METHOD 108 -

DETERMINATION OF PARTICULATE AND GASEOUS ARSENIC EMISSIONS

NOTE: This method does not include all of the

specifications (e.g.,

equipment and supplies) and procedures (e.g., sampling and analytical) essential to its

performance. Some material is incorporated by reference from other methods in

Appendix A to 40 CFR Part 60. Therefore, to obtain reliable results, persons

using this method should have a thorough knowledge of at least the following

additional test methods: Method 1, Method 2, Method 3, Method 5, and Method 12.

8.0 Sample Collection,

Preservation, Transport, and Storage.

10.0 Calibration and

Standardization.

10.2 Preparation of

Standard Solutions.

10.4 Spectrophotometer

Calibration Quality Control.

11.3 Spectrophotometer

Preparation.

11.5 Check for matrix

effects on the arsenic results.

12.0 Data Analysis and

Calculations.

14.0 Pollution

Prevention. [Reserved]

15.0 Waste Management.

[Reserved]

17.0 Tables, Diagrams,

Flowcharts, and Validation Data.

1.0 Scope and Application.

1.1 Analytes.

1.2 Applicability.

This method is

applicable for the determination of inorganic As emissions from stationary

sources as specified in an applicable subpart of the regulations.

1.3 Data Quality Objectives.

Adherence to the

requirements of this method will enhance the quality of the data obtained from

air pollutant sampling methods.

2.0 Summary of Method.

Particulate and

gaseous As emissions are withdrawn isokinetically from the source and are

collected on a glass mat filter and in water. The collected arsenic is then

analyzed by means of atomic absorption spectrophotometry (AAS).

3.0 Definitions. [Reserved]

4.0 Interferences.

Analysis for As by

flame AAS is sensitive to the chemical composition and to the physical

properties (e.g., viscosity,

pH) of the sample. The analytical procedure includes a check for matrix effects

(Section 11.5).

5.0 Safety.

5.1 This method may

involve hazardous materials, operations, and equipment. This test method may

not address all of the safety problems associated with its use. It is the

responsibility of the user to establish appropriate safety and health practices

and determine the applicability of regulatory limitations prior to performing

this test method.

5.2 Corrosive

reagents. The following reagents are hazardous. Personal protective equipment

and safe procedures that prevent chemical splashes are recommended. If contact

occurs, immediately flush with copious amounts of water for at least 15

minutes. Remove clothing under shower and decontaminate. Treat residual

chemical burns as thermal burns.

5.2.1 Hydrochloric

Acid (HCl). Highly corrosive liquid with toxic vapors. Vapors are highly irritating

to eyes, skin, nose, and lungs, causing severe damage. May cause bronchitis,

pneumonia, or edema of lungs. Exposure to concentrations of 0.13 to 0.2 percent

can be lethal to humans in a few minutes. Provide ventilation to limit

exposure. Reacts with metals, producing hydrogen gas.

5.2.2 Hydrogen

Peroxide (H2O2). Very harmful to

eyes. 30% H2O2 can burn skin, nose,

and lungs.

5.2.3 Nitric Acid

(HNO3). Highly corrosive to eyes, skin, nose, and

lungs. Vapors are highly toxic and can cause bronchitis, pneumonia, or edema of

lungs. Reaction to inhalation may be delayed as long as 30 hours and still be

fatal. Provide ventilation to limit exposure. Strong oxidizer. Hazardous

reaction may occur with organic materials such as solvents.

5.2.4 Sodium Hydroxide

(NaOH). Causes severe damage to eyes and skin. Inhalation causes irritation to

nose, throat, and lungs. Reacts exothermically with small amounts of water.

6.0 Equipment and Supplies.

6.1 Sample Collection.

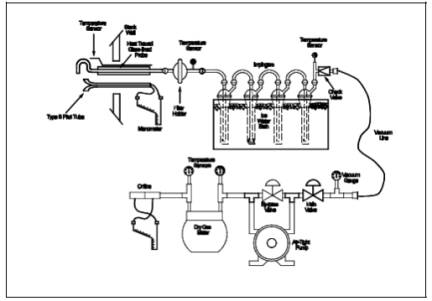

A schematic of the

sampling train used in performing this method is shown in Figure

108-1; it is similar to the Method 5 sampling train of 40 CFR Part 60,

Appendix A. The following items are required for sample collection:

6.1.1 Probe Nozzle,

Probe Liner, Pitot Tube, Differential Pressure Gauge, Filter Holder, Filter

Heating System, Temperature Sensor, Metering System, Barometer, and Gas Density

Determination Equipment. Same as Method 5,

Sections 6.1.1.1 to 6.1.1.7, 6.1.1.9, 6.1.2, and 6.1.3, respectively.

6.1.2 Impingers. Four

impingers connected in series with leak-free ground-glass fittings or any

similar leak-free noncontaminating fittings. For the first, third, and fourth

impingers, use the Greenburg-Smith design, modified by replacing the tip with a

1.3-cm ID (0.5-in.) glass tube extending to about 1.3 cm (0.5 in.) from the

bottom of the flask. For the second impinger, use the Greenburg-Smith design

with the standard tip. Modifications (e.g., flexible connections between the impingers, materials other than

glass, or flexible vacuum lines to connect the filter holder to the condenser)

are subject to the approval of the Administrator.

6.1.3 Temperature

Sensor. Place a temperature sensor, capable of measuring temperature to within

1 ¼C (2 ¼F), at the outlet of the fourth impinger for monitoring purposes.

6.2 Sample Recovery.

The following items

are required for sample recovery:

6.2.1 Probe-Liner and

Probe-Nozzle Brushes, Petri Dishes, Graduated Cylinder and/or Balance, Plastic

Storage Containers, and Funnel and Rubber Policeman. Same as Method 5, Sections 6.2.1 and 6.2.4 to 6.2.8,

respectively.

6.2.2 Wash Bottles.

Polyethylene (2).

6.2.3 Sample Storage

Containers. Chemically resistant, polyethylene or polypropylene for glassware

washes, 500- or 1000-ml.

6.3 Analysis.

The following items

are required for analysis:

6.3.1

Spectrophotometer. Equipped with an electrodeless discharge lamp and a

background corrector to measure absorbance at 193.7 nanometers (nm). For

measuring samples having less than 10 µg As/ml, use a vapor generator accessory

or a graphite furnace.

6.3.2 Recorder. To

match the output of the spectrophotometer.

6.3.3 Beakers. 150

ml.

6.3.4 Volumetric

Flasks. Glass 50-, 100-, 200-, 500-, and 1000-ml; and polypropylene, 50-ml.

6.3.5 Balance. To

measure within 0.5 g.

6.3.6 Volumetric

Pipets. 1-, 2-, 3-, 5-, 8-, and 10-ml.

6.3.7 Oven.

6.3.8 Hot Plate.

7.0 Reagents and Standards.

Unless otherwise

indicated, it is intended that all reagents conform to the specifications

established by the Committee on Analytical Reagents of the American Chemical

Society, where such specifications are available; otherwise, use the best

available grade.

7.1 Sample Collection

The following

reagents are required for sample collection:

7.1.1 Filters. Same

as Method 5, Section 7.1.1, except that the

filters need not be unreactive to SO2.

7.1.2 Silica Gel,

Crushed Ice, and Stopcock Grease. Same as Method 5, Sections 7.1.2, 7.1.4, and

7.1.5, respectively.

7.1.3 Water.

Deionized distilled to meet ASTM D 1193-77 or 91 (incorporated by reference)see ¤ 61.18), Type 3. When high concentrations of organic matter

are not expected to be present, the KMnO4 test for

oxidizable organic matter may be omitted.

7.2 Sample Recovery.

7.2.1 0.1 N NaOH. Dissolve

4.00 g of NaOH in about 500 ml of water in a 1-liter volumetric flask. Then,

dilute to exactly 1.0 liter with water.

7.3 Analysis.

The following

reagents and standards are required for analysis:

7.3.1 Water. Same as

Section 7.1.3.

7.3.2 Sodium Hydroxide,

0.1 N. Same as in Section 7.2.1.

7.3.3 Sodium

Borohydride (NaBH4), 5 Percent Weight by Volume (W/V). Dissolve

50.0 g of NaBH4 in about 500 ml of 0.1 N NaOH in a 1-liter

volumetric flask. Then, dilute to exactly 1.0 liter with 0.1 N NaOH.

7.3.4 Hydrochloric

Acid, Concentrated.

7.3.5 Potassium

Iodide (KI), 30 Percent (W/V). Dissolve 300 g of KI in 500 ml of water in a 1

liter volumetric flask. Then, dilute to exactly 1.0 liter with water.

7.3.6 Nitric Acid,

Concentrated.

7.3.7 Nitric Acid,

0.8 N. Dilute 52 ml of concentrated HNO3 to

exactly 1.0 liter with water.

7.3.8 Nitric Acid, 50

Percent by Volume (V/V). Add 50 ml concentrated HNO3 to 50 ml water.

7.3.9 Stock Arsenic

Standard, 1 mg As/ml. Dissolve 1.3203 g of primary standard grade As2O3 in 20 ml of 0.1 N NaOH in a 150 ml beaker.

Slowly add 30 ml of concentrated HNO3. Heat the

resulting solution and evaporate just to dryness. Transfer the residue

quantitatively to a 1-liter volumetric flask, and dilute to 1.0 liter with

water.

7.3.10 Arsenic

Working Solution, 1.0 µg As/ml. Pipet exactly 1.0 ml of stock arsenic standard

into an acid-cleaned, appropriately labeled 1-liter volumetric flask containing

about 500 ml of water and 5 ml of concentrated HNO3. Dilute to exactly 1.0 liter with water.

7.3.11 Air. Suitable

quality for AAS analysis.

7.3.12 Acetylene.

Suitable quality for AAS analysis.

7.3.13 Nickel

Nitrate, 5 Percent Ni (W/V). Dissolve 24.780 g of nickel nitrate hexahydrate

[Ni(NO3)26H2O] in water in a 100-ml volumetric flask, and dilute to 100 ml with

water.

7.3.14 Nickel

Nitrate, 1 Percent Ni (W/V). Pipet 20 ml of 5 percent nickel nitrate solution

into a 100-ml volumetric flask, and dilute to exactly 100 ml with water.

7.3.15 Hydrogen

Peroxide, 3 Percent by Volume. Pipet 50 ml of 30 percent H2O2 into a 500-ml volumetric flask, and dilute to

exactly 500 ml with water.

7.3.16 Quality

Assurance Audit Samples. When making compliance determinations, and upon

availability, audit samples may be obtained from the appropriate EPA regional

Office or from the responsible enforcement authority.

NOTE: The responsible enforcement authority should be

notified at least 30 days prior to the test date to allow sufficient time for

sample delivery.

8.0 Sample Collection, Preservation, Transport, and Storage.

8.1 Pretest

Preparation. Follow the general procedure given in Method 5, Section 8.1, except the filter need

not be weighed, and the 200 ml of 0.1N NaOH and Container 4 should be tared to

within 0.5 g.

8.2 Preliminary

Determinations. Follow the general procedure given in Method 5, Section 8.2, except select the nozzle

size to maintain isokinetic sampling rates below 28 liters/min (1.0 cfm).

8.3 Preparation of

Sampling Train. Follow the general procedure given in Method 5, Section 8.3.

8.4 Leak-Check

Procedures. Same as Method 5, Section 8.4.

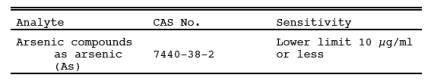

8.5 Sampling Train

Operation. Follow the general procedure given in Method

5, Section 8.5, except maintain isokinetic sampling flow rates below 28

liters/min (1.0 cfm). For each run, record the data required on a data sheet

similar to the one shown in Figure 108-2.

8.6 Calculation of

Percent Isokinetic. Same as Method 5, Section 8.6.

8.7 Sample Recovery.

Same as Method 5, Section 8.7, except that

0.1 N NaOH is used as the cleanup solvent instead of acetone and that the

impinger water is treated as follows:

8.7.1 Container

Number 4 (Impinger Water). Clean each of the first three impingers and

connecting glassware in the following manner:

8.7.1.1 Wipe the

impinger ball joints free of silicone grease, and cap the joints.

8.7.1.2 Rotate and

agitate each of the first two impingers, using the impinger contents as a rinse

solution.

8.7.1.3 Transfer the

liquid from the first three impingers to Container Number 4. Remove the outlet

ball-joint cap, and drain the contents through this opening. Do not separate

the impinger parts (inner and outer tubes) while transferring their contents to

the container.

8.7.1.4 Weigh the

contents of Container No. 4 to within 0.5 g. Record in the log the weight of

liquid along with a notation of any color or film observed in the impinger

catch. The weight of liquid is needed along with the silica gel data to

calculate the stack gas moisture content.

NOTE: Measure and record the total amount of 0.1 N

NaOH used for rinsing under Sections 8.7.1.5 and 8.7.1.6.

8.7.1.5 Pour

approximately 30 ml of 0.1 NaOH into each of the first two impingers, and

agitate the impingers. Drain the 0.1 N NaOH through the outlet arm of each

impinger into Container Number 4. Repeat this operation a second time; inspect

the impingers for any abnormal conditions.

8.7.1.6 Wipe the ball

joints of the glassware connecting the impingers and the back half of the filter

holder free of silicone grease, and rinse each piece of glassware twice with

0.1 N NaOH; transfer this rinse into Container Number 4. (DO NOT RINSE or brush

the glass-fritted filter support.) Mark the height of the fluid level to

determine whether leakage occurs during transport. Label the container to

identify clearly its contents.

8.8 Blanks.

8.8.1 Sodium

Hydroxide. Save a portion of the 0.1 N NaOH used for cleanup as a blank. Take

200 ml of this solution directly from the wash bottle being used and place it

in a plastic sample container labeled "NaOH blank."

8.8.2 Water. Save a

sample of the water, and place it in a container labeled "H2O blank."

8.8.3 Filter. Save

two filters from each lot of filters used in sampling. Place these filters in a

container labeled "filter blank."

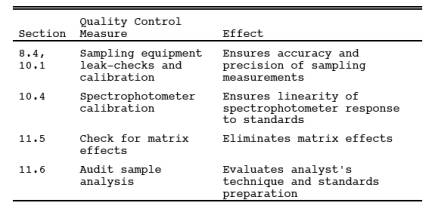

9.0 Quality Control.

9.1 Miscellaneous

Quality Control Measures.

9.2 Volume Metering

System Checks. Same as Method 5, Section 9.2.

10.0 Calibration and Standardization.

NOTE: Maintain a laboratory log of all calibrations.

10.1 Sampling Equipment.

Same as Method 5, Section 10.0.

10.2 Preparation of Standard Solutions.

10.2.1 For the high

level procedure, pipet 1, 3, 5, 8, and 10 ml of the 1.0 mg As/ml stock solution

into separate 100 ml volumetric flasks, each containing 5 ml of concentrated

HNO3. Dilute to the mark with water.

10.2.2 For the low

level vapor generator procedure, pipet 1, 2, 3, and 5 ml of 1.0 µg As/ml

standard solution into separate reaction tubes. Dilute to the mark with water.

10.2.3 For the low

level graphite furnace procedure,pipet 1, 5, 10 and 15 ml of 1.0 µg As/ml

standard solution into separate flasks along with 2 ml of the 5 percent nickel

nitrate solution and 10 ml of the 3 percent H202 solution. Dilute to the mark with water.

10.3 Calibration Curve.

Analyze a 0.8 N HNO3 blank and each standard solution according to the procedures

outlined in Section 11.4.1. Repeat this procedure on each standard solution

until two consecutive peaks agree within 3 percent of their average value.

Subtract the average peak height (or peak area) of the blank - which must be

less than 2 percent of recorder full scale - from the averaged peak height of

each standard solution. If the blank absorbance is greater than 2 percent of

full-scale, the probable cause is As contamination of a reagent or carry-over

of As from a previous sample. Prepare the calibration curve by plotting the corrected

peak height of each standard solution versus the corresponding final total As

weight in the solution.

10.4 Spectrophotometer Calibration Quality Control.

Calculate the least

squares slope of the calibration curve.

The line must pass through the origin or through a point no further from

the origin than ±2 percent of the recorder full scale. Multiply the corrected

peak height by the reciprocal of the least squares slope to determine the

distance each calibration point lies from the theoretical calibration line. The

difference between the calculated concentration values and the actual

concentrations (e.g., 1, 3,

5, 8, and 10 mg As for the high-level procedure) must be less than 7 percent

for all standards.

NOTE: For instruments equipped with direct concentration

readout devices, preparation of a standard curve will not be necessary. In all

cases, follow calibration and operational procedures in the manufacturers'

instruction manual.

11.0 Analytical Procedure.

11.1 Sample Loss Check.

Prior to analysis,

check the liquid level in Containers Number 2 and Number 4. Note on the

analytical data sheet whether leakage occurred during transport. If a

noticeable amount of leakage occurred, either void the sample or take steps,

subject to the approval of the Administrator, to adjust the final results.

11.2 Sample Preparation.

11.2.1 Container

Number 1 (Filter). Place the filter and loose particulate matter in a 150 ml

beaker. Also, add the filtered solid material from Container Number 2 (see

Section 11.2.2). Add 50 ml of 0.1 N NaOH. Then stir and warm on a hot plate at

low heat (do not boil) for about 15 minutes. Add 10 ml of concentrated HNO3, bring to a boil, then simmer for about 15 minutes. Filter the

solution through a glass fiber filter. Wash with hot water, and catch the

filtrate in a clean 150 ml beaker. Boil the filtrate, and evaporate to dryness.

Cool, add 5 ml of 50 percent HNO3, and then warm and

stir. Allow to cool. Transfer to a 50-ml volumetric flask, dilute to volume

with water, and mix well.

11.2.2 Container

Number 2 (Probe Wash).

11.2.2.1 Filter

(using a glass fiber filter) the contents of Container Number 2 into a 200 ml

volumetric flask. Combine the filtered (solid) material with the contents of

Container Number 1 (Filter).

11.2.2.2 Dilute the

filtrate to exactly 200 ml with water. Then pipet 50 ml into a 150 ml beaker.

Add 10 ml of concentrated HNO3, bring to a boil, and

evaporate to dryness. Allow to cool, add 5 ml of 50 percent HNO3, and then warm and stir. Allow the solution to cool, transfer to a

50-ml volumetric flask, dilute to volume with water, and mix well.

11.2.3 Container

Number 4 (Impinger Solution). Transfer the contents of Container Number 4 to a

500 ml volumetric flask, and dilute to exactly 500-ml with water. Pipet 50 ml

of the solution into a 150-ml beaker. Add 10 ml of concentrated HNO3, bring to a boil, and evaporate to dryness. Allow to cool, add 5

ml of 50 percent HNO3, and then warm and stir. Allow the solution to

cool, transfer to a 50-ml volumetric flask, dilute to volume with water, and

mix well.

11.2.4 Filter Blank.

Cut each filter into strips, and treat each filter individually as directed in

Section 11.2.1, beginning with the sentence, "Add 50 ml of 0.1 N

NaOH."

11.2.5 Sodium

Hydroxide and Water Blanks. Treat separately 50 ml of 0.1 N NaOH and 50 ml

water, as directed under Section 11.2.3, beginning with the sentence,

"Pipet 50 ml of the solution into a 150-ml beaker."

11.3 Spectrophotometer Preparation.

Turn on the power;

set the wavelength, slit width, and lamp current. Adjust the background

corrector as instructed by the manufacturer's manual for the particular atomic

absorption spectrophotometer. Adjust the burner and flame characteristics as

necessary.

11.4 Analysis.

Calibrate the analytical

equipment and develop a calibration curve as outlined in Sections 10.2 through

10.4

11.4.1 Arsenic

Samples. Analyze an appropriately sized aliquot of each diluted sample (from

Sections 11.2.1 through 11.2.3) until two consecutive peak heights agree within

3 percent of their average value. If applicable, follow the procedures outlined

in Section 11.4.1.1. If the sample concentration falls outside the range of the

calibration curve, make an appropriate dilution with 0.8 N HNO3 so that the final concentration falls within the range of the

curve. Using the calibration curve, determine the arsenic concentration in each

sample fraction.

NOTE: Because instruments vary between

manufacturers, no detailed operating instructions will be given here. Instead,

the instrument manufacturer's detailed operating instructions should be

followed.

11.4.1.1 Arsenic

Determination at Low Concentration. The lower limit of flame AAS is 10 µg

As/ml. If the arsenic concentration of any sample is at a lower level, use the

graphite furnace or vapor generator which is available as an accessory

component. Flame, graphite furnace, or vapor generators may be used for samples

whose concentrations are between 10 and 30 µg/ml. Follow the manufacturer's

instructions in the use of such equipment.

11.4.1.1.1 Vapor

Generator Procedure. Place a sample containing between 0 and 5 µg of arsenic in

the reaction tube, and dilute to 15 ml with water. Since there is some trial and

error involved in this procedure, it may be necessary to screen the samples by

conventional atomic absorption until an approximate concentration is

determined. After determining the approximate concentration, adjust the volume

of the sample accordingly. Pipet 15 ml of concentrated HCl into each tube. Add

1 ml of 30 percent KI solution. Place the reaction tube into a 50 ¼C (120 ¼F)

water bath for 5 minutes. Cool to room temperature. Connect the reaction tube

to the vapor generator assembly. When the instrument response has returned to

baseline, inject 5.0 ml of 5 percent NaBH4, and

integrate the resulting spectrophotometer signal over a 30-second time period.

11.4.1.1.2 Graphite

Furnace Procedure. Dilute the digested sample so that a 5 ml aliquot contains

less than 1.5 µg of arsenic. Pipet 5 ml of this digested solution into a 10-ml

volumetric flask. Add 1 ml of the 1 percent nickel nitrate solution, 0.5 ml of

50 percent HNO3, and 1 ml of the 3 percent hydrogen peroxide

and dilute to 10 ml with water. The sample is now ready for analysis.

11.4.1.2 Run a blank

(0.8 N HNO3) and standard at least after every five samples

to check the spectrophotometer calibration. The peak height of the blank must

pass through a point no further from the origin than ±2 percent of the recorder

full scale. The difference between the measured concentration of the standard

(the product of the corrected average peak height and the reciprocal of the

least squares slope) and the actual concentration of the standard must be less

than 7 percent, or recalibration of the analyzer is required.

11.4.1.3 Determine

the arsenic concentration in the filter blank (i.e., the average of the two blank values from each

lot).

11.4.2 Container

Number 3 (Silica Gel). This step may be conducted in the field. Weigh the spent

silica gel (or silica gel plus impinger) to the nearest 0.5 g; record this

weight.

11.5 Check for matrix effects on the arsenic results.

Same as Method 12, Section 11.5.

11.6 Audit Sample Analysis.

11.6.1 When the

method is used to analyze samples to demonstrate compliance with a source

emission regulation, a set of EPA audit samples must be analyzed, subject to

availability.

11.6.2 Concurrently

analyze the audit samples and the compliance samples in the same manner to

evaluate the technique of the analyst and the standards preparation.

NOTE: It is recommended that known quality control

samples be analyzed prior to the compliance and audit sample analyses to

optimize the system accuracy and precision. These quality control samples may

be obtained by contacting the appropriate EPA regional Office or the

responsible enforcement authority.

11.6.3 The same

analyst, analytical reagents, and analytical system shall be used for the

compliance samples and the EPA audit samples. If this condition is met,

duplicate auditing of subsequent compliance analyses for the same enforcement

agency within a 30-day period is waived. An audit sample set may not be used to

validate different sets of compliance samples under the jurisdiction of

separate enforcement agencies, unless prior arrangements have been made with

both enforcement agencies.

11.7 Audit Sample Results.

11.7.1 Calculate the

audit sample concentrations in g/m3 and

submit results using the instructions provided with the audit samples.

11.7.2 Report the

results of the audit samples and the compliance determination samples along

with their identification numbers, and the analyst's name to the responsible

enforcement authority. Include this information with reports of any subsequent

compliance analyses for the same enforcement authority during the 30-day

period.

11.7.3 The

concentrations of the audit samples obtained by the analyst shall agree within 10

percent of the actual concentrations. If the 10 percent specification is not

met, reanalyze the compliance and audit samples, and include initial and

reanalysis values in the test report.

11.7.4 Failure to

meet the 10 percent specification may require retests until the audit problems

are resolved. However, if the audit results do not affect the compliance or

noncompliance status of the affected facility, the Administrator may waive the

reanalysis requirement, further audits, or retests and accept the results of

the compliance test. While steps are being taken to resolve audit analysis

problems, the Administrator may also choose to use the data to determine the

compliance or noncompliance status of the affected facility.

12.0 Data Analysis and Calculations.

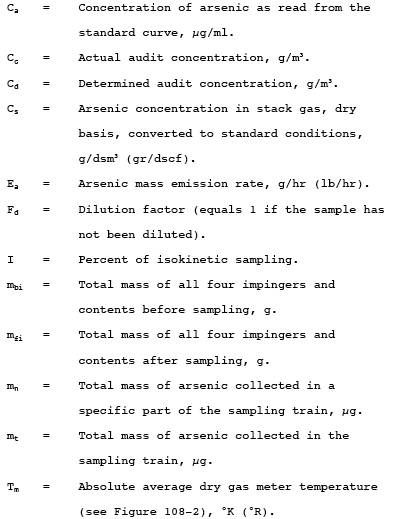

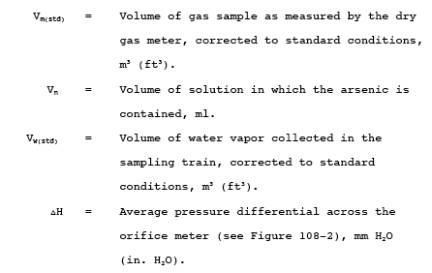

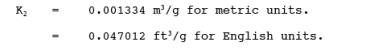

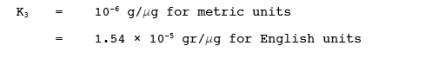

12.1 Nomenclature.

12.2 Average Dry Gas

Meter Temperatures (Tm) and Average Orifice Pressure Drop (ÆH). See

data sheet (Figure 108-2).

12.3 Dry Gas Volume.

Using data from this test, calculate Vm(std) according

to the procedures outlined in Method 5, Section

12.3.

12.4 Volume of Water

Vapor.

![]()

where:

12.5 Moisture

Content.

12.6 Amount of

Arsenic Collected.

12.6.1 Calculate the

amount of arsenic collected in each part of the sampling train, as follows:

![]()

12.6.2 Calculate the

total amount of arsenic collected in the sampling train as follows:

12.7 Calculate the arsenic

concentration in the stack gas (dry basis, adjusted to standard conditions) as

follows:

![]()

where:

12.8 Stack Gas

Velocity and Volumetric Flow Rate. Calculate the average stack gas velocity and

volumetric flow rate using data obtained in this method and the equations in Sections 12.2 and 12.3 of Method 2.

12.9 Pollutant Mass

Rate. Calculate the arsenic mass emission rate as follows:

![]()

12.10 Isokinetic

Variation. Same as Method 5, Section 12.11.

13.0 Method Performance.

13.1 Sensitivity. The

lower limit of flame AAS 10 µg As/ml. The analytical procedure includes provisions

for the use of a graphite furnace or vapor generator for samples with a lower

arsenic concentration.

14.0 Pollution Prevention. [Reserved]

15.0 Waste Management. [Reserved]

16.0 References.

Same as References 1

through 9 of Method 5, Section 17.0, with the

addition of the following:

1. Perkin Elmer

Corporation. Analytical Methods for Atomic Absorption Spectrophotometry.

303-0152. Norwalk, Connecticut. September 1976. pp. 5-6.

2. Standard

Specification for Reagent Water. In: Annual Book of American Society for

Testing and Materials Standards. Part 31: Water, Atmospheric Analysis. American

Society for Testing and Materials. Philadelphia, PA. 1974. pp. 40-42.

3. Stack Sampling

Safety Manual (Draft). U.S. Environmental Protection Agency, Office of Air

Quality Planning and Standard, Research Triangle Park, NC. September 1978.

17.0 Tables, Diagrams, Flowcharts, and Validation Data.

Figure

108-1. Arsenic Sampling Train

Figure

108-2. Arsenic Field Data Sheet.