METHOD

13B - DETERMINATION OF TOTAL FLUORIDE EMISSIONS FROM STATIONARY SOURCES

(SPECIFIC ION ELECTRODE METHOD)

NOTE: This method does not include all of the

specifications (e.g.,

equipment and supplies) and procedures (e.g., sampling and analytical) essential to its

performance. Some material is incorporated by reference from other methods in

this part. Therefore, to obtain reliable results, persons using this method

should have a thorough knowledge of at least the following additional test

methods: Method 1, Method 2,

Method 3, Method 5, and

Method 13A.

6.1 Sample Collection

and Sample Recovery.

6.2 Sample Preparation

and Analysis.

7.1 Sample Collection

and Sample Recovery.

7.2 Sample Preparation

and Analysis.

8.0 Sample Collection,

Preservation, Storage, and Transport.

10.0 Calibration and

Standardizations.

11.1 Sample Loss Check,

Sample Preparation, and Distillation.

12.0 Data Analysis and

Calculations.

14.0 Pollution

Prevention. [Reserved]

15.0 Waste Management.

[Reserved]

18.0 Tables, Diagrams, Flowcharts, and Validation Data [Reserved]

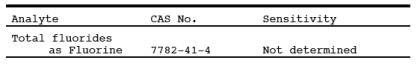

1.0 Scope and Application.

1.1 Analytes.

1.2 Applicability.

This method is

applicable for the determination of fluoride (F-)

emissions from sources as specified in the regulations. It does not measure

fluorocarbons, such as Freons.

1.3 Data Quality Objectives.

Adherence to the

requirements of this method will enhance the quality of the data obtained from

air pollutant sampling methods.

2.0 Summary.

Gaseous and

particulate F- are withdrawn isokinetically from the source and

collected in water and on a filter. The total F- is

then determined by the specific ion electrode method.

3.0 Definitions. [Reserved]

4.0 Interferences.

Grease on

sample-exposed surfaces may cause low F-results because of adsorption.

5.0 Safety.

5.1 Disclaimer.

This method may

involve hazardous materials, operations, and equipment. This test method does

not purport to address all of the safety problems associated with its use. It

is the responsibility of the user of this test method to establish appropriate

safety and health practices and to determine the applicability of regulatory

limitations prior to performing this test method.

5.2 Corrosive Reagents.

The following

reagents are hazardous. Personal protective equipment and safe procedures are

useful in preventing chemical splashes. If contact occurs, immediately flush

with copious amounts of water at least 15 minutes. Remove clothing under shower

and decontaminate. Treat residual chemical burn as thermal burn.

5.2.1 Sodium

Hydroxide (NaOH). Causes severe damage to eye tissues and to skin. Inhalation

causes irritation to nose, throat, and lungs. Reacts exothermically with

limited amounts of water.

5.2.2 Sulfuric Acid

(H2SO4). Rapidly

destructive to body tissue. Will cause third degree burns. Eye damage may

result in blindness. Inhalation may be fatal from spasm of the larynx, usually

within 30 minutes. May cause lung tissue damage with edema. 1 mg/m3 for 8 hours will cause lung damage or, in higher concentrations,

death. Provide ventilation to limit inhalation. Reacts violently with metals

and organics.

6.0 Equipment and Supplies.

6.1 Sample Collection and Sample Recovery.

Same as Method 13A, Sections 6.1 and 6.2,

respectively.

6.2 Sample Preparation and Analysis.

The following items

are required for sample preparation and analysis:

6.2.1 Distillation

Apparatus, Bunsen Burner, Electric Muffle Furnace, Crucibles, Beakers,

Volumetric Flasks, Erlenmeyer Flasks or Plastic Bottles, Constant Temperature

Bath, and Balance. Same as Method 13A,

Sections 6.3.1 to 6.3.9, respectively.

6.2.2 Fluoride Ion

Activity Sensing Electrode.

6.2.3 Reference

Electrode.

Single junction,

sleeve type.

6.2.4 Electrometer. A

pH meter with millivolt-scale capable of ± 0.1-mv resolution, or a specific ion

meter made specifically for specific ion electrode use.

6.2.5 Magnetic

Stirrer and Tetrafluoroethylene (TFE) Fluorocarbon-Coated Stirring Bars.

6.2.6 Beakers.

Polyethylene, 100-ml.

7.0 Reagents and Standards.

Unless otherwise

indicated, all reagents are to conform to the specifications established by the

Committee on Analytical Reagents of the American Chemical Society, where such

specifications are available. Otherwise, use the best available grade.

7.1 Sample Collection and Sample Recovery.

Same as Method 13A, Sections 7.1 and 7.2,

respectively.

7.2 Sample Preparation and Analysis.

The following

reagents and standards are required for sample analysis:

7.2.1 Calcium Oxide

(CaO). Certified grade containing 0.005 percent F- or

less.

7.2.2 Phenolphthalein

Indicator. Dissolve 0.1 g phenolphthalein in a mixture of 50 ml of 90 percent

ethanol and 50 ml water.

7.2.3 Sodium

Hydroxide (NaOH), Pellets.

7.2.4 Sulfuric Acid

(H2SO4),

Concentrated.

7.2.5 Filters.

Whatman No. 541, or equivalent.

7.2.6 Water. Same as

Section 7.1.2 of Method 13A.

7.2.7 Sodium

Hydroxide, 5 M. Dissolve 20 g of NaOH in 100 ml of water.

7.2.8 Sulfuric Acid,

25 Percent (v/v). Mix 1 part of concentrated H2SO4 with 3 parts of water.

7.2.9 Total Ionic

Strength Adjustment Buffer (TISAB). Place approximately 500 ml of water in a

1-liter beaker. Add 57 ml of glacial acetic acid, 58 g of sodium chloride, and

4 g of cyclohexylene dinitrilo tetraacetic acid. Stir to dissolve. Place the

beaker in a water bath and cool to 20 ûC (68 ûF). Slowly add 5 M NaOH to the

solution, measuring the pH continuously with a calibrated pH/reference

electrode pair, until the pH is 5.3. Pour into a 1-liter volumetric flask, and

dilute to volume with deionized, distilled water. Commercially prepared TISAB

may be substituted for the above.

7.2.10 Fluoride

Standard Solution, 0.1 M. Oven dry approximately 10 g of sodium fluoride (NaF)

for a minimum of 2 hours at 110 ûC (230 ûF), and store in a desiccator. Then

add 4.2 g of NaF to a 1-liter volumetric flask, and add enough water to

dissolve. Dilute to volume with water.

8.0 Sample Collection, Preservation, Storage, and Transport.

Same as Method 13A, Section 8.0.

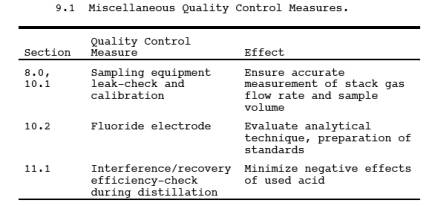

9.0 Quality Control.

9.1 Miscellaneous

Quality Control Measures.

9.2 Volume Metering

System Checks. Same as Method 5, Section 9.2.

10.0 Calibration and Standardizations.

NOTE: Maintain a laboratory log of all calibrations.

10.1 Sampling Equipment.

Same as Method 13A, Section 10.1.

10.2 Fluoride Electrode.

Prepare fluoride

standardizing solutions by serial dilution of the 0.1 M fluoride standard

solution. Pipet 10 ml of 0.1 M fluoride standard solution into a 100-ml

volumetric flask, and make up to the mark with water for a 10-2 M standard solution. Use 10 ml of 10-2 M solution to make a 10-3 M solution in the same manner. Repeat the

dilution procedure, and make 10-4 and 10-5 M solutions.

10.2.1 Pipet 50 ml of

each standard into a separate beaker. Add 50 ml of TISAB to each beaker. Place the

electrode in the most dilute standard solution. When a steady millivolt reading

is obtained, plot the value on the linear axis of semi-log graph paper versus

concentration on the log axis. Plot the nominal value for concentration of the

standard on the log axis, (e.g.,

when 50 ml of 10-2 M standard is diluted with 50 ml of TISAB, the

concentration is still designated "10-2 M").

10.2.2 Between

measurements, soak the fluoride sensing electrode in water for 30 seconds, and

then remove and blot dry. Analyze the standards going from dilute to

concentrated standards. A straight-line calibration curve will be obtained,

with nominal concentrations of 10-4, 10-3, 10-2, 10-1 fluoride

molarity on the log axis plotted versus electrode potential (in mv) on the

linear scale. Some electrodes may be slightly nonlinear between 10-5 and 10-4 M. If

this occurs, use additional standards between these two concentrations.

10.2.3 Calibrate the

fluoride electrode daily, and check it hourly. Prepare fresh fluoride

standardizing solutions daily (10-2 M or

less). Store fluoride standardizing solutions in polyethylene or polypropylene

containers.

NOTE: Certain specific ion meters have been designed

specifically for fluoride electrode use and give a direct readout of fluoride

ion concentration. These meters may be used in lieu of calibration curves for

fluoride measurements over a narrow concentration ranges. Calibrate the meter

according to the manufacturer's instructions.

11.0 Analytical Procedures.

11.1 Sample Loss Check, Sample Preparation, and Distillation.

Same as Method 13A, Sections 11.1 through 11.3, except

that the NOTE following

Section 11.3.1 is not applicable.

11.2 Analysis.

11.2.1 Containers No.

1 and No. 2. Distill suitable aliquots from Containers No. 1 and No. 2. Dilute

the distillate in the volumetric flasks to exactly 250 ml with water, and mix

thoroughly. Pipet a 25-ml aliquot from each of the distillate into separate

beakers. Add an equal volume of TISAB, and mix. The sample should be at the

same temperature as the calibration standards when measurements are made. If

ambient laboratory temperature fluctuates more than ± 2 ûC from the temperature

at which the calibration standards were measured, condition samples and standards

in a constant-temperature bath before measurement. Stir the sample with a

magnetic stirrer during measurement to minimize electrode response time. If the

stirrer generates enough heat to change solution temperature, place a piece of

temperature insulating material, such as cork, between the stirrer and the

beaker. Hold dilute samples (below 10-4 M

fluoride ion content) in polyethylene beakers during measurement.

11.2.2 Insert the

fluoride and reference electrodes into the solution. When a steady millivolt

reading is obtained, record it. This may take several minutes. Determine

concentration from the calibration curve. Between electrode measurements, rinse

the electrode with water.

11.2.3 Container No.

3 (Silica Gel). Same as in Method 13A,

Section 11.4.2.

12.0 Data Analysis and Calculations.

Carry out

calculations, retaining at least one extra significant figure beyond that of

the acquired data. Round off figures after final calculation.

12.1 Nomenclature.

Same as Method 13A, Section 12.1, with the

addition of the following:

M = F- concentration from calibration curve, molarity.

12.2 Average DGM

Temperature and Average Orifice Pressure Drop, Dry Gas Volume, Volume of Water

Vapor and Moisture Content, Fluoride Concentration in Stack Gas, and Isokinetic

Variation. Same as Method 13A, Sections 12.2 to 12.4, 12.6, and 12.7,

respectively.

12.3 Total Fluoride

in Sample. Calculate the amount of F- in the

sample using Equation 13B-1:

![]()

where:

K = 19

[(mgál)/(moleáml)] (metric units)

= 0.292 [(grál)/(moleáml)]

(English units)

13.0 Method Performance.

The following

estimates are based on a collaborative test done at a primary aluminum smelter.

In the test, six laboratories each sampled the stack simultaneously using two

sampling trains for a total of 12 samples per sampling run. Fluoride

concentrations encountered during the test ranged from 0.1 to 1.4 mg F-/m3.

13.1 Precision. The

intra-laboratory and inter-laboratory standard deviations, which include

sampling and analysis errors, are 0.037 mg F-/m3 with 60 degrees of freedom and 0.056 mg F-/m3 with five degrees of freedom, respectively.

13.2 Bias. The collaborative

test did not find any bias in the analytical method.

13.3 Range. The range

of this method is 0.02 to 2,000 µg F-/ml;

however, measurements of less than 0.1 µg F- /ml

require extra care.

14.0 Pollution Prevention. [Reserved]

15.0 Waste Management. [Reserved]

16.0 Alternative Procedures.

16.1 Compliance with

ASTM D 3270-73T, 91, 95 "Analysis for Fluoride Content of the Atmosphere

and Plant Tissues (Semi-automated Method)" is an acceptable alternative

for the distillation and analysis requirements specified in Sections 11.1 and

11.2 when applied to suitable aliquots of Containers 1 and 2 samples.

17.0 References.

Same as Method 13A, Section 16.0, References 1 and 2,

with the following addition:

1. MacLeod, Kathryn

E., and Howard L. Crist. Comparison of the SPADNS- Zirconium Lake and Specific

Ion Electrode Methods of Fluoride Determination in Stack Emission Samples.

Analytical Chemistry. 45:1272-1273. 1973.

18.0 Tables,

Diagrams, Flowcharts, and Validation Data. [Reserved]