METHOD

303A-DETERMINATION OF VISIBLE EMISSIONS FROM

NONRECOVERY COKE

OVEN BATTERIES

NOTE: This method does not include all of the

specifications pertaining to observer certification. Some material is

incorporated by reference from other methods in this part and in appendix A to

40 CFR Part 60. Therefore, to obtain reliable results, persons using this

method should have a thorough knowledge of Method 9 and Method 303.

3.4 Nonrecovery coke

oven battery

6.0 Equipment and

Supplies. [Reserved]

7.0 Reagents and

Standards. [Reserved]

8.0 Sample Collection,

Preservation, Transport, and Storage. [Reserved]

9.0 Quality Control.

[Reserved]

10.0 Calibration and

Standardization.

12.0 Data Analysis and

Calculations.

13.0 Method

Performance. [Reserved]

14.0 Pollution

Prevention. [Reserved]

15.0 Waste Management.

[Reserved]

17.0 Tables, Diagrams,

Flowcharts, and Validation Data.

1.0 Scope and Application.

1.1 Applicability.

This method is applicable for the determination of visible emissions (VE) from

leaking doors at nonrecovery coke oven batteries.

2.0 Summary of Method.

2.1 A certified

observer visually determines the VE from coke oven battery sources while

walking at a normal pace. This method does not require that opacity of

emissions be determined or that magnitude be differentiated.

3.0 Definitions.

3.1 Bench

Means the platform

structure in front of the oven doors.

3.2 Coke oven door

Means each end

enclosure on the push side and the coking side of an oven.

3.3 Coke side

Means the side of a

battery from which the coke is discharged from ovens at the end of the coking

cycle.

3.4 Nonrecovery coke oven battery

Means a source

consisting of a group of ovens connected by common walls and operated as a

unit, where coal undergoes destructive distillation under negative pressure to

produce coke, and which is designed for the combustion of coke oven gas from

which by-products are not recovered.

3.5 Operating oven

Means any oven not

out of operation for rebuild or maintenance work extensive enough to require

the oven to be skipped in the charging sequence.

3.6 Oven

Means a chamber in

the coke oven battery in which coal undergoes destructive distillation to

produce coke.

3.7 Push side

Means the side of the

battery from which the coke is pushed from ovens at the end of the coking

cycle.

3.8 Run

Means the observation

of visible emissions from coke oven doors in accordance with this method.

3.9 Shed

Means an enclosure

that covers the side of the coke oven battery, captures emissions from pushing

operations and from leaking coke oven doors on the coke side or push side of

the coke oven battery, and routes the emissions to a control device or system.

3.10 Traverse time

Means accumulated

time for a traverse as measured by a stopwatch. Traverse time includes time to stop and write down oven

numbers but excludes time waiting for obstructions of view to clear or for time

to walk around obstacles.

3.11 Visible Emissions or VE

Means any emission

seen by the unaided (except for corrective lenses) eye, excluding steam or

condensing water.

4.0 Interferences. [Reserved]

5.0 Safety.

5.1 Disclaimer.

This method may

involve hazardous materials, operations, and equipment. This test method may

not address all of the safety problems associated with its use. It is the

responsibility of the user of this test method to establish appropriate safety

and health practices and determine the applicability of regulatory limitations

prior to performing this test method.

5.2 Safety Training.

Because coke oven

batteries have hazardous environments, the training materials and the field

training (Section 10.0) shall cover the precautions required by the company to

address health and safety hazards. Special emphasis shall be given to the

Occupational Safety and Health Administration (OSHA) regulations pertaining to

exposure of coke oven workers (see Reference 3 in Section 16.0). In general,

the regulation requires that special fire-retardant clothing and respirators be worn in certain

restricted areas of the coke oven battery. The OSHA regulation also prohibits

certain activities, such as chewing gum, smoking, and eating in these areas.

6.0 Equipment and Supplies. [Reserved]

7.0 Reagents and Standards. [Reserved]

8.0 Sample Collection, Preservation, Transport, and Storage. [Reserved]

9.0 Quality Control. [Reserved]

10.0 Calibration and Standardization.

10.1 Training.

This method requires

only the determination of whether VE occur and does not require the

determination of opacity levels; therefore, observer certification according to

Method 9 in Appendix A to Part 60 is not required. However, the first-time

observer (trainee) shall have attended the lecture portion of the Method 9

certification course. Furthermore, before conducting any VE observations, an

observer shall become familiar with nonrecovery coke oven battery operations

and with this test method by observing for a minimum of 4 hours the operation

of a nonrecovery coke oven battery in the presence of personnel experienced in

performing Method 303 assessments.

11.0 Procedure.

The intent of this

procedure is to determine VE from coke oven door areas by carefully observing

the door area while walking at a normal pace.

11.1 Number of Runs.

Refer to ¤

63.309(c)(1) of this part for the appropriate number of runs.

11.2 Battery Traverse.

To conduct a battery

traverse, walk the length of the battery on the outside of the pusher machine

and quench car tracks at a steady, normal walking pace, pausing to make

appropriate entries on the door area inspection sheet (Figure 303A-1). The

walking pace shall be such that the duration of the traverse does not exceed an

average of 4 seconds per oven door, excluding time spent moving around

stationary obstructions or waiting for other obstructions to move from

positions blocking the view of a series of doors. Extra time is allowed for

each leak (a maximum of 10 additional seconds for each leaking door) for the

observer to make the proper notation. A walking pace of 3 seconds per oven door

has been found to be typical. Record the actual traverse time with a stopwatch.

A single test run consists of two timed traverses, one for the coke side and

one for the push side.

11.2.1 Various

situations may arise that will prevent the observer from viewing a door or a

series of doors. The observer has two options for dealing with obstructions to

view: (a) wait for the equipment to move or the fugitive emissions to dissipate

before completing the traverse; or (b) skip the affected ovens and move to an

unobstructed position to continue the traverse. Continue the traverse. After

the completion of the traverse, if the equipment has

moved or the fugitive

emissions have dissipated, complete the traverse by inspecting the affected

doors. Record the oven numbers and make an appropriate notation under

"Comments" on the door area inspection sheet (Figure 303A-1).

NOTE: Extra time incurred for handling obstructions is

not counted in the traverse time.

11.2.2 When batteries

have sheds to control pushing emissions, conduct the inspection from outside

the shed, if the shed allows such observations, or from the bench. Be aware of

special safety considerations pertinent to walking on the bench and follow the

instructions of company personnel on the required equipment and operations

procedures. If possible, conduct the bench traverse whenever the bench is clear

of the door machine and hot coke guide.

11.3 Observations.

Record all the

information requested at the top of the door area inspection sheet (Figure

303A-1), including the number of non-operating ovens. Record which side is

being inspected, i.e., coke

side or push side. Other information may be recorded at the discretion of the

observer, such as the location of the leak (e.g., top of the door), the reason for any

interruption of the traverse, or the position of the sun relative to the

battery and sky conditions (e.g.,

overcast, partly sunny, etc.).

11.3.1 Begin the test

run by traversing either the coke side or the push side of the battery. After

completing one side, traverse the other side.

11.3.2 During the

traverse, look around the entire perimeter of each oven door. The door is

considered leaking if VE are detected in the coke oven door area. The coke oven

door area includes the entire area on the vertical face of a coke oven between

the bench and the top of the battery and the adjacent doors on both sides.

Record the oven number and make the appropriate notation on the door area

inspection sheet (Figure 303A-1).

11.3.3 Do not record

the following sources as door area VE:

11.3.3.1 VE from

ovens with doors removed. Record the oven number and make an appropriate

notation under "Comments";

11.3.3.2 VE from

ovens where maintenance work is being conducted. Record the oven number and

make an appropriate notation under "Comments"; or

11.3.3.3 VE from hot

coke that has been spilled on the bench as a result of pushing.

12.0 Data Analysis and Calculations.

Same as Method 303,

Section 12.1, 12.2, 12.3, 12.4, and 12.5.

13.0 Method Performance. [Reserved]

14.0 Pollution Prevention. [Reserved]

15.0 Waste Management. [Reserved]

16.0 References.

Same as Method 303,

Section 16.0.

17.0 Tables, Diagrams, Flowcharts, and Validation Data.

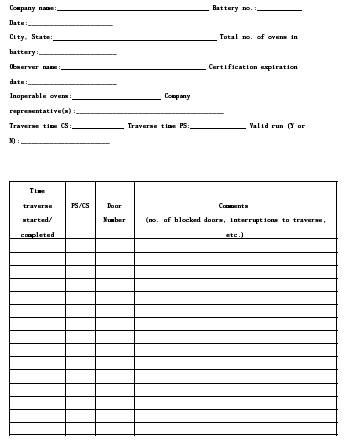

Figure 303A-1.

Door Area Inspection.