METHOD 12 - DETERMINATION OF INORGANIC LEAD EMISSIONS FROM STATIONARY SOURCES

NOTE: This method does not include all of the

specifications (e.g.,

equipment and supplies) and procedures (e.g., sampling and analytical) essential to its

performance. Some material is incorporated by reference from other methods in

this part. Therefore, to obtain reliable results, persons using this method

should have a thorough knowledge of at least the following additional test

methods: Method 1, Method 2,

Method 3, and Method 5.

8.0 Sample Collection,

Preservation, Storage, and Transport.

10.0 Calibration and

Standardizations.

11.3 Spectrophotometer

Preparation.

11.5 Check for Matrix

Effects.

12.0 Data Analysis and

Calculations.

14.0 Pollution

Prevention. [Reserved]

15.0 Waste Management.

[Reserved]

16.1 Simultaneous

Determination of Particulate and Lead Emissions.

18.0 Tables, Diagrams,

Flowcharts, and Validation Data.

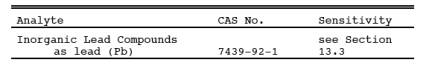

1.0 Scope and Application.

1.1 Analytes.

1.2 Applicability.

This method is

applicable for the determination of inorganic lead emissions from stationary

sources, only as specified in an applicable subpart of the regulations.

1.3 Data Quality Objectives.

Adherence to the

requirements of this method will enhance the quality of the data obtained from

air pollutant sampling methods.

2.0 Summary of Method.

2.1 Particulate and

gaseous Pb emissions are withdrawn isokinetically from the source and are

collected on a filter and in dilute nitric acid. The collected samples are

digested in acid solution and are analyzed by atomic absorption

spectrophotometry using an air/acetylene flame.

3.0 Definitions. [Reserved]

4.0 Interferences.

4.1 Copper.

High concentrations

of copper may interfere with the analysis of Pb at 217.0 nm. This interference

can be avoided by analyzing the samples at 283.3 nm.

4.2 Matrix Effects.

Analysis for Pb by

flame atomic absorption spectrophotometry is sensitive to the chemical

composition and to the physical properties (e.g., viscosity, pH) of the sample. The analytical

procedure requires the use of the Method of Standard Additions to check for

these matrix effects, and requires sample analysis using the Method of Standard

Additions if significant matrix effects are found to be present.

5.0 Safety.

5.1 Disclaimer.

This method may

involve hazardous materials, operations, and equipment. This test method may

not address all of the safety problems associated with its use. It is the

responsibility of the user of this test method to establish appropriate safety

and health practices and to determine the applicability of regulatory

limitations prior to performing this test method.

5.2 Corrosive Reagents.

The following

reagents are hazardous. Personal protective equipment and safe procedures are

useful in preventing chemical splashes. If contact occurs, immediately flush

with copious amounts of water at least 15 minutes. Remove clothing under shower

and decontaminate. Treat residual chemical burn as thermal burn.

5.2.1 Hydrogen

Peroxide (H2O2). Irritating to eyes,

skin, nose, and lungs.

5.2.2 Nitric Acid

(HNO3). Highly corrosive to eyes, skin, nose, and lungs.

Vapors cause bronchitis, pneumonia, or edema of lungs. Reaction to inhalation

may be delayed as long as 30 hours and still be fatal. Provide ventilation to

limit exposure. Strong oxidizer. Hazardous reaction may occur with organic

materials such as solvents.

6.0 Equipment and Supplies.

6.1 Sample Collection.

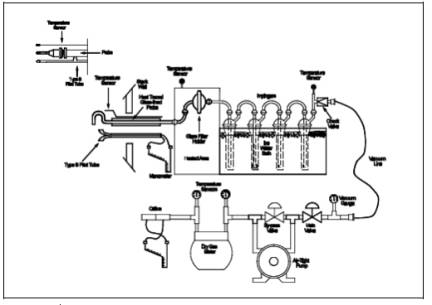

A schematic of the

sampling train used in performing this method is shown in Figure

12-1 in Section 18.0; it is similar to the Method 5 train. The following

items are needed for sample collection:

6.1.1 Probe Nozzle,

Probe Liner, Pitot Tube, Differential Pressure Gauge, Filter Holder, Filter

Heating System, Temperature Sensor, Metering System, Barometer, and Gas Density

Determination Equipment. Same as Method 5,

Sections 6.1.1.1 through 6.1.1.7, 6.1.1.9, 6.1.2, and 6.1.3, respectively.

6.1.2 Impingers. Four

impingers connected in series with leak-free ground glass fittings or any

similar leak-free noncontaminating fittings are needed. For the first, third,

and fourth impingers, use the Greenburg-Smith design, modified by replacing the

tip with a 1.3 cm (1/2 in.) ID glass tube extending to about 1.3 cm (1/2 in.)

from the bottom of the flask. For the second impinger, use the Greenburg-Smith

design with the standard tip.

6.1.3 Temperature

Sensor. Place a temperature sensor, capable of measuring temperature to within

1¼C (2¼F) at the outlet of the fourth impinger for monitoring purposes.

6.2 Sample Recovery.

The following items

are needed for sample recovery:

6.2.1 Probe-Liner and

Probe-Nozzle Brushes, Petri Dishes, Graduated Cylinder and/or Balance, Plastic

Storage Containers, and Funnel and Rubber Policeman. Same as Method 5, Sections 6.2.1 and 6.2.4 through

6.2.7, respectively.

6.2.2 Wash Bottles.

Glass (2).

6.2.3 Sample Storage

Containers. Chemically resistant, borosilicate glass bottles, for 0.1 N nitric

acid (HNO3) impinger and probe solutions and washes,

1000-ml. Use screw-cap liners that are either rubber-backed Teflon or leak-free

and resistant to chemical attack by 0.1 N HNO3.

(Narrow mouth glass bottles have been found to be less prone to leakage.)

6.2.4 Funnel. Glass,

to aid in sample recovery.

6.3 Sample Analysis.

The following items

are needed for sample analysis:

6.3.1 Atomic

Absorption Spectrophotometer. With lead hollow cathode lamp and burner for

air/acetylene flame.

6.3.2 Hot Plate.

6.3.3 Erlenmeyer

Flasks. 125-ml, 24/40 standard taper.

6.3.4 Membrane Filters.

Millipore SCWPO 4700, or equivalent.

6.3.5 Filtration

Apparatus. Millipore vacuum filtration unit, or equivalent, for use with the

above membrane filter.

6.3.6 Volumetric

Flasks. 100-ml, 250-ml, and 1000-ml.

7.0 Reagents and Standards.

NOTE: Unless otherwise indicated, it is intended that

all reagents conform to the specifications established by the Committee on

Analytical Reagents of the American Chemical Society, where such specifications

are available; otherwise, use the best available grade.

7.1 Sample Collection.

The following

reagents are needed for sample collection:

7.1.1 Filter. Gelman

Spectro Grade, Reeve Angel 934 AH, MSA 1106 BH, all with lot assay for Pb, or

other high purity glass fiber filters, without organic binder, exhibiting at

least 99.95 percent efficiency (<0.05 percent penetration) on 0.3 micron

dioctyl phthalate smoke particles. Conduct the filter efficiency test using

ASTM D 2986-71, 78, or 95a (incorporated by reference - see ¤ 60.17) or use

test data from the supplier's quality control program.

7.1.2 Silica Gel,

Crushed Ice, and Stopcock Grease. Same as Method

5, Sections 7.1.2, 7.1.4, and 7.1.5, respectively.

7.1.3 Water.

Deionized distilled, to conform to ASTM D 1193-77 or 91, Type 3 (incorporated

by reference--see ¤ 60.17). If high concentrations of organic matter are not

expected to be present, the potassium permanganate test for oxidizable organic

matter may be omitted.

7.1.4 Nitric Acid,

0.1 N. Dilute 6.5 ml of concentrated HNO3 to 1

liter with water. (It may be desirable to run blanks before field use to

eliminate a high blank on test samples.)

7.2 Sample Recovery.

0.1 N HNO3 (Same as in Section 7.1.4 above).

7.3 Sample Analysis.

The following

reagents and standards are needed for sample analysis:

7.3.1 Water. Same as

in Section 7.1.3.

7.3.2 Nitric Acid,

Concentrated.

7.3.3 Nitric Acid, 50

Percent (v/v). Dilute 500 ml of concentrated HNO3 to

1 liter with water.

7.3.4 Stock Lead Standard

Solution, 1000 µg Pb/ml. Dissolve 0.1598 g of lead nitrate [Pb(NO3)2] in about 60 ml water, add 2 ml concentrated

HNO3, and dilute to 100 ml with water.

7.3.5 Working Lead

Standards. Pipet 0.0, 1.0, 2.0, 3.0, 4.0, and 5.0 ml of the stock lead standard

solution (Section 7.3.4) into 250-ml volumetric flasks. Add 5 ml of

concentrated HNO3 to each flask, and dilute to volume with water.

These working standards contain 0.0, 4.0, 8.0, 12.0, 16.0, and 20.0 µg Pb/ml,

respectively. Prepare, as needed, additional standards at other concentrations

in a similar manner.

7.3.6 Air. Suitable

quality for atomic absorption spectrophotometry.

7.3.7 Acetylene.

Suitable quality for atomic absorption spectrophotometry.

7.3.8 Hydrogen

Peroxide, 3 Percent (v/v). Dilute 10 ml of 30 percent H2O2 to 100 ml with water.

8.0 Sample Collection, Preservation, Storage, and

Transport.

8.1 Pretest

Preparation. Follow the same general procedure given in Method 5, Section 8.1, except that the filter

need not be weighed.

8.2 Preliminary

Determinations. Follow the same general procedure given in Method 5, Section 8.2.

8.3 Preparation of

Sampling Train. Follow the same general procedure given in Method 5, Section 8.3, except place 100 ml of

0.1 N HNO3 (instead of water) in each of the first two

impingers. As in Method 5, leave the third impinger empty and transfer

approximately 200 to 300 g of pre-weighed silica gel from its container to the

fourth impinger. Set up the train as shown in Figure 12-1.

8.4 Leak-Check

Procedures. Same as Method 5, Section 8.4.

8.5 Sampling Train

Operation. Same as Method 5, Section 8.5.

8.6 Calculation of

Percent Isokinetic. Same as Method 5, Section 8.6.

8.7 Sample Recovery.

Same as Method 5, Sections 8.7.1 through

8.7.6.1, with the addition of the following:

8.7.1 Container No. 2

(Probe).

8.7.1.1 Taking care

that dust on the outside of the probe or other exterior surfaces does not get

into the sample, quantitatively recover sample matter and any condensate from

the probe nozzle, probe fitting, probe liner, and front half of the filter

holder by washing these components with 0.1 N HNO3 and

placing the wash into a glass sample storage container. Measure and record (to

the nearest 2 ml) the total amount of 0.1 N HNO3 used

for these rinses. Perform the 0.1 N HNO3 rinses as

follows:

8.7.1.2 Carefully

remove the probe nozzle, and rinse the inside surfaces with 0.1 N HNO3 from a wash bottle while brushing with a stainless steel,

Nylon-bristle brush. Brush until the 0.1 N HNO3 rinse

shows no visible particles, then make a final rinse of the inside surface with

0.1 N HNO3.

8.7.1.3 Brush and

rinse with 0.1 N HNO3

the inside parts of the Swagelok

fitting in a similar way until no visible particles remain.

8.7.1.4 Rinse the

probe liner with 0.1 N HNO3. While rotating the probe so that all inside

surfaces will be rinsed with 0.1 N HNO3, tilt the

probe, and squirt 0.1 N HNO3 into its upper end.

Let the 0.1 N HNO3 drain from the lower end into the sample

container. A glass funnel may be used to aid in transferring liquid washes to

the container. Follow the rinse with a probe brush. Hold the probe in an

inclined position, squirt 0.1 N HNO3 into the

upper end of the probe as the probe brush is being pushed with a twisting

action through the probe; hold the sample container underneath the lower end of

the probe, and catch any 0.1 N HNO3 and

sample matter that is brushed from the probe. Run the brush through the probe

three times or more until no visible sample matter is carried out with the 0.1

N HNO3 and none remains on the probe liner on visual

inspection. With stainless steel or other metal probes, run the brush through

in the above-prescribed manner at least six times, since metal probes have

small crevices in which sample matter can be entrapped. Rinse the brush with

0.1 N HNO3, and quantitatively collect these washings in

the sample container. After the brushing, make a final rinse of the probe as

described above.

8.7.1.5 It is

recommended that two people clean the probe to minimize loss of sample. Between

sampling runs, keep brushes clean and protected from contamination.

8.7.1.6 After

ensuring that all joints are wiped clean of silicone grease, brush and rinse

with 0.1 N HNO3 the inside of the from half of the filter

holder. Brush and rinse each surface three times or more, if needed, to remove

visible sample matter. Make a final rinse of the brush and filter holder. After

all 0.1 N HNO3 washings and sample matter are collected in the

sample container, tighten the lid on the sample container so that the fluid

will not leak out when it is shipped to the laboratory. Mark the height of the

fluid level to determine whether leakage occurs during transport. Label the

container to identify its contents clearly.

8.7.2 Container No. 3

(Silica Gel). Note the color of the indicating silica gel to determine if it

has been completely spent, and make a notation of its condition. Transfer the

silica gel from the fourth impinger to the original container, and seal. A

funnel may be used to pour the silica gel from the impinger and a rubber

policeman may be used to remove the silica gel from the impinger. It is not

necessary to remove the small amount of particles that may adhere to the walls

and are difficult to remove. Since the gain in weight is to be used for

moisture calculations, do not use any water or other liquids to transfer the

silica gel. If a balance is available in the field, follow the procedure for

Container No. 3 in Section 11.4.2.

8.7.3 Container No. 4

(Impingers). Due to the large quantity of liquid involved, the impinger

solutions may be placed in several containers. Clean each of the first three

impingers and connecting glassware in the following manner:

8.7.3.1. Wipe the

impinger ball joints free of silicone grease, and cap the joints.

8.7.3.2. Rotate and

agitate each impinger, so that the impinger contents might serve as a rinse solution.

8.7.3.3. Transfer the

contents of the impingers to a 500-ml graduated cylinder. Remove the outlet

ball joint cap, and drain the contents through this opening. Do not separate

the impinger parts (inner and outer tubes) while transferring their contents to

the cylinder. Measure the liquid volume to within 2 ml. Alternatively,

determine the weight of the liquid to within 0.5 g. Record in the log the

volume or weight of the liquid present, along with a notation of any color or

film observed in the impinger catch. The liquid volume or weight is needed,

along with the silica gel data, to calculate the stack gas moisture content

(see Method 5, Figure 5-6).

8.7.3.4. Transfer the

contents to Container No. 4.

NOTE: In Sections 8.7.3.5 and 8.7.3.6, measure and

record the total amount of 0.1 N HNO3 used for

rinsing.

8.7.3.5. Pour

approximately 30 ml of 0.1 N HNO3 into each of the

first three impingers and agitate the impingers. Drain the 0.1 N HNO3 through the outlet arm of each impinger into Container No. 4.

Repeat this operation a second time; inspect the impingers for any abnormal

conditions.

8.7.3.6. Wipe the

ball joints of the glassware connecting the impingers free of silicone grease

and rinse each piece of glassware twice with 0.1 N HNO3; transfer this rinse into Container No. 4. Do not rinse or brush

the glass-fritted filter support. Mark the height of the fluid level to

determine whether leakage occurs during transport. Label the container to

identify its contents clearly.

8.8 Blanks.

8.8.1 Nitric Acid.

Save 200 ml of the 0.1 N HNO3 used for sampling and

cleanup as a blank. Take the solution directly from the bottle being used and

place into a glass sample container labeled "0.1 N HNO3 blank."

8.8.2 Filter. Save

two filters from each lot of filters used in sampling. Place these filters in a

container labeled "filter blank."

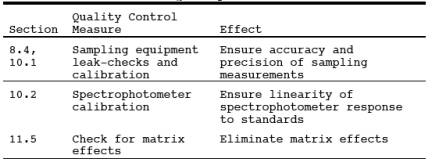

9.0 Quality Control.

9.1 Miscellaneous

Quality Control Measures. Section

9.2 Volume Metering

System Checks. Same as Method 5, Section 9.2.

10.0 Calibration and Standardizations.

NOTE: Maintain a laboratory log of all calibrations.

10.1 Sampling

Equipment. Same as Method 5, Section 10.0.

10.2.1 Measure the

absorbance of the standard solutions using the instrument settings recommended

by the spectrophotometer manufacturer. Repeat until good agreement (±3 percent)

is obtained between two consecutive readings. Plot the absorbance (y-axis)

versus concentration in µg Pb/ml (x-axis). Draw or compute a straight line

through the linear portion of the curve. Do not force the calibration curve

through zero, but if the curve does not pass through the origin or at least lie

closer to the origin than ±0.003 absorbance units, check for incorrectly

prepared standards and for curvature in the calibration curve.

10.2.2 To determine

stability of the calibration curve, run a blank and a standard after every five

samples, and recalibrate as necessary.

11.0 Analytical Procedures.

11.1 Sample Loss Check.

Prior to analysis,

check the liquid level in Containers Number 2 and Number 4. Note on the

analytical data sheet whether leakage occurred during transport. If a

noticeable amount of leakage occurred, either void the sample or take steps,

subject to the approval of the Administrator, to adjust the final results.

11.2 Sample Preparation.

11.2.1 Container No.

1 (Filter). Cut the filter into strips and transfer the strips and all loose

particulate matter into a 125-ml Erlenmeyer flask. Rinse the Petri dish with 10

ml of 50 percent HNO3

to ensure a quantitative transfer,

and add to the flask.

NOTE: If the total volume required in Section 11.2.3

is expected to exceed 80 ml, use a 250-ml flask in place of the 125-ml flask.

11.2.2 Containers No.

2 and No. 4 (Probe and Impingers). Combine the contents of Containers No. 2 and

No. 4, and evaporate to dryness on a hot plate.

11.2.3 Sample Extraction

for Lead.

11.2.3.1 Based on the

approximate stack gas particulate concentration and the total volume of stack

gas sampled, estimate the total weight of particulate sample collected. Next,

transfer the residue from Containers No. 2 and No. 4 to the 125-ml Erlenmeyer

flask that contains the sampling filter using a rubber policeman and 10 ml of

50 percent HNO3 for every 100 mg of sample collected in the

train or a minimum of 30 ml of 50 percent HNO3,

whichever is larger.

11.2.3.2 Place the

Erlenmeyer flask on a hot plate, and heat with periodic stirring for 30 minutes

at a temperature just below boiling. If the sample volume falls below 15 ml,

add more 50 percent HNO3. Add 10 ml of 3 percent H2O2, and continue heating for 10 minutes. Add 50 ml

of hot (80ûC, 176ûF) water, and heat for 20 minutes. Remove the flask from the

hot plate, and allow to cool. Filter the sample through a Millipore membrane

filter, or equivalent, and transfer the filtrate to a 250-ml volumetric flask.

Dilute to volume with water.

11.2.4 Filter Blank.

Cut each filter into strips, and place each filter in a separate 125-ml

Erlenmeyer flask. Add 15 ml of 50 percent HNO3,

and treat as described in Section 11.2.3 using 10 ml of 3 percent H2O2 and 50 ml of hot water. Filter and dilute to a

total volume of 100 ml using water.

11.2.5 Nitric Acid

Blank, 0.1 N. Take the entire 200 ml of 0.1 N HNO3 to

dryness on a steam bath, add 15 ml of 50 percent HNO3, and treat as described in Section 11.2.3 using 10 ml of 3 percent

H202 and 50 ml of hot water.

Dilute to a total volume of 100 ml using water.

11.3 Spectrophotometer Preparation.

Turn on the power;

set the wavelength, slit width, and lamp current; and adjust the background

corrector as instructed by the manufacturer's manual for the particular atomic

absorption spectrophotometer. Adjust the burner and flame characteristics as

necessary.

11.4 Analysis.

11.4.1 Lead

Determination. Calibrate the spectrophotometer as outlined in Section 10.2, and determine the absorbance for each

source sample, the filter blank, and 0.1 N HNO3 blank.

Analyze each sample three times in this manner. Make appropriate dilutions, as

needed, to bring all sample Pb concentrations into the linear absorbance range

of the spectrophotometer. Because instruments vary between manufacturers, no

detailed operating instructions will be given here. Instead, the instructions

provided with the particular instrument should be followed. If the Pb

concentration of a sample is at the low end of the calibration curve and high

accuracy is required, the sample can be taken to dryness on a hot plate and the

residue dissolved in the appropriate volume of water to bring it into the

optimum range of the calibration curve.

11.4.2

Container No. 3 (Silica Gel). This step may be conducted in the field. Weigh

the spent silica gel (or silica gel plus impinger) to the nearest 0.5 g; record

this weight.

11.5 Check for Matrix Effects.

Use the Method of

Standard Additions as follows to check at least one sample from each source for

matrix effects on the Pb results:

11.5.1 Add or spike

an equal volume of standard solution to an aliquot of the sample solution.

11.5.2 Measure the

absorbance of the resulting solution and the absorbance of an aliquot of

unspiked sample.

11.5.3 Calculate the

Pb concentration Cm

in µg/ml of the sample solution

using Equation 12-1 in Section 12.5. Volume

corrections will not be required if the solutions as analyzed have been made to

the same final volume. Therefore, Cm and Ca represent Pb concentration before dilutions. Method of Standard

Additions procedures described on pages 9-4 and 9-5 of the section entitled

"General Information" of the Perkin Elmer Corporation Atomic

Absorption Spectrophotometry Manual, Number 303-0152 (Reference 1 in Section 17.0) may also be used. In any event, if the

results of the Method of Standard Additions procedure used on the single source

sample do not agree to within ±5 percent of the value obtained by the routine

atomic absorption analysis, then reanalyze all samples from the source using

the Method of Standard Additions procedure.

12.0 Data Analysis and Calculations.

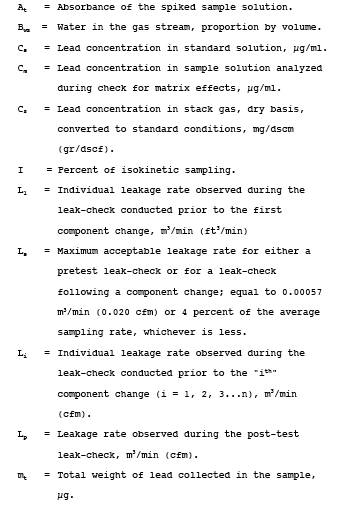

12.1 Nomenclature.

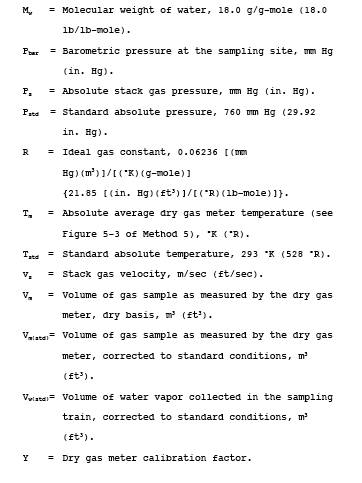

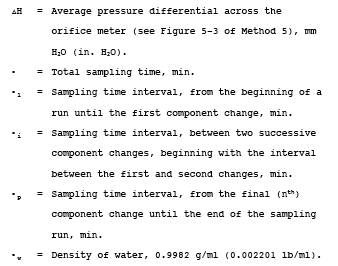

![]()

12.2 Average Dry Gas

Meter Temperatures (Tm) and Average Orifice Pressure Drop (ÆH). See

data sheet (Figure 5-3 of Method 5).

12.3 Dry Gas Volume,

Volume of Water Vapor, and Moisture Content. Using data obtained in this test,

calculate Vm(std), Vw(std), and

Bws according to the procedures outlined in Method 5, Sections 12.3 through 12.5.

12.4 Total Lead in

Source Sample. For each source sample, correct the average absorbance for the

contribution of the filter blank and the 0.1 N HNO3 blank. Use the calibration curve and this corrected absorbance to determine

the Pb concentration in the sample aspirated into the spectrophotometer.

Calculate the total Pb content mt (in µg) in the

original source sample; correct for all the dilutions that were made to bring

the Pb concentration of the sample into the linear range of the

spectrophotometer.

12.5

Sample Lead Concentration. Calculate the Pb concentration of the sample using

the following equation:

12.6 Lead

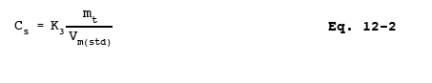

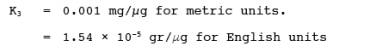

Concentration. Calculate the stack gas Pb concentration Cs using Equation 12-2:

where:

12.7 Stack Gas

Velocity and Volumetric Flow Rate. Calculate the average stack gas velocity and

volumetric flow rate using data obtained in this method and the equations in Sections 12.2 and 12.3 of Method 2.

12.8 Isokinetic

Variation. Same as Method 5, Section 12.11.

13.0 Method Performance.

13.1 Precision.

The within-laboratory

precision, as measured by the coefficient of variation, ranges from 0.2 to 9.5

percent relative to a run-mean concentration. These values were based on tests

conducted at a gray iron foundry, a lead storage battery manufacturing plant, a

secondary lead smelter, and a lead recovery furnace of an alkyl lead

manufacturing plant. The concentrations encountered during these tests ranged

from 0.61 to 123.3 mg Pb/m3.

13.2 Analytical Range.

For a minimum

analytical accuracy of ±10 percent, the lower limit of the range is 100 µg. The

upper limit can be extended considerably by dilution.

13.3 Analytical Sensitivity.

Typical sensitivities

for a 1-percent change in absorption (0.0044 absorbance units) are 0.2 and 0.5

µg Pb/ml for the 217.0 and 283.3 nm lines, respectively.

14.0 Pollution Prevention. [Reserved]

15.0 Waste Management. [Reserved]

16.0 Alternative Procedures.

16.1 Simultaneous Determination of Particulate and Lead Emissions.

Method 5 may be used

to simultaneously determine Pb provided: (1) acetone is used to remove

particulate from the probe and inside of the filter holder as specified by

Method 5, (2) 0.1 N HNO3

is used in the impingers, (3) a

glass fiber filter with a low Pb background is used, and (4) the entire train

contents, including the impingers, are treated and analyzed for Pb as described

in Sections 8.0 and 11.0 of this

method.

16.2 Filter Location.

A filter may be used

between the third and fourth impingers provided the filter is included in the

analysis for Pb.

16.3 In-Stack Filter.

An in-stack filter

may be used provided: (1) a glass-lined probe and at least two impingers, each

containing 100 ml of 0.1 N HNO3 after the in-stack

filter, are used and (2) the probe and impinger contents are recovered and

analyzed for Pb. Recover sample from the nozzle with acetone if a particulate

analysis is to be made.

17.0 References.

Same

as Method 5, Section 17.0, References 2, 3, 4,

5, and 7, with the addition of the following:

1. Perkin Elmer

Corporation. Analytical Methods for Atomic Absorption Spectrophotometry.

Norwalk, Connecticut. September 1976.

2. American Society

for Testing and Materials. Annual Book of ASTM Standards, Part 31: Water,

Atmospheric Analysis. Philadelphia, PA 1974. p. 40-42.

3. Kelin, R., and C.

Hach. Standard AdditionsÑUses and Limitations in Spectrophotometric Analysis.

Amer. Lab. 9:21-27. 1977.

4. Mitchell, W.J.,

and M.R. Midgett. Determining Inorganic and Alkyl Lead Emissions from

Stationary Sources. U.S. Environmental Protection Agency. Emission Monitoring

and Support Laboratory. Research Triangle Park, NC. (Presented at National APCA

Meeting, Houston. June 26, 1978).

18.0 Tables, Diagrams, Flowcharts, and Validation Data.

Figure

12-1. Inorganic Lead Sampling Train.