METHOD

303-DETERMINATION OF VISIBLE EMISSIONS FROM

BY-PRODUCT COKE

OVEN BATTERIES

NOTE: This method is not inclusive with respect to

observer certification. Some material is incorporated by reference from other

methods in appendix A to 40 CFR part 60. Therefore, to obtain reliable results,

persons using this method should have a thorough knowledge of Method 9.

3.2 By-product Coke

Oven Battery

6.0 Equipment and

Supplies. [Reserved]

7.0 Reagents and

Standards. [Reserved]

8.0 Sample Collection,

Preservation, Transport, and Storage. [Reserved]

9.0 Quality Control.

[Reserved]

10.0 Calibration and

Standardization.

10.1 Certification

Procedures.

10.2 Observer

Certification/Recertification.

11.1 Procedure for

Determining VE from Charging Systems During Charging.

11.1.1 Number of Oven

Charges.

11.1.8 Determination of

Validity of a Set of Observations.

11.2. Procedure for

Determining VE from Coke Oven Door Areas.

11.2.4 Criteria for

Acceptance.

11.3 Procedure for

Determining VE from Topside Port Lids and Off-take Systems.

11.3.3 Topside Port Lid

Observations.

11.3.4 Off-take Systems

Observations.

11.3.5 Criteria for

Acceptance.

11.3.6 Determining

Leakage Percent

11.3.7 Percent Leaking

Topside Port Lids and Off-take Systems.

11.4 Procedure for

Determining VE from Collecting Mains.

11.4.3 Collecting Main

Pressure Check.

12.0 Data Analysis and

Calculations.

12.2 Criteria for

Acceptance for VE Determinations from Coke Oven Door Areas.

12.3 Criteria for

Acceptance for VE Determinations from Topside Port Lids and Off-take Systems.

12.4 Average Duration

of VE from Charging Operations.

12.5 Percent Leaking

Doors (PLD).

13.0 Method

Performance. [Reserved]

14.0 Pollution

Prevention. [Reserved]

15.0 Waste Management.

[Reserved]

17.0 Tables, Diagrams,

Flowcharts, and Validation Data.

1.0 Scope and Application.

1.1 Applicability.

This method is applicable for the determination of visible emissions (VE) from

the following by-product coke oven battery sources: charging systems during

charging; doors, topside port lids, and off-take systems on operating coke

ovens; and collecting mains. This method is also applicable for qualifying

observers for visually determining the presence of VE.

2.0 Summary of Method.

2.1 A certified

observer visually determines the VE from coke oven battery sources.

Certification procedures are presented. This method does not require that

opacity of emissions be determined or that magnitude be differentiated.

3.0 Definitions.

3.1 Bench

Means the platform

structure in front of the oven doors.

3.2 By-product Coke Oven Battery

Means a source

consisting of a group of ovens connected by common walls, where coal undergoes

destructive distillation under positive pressure to produce coke and coke oven

gas, from which byproducts are recovered.

3.3 Charge or charging period

Means the period of

time that commences when coal begins to flow into an oven through a topside

port and ends when the last charging port is recapped.

3.4 Charging system

Means an apparatus

used to charge coal to a coke oven (e.g., a larry car for wet coal charging systems).

3.5 Coke oven door

Means each end

enclosure on the push side and the coking side of an oven. The chuck, or

leveler-bar, door is considered part of the push side door. The coke oven door

area includes the entire area on the vertical face of a coke oven between the

bench and the top of the battery between two adjacent buck stays.

3.6 Coke side

Means the side of a

battery from which the coke is discharged from ovens at the end of the coking

cycle.

3.7 Collecting main

Means any apparatus

that is connected to one or more off-take systems and that provides a passage

for conveying gases under positive pressure from the by-product coke oven

battery to the by-product recovery system.

3.8 Consecutive charges

Means charges

observed successively, excluding any charge during which the observer's view of

the charging system or topside ports is obscured.

3.9 Damper-off

Means to close off

the gas passage between the coke oven and the collecting main, with no flow of

raw coke oven gas from the collecting main into the oven or into the oven's

off-take system(s).

3.10 Decarbonization period

Means the period of

time for combusting oven carbon that commences when the oven lids are removed

from an empty oven or when standpipe caps of an oven are opened. The period

ends with the initiation of the next charging period for that oven.

3.11 Larry car

Means an apparatus

used to charge coal to a coke oven with a wet coal charging system.

3.12 Log average

Means logarithmic

average as calculated in Section 12.4.

3.13 Off-take system

Means any individual

oven apparatus that is stationary and provides a passage for gases from an oven

to a coke oven battery collecting main or to another oven. Off-take system

components include the standpipe and standpipe caps, goosenecks, stationary

jumper pipes, mini-standpipes, and standpipe and gooseneck connections.

3.14 Operating oven

Means any oven not

out of operation for rebuild or maintenance work extensive enough to require

the oven to be skipped in the charging sequence.

3.15 Oven

Means a chamber in

the coke oven battery in which coal undergoes destructive distillation to

produce coke.

3.16 Push side

Means the side of the

battery from which the coke is pushed from ovens at the end of the coking

cycle.

3.17 Run

Means the observation

of visible emissions from topside port lids, off-take systems, coke oven doors,

or the charging of a single oven in accordance with this method.

3.18 Shed

Means an enclosure

that covers the side of the coke oven battery, captures emissions from pushing

operations and from leaking coke oven doors on the coke side or push side of

the coke oven battery, and routes the emissions to a control device or system.

3.19 Standpipe cap

Means An apparatus

used to cover the opening in the gooseneck of an off-take system.

3.20 Topside port lid

Means a cover,

removed during charging or decarbonizing, that is placed over the opening

through which coal can be charged into the oven of a byproduct coke oven

battery.

3.21 Traverse time

Means accumulated

time for a traverse as measured by a stopwatch. Traverse time includes time to

stop and write down oven numbers but excludes time waiting for obstructions of

view to clear or for time to walk around obstacles.

3.22 Visible Emissions or VE

Means any emission

seen by the unaided (except for corrective lenses) eye, excluding steam or

condensing water.

4.0 Interferences. [Reserved]

5.0 Safety.

5.1 Disclaimer.

This method may

involve hazardous materials, operations, and equipment. This test method may

not address all of the safety problems associated with its use. It is the

responsibility of the user of this test method to establish appropriate safety

and health practices and determine the applicability of regulatory limitations

prior to performing

this test method.

5.2 Safety Training.

Because coke oven

batteries have hazardous environments, the training materials and the field

training (Section 10.0) shall cover the precautions required by the company to

address health and safety hazards. Special emphasis shall be given to the

Occupational Safety and Health Administration (OSHA) regulations pertaining to

exposure of coke oven workers (see Reference 3 in Section 16.0). In general,

the regulation requires that special fire-retardant clothing and respirators be

worn in certain restricted areas of the coke oven battery. The OSHA regulation

also prohibits certain activities, such as chewing gum, smoking, and eating in

these areas.

6.0 Equipment and Supplies. [Reserved]

7.0 Reagents and Standards. [Reserved]

8.0 Sample Collection, Preservation, Transport, and Storage. [Reserved]

9.0 Quality Control. [Reserved]

10.0 Calibration and Standardization.

Observer

certification and training requirements areas follows:

10.1 Certification Procedures.

This method requires

only the determination of whether VE occur and does not require the

determination of opacity levels; therefore, observer certification according to

Method 9 in appendix A to part 60 of this chapter is not required to obtain

certification under this method. However, in order to receive Method 303

observer certification, the first-time observer (trainee) shall have attended

the lecture portion of the Method 9 certification course. In addition, the

trainee shall successfully complete the Method 303 training course, satisfy the

field observation requirement, and demonstrate adequate performance and

sufficient knowledge of Method 303. The Method 303 training course shall be

conducted by or under the sanction of the EPA and shall consist of classroom

instruction and field observations, and a proficiency test.

10.1.1 The classroom

instruction shall familiarize the trainees with Method 303 through lecture,

written training materials, and a Method 303 demonstration video. A successful

completion of the classroom portion of the Method 303 training course shall be

demonstrated by a perfect score on a written test. If the trainee fails to

answer all of the questions correctly, the trainee may review the appropriate

portion of the training materials and retake the test.

10.1.2 The field

observations shall be a minimum of 12 hours and shall be completed before

attending the Method 303 certification course. Trainees shall observe the

operation of a coke oven battery as it pertains to Method 303, including

topside operations, and shall also practice conducting Method 303 or similar

methods. During the field observations, trainees unfamiliar with coke battery

operations shall receive instruction from an experienced coke oven observer familiar

with Method 303 or similar methods and with the operation of coke batteries.

The trainee must verify completion of at least 12 hours of field observation

prior to attending the Method 303 certification course.

10.1.3 All trainees

must demonstrate proficiency in the application of Method 303 to a panel of

three certified Method 303 observers, including an ability to differentiate

coke oven emissions from condensing water vapor and smoldering coal. Each panel

member shall have at least 120 days experience in reading visible emissions

from coke ovens. The visible emissions inspections that will satisfy the

experience requirement must be inspections of coke oven battery fugitive

emissions from the emission points subject to emission standards under subpart L

of this part (i.e., coke

oven doors, topside port lids, off-take system(s), and charging operations),

using either Method 303 or predecessor State or local test methods. A

"day's experience" for a particular inspection is a day on which one

complete inspection was performed for that emission point under Method 303 or a

predecessor State or local method. A "day's experience" does not mean

8 or 10 hours performing inspections, or any particular time expressed in

minutes or hours that may have been spent performing them. Thus, it would be

possible for an individual to qualify as a Method 303 panel member for some

emission points, but not others (e.g., an individual might satisfy the experience requirement for coke

oven doors, but not topside port lids).

Until November 15,

1994, the EPA may waive the certification requirement (but not the experience

requirement) for panel members. The composition of the panel shall be approved

by the EPA. The panel shall observe the trainee in a series of training runs

and a series of certification runs. There shall be a minimum of 1 training run

for doors, topside port lids, and off-take systems, and a minimum of 5 training

runs (i.e., 5 charges) for

charging. During training runs, the panel can advise the trainee on proper procedures.

There shall be a minimum of 3 certification runs for doors, topside port lids,

and off-take systems, and a minimum of 15 certification runs for charging (i.e., 15 charges). The certifications runs shall be

unassisted. Following the certification test runs, the panel shall approve or

disapprove certification based on the trainee's performance during the

certification runs. To obtain certification, the trainee shall demonstrate to

the satisfaction of the panel a high degree of proficiency in performing Method

303. To aid in evaluating the trainee's performance, a checklist, provided by

the EPA, will be used by the panel members.

10.2 Observer Certification/Recertification.

The coke oven

observer certification is valid for 1 year from date of issue. The observer

shall recertify annually by viewing the training video and answering all of the

questions on the certification test correctly. Every 3 years, an observer shall

be required to pass the proficiency test in Section 10.1.3 in order to be

certified.

10.3 The EPA.

The EPA (or

applicable enforcement agency) shall maintain records reflecting a certified

observer's successful completion of the proficiency test, which shall include

the completed proficiency test checklists for the certification runs.

10.4 An owner or operator

An owner or operator

of a coke oven battery subject to subpart L of this part may observe a training

and certification program under this section.

11.0 Procedure.

11.1 Procedure for Determining VE from Charging Systems During Charging.

11.1.1 Number of Oven Charges.

Refer to ¤

63.309(c)(1) of this part for the number of oven charges to observe. The

observer shall observe consecutive charges. Charges that are nonconsecutive can

only be observed when necessary to replace observations terminated prior to the

completion of a charge because of visual interferences. (See Section 11.1.5).

11.1.2 Data Records.

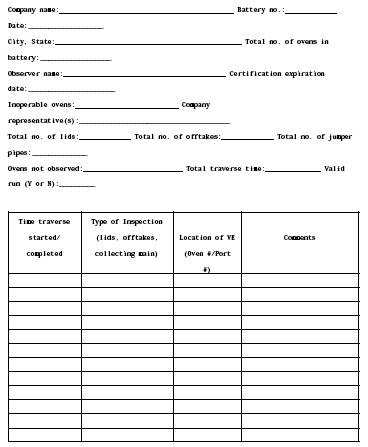

Record all the

information requested at the top of the charging system inspection sheet

(Figure 303-1). For each charge, record the identification number of the oven

being charged, the approximate beginning time of the charge, and the

identification of the larry car used for the charge.

11.1.3 Observer Position.

Stand in an area or

move to positions on the topside of the coke oven battery with an unobstructed

view of the entire charging system. For wet coal charging systems or

non-pipeline coal charging systems, the observer should have an unobstructed

view of the emission points of the charging system, including larry car hoppers,

drop sleeves, and the topside ports of the oven being charged. Some charging

systems are configured so that all emission points can only be seen from a

distance of five ovens. For other batteries, distances of 8 to 12 ovens are

adequate.

11.1.4 Observation.

The charging period

begins when coal begins to flow into the oven and ends when the last charging

port is recapped. During the charging period, observe all of the potential

sources of VE from the entire charging system. For wet coal charging systems or

non-pipeline coal charging systems, sources of VE typically include the larry

car hoppers, drop sleeves, slide gates, and topside ports on the oven being

charged. Any VE from an open standpipe cap on the oven being charged is

included as charging VE.

11.1.4.1 Using an

accumulative-type stopwatch with unit divisions of at least 0.5 seconds,

determine the total time VE are observed as follows. Upon observing any VE

emerging from any part of the charging system, start the stopwatch. Stop the

watch when VE are no longer observed emerging, and restart the watch when VE

reemerges.

11.1.4.2 When VE

occur simultaneously from several points during a charge, consider the sources

as one. Time overlapping VE as continuous VE. Time single puffs of VE only for

the time it takes for the puff to emerge from the charging system. Continue to

time VE in this manner for the entire charging period. Record the accumulated

time to the nearest 0.5 second under "Visible emissions, seconds" on

Figure 303-1.

11.1.5 Visual Interference.

If fugitive VE from

other sources at the coke oven battery site (e.g., door leaks or condensing water vapor from the

coke oven wharf) prevent a clear view of the charging system during a charge,

stop the stopwatch and make an appropriate notation under "Comments"

on Figure 303-1. Label the observation an observation of an incomplete charge,

and observe another charge to fulfill the requirements of Section 11.1.1.

11.1.6 VE Exemptions.

Do not time the

following VE:

11.1.6.1 The VE from

burning or smoldering coal spilled on top of the oven, topside port lid, or

larry car surfaces;

NOTE: The VE from smoldering coal are generally white

or gray. These VE generally have a plume of less than 1 meter long. If the

observer cannot safely and with reasonable confidence determine that VE are

from charging, do not count them as charging emissions.

11.1.6.2 The VE from

the coke oven doors or from the leveler bar; or

11.1.6.3 The VE that

drift from the top of a larry car hopper if the emissions had already been

timed as VE from the drop sleeve.

NOTE: When the slide gate on a larry car hopper closes

after the coal has been added to the oven, the seal may not be airtight. On

occasions, a puff of smoke observed at the drop sleeves is forced past the

slide gate up into the larry car hopper and may drift from the top; time these

VE either at the drop sleeves or the hopper. If the larry car hopper does not

have a slide gate or the slide gate is left open or partially closed, VE may

quickly pass through the larry car hopper without being observed at the drop

sleeves and will appear as a strong surge of smoke; time these as charging VE.

11.1.7 Total Time Record.

Record the total time

that VE were observed for each charging operation in the appropriate column on

the charging system inspection sheet.

11.1.8 Determination of Validity of a Set of Observations.

Five charging

observations (runs) obtained in accordance with this method shall be considered

a valid set of observations for that day. No observation of an incomplete

charge shall be included in a daily set of observations that is lower than the

lowest reading for a complete charge. If both complete and incomplete charges

have been observed, the daily set of observations shall include the five

highest values observed. Four or three charging observations (runs) obtained in

accordance with this method shall be considered a valid set of charging

observations only where it is not possible to obtain five charging

observations, because visual interferences (see Section 11.1.5) or inclement

weather prevent a clear view of the charging system during charging. However,

observations from three or four charges that satisfy these requirements shall

not be considered a valid set of charging observations if use of such set of observations

in a calculation under Section 12.4 would cause the value of A to be less than

145.

11.1.9 Log Average.

For each day on which

a valid daily set of observations is obtained, calculate the daily 30-day

rolling log average of seconds of visible emissions from the charging operation

for each battery using these data and the 29 previous valid daily sets of

observations, in accordance with Section 12.4.

11.2. Procedure for Determining VE from Coke Oven Door Areas.

The intent of this

procedure is to determine VE from coke oven door areas by carefully observing

the door area from a standard distance while walking at a normal pace.

11.2.1 Number of Runs.

Refer to ¤

63.309(c)(1) of this part for the appropriate number of runs.

11.2.2 Battery Traverse.

To conduct a battery

traverse, walk the length of the battery on the outside of the pusher machine

and quench car tracks at a steady, normal walking pace, pausing to make

appropriate entries on the door area inspection sheet (Figure 303-2). A single

test run consists of two timed traverses, one for the coke side and one for the

push side. The walking pace shall be such that the duration of the traverse

does not exceed an average of 4 seconds per oven door, excluding time spent

moving around stationary obstructions or waiting for other obstructions to move

from positions blocking the view of a series of doors. Extra time is allowed

for each leak (a maximum of 10 additional seconds for each leaking door) for

the observer to make the proper notation. A walking pace of 3 seconds per oven

door has been found to be typical. Record the actual traverse time with a

stopwatch.

11.2.2.1 Include in

the traverse time only the time spent observing the doors and recording door

leaks. To measure actual traverse time, use an accumulative-type stopwatch with

unit divisions of 0.5 seconds or less. Exclude interruptions to the traverse

and time required for the observer to move to positions where the view of the

battery is unobstructed, or for obstructions, such as the door machine, to move

from positions blocking the view of a series of doors.

11.2.2.2 Various

situations may arise that will prevent the observer from viewing a door or a

series of doors. Prior to the door inspection, the owner or operator may elect

to temporarily suspend charging operations for the duration of the inspection,

so that all of the doors can be viewed by the observer. The observer has two

options for dealing with obstructions to view: (a) stop the stopwatch and wait

for the equipment to move or the fugitive emissions to dissipate before

completing the traverse; or (b) stop the stopwatch, skip the affected ovens,

and move to an unobstructed position to continue the traverse. Restart the

stopwatch and continue the traverse. After the completion of the traverse, if

the equipment has moved or the fugitive emissions have dissipated, inspect the

affected doors. If the equipment is still preventing the observer from viewing

the doors, then the affected doors may be counted as not observed. If option

(b) is used because of doors blocked by machines during charging operations,

then, of the affected doors, exclude the door from the most recently charged

oven from the inspection. Record the oven numbers and make an appropriate

notation under "Comments" on the door area inspection sheet (Figure

303-2).

11.2.2.3 When

batteries have sheds to control emissions, conduct the inspection from outside

the shed unless the doors cannot be adequately viewed. In this case, conduct

the inspection from the bench. Be aware of special safety considerations

pertinent to walking on the bench and follow the instructions of company

personnel on the required equipment and procedures. If possible, conduct the

bench traverse whenever the bench is clear of the door machine and hot coke guide.

11.2.3 Observations.

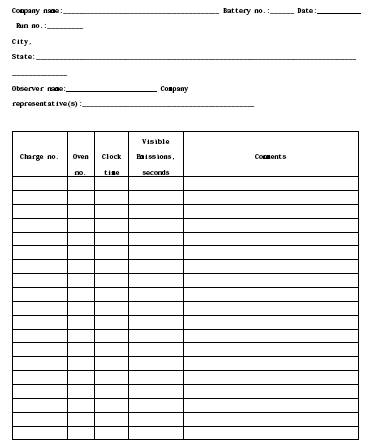

Record all the

information requested at the top of the door area inspection sheet (Figure

303-2), including the number of non-operating ovens. Record the clock time at

the start of the traverse on each side of the battery. Record which side is

being inspected (i.e., coke

side or push side). Other information may be recorded at the discretion of the

observer, such as the location of the leak (e.g., top of the door, chuck door, etc.), the reason

for any interruption of the traverse, or the position of the sun relative to

the battery and sky conditions (e.g., overcast, partly sunny, etc.).

11.2.3.1 Begin the

test run by starting the stopwatch and traversing either the coke side or the

push side of the battery. After completing one side, stop the watch. Complete

this procedure on the other side. If inspecting more than one battery, the

observer may view the push sides and the coke sides sequentially.

11.2.3.2 During the

traverse, look around the entire perimeter of each oven door. The door is

considered leaking if VE are detected in the coke oven door area. The coke oven

door area includes the entire area on the vertical face of a coke oven between

the bench and the top of the battery between two adjacent buck stays (e.g., the oven door, chuck door, between the masonry

brick, buck stay or jamb, or other sources). Record the oven number and make

the appropriate notation on the door area inspection sheet (Figure 303-2).

NOTE: Multiple VE from the same door area (e.g., VE from both the chuck door and the push side

door) are counted as only one emitting door, not as multiple emitting doors.

11.2.3.3 Do not

record the following sources as door area VE:

11.2.3.3.1 VE from

ovens with doors removed. Record the oven number and make an appropriate

notation under "Comments;"

11.2.3.3.2 VE from

ovens taken out of service. The owner or operator shall notify the observer as

to which ovens are out of service. Record the oven number and make an

appropriate notation under "Comments;" or

11.2.3.3.3 VE from

hot coke that has been spilled on the bench as a result of pushing.

11.2.4 Criteria for Acceptance.

After completing the

run, calculate the maximum time allowed to observe the ovens using the equation

in Section 12.2. If the total traverse time exceeds T, void the run, and

conduct another run to satisfy the requirements of ¤63.309(c)(1) of this part.

11.2.5 Percent Leaking Doors.

For each day on which

a valid observation is obtained, calculate the daily 30-day rolling average for

each battery using these data and the 29 previous valid daily observations, in

accordance with Section 12.5.

11.3 Procedure for Determining VE from Topside Port Lids and Off-take Systems.

11.3.1 Number of Runs.

Refer to ¤

63.309(c)(1) of this part for the number of runs to be conducted. Simultaneous

runs or separate runs for the topside port lids and off-take systems may be

conducted.

11.3.2 Battery Traverse.

To conduct a topside

traverse of the battery, walk the length of the battery at a steady, normal

walking pace, pausing only to make appropriate entries on the topside

inspection sheet (Figure 303-3). The walking pace shall not exceed an average

rate of 4 seconds per oven, excluding time spent moving around stationary

obstructions or waiting for other obstructions to move from positions blocking

the view. Extra time is allowed for each leak for the observer to make the

proper notation. A walking pace of 3 seconds per oven is typical. Record the

actual traverse time with a stopwatch.

11.3.3 Topside Port Lid Observations.

To observe lids of

the ovens involved in the charging operation, the observer shall wait to view

the lids until approximately 5 minutes after the completion of the charge.

Record all the information requested on the topside inspection sheet (Figure

303-3). Record the clock time when traverses begin and end. If the observer's

view is obstructed during the traverse (e.g., steam from the coke wharf, larry car, etc.),

follow the guidelines given in Section 11.2.2.2.

11.3.3.1 To perform a

test run, conduct a single traverse on the topside of the battery. The observer

shall walk near the center of the battery but may deviate from this path to

avoid safety hazards (such as open or closed charging ports, luting buckets,

lid removal bars, and topside port lids that have been removed) and any other

obstacles. Upon noting VE from the topside port lid(s) of an oven, record the

oven number and port number, then resume the traverse. If any oven is

dampered-off from the collecting main for decarbonization, note this under

"Comments" for that particular oven.

NOTE: Count the number of topside ports, not the

number of points, exhibiting VE, i.e., if a topside port has several points of VE, count this as one

port exhibiting VE.

11.3.3.2 Do not count

the following as topside port lid VE:

11.3.3.2.1 VE from

between the brickwork and oven lid casing or VE from cracks in the oven

brickwork. Note these VE under "Comments;"

11.3.3.2.2 VE from

topside ports involved in a charging operation. Record the oven number, and make

an appropriate notation (e.g.,

not observed because ports open for charging) under "Comments;"

11.3.3.2.3 Topside

ports having maintenance work done. Record the oven number and make an

appropriate notation under "Comments;" or

11.3.3.2.4 Condensing

water from wet-sealing material. Ports with only visible condensing water from

wet-sealing material are counted as observed but not as having VE.

11.3.3.2.5 Visible

emissions from the flue inspection ports and caps.

11.3.4 Off-take Systems Observations.

To perform a test

run, traverse the battery as in Section 11.3.3.1. Look ahead and back two to

four ovens to get a clear view of the entire off-take system for each oven.

Consider visible emissions from the following points as off-take system VE: (a)

the flange between the gooseneck and collecting main ("saddle"), (b)

the junction point of the standpipe and oven ("standpipe base"), (c)

the other parts of the off-take system (e.g., the standpipe cap), and (d) the junction

points with ovens and flanges of jumper pipes.

11.3.4.1 Do not stray

from the traverse line in order to get a "closer look" at any part of

the off-take system unless it is to distinguish leaks from interferences from

other sources or to avoid obstacles.

11.3.4.2 If the

centerline does not provide a clear view of the entire off-take system for each

oven (e.g., when standpipes

are longer than 15 feet), the observer may conduct the traverse farther from

(rather than closer to) the off-take systems.

11.3.4.3 Upon noting

a leak from an off-take system during a traverse, record the oven number.

Resume the traverse. If the oven is dampered-off from the collecting main for

decarbonization and VE are observed, note this under "Comments" for

that particular oven.

11.3.4.4 If any part

or parts of an off-take system have VE, count it as one emitting off-take

system. Each stationary jumper pipe is considered a single off-take system.

11.3.4.5 Do not count

standpipe caps open for a decarbonization period or standpipes of an oven being

charged as source of off-take system VE. Record the oven number and write

"Not observed" and the reason (i.e., decarb or charging) under

"Comments."

NOTE: VE from open standpipes of an oven being charged

count as charging emissions. All VE from closed standpipe caps count as

off-take leaks.

11.3.5 Criteria for Acceptance.

After completing the

run (allow 2 traverses for batteries with double mains), calculate the maximum

time allowed to observe the topside port lids and/or off-take systems using the

equation in Section 12.3. If the total traverse time exceeds T, void the run

and conduct another run to satisfy the requirements of ¤ 63.309(c)(1) of this

part.

11.3.6 Determining Leakage Percent

In determining the

percent leaking topside port lids and percent leaking off-take systems, do not

include topside port lids or off-take systems with VE from the following ovens:

11.3.6.1 Empty ovens,

including ovens undergoing maintenance, which are properly dampered off from

the main.

11.3.6.2 Ovens being

charged or being pushed.

11.3.6.3 Up to 3 full

ovens that have been dampered off from the main prior to pushing.

11.3.6.4 Up to 3

additional full ovens in the pushing sequence that have been dampered off from

the main for off-take system cleaning, for decarbonization, for safety reasons,

or when a charging/pushing schedule involves widely separated ovens (e.g., a Marquard system); or that have been dampered

off from the main for maintenance near the end of the coking cycle. Examples of

reasons that ovens are dampered off for safety reasons are to avoid exposing

workers in areas with insufficient clearance between standpipes and the larry

car, or in areas where workers could be exposed to flames or hot gases from

open standpipes, and to avoid the potential for removing a door on an oven that

is not dampered off from the main.

11.3.7 Percent Leaking Topside Port Lids and Off-take Systems.

For each day on which

a valid observation is obtained, calculate the daily 30-day rolling average for

each battery using these data and the 29 previous valid daily observations, in

accordance with Sections 12.6 and 12.7.

11.4 Procedure for Determining VE from Collecting Mains.

11.4.1 Traverse.

To perform a test

run, traverse both the collecting main catwalk and the battery topside along

the side closest to the collecting main. If the battery has a double main,

conduct two sets of traverses for each run, i.e., one set for each main.

11.4.2 Data Recording.

Upon noting VE from

any portion of a collection main, identify the source and approximate location

of the source of VE and record the time under "Collecting main" on

Figure 303-3; then resume the traverse.

11.4.3 Collecting Main Pressure Check.

After the completion

of the door traverse, the topside port lids, and off-take systems, compare the

collecting main pressure during the inspection to the collecting main pressure

during the previous 8 to 24 hours. Record the following: (a) the pressure

during inspection, (b) presence of pressure deviation from normal operations,

and (c) the explanation for any pressure deviation from normal operations, if

any, offered by the operators. The owner or operator of the coke battery shall

maintain the pressure recording equipment and conduct the quality

assurance/quality control (QA/QC) necessary to ensure reliable pressure

readings and shall keep the QA/QC records for at least 6 months. The observer

may periodically check the QA/QC records to determine their completeness. The

owner or operator shall provide access to the records within 1 hour of an

observer's request.

12.0 Data Analysis and Calculations.

12.1 Nomenclature.

A = 150 or the number

of valid observations (runs). The value of A shall not be less than 145, except

for purposes of determinations under ¤63.306(c) [work practice plan

implementation] or ¤63.306(d) [work practice plan revisions] of this part. No

set of observations shall be considered valid for such a recalculation that

otherwise would not be considered a valid set of observations for a calculation

under this paragraph.

Di = Number of doors on non-operating ovens.

Dno = Number of doors not observed.

Dob = Total number of doors observed on operating

ovens.

Dt = Total number of oven doors on the battery.

e = 2.72

J = Number of

stationary jumper pipes.

L = Number of doors

with VE.

Lb = Yard-equivalent reading.

Ls = Number of doors with VE observed from the bench under sheds.

Ly = Number of doors with VE observed from the yard.

Ly = Number of doors with VE observed from the yard on the push side.

ln = Natural

logarithm.

N = Total number of

ovens in the battery.

Ni = Total number of inoperable ovens.

PNO = Number of ports not observed.

Povn = Number of ports per oven.

PVE = Number of topside port lids with VE.

PLD = Percent leaking

coke oven doors for the test run.

PLL = Percent leaking

topside port lids for the run.

PLO = Percent leaking

off-take systems.

T = Total time

allowed for traverse, seconds.

Tovn = Number of off-take systems (excluding jumper

pipes) per oven.

TNO = Number of off-take systems not observed.

TVE = Number of off-take systems with VE.

Xi = Seconds of VE during the ith charge.

Z = Number of topside

port lids or off-take systems with VE.

12.2 Criteria for Acceptance for VE Determinations from Coke Oven Door Areas.

After completing the

run, calculate the maximum time allowed to observe the ovens using the

following equation:

![]()

12.3 Criteria for Acceptance for VE Determinations from Topside Port Lids and Off-take Systems.

After completing the

run (allow 2 traverses for batteries with double mains), calculate the maximum

time allowed to observe the topside port lids and/or off-take systems by the

following equation:

![]()

12.4 Average Duration of VE from Charging Operations.

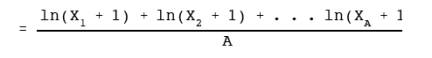

Use Equation 303

![]()

12.5 Percent Leaking Doors (PLD).

Determine the total

number of doors for which observations were made on the coke oven battery as

follows:

![]()

12.5.1 For each test

run (one run includes both the coke side and the push side traverses), sum the

number of doors with door area VE. For batteries subject to an approved

alternative standard under ¤ 63.305 of this part, calculate the push side and

the coke side PLD separately.

12.5.2 Calculate

percent leaking doors by using Equation 303-5:

12.5.3 When traverses

are conducted from the bench under sheds, calculate the coke side and the push

side separately. Use Equation 303-6 to calculate a yard-equivalent reading:

![]()

If Lb is less than zero, use zero for Lb in

Equation 303-7 in the calculation of PLD.

12.5.3.1 Use Equation

303-7 to calculate PLD:

Round off PLD to the

nearest hundredth of 1 percent and record as the percent leaking coke oven

doors for the run.

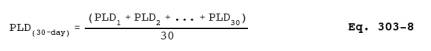

12.5.3.2 Average

Percent Leaking Doors. Use Equation 303-8 to calculate the daily 30-day rolling

average percent leaking doors for each battery using these current day's

observations and the 29 previous valid daily sets of observations.

12.6 Topside Port Lids.

Determine the percent

leaking topside port lids for each run as follows:

![]()

12.6.1 Round off this

percentage to the nearest hundredth of 1 percent and record this percentage as

the percent leaking topside port lids for the run.

12.6.2 Average

Percent Leaking Topside Port Lids. Use Equation 303-10 to calculate the daily

30-day rolling average percent leaking topside port lids for each battery using

these current day's observations and the 29 previous valid daily sets of

observations.

![]()

12.7 Off-take Systems.

Determine the percent

leaking off-take systems for the run as follows:

![]()

12.7.1 Round off this

percentage to the nearest hundredth of 1 percent and record this percentage as

the percent leaking off-take systems for the run.

12.7.2 Average

Percent Leaking Off-take Systems. Use Equation 303-12 to calculate the daily

30-day rolling average percent leaking off-take systems for each battery using

these current day's observations and the 29 previous valid daily sets of

observations.

![]()

13.0 Method Performance. [Reserved]

14.0 Pollution Prevention. [Reserved]

15.0 Waste Management. [Reserved]

16.0 References.

1. Missan, R., and A.

Stein. Guidelines for Evaluation of Visible Emissions Certification, Field

Procedures, Legal Aspects, and Background Material. U.S. Environmental

Protection Agency. EPA Publication No. EPA-340/1-75-007. April 1975.

2. Wohlschlegel, P.,

and D. E. Wagoner. Guideline for Development of a Quality Assurance Program:

Volume IX -Visual Determination of Opacity Emission from Stationary Sources.

U.S. Environmental Protection Agency. EPA Publication No. EPA-650/4-74-005i.

November 1975.

3. U.S. Occupational

Safety and Health Administration. Code of Federal Regulations. Title 29,

Chapter XVII, Section 1910.1029(g). Washington, D.C. Government Printing

Office. July 1, 1990.

4. U.S. Environmental

Protection Agency. National Emission Standards for Hazardous Air Pollutants;

Coke Oven Emissions from Wet-Coal Charged By-Product Coke Oven Batteries;

Proposed Rule and Notice of Public Hearing. Washington, D.C. Federal Register.

Vol. 52, No. 78 (13586). April 23, 1987.

17.0 Tables, Diagrams, Flowcharts, and Validation Data.

Figure 303-1.

Charging System Inspection.

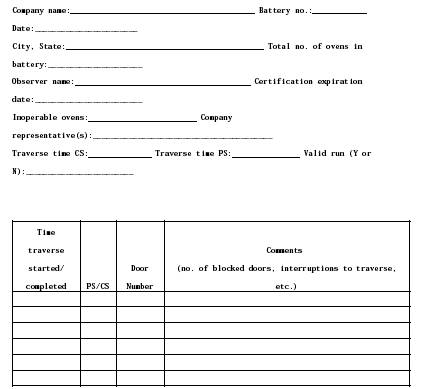

Figure 303-2. Door

Area Inspection.

Figure 303-3.

Topside Inspection.