METHOD 6B -

DETERMINATION OF SULFUR DIOXIDE AND CARBON DIOXIDE DAILY AVERAGE EMISSIONS FROM

FOSSIL FUEL COMBUSTION SOURCES

NOTE: This method does not include all of the

specifications (e.g.,

equipment and supplies) and procedures (e.g., sampling and analytical) essential to its

performance. Some material is incorporated by reference from other methods in

this part. Therefore, to obtain reliable results, persons using this method

should have a thorough knowledge of at least the following additional test

methods: Method 1, Method 2,

Method 3, Method 5, Method 6, and Method 6A.

6.1 The isopropanol

bubbler is not used.

6.2 For intermittent

operation, include an industrial timer-switch

6.3 Stainless steel

sampling probes, type 316, are not recommended

8.0 Sample Collection,

Preservation, Transport, and Storage.

8.1 Preparation of

Sampling Train.

8.2 Sampling Train

Leak-Check Procedure.

10.0 Calibration and

Standardization.

10.1 Periodic

Calibration Check.

11.1 Sample Loss Check

and Analysis.

11.2 Quality Assurance

(QA) Audit Samples.

12.0 Data Analysis and

Calculations.

13.2 Repeatability and

Reproducibility.

14.0 Pollution

Prevention. [Reserved]

15.0 Waste Management.

[Reserved]

18.0 Tables, Diagrams,

Flowcharts, and Validation Data.

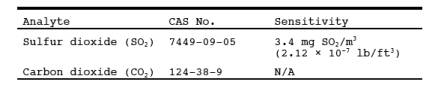

1.0 Scope and Application.

1.1 Analytes.

1.2 Applicability.

This method is

applicable for the determination of SO2 emissions

from combustion sources in terms of concentration (ng/dscm or lb/dscf) and emission

rate (ng/J or lb/106

Btu), and for the determination of

CO2 concentration (percent) on a daily (24 hours)

basis.

1.3 Data Quality Objectives.

Adherence to the

requirements of this method will enhance the quality of the data obtained from

air pollutant sampling methods.

2.0 Summary of Method.

2.1 A gas sample is

extracted from the sampling point in the stack intermittently over a 24-hour or

other specified time period. The SO2 fraction

is measured by the barium-thorin titration method. Moisture and CO2 fractions are collected in the same sampling train, and are

determined gravimetrically.

3.0 Definitions. [Reserved]

4.0 Interferences.

Same as Method 6, Section 4.0.

5.0 Safety.

5.1 Disclaimer.

This method may

involve hazardous materials, operations, and equipment. This test method may

not address all of the safety problems associated with its use. It is the

responsibility of the user to establish appropriate safety and health practices

and determine the applicability of regulatory limitations prior to performing

this test method.

5.2 Corrosive Reagents.

Same as Method 6, Section 5.2.

6.0 Equipment and Supplies.

Same as Method 6A, Section 6.0, with the following exceptions

and additions:

6.1 The isopropanol bubbler is not used.

An empty bubbler for

the collection of liquid droplets , that does not allow direct contact between

the collected liquid and the gas sample, may be included in the sampling train.

6.2 For intermittent operation, include an industrial timer-switch

For intermittent

operation, include an industrial timer-switch designed to operate in the

"on" position at least 2 minutes continuously and "off" the

remaining period over a repeating cycle. The cycle of operation is designated

in the applicable regulation. At a minimum, the sampling operation should

include at least 12, equal, evenly-spaced periods per 24 hours.

6.3 Stainless steel sampling probes, type 316, are not recommended

Stainless steel

sampling probes, type 316, are not recommended for use with Method 6B because

of potential sample contamination due to corrosion. Glass probes or other types

of stainless steel, e.g.,

Hasteloy or Carpenter 20, are recommended for long-term use.

NOTE: For applications downstream of wet scrubbers,

a heated out-of-stack filter (either borosilicate glass wool or glass fiber

mat) is necessary. Probe and filter heating systems capable of maintaining a

sample gas temperature of between 20 and 120 ûC (68 and 248 ûF) at the filter

are also required in these cases. The electric supply for these heating systems

should be continuous and separate from the timed operation of the sample pump.

7.0 Reagents and Standards.

Same as Method 6A, Section 7.0, with the following exceptions:

7.1 Isopropanol is

not used for sampling.

7.2 The hydrogen

peroxide absorbing solution shall be diluted to no less than 6 percent by

volume, instead of 3 percent as specified in Methods 6 and 6A.

7.3 If the Method 6B

sampling train is to be operated in a low sample flow condition (less than 100

ml/min or 0.21 ft3/hr), molecular sieve material may be

substituted for Ascarite II as the CO2 absorbing

material. The recommended molecular sieve material is Union Carbide 1/16 inch

pellets, 5 Aû, or equivalent. Molecular sieve material need not be discarded

following the sampling run, provided that it is regenerated as per the

manufacturer's instruction. Use of molecular sieve material at flow rates

higher than 100 ml/min (0.21 ft3/hr) may cause

erroneous CO2 results.

8.0 Sample Collection, Preservation, Transport, and Storage.

8.1 Preparation of Sampling Train.

Same as Method 6A, Section 8.1, with the addition of

the following:

8.1.1 The sampling

train is assembled as shown in Figure 6A-1 of

Method 6A, except that the isopropanol bubbler is not included.

8.1.2 Adjust the

timer-switch to operate in the "on" position from 2 to 4 minutes on a

2-hour repeating cycle or other cycle specified in the applicable regulation.

Other timer sequences may be used with the restriction that the total sample

volume collected is between 25 and 60 liters (0.9 and 2.1 ft3) for the amounts of sampling reagents prescribed in this method.

8.1.3 Add cold water

to the tank until the impingers and bubblers are covered at least two-thirds of

their length. The impingers and bubbler tank must be covered and protected from

intense heat and direct sunlight. If freezing conditions exist, the impinger

solution and the water bath must be protected.

NOTE: Sampling may be conducted continuously if a low

flow-rate sample pump [20 to 40 ml/min (0.04 to 0.08 ft3/hr) for the reagent volumes described in this method] is used. If

sampling is continuous, the timer-switch is not necessary. In addition, if the

sample pump is designed for constant rate sampling, the rate meter may be

deleted. The total gas volume collected should be between 25 and 60 liters (0.9

and 2.1 ft3) for the amounts of sampling reagents

prescribed in this method.

8.2 Sampling Train Leak-Check Procedure.

Same as Method 6, Section 8.2.

8.3 Sample Collection.

8.3.1 The probe and

filter (either in-stack, out-of-stack, or both) must be heated to a temperature

sufficient to prevent water condensation.

8.3.2 Record the

initial dry gas meter reading. To begin sampling, position the tip of the probe

at the sampling point, connect the probe to the first impinger (or filter), and

start the timer and the sample pump. Adjust the sample flow to a constant rate

of approximately 1.0 liter/min (0.035 cfm) as indicated by the rotameter.

Observe the operation of the timer, and determine that it is operating as

intended (i.e., the timer is

in the "on" position for the desired period, and the cycle repeats as

required).

8.3.3 One time

between 9:00 a.m. and 11:00 a.m. during the 24-hour sampling period, record the

dry gas meter temperature (Tm) and the barometric

pressure (P(bar)).

8.3.4 At the

conclusion of the run, turn off the timer and the sample pump, remove the probe

from the stack, and record the final gas meter volume reading. Conduct a leak-

check as described in Section 8.2. If a leak is found, void the test run or use

procedures acceptable to the Administrator to adjust the sample volume for

leakage. Repeat the steps in Sections 8.3.1 to 8.3.4 for successive runs.

8.4 Sample Recovery.

The procedures for

sample recovery (moisture measurement, peroxide solution, and CO2 absorber) are the same as those in Method

6A, Section 8.3.

9.0 Quality Control.

Same as Method 6, Section 9.0., with the exception of the

isopropanol-check.

10.0 Calibration and Standardization.

Same as Method 6, Section 10.0, with the addition of

the following:

10.1 Periodic Calibration Check.

After 30 days of

operation of the test train, conduct a calibration check according to the same

procedures as the post-test calibration check (Method 6, Section 10.1.2). If

the deviation between initial and periodic calibration factors exceeds 5

percent, use the smaller of the two factors in calculations for the preceding

30 days of data, but use the most recent calibration factor for succeeding test

runs.

11.0 Analytical Procedures.

11.1 Sample Loss Check and Analysis.

Same as Method 6, Sections 11.1 and 11.2, respectively.

11.2 Quality Assurance (QA) Audit Samples.

Analysis of QA audit

samples is required only when this method is used for compliance

determinations. Obtain an audit sample set as directed in Section 7.3.6 of

Method 6. Analyze the audit samples at least once for every 30 days of sample

collection, and report the results as directed in Section 11.3 of Method 6. The

analyst performing the sample analyses shall perform the audit analyses. If

more than one analyst performs the sample analyses during the 30-day sampling

period, each analyst shall perform the audit analyses and all audit results

shall be reported. Acceptance criteria for the audit results are the same as

those in Method 6.

12.0 Data Analysis and Calculations.

Same as Method 6A, Section 12.0, except that Pbar and Tm correspond

to the values recorded in Section 8.3.3 of this method. The values are as

follows:

Pbar = Initial barometric pressure for the test

period, mm Hg.

Tm = Absolute meter temperature for the test period, ûK.

13.0 Method Performance.

13.1 Range.

13.1.1 Sulfur

Dioxide. Same as Method 6.

13.1.2 Carbon

Dioxide. Not determined.

13.2 Repeatability and Reproducibility.

EPA-sponsored

collaborative studies were undertaken to determine the magnitude of

repeatability and reproducibility achievable by qualified testers following the

procedures in this method. The results of the studies evolve from field tests

including comparisons with Methods 3 and 6. For measurements of emission rates

from wet, flue gas desulfurization units in (ng/J), the repeatability

(intralaboratory precision) is 8.0 percent and the reproducibility

(inter-laboratory precision) is 11.1 percent.

14.0 Pollution Prevention. [Reserved]

15.0 Waste Management. [Reserved]

16.0 Alternative Methods.

Same as Method 6A, Section 16.0, except that the timer

is needed and is operated as outlined in this method.

17.0 References.

Same as Method 6A, Section 17.0, with the addition of

the following:

1. Butler, Frank E., et.

al. The Collaborative Test of

Method 6B: Twenty-Four-Hour Analysis of SO2 and CO2. JAPCA. Vol. 33, No. 10. October 1983.

18.0 Tables, Diagrams, Flowcharts, and Validation Data.

[Reserved]