METHOD

13A - DETERMINATION OF TOTAL FLUORIDE EMISSIONS FROM STATIONARY SOURCES (SPADNS

ZIRCONIUM LAKE METHOD)

NOTE: This method does not include all of the

specifications (e.g.,

equipment and supplies) and procedures (e.g., sampling and analytical) essential to its

performance. Some material is incorporated by reference from other methods in

this part. Therefore, to obtain reliable results, persons using this method

should have a thorough knowledge of at least the following additional test

methods: Method 1, Method 2, Method 3, and Method 5.

5.2.1 Hydrochloric Acid

(HCl). Highly toxic.

5.2.2 Sodium Hydroxide

(NaOH).

6.3 Sample Preparation

and Analysis.

7.3 Sample Preparation

and Analysis.

8.0 Sample Collection,

Preservation, Storage, and Transport.

8.2 Preliminary

Determinations.

8.3 Preparation of

Sampling Train.

10.0 Calibration and

Standardization.

12.0 Data Analysis and

Calculations.

14.0 Pollution

Prevention. [Reserved]

15.0 Waste Management.

[Reserved]

18.0 Tables, Diagrams,

Flowcharts, and Validation Data.

1.0 Scope and Application.

1.1 Analytes.

1.2 Applicability.

This method is

applicable for the determination of fluoride (F-)

emissions from sources as specified in the regulations. It does not measure

fluorocarbons, such as Freons.

1.3 Data Quality Objectives.

Adherence to the

requirements of this method will enhance the quality of the data obtained from

air pollutant sampling methods.

2.0 Summary.

Gaseous and

particulate F- are withdrawn isokinetically from the source and

collected in water and on a filter. The total F- is then

determined by the SPADNS Zirconium Lake Colorimetric method.

3.0 Definitions. [Reserved]

4.0 Interferences.

4.1 Chloride.

Large quantities of

chloride will interfere with the analysis, but this interference can be

prevented by adding silver sulfate into the distillation flask (see Section 11.3). If chloride ion is present, it may be

easier to use the specific ion electrode method of analysis (Method 13B).

4.2 Grease.

Grease on sample-exposed

surfaces may cause low F-

results due to adsorption.

5.0 Safety.

5.1 Disclaimer.

This method may

involve hazardous materials, operations, and equipment. This test method may

not address all of the safety problems associated with its use. It is the

responsibility of the user of this test method to establish appropriate safety

and health practices and to determine the applicability of regulatory

limitations prior to performing this test method.

5.2 Corrosive Reagents.

The following

reagents are hazardous. Personal protective equipment and safe procedures are

useful in preventing chemical splashes. If contact occurs, immediately flush

with copious amounts of water at least 15 minutes. Remove clothing under shower

and decontaminate. Treat residual chemical burn as thermal burn.

5.2.1 Hydrochloric Acid (HCl). Highly toxic.

Vapors are highly

irritating to eyes, skin, nose, and lungs, causing severe damage. May cause

bronchitis, pneumonia, or edema of lungs. Exposure to concentrations of 0.13 to

0.2 percent can be lethal in minutes. Will react with metals, producing

hydrogen.

5.2.2 Sodium Hydroxide (NaOH).

Causes severe damage

to eye tissues and to skin. Inhalation causes irritation to nose, throat, and

lungs. Reacts exothermically with limited amounts of water.

5.2.3 Sulfuric Acid (H2SO4).

Rapidly destructive

to body tissue. Will cause third degree burns. Eye damage may result in

blindness. Inhalation may be fatal from spasm of the larynx, usually within 30

minutes. May cause lung tissue damage with edema. 1 mg/m3 for 8 hours will cause lung damage or, in higher concentrations,

death. Provide ventilation to limit inhalation. Reacts violently with metals

and organics.

6.0 Equipment and Supplies.

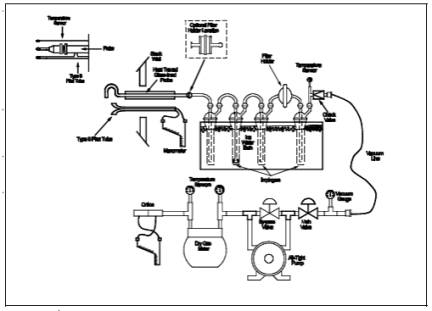

6.1 Sample Collection.

A schematic of the

sampling train used in performing this method is shown in Figure

13A-1; it is similar to the Method 5 sampling train except that the filter

position is interchangeable. The sampling train consists of the following

components:

6.1.1 Probe Nozzle, Pitot Tube, Differential Pressure Gauge, Filter Heating System, Temperature Sensor, Metering System, Barometer, and Gas Density Determination Equipment.

Same as Method 5, Sections 6.1.1.1, 6.1.1.3 through

6.1.1.7, 6.1.1.9, 6.1.2, and 6.1.3, respectively. The filter heating system and

temperature sensor are needed only when moisture condensation is a problem.

6.1.2 Probe Liner.

Borosilicate glass or

316 stainless steel. When the filter is located immediately after the probe, a

probe heating system may be used to prevent filter plugging resulting from

moisture condensation, but the temperature in the probe shall not be allowed to

exceed 120 ± 14 ûC (248 ± 25 ûF).

6.1.3 Filter Holder.

With positive seal

against leakage from the outside or around the filter. If the filter is located

between the probe and first impinger, use borosilicate glass or stainless steel

with a 20-mesh stainless steel screen filter support and a silicone rubber

gasket; do not use a glass frit or a sintered metal filter support. If the

filter is located between the third and fourth impingers, borosilicate glass

with a glass frit filter support and a silicone rubber gasket may be used.

Other materials of construction may be used, subject to the approval of the

Administrator.

6.1.4 Impingers.

Four impingers

connected as shown in Figure 13A-1 with ground-glass (or equivalent),

vacuum-tight fittings. For the first, third, and fourth impingers, use the

Greenburg-Smith design, modified by replacing the tip with a 1.3-cm (1/2-in.)

ID glass tube extending to 1.3 cm (1/2 in.) from the bottom of the flask. For

the second impinger, use a Greenburg-Smith impinger with the standard tip.

Modifications (e.g.,

flexible connections between the impingers or materials other than glass) may

be used, subject to the approval of the Administrator. Place a temperature

sensor, capable of measuring temperature to within 1 ûC (2 ûF), at the outlet

of the fourth impinger for monitoring purposes.

6.2 Sample Recovery.

The following items

are needed for sample recovery:

6.2.1 Probe-liner and

Probe-Nozzle Brushes, Wash Bottles, Graduated Cylinder and/or Balance, Plastic

Storage Containers, Funnel and Rubber Policeman, and Funnel. Same as Method 5, Sections 6.2.1, 6.2.2 and 6.2.5 to

6.2.8, respectively.

6.2.2 Sample Storage

Container. Wide-mouth, high-density polyethylene bottles for impinger water

samples, 1 liter.

6.3 Sample Preparation and Analysis.

The following items

are needed for sample preparation and analysis:

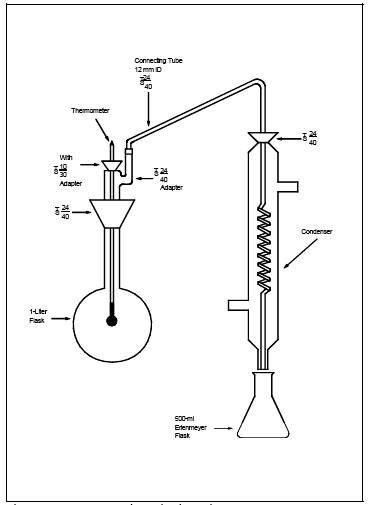

6.3.1

Distillation Apparatus. Glass distillation apparatus assembled as shown in Figure 13A-2.

6.3.2 Bunsen Burner.

6.3.3 Electric Muffle

Furnace. Capable of heating to 600 ûC (1100 ûF).

6.3.4 Crucibles.

Nickel, 75- to 100-ml.

6.3.5 Beakers. 500-ml

and 1500-ml.

6.3.6 Volumetric

Flasks. 50-ml.

6.3.7 Erlenmeyer

Flasks or Plastic Bottles. 500-ml.

6.3.8 Constant Temperature

Bath. Capable of maintaining a constant temperature of ±1.0 ûC at room

temperature conditions.

6.3.9 Balance. 300-g

capacity, to measure to ±0.5 g.

6.3.10

Spectrophotometer. Instrument that measures absorbance at 570 nm and provides

at least a 1-cm light path.

6.3.11

Spectrophotometer Cells. 1-cm path length.

7.0 Reagents and Standards.

Unless otherwise

indicated, all reagents are to conform to the specifications established by the

Committee on Analytical Reagents of the American Chemical Society, where such

specifications are available. Otherwise, use the best available grade.

7.1 Sample Collection.

The following

reagents are needed for sample collection:

7.1.1 Filters.

7.1.1.1 If the filter

is located between the third and fourth impingers, use a Whatman No. 1 filter,

or equivalent, sized to fit the filter holder.

7.1.1.2 If the filter

is located between the probe and first impinger, use any suitable medium (e.g., paper, organic membrane) that can withstand

prolonged exposure to temperatures up to 135 ûC (275 ûF), and has at least 95

percent collection efficiency (<5 percent penetration) for 0.3 µm dioctyl

phthalate smoke particles. Conduct the filter efficiency test before the test

series, using ASTM D 2986-71, 78, or 95a (incorporated by referenceÑsee ¤

60.17), or use test data from the supplier's quality control program. The

filter must also have a low F- blank value

(<0.015 mg F-/cm2 of filter

area). Before the test series, determine the average F- blank value of at least three filters (from the lot to be used for

sampling) using the applicable procedures described in Sections

8.3 and 8.4 of this method. In general, glass fiber filters have high

and/or variable F- blank values, and will not be acceptable for

use.

7.1.2 Water.

Deionized distilled, to conform to ASTM D 1193-77 or 91, Type 3 (incorporated

by reference--see ¤ 60.17). If high concentrations of organic matter are not

expected to be present, the potassium permanganate test for oxidizable organic

matter may be deleted.

7.1.3 Silica Gel,

Crushed Ice, and Stopcock Grease. Same as Method 5,

Sections 7.1.2, 7.1.4, and 7.1.5, respectively.

7.2 Sample Recovery.

Water, as described

in Section 7.1.2, is needed for sample recovery.

7.3 Sample Preparation and Analysis.

The following

reagents and standards are needed for sample preparation and analysis:

7.3.1 Calcium Oxide

(CaO). Certified grade containing 0.005 percent F- or

less.

7.3.2 Phenolphthalein

Indicator. Dissolve 0.1 g of phenolphthalein in a mixture of 50 ml of 90

percent ethanol and 50 ml of water.

7.3.3 Silver Sulfate

(Ag2SO4).

7.3.4 Sodium

Hydroxide (NaOH), Pellets.

7.3.5 Sulfuric Acid

(H2SO4),

Concentrated.

7.3.6 Sulfuric Acid,

25 Percent (v/v). Mix 1 part of concentrated H2SO4 with 3 parts of water.

7.3.7 Filters.

Whatman No. 541, or equivalent.

7.3.8 Hydrochloric

Acid (HCl), Concentrated.

7.3.9 Water. Same as

in Section 7.1.2.

7.3.10 Fluoride

Standard Solution, 0.01 mg F-/ml. Dry approximately

0.5 g of sodium fluoride (NaF) in an oven at 110 ûC (230 ûF) for at least 2

hours. Dissolve 0.2210 g of NaF in 1 liter of water. Dilute 100 ml of this

solution to 1 liter with water.

7.3.11 SPADNS

Solution [4,5 Dihydroxyl-3- (p-Sulfophenylazo)-2,7-Naphthalene-Disulfonic Acid

Trisodium Salt]. Dissolve 0.960 ± 0.010 g of SPADNS reagent in 500 ml water. If

stored in a well-sealed bottle protected from the sunlight, this solution is

stable for at least 1 month.

7.3.12

Spectrophotometer Zero Reference Solution. Add 10 ml of SPADNS solution to 100

ml water, and acidify with a solution prepared by diluting 7 ml of concentrated

HCl to 10 ml with deionized, distilled water. Prepare daily.

7.3.13

SPADNS Mixed Reagent. Dissolve 0.135 ± 0.005 g of zirconyl chloride octahydrate

(ZrOCl2 8H2O) in 25

ml of water. Add 350 ml of concentrated HCl, and dilute to 500 ml with

deionized, distilled water. Mix equal volumes of this solution and SPADNS

solution to form a single reagent. This reagent is stable for at least 2

months.

8.0 Sample Collection, Preservation, Storage, and

Transport.

8.1 Pretest Preparation.

Follow the general

procedure given in Method 5, Section 8.1,

except that the filter need not be weighed.

8.2 Preliminary Determinations.

Follow the general

procedure given in Method 5, Section 8.2,

except that the nozzle size must be selected such that isokinetic sampling

rates below 28 liters/min (1.0 cfm) can be maintained.

8.3 Preparation of Sampling Train.

Follow the general

procedure given in Method 5, Section 8.3,

except for the following variation: Assemble the train as shown in Figure 13A-1

with the filter between the third and fourth impingers. Alternatively, if a

20-mesh stainless steel screen is used for the filter support, the filter may

be placed between the probe and first impinger. A filter heating system to

prevent moisture condensation may be used, but shall not allow the temperature

to exceed 120 ± 14 ûC (248 ± 25 ûF). Record the filter location on the data

sheet (see Section 8.5).

8.4 Leak-Check Procedures.

Follow the leak-check

procedures given in Method 5, Section 8.4.

8.5 Sampling Train Operation.

Follow the general

procedure given in Method 5, Section 8.5,

keeping the filter and probe temperatures (if applicable) at 120 ± 14 ûC (248 ±

25 ûF) and isokinetic sampling rates below 28 liters/min (1.0 cfm). For each

run, record the data required on a data sheet such as the one shown in Method 5, Figure 5-3.

8.6 Sample Recovery.

Proper cleanup

procedure begins as soon as the probe is removed from the stack at the end of

the sampling period. Allow the probe to cool.

8.6.1 When the probe

can be safely handled, wipe off all external particulate matter near the tip of

the probe nozzle, and place a cap over it to keep from losing part of the

sample. Do not cap off the probe tip tightly while the sampling train is

cooling down as this would create a vacuum in the filter holder, thus drawing

water from the impingers into the filter holder.

8.6.2 Before moving

the sample train to the cleanup site, remove the probe from the sample train,

wipe off any silicone grease, and cap the open outlet of the probe. Be careful

not to lose any condensate that might be present. Remove the filter assembly,

wipe off any silicone grease from the filter holder inlet, and cap this inlet.

Remove the umbilical cord from the last impinger, and cap the impinger. After

wiping off any silicone grease, cap off the filter holder outlet and any open impinger

inlets and outlets. Ground-glass stoppers, plastic caps, or serum caps may be

used to close these openings.

8.6.3 Transfer the

probe and filter-impinger assembly to the cleanup area. This area should be

clean and protected from the wind so that the chances of contaminating or

losing the sample will be minimized.

8.6.4 Inspect the

train prior to and during disassembly, and note any abnormal conditions. Treat

the samples as follows:

8.6.4.1 Container No.

1 (Probe, Filter, and Impinger Catches).

8.6.4.1.1 Using a

graduated cylinder, measure to the nearest ml, and record the volume of the

water in the first three impingers; include any condensate in the probe in this

determination. Transfer the impinger water from the graduated cylinder into a

polyethylene container. Add the filter to this container. (The filter may be

handled separately using procedures subject to the Administrator's approval.)

Taking care that dust on the outside of the probe or other exterior surfaces

does not get into the sample, clean all sample-exposed surfaces (including the

probe nozzle, probe fitting, probe liner, first three impingers, impinger

connectors, and filter holder) with water. Use less than 500 ml for the entire

wash. Add the washings to the sample container. Perform the water rinses as

follows:

8.6.4.1.2 Carefully

remove the probe nozzle and rinse the inside surface with water from a wash

bottle. Brush with a Nylon bristle brush, and rinse until the rinse shows no

visible particles, after which make a final rinse of the inside surface. Brush

and rinse the inside parts of the Swagelok fitting with water in a similar way.

8.6.4.1.3 Rinse the

probe liner with water. While squirting the water into the upper end of the

probe, tilt and rotate the probe so that all inside surfaces will be wetted

with water. Let the water drain from the lower end into the sample container. A

funnel (glass or polyethylene) may be used to aid in transferring the liquid

washes to the container. Follow the rinse with a probe brush. Hold the probe in

an inclined position, and squirt water into the upper end as the probe brush is

being pushed with a twisting action through the probe. Hold the sample

container underneath the lower end of the probe, and catch any water and

particulate matter that is brushed from the probe. Run the brush through the

probe three times or more. With stainless steel or other metal probes, run the

brush through in the above prescribed manner at least six times since metal

probes have small crevices in which particulate matter can be entrapped. Rinse

the brush with water, and quantitatively collect these washings in the sample

container. After the brushing, make a final rinse of the probe as described

above.

8.6.4.1.4 It is recommended

that two people clean the probe to minimize sample losses. Between sampling

runs, keep brushes clean and protected from contamination.

8.6.4.1.5 Rinse the

inside surface of each of the first three impingers (and connecting glassware)

three separate times. Use a small portion of water for each rinse, and brush

each sample-exposed surface with a Nylon bristle brush, to ensure recovery of

fine particulate matter. Make a final rinse of each surface and of the brush.

8.6.4.1.6 After

ensuring that all joints have been wiped clean of the silicone grease, brush

and rinse with water the inside of the filter holder (front-half only, if

filter is positioned between the third and fourth impingers). Brush and rinse

each surface three times or more if needed. Make a final rinse of the brush and

filter holder.

8.6.4.1.7 After all

water washings and particulate matter have been collected in the sample

container, tighten the lid so that water will not leak out when it is shipped

to the laboratory. Mark the height of the fluid level to transport. Label the

container clearly to identify its contents.

8.6.4.2 Container No.

2 (Sample Blank). Prepare a blank by placing an unused filter in a polyethylene

container and adding a volume of water equal to the total volume in Container

No. 1. Process the blank in the same manner as for Container No. 1.

8.6.4.3 Container No.

3 (Silica Gel). Note the color of the indicating silica gel to determine

whether it has been completely spent, and make a notation of its condition. Transfer

the silica gel from the fourth impinger to its original container, and seal. A

funnel may be used to pour the silica gel and a rubber policeman to remove the

silica gel from the impinger. It is not necessary to remove the small amount of

dust particles that may adhere to the impinger wall and are difficult to

remove. Since the gain in weight is to be used for moisture calculations, do

not use any water or other liquids to transfer the silica gel. If a balance is

available in the field, follow the analytical procedure for Container No. 3 in Section 11.4.2.

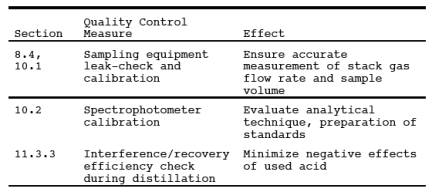

9.0 Quality Control.

9.1 Miscellaneous

Quality Control Measures.

9.2 Volume Metering

System Checks. Same as Method 5, Section 9.2.

10.0 Calibration and Standardization.

NOTE: Maintain a laboratory log of all calibrations.

10.1 Sampling Equipment.

Calibrate the probe

nozzle, pitot tube, metering system, probe heater, temperature sensors, and

barometer according to the procedures outlined in Method 5, Sections 10.1 through 10.6. Conduct

the leak-check of the metering system according to the procedures outlined in Method 5, Section 8.4.1.

10.2 Spectrophotometer.

10.2.1 Prepare the

blank standard by adding 10 ml of SPADNS mixed reagent to 50 ml of water.

10.2.2 Accurately

prepare a series of standards from the 0.01 mg F-/ml standard

fluoride solution (Section 860 7.3.10) by diluting 0, 2, 4, 6, 8, 10, 12, and

14 ml to 100 ml with deionized, distilled water. Pipet 50 ml from each

solution, and transfer each to a separate 100-ml beaker. Then add 10 ml of

SPADNS mixed reagent (Section 7.3.13) to each. These standards will contain 0,

10, 20, 30, 40, 50, 60, and 70 µg F- (0 to 1.4

µg/ml), respectively.

10.2.3 After mixing,

place the blank and calibration standards in a constant temperature bath for 30

minutes before reading the absorbance with the spectrophotometer. Adjust all

samples to this same temperature before analyzing.

10.2.4 With the

spectrophotometer at 570 nm, use the blank standard to set the absorbance to

zero. Determine the absorbance of the standards.

10.2.5 Prepare a

calibration curve by plotting µg F-/50 ml

versus absorbance on linear graph paper. Prepare the standard curve initially

and thereafter whenever the SPADNS mixed reagent is newly made. Also, run a

calibration standard with each set of samples and, if it differs from the

calibration curve by more than ±2 percent, prepare a new standard curve.

11.0 Analytical Procedures.

11.1 Sample Loss Check.

Note the liquid

levels in Containers No. 1 and No. 2, determine whether leakage occurred during

transport, and note this finding on the analytical data sheet. If noticeable

leakage has occurred, either void the sample or use methods, subject to the

approval of the Administrator, to correct the final results.

11.2 Sample Preparation.

Treat the contents of

each sample container as described below:

11.2.1 Container No.

1 (Probe, Filter, and Impinger Catches). Filter this container's contents,

including the sampling filter, through Whatman No. 541 filter paper, or

equivalent, into a 1500-ml beaker.

11.2.1.1 If the filtrate

volume exceeds 900 ml, make the filtrate basic (red to phenolphthalein) with

NaOH, and evaporate to less than 900 ml.

11.2.1.2 Place the

filtered material (including sampling filter) in a nickel crucible, add a few

ml of water, and macerate the filters with a glass rod.

11.2.1.2.1 Add 100 mg

CaO to the crucible, and mix the contents thoroughly to form a slurry. Add two

drops of phenolphthalein indicator. Place the crucible in a hood under infrared

lamps or on a hot plate at low heat. Evaporate the water completely. During the

evaporation of the water, keep the slurry basic (red to phenolphthalein) to

avoid loss of F-. If the indicator turns colorless (acidic)

during the evaporation, add CaO until the color turns red again.

11.2.1.2.2 After

evaporation of the water, place the crucible on a hot plate under a hood, and

slowly increase the temperature until the Whatman No. 541 and sampling filters

char. It may take several hours to char the filters completely.

11.2.1.2.3 Place the

crucible in a cold muffle furnace. Gradually (to prevent smoking) increase the

temperature to 600 ûC (1100 ûF), and maintain this temperature until the

contents are reduced to an ash. Remove the crucible from the furnace, and allow

to cool.

11.2.1.2.4 Add approximately

4 g of crushed NaOH to the crucible, and mix. Return the crucible to the muffle

furnace, and fuse the sample for 10 minutes at 600 ûC.

11.2.1.2.5 Remove the

sample from the furnace, and cool to ambient temperature. Using several

rinsings of warm water, transfer the contents of the crucible to the beaker

containing the filtrate. To ensure complete sample removal, rinse finally with

two 20-ml portions of 25 percent H2SO4, and carefully add to the beaker. Mix well, and transfer to a

1-liter volumetric flask. Dilute to volume with water, and mix thoroughly.

Allow any undissolved solids to settle.

11.2.2 Container No.

2 (Sample Blank). Treat in the same manner as described in Section 11.2.1

above.

11.2.3 Adjustment of

Acid/Water Ratio in Distillation Flask. Place 400 ml of water in the

distillation flask, and add 200 ml of concentrated H2SO4. Add some soft glass beads and several small

pieces of broken glass tubing, and assemble the apparatus as shown in Figure

13A-2. Heat the flask until it reaches a temperature of 175 ûC (347 ûF) to

adjust the acid/water ratio for subsequent distillations. Discard the

distillate. CAUTION: Use a

protective shield when carrying out this procedure. Observe standard

precautions when mixing H2SO4 with

water. Slowly add the acid to the flask with constant swirling.

11.3 Distillation.

11.3.1 Cool the

contents of the distillation flask to below 80 ûC (180 ûF). Pipet an aliquot of

sample containing less than 10.0 mg F- directly

into the distillation flask, and add water to make a total volume of 220 ml

added to the distillation flask. (To estimate the appropriate aliquot size,

select an aliquot of the solution, and treat as described in Section 11.4.1.

This will be an approximation of the F- content

because of possible interfering ions.)

NOTE: If the sample contains chloride, add 5 mg of

Ag2SO4 to the

flask for every mg of chloride.

11.3.2 Place a 250-ml

volumetric flask at the condenser exit. Heat the flask as rapidly as possible

with a Bunsen burner, and collect all the distillate up to 175 ûC (347 ûF).

During heatup, play the burner flame up and down the side of the flask to

prevent bumping. Conduct the distillation as rapidly as possible (15 minutes or

less). Slow distillations have been found to produce low F- recoveries. Be

careful not to exceed 175 ûC (347 ûF) to avoid causing H2SO4 to distill over. If F- distillation in the mg range is to be followed by a distillation in

the fractional mg range, add 220 ml of water and distill it over as in the acid

adjustment step to remove residual F- from the

distillation system.

11.3.3 The acid in

the distillation flask may be used until there is carry-over of interferences

or poor F- recovery. Check for interference and for recovery efficiency every

tenth distillation using a water blank and a standard solution. Change the acid

whenever the F- recovery is less than 90 percent or the blank value exceeds 0.1

µg/ml.

11.4 Sample Analysis.

11.4.1 Containers No.

1 and No. 2.

11.4.1.1 After

distilling suitable aliquots from Containers No. 1 and No. 2 according to

Section 11.3, dilute the distillate in the volumetric flasks to exactly 250 ml

with water, and mix thoroughly. Pipet a suitable aliquot of each sample

distillate (containing 10 to 40 µg F-/ml) into

a beaker, and dilute to 50 ml with water. Use the same aliquot size for the

blank. Add 10 ml of SPADNS mixed reagent (Section

7.3.13), and mix thoroughly.

11.4.1.2 After

mixing, place the sample in a constant-temperature bath containing the standard

solutions for 30 minutes before reading the absorbance on the

spectrophotometer.

NOTE: After the sample and colorimetric reagent are

mixed, the color formed is stable for approximately 2 hours. Also, a 3 ûC (5.4

ûF) temperature difference between the sample and standard solutions produces

an error of approximately 0.005 mg F-/liter. To

avoid this error, the absorbencies of the sample and standard solutions must be

measured at the same temperature.

11.4.1.3 Set the spectrophotometer

to zero absorbance at 570 nm with the zero reference solution (Section 7.3.12),

and check the spectrophotometer calibration with the standard solution (Section

7.3.10). Determine the absorbance of the samples, and determine the concentration

from the calibration curve. If the concentration does not fall within the range

of the calibration curve, repeat the procedure using a different size aliquot.

11.4.2

Container No. 3 (Silica Gel). Weigh the spent silica gel (or silica gel plus

impinger) to the nearest 0.5 g

using a balance. This step may be conducted in the field.

12.0 Data Analysis and Calculations.

Carry out

calculations, retaining at least one extra significant figure beyond that of

the acquired data. Round off figures after final calculation. Other forms of

the equations may be used, provided that they yield equivalent results.

Ad = Aliquot of distillate taken for color development, ml.

At = Aliquot of total sample added to still, ml.

Bws = Water vapor in the gas stream, portion by

volume.

Cs = Concentration of F- in stack gas, mg/dscm

(gr/dscf).

Fc = F- concentration from the calibration curve, µg.

Ft = Total F-

in sample, mg.

Tm = Absolute average dry gas meter (DGM) temperature (see Figure 5-3 of Method 5), ûK (ûR).

Ts = Absolute average stack gas temperature (see Figure 5-3 of Method

5), ûK (ûR).

Vd = Volume of distillate as diluted, ml.

Vm(std) = Volume of gas sample as measured by DGM at

standard conditions, dscm (dscf).

Vt = Total volume of F- sample, after final

dilution, ml.

Vw(std) = Volume of water vapor in the gas sample at

standard conditions, scm (scf)

12.2 Average DGM

Temperature and Average Orifice Pressure Drop (see Figure 5-3 of Method 5).

12.3 Dry Gas Volume.

Calculate Vm(std), and adjust for leakage, if necessary, using Equation 5-1 of Method 5.

12.4 Volume of Water

Vapor and Moisture Content. Calculate Vw(std) and

Bws from the data obtained in this method. Use Equations

5-2 and 5-3 of Method 5.

12.5 Total Fluoride

in Sample. Calculate the amount of F- in the

sample using the following equation:

where:

K = 10-3 mg/µg (metric units)

= 1.54 x 10-5 gr/µg (English units)

12.6 Fluoride Concentration

in Stack Gas. Determine the F- concentration in the

stack gas using the following equation:

12.7 Isokinetic

Variation. Same as Method 5, Section 12.11.

13.0 Method Performance.

The following

estimates are based on a collaborative test done at a primary aluminum smelter.

In the test, six laboratories each sampled the stack simultaneously using two

sampling trains for a total of 12 samples per sampling run. Fluoride

concentrations encountered during the test ranged from 0.1 to 1.4 mg F-/m3.

13.1 Precision. The

intra- and inter-laboratory standard deviations, which include sampling and

analysis errors, were 0.044 mg F-/m3 with 60 degrees of freedom and 0.064 mg F-/m3 with five degrees of freedom, respectively.

13.2 Bias. The

collaborative test did not find any bias in the analytical method.

13.3 Range. The range

of this method is 0 to 1.4 µg F-/ml.

14.0 Pollution Prevention. [Reserved]

15.0 Waste Management. [Reserved]

16.0 Alternative Procedures.

16.1 Compliance with

ASTM D 3270-73T, 80, 91, or 95 (incorporated by reference - see ¤ 60.17) "Analysis of Fluoride Content of the

Atmosphere and Plant Tissues (Semi-automated Method) is an acceptable alternative

for the requirements specified in Sections 11.2, 11.3, and 11.4.1 when applied

to suitable aliquots of Containers 1 and 2 samples.

17.0 References.

1. Bellack, Ervin.

Simplified Fluoride Distillation Method. J. of the American Water Works Association.

50:5306. 1958.

2. Mitchell, W.J.,

J.C. Suggs, and F.J. Bergman. Collaborative Study of EPA Method 13A and Method

13B. Publication No. EPA-300/4-77-050. U.S. Environmental Protection Agency,

Research Triangle Park, NC. December 1977.

3. Mitchell, W.J.,

and M.R. Midgett. Adequacy of Sampling Trains and Analytical Procedures Used

for Fluoride. Atm. Environ. 10:865-872. 1976.

18.0 Tables, Diagrams, Flowcharts, and Validation Data.

Figure

13A-1. Fluoride Sampling Train.

Figure

13A-2. Fluoride Distillation Apparatus.