 25 percent of

the wavenumber position of at least one CTS absorption band.

4.5.2 The absorption bands

in section 4.5.1 of this addendum shall exhibit peak absorbances greater than

ten times the value RMSEST

(see section 4.12 of this addendum) but

less than 1.5 absorbance units.

4.5.3 At least one

absorption CTS band within the operating range of the FTIR instrument shall

have an instrument-independent line-width no greater than the narrowest analyte

absorption band. Perform and document measurements or cite Studies to determine

analyte and CTS compound line-widths.

4.5.4 For each analytical

region, specify the upper and lower wavenumber positions (FFUm and FFLm, respectively) that bracket the CTS absorption band

or bands for the associated analytical region. Specify the wavenumber range,

FNU to FNL, containing the absorption band that meets the criterion of section

4.5.3 of this addendum.

4.5.5 Associate, whenever

possible, a single set of CTS gas cylinders with a set of reference spectra.

Replacement CTS gas cylinders shall contain the same compounds at

concentrations within 5 percent of that of the original CTS cylinders; the

entire absorption spectra (not individual spectral segments) of the replacement

gas shall be scaled by a factor between 0.95 and 1.05 to match the original CTS

spectra.

4.6 Prepare Reference Spectra.

Note: Reference spectra