METHOD 5A -

DETERMINATION OF PARTICULATE MATTER EMISSIONS FROM THE ASPHALT PROCESSING AND

ASPHALT ROOFING INDUSTRY

NOTE: This method does not include all of the

specifications (e.g.,

equipment and supplies) and procedures (e.g., sampling and analytical) essential to its

performance. Some material is incorporated by reference from other methods in

this part. Therefore, to obtain reliable results, persons using this method

should have a thorough knowledge of at least the following additional test

methods: Method 1, Method 2,

Method 3, and Method 5.

8.0. Sample Collection,

Preservation, Storage, and Transport.

8.2 Preliminary

Determinations.

8.3 Preparation of

Sampling Train.

8.6 Calculation of

Percent Isokinetic.

9.1 Miscellaneous

Quality Control Measures. Section Quality Control Measures

10.0 Calibration and

Standardization.

12.0 Data Analysis and

Calculations.

12.2 Dry Gas Meter

Temperature, Orifice Pressure Drop, and Dry Gas Volume.

13.0 Method

Performance. [Reserved]

14.0 Pollution

Prevention. [Reserved]

15.0 Waste Management.

[Reserved]

17.0 Tables, Diagrams,

Flowcharts, and Validation Data.

1.0 Scope and Applications.

1.1 Analyte.

Particulate matter (PM). No CAS number assigned.

1.2 Applicability.

This method is applicable for the determination of PM emissions from asphalt

roofing industry process saturators, blowing stills, and other sources as

specified in the regulations.

1.3 Data Quality

Objectives. Adherence to the requirements of this method will enhance the

quality of the data obtained from air pollutant sampling methods.

2.0 Summary of Method.

Particulate matter is

withdrawn isokinetically from the source and collected on a glass fiber filter

maintained at a temperature of 42 ± 10 ¡C (108 ± 18 ¡F). The PM mass, which

includes any material that condenses at or above the filtration temperature, is

determined gravimetrically after the removal of uncombined water.

3.0 Definitions. [Reserved]

4.0 Interferences. [Reserved]

5.0 Safety.

5.1 Disclaimer. This

method may involve hazardous materials, operations, and equipment. This test

method may not address all of the safety problems associated with its use. It

is the responsibility of the user of this test method to establish appropriate

safety and health practices and to determine the applicability of regulatory

limitations prior to performing this test method.

6.0 Equipment and Supplies.

6.1 Sample Collection.

Same as Method 5, Section 6.1, with the following

exceptions and additions:

6.1.1 Probe Liner.

Same as Method 5,

Section 6.1.1.2, with the note that at high stack gas temperatures greater than

250 ¡C (480 ¡F), water-cooled probes may be required to control the probe exit

temperature to 42 ± 10 ¡C

(108 ± 18 ¡F).

6.1.2 Precollector Cyclone.

Borosilicate glass

following the construction details shown in Air Pollution Technical Document

(APTD)-0581, "Construction Details of Isokinetic Source-Sampling

Equipment" (Reference 2 in Method 5,

Section 17.0).

NOTE: The cyclone shall be used when the stack gas

moisture is greater than 10 percent, and shall not be used otherwise.

6.1.3 Filter Heating System.

Any heating (or

cooling) system capable of maintaining a sample gas temperature at the exit end

of the filter holder during sampling at 42 ± 10 ¡C (108 ± 18 ¡F).

6.2 Sample Recovery.

The following items

are required for sample recovery:

6.2.1 Probe-Liner and

Probe-Nozzle Brushes, Graduated Cylinder and/or Balance, Plastic Storage

Containers, and Funnel and Rubber Policeman. Same as in Method 5, Sections 6.2.1, 6.2.5, 6.2.6, and

6.2.7, respectively.

6.2.2 Wash Bottles.

Glass.

6.2.3 Sample Storage

Containers. Chemically resistant 500-ml or 1,000-ml borosilicate glass bottles,

with rubber-backed Teflon screw cap liners or caps that are constructed so as

to be leak-free, and resistant to chemical attack by 1,1,1-trichloroethane

(TCE). (Narrow-mouth glass bottles have been found to be less prone to

leakage.)

6.2.4 Petri Dishes.

Glass, unless otherwise specified by the Administrator.

6.2.5 Funnel. Glass.

6.3 Sample Analysis.

Same as Method 5,

Section 6.3, with the following additions:

6.3.1 Beakers. Glass,

250-ml and 500-ml.

6.3.2 Separatory

Funnel. 100-ml or greater.

7.0. Reagents and Standards.

7.1 Sample Collection.

The following

reagents are required for sample collection:

7.1.1 Filters, Silica

Gel, Water, and Crushed Ice. Same as in Method

5, Sections 7.1.1, 7.1.2, 7.1.3, and 7.1.4, respectively.

7.1.2 Stopcock

Grease. TCE-insoluble, heat-stable grease (if needed). This is not necessary if

screw-onconnectors with Teflon sleeves, or similar, are used.

7.2 Sample Recovery.

Reagent grade TCE, ²

0.001 percent residue and stored in glass bottles. Run TCE blanks before field

use, and use only TCE with low blank values (²0.001 percent). In no case shall

a blank value of greater than 0.001 percent of the weight of TCE used be

subtracted from the sample weight.

7.3 Analysis.

Two reagents are

required for the analysis:

7.3.1 TCE. Same as in

Section 7.2.

7.3.2 Desiccant. Same

as in Method 5, Section 7.3.2.

8.0. Sample Collection, Preservation, Storage, and Transport.

8.1. Pretest Preparation.

Unless otherwise

specified, maintain and calibrate all components according to the procedure

described in APTD-0576, "Maintenance, Calibration, and Operation of

Isokinetic Source-Sampling Equipment" (Reference

3 in Method 5, Section 17.0).

8.1.1 Prepare probe

liners and sampling nozzles as needed for use. Thoroughly clean each component

with soap and water followed by a minimum of three TCE rinses. Use the probe

and nozzle brushes during at least one of the TCE rinses (refer to Section 8.7

for rinsing techniques). Cap or seal the open ends of the probe liners and

nozzles to prevent contamination during shipping.

8.1.2 Prepare silica

gel portions and glass filters as specified in Method

5, Section 8.1.

8.2 Preliminary Determinations.

Select the sampling

site, probe nozzle, and probe length as specified in Method 5, Section 8.2.

Select a total sampling time greater than or equal to the minimum total sampling

time specified in the "Test Methods and Procedures" section of the

applicable subpart of the regulations. Follow the guidelines outlined in Method 5, Section 8.2 for sampling time per

point and total sample volume collected.

8.3 Preparation of Sampling Train.

Prepare the sampling

train as specified in Method 5, Section 8.3,

with the addition of the precollector cyclone, if used, between the probe and

filter holder. The temperature of the precollector cyclone, if used, should be

maintained in the same range as that of the filter, i.e., 42 ± 10 ¡C (108 ± 18 ¡F). Use no stopcock

grease on ground glass joints unless grease is insoluble in TCE.

8.4 Leak-Check Procedures.

Same as Method 5, Section 8.4.

8.5 Sampling Train Operation.

Operate the sampling

train as described in Method 5, Section 8.5,

except maintain the temperature of the gas exiting the filter holder at 42 ±

10 ¡C (108 ± 18 ¡F).

8.6 Calculation of Percent Isokinetic.

Same as Method 5, Section 8.6.

8.7 Sample Recovery.

Same as Method 5, Section 8.7.1 through 8.7.6.1, with

the addition of the following:

8.7.1 Container No. 2

(Probe to Filter Holder).

8.7.1.1 Taking care

to see that material on the outside of the probe or other exterior surfaces

does not get into the sample, quantitatively recover PM or any condensate from

the probe nozzle, probe fitting, probe liner, precollector cyclone and

collector flask (if used), and front half of the filter holder by washing these

components with TCE and placing the wash in a glass container. Carefully measure the total amount of

TCE used in the rinses. Perform the TCE rinses as described in Method 5, Section 8.7.6.2, using TCE instead

of acetone.

8.7.1.2 Brush and

rinse the inside of the cyclone, cyclone collection flask, and the front half

of the filter holder. Brush and rinse each surface three times or more, if

necessary, to remove visible PM.

8.7.2 Container No. 3

(Silica Gel). Same as in Method 5, Section 8.7.6.3.

8.7.3 Impinger Water.

Same as Method 5, Section 8.7.6.4.

8.8 Blank.

Save a portion of the

TCE used for cleanup as a blank. Take 200 ml of this TCE directly from the wash

bottle being used, and place it in a glass sample container labeled "TCE

Blank."

9.0 Quality Control.

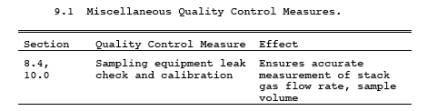

9.1 Miscellaneous Quality Control Measures. Section Quality Control

Measures

9.2 Quality Control Check

A quality control (QC)

check of the volume metering system at the field site is suggested before

collecting the sample. Use the procedure outlined in Method 5, Section 9.2.

10.0 Calibration and Standardization.

Same as Method 5, Section 10.0.

11.0 Analytical Procedures.

11.1 Analysis.

Record the data

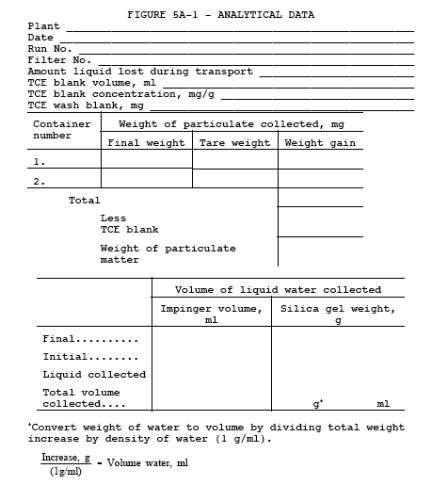

required on a sheet such as the one shown in Figure 5A-1.

Handle each sample container as follows:

11.1.1 Container No.

1 (Filter). Transfer the filter from the sample container to a tared glass

weighing dish, and desiccate for 24 hours in a desiccator containing anhydrous

calcium sulfate. Rinse Container No. 1 with a measured amount of TCE, and

analyze this rinse with the contents of Container No. 2. Weigh the filter to a

constant weight. For the purpose of this analysis, the term "constant

weight" means a difference of no more than 10 percent of the net filter

weight or 2 mg (whichever is greater) between two consecutive weighings made 24

hours apart. Report the "final weight" to the nearest 0.1 mg as the

average of these two values.

11.1.2 Container No.

2 (Probe to Filter Holder).

11.1.2.1 Before

adding the rinse from Container No. 1 to Container No. 2, note the level of

liquid in Container No. 2, and confirm on the analysis sheet whether leakage

occurred during transport. If noticeable leakage occurred, either void the

sample or take steps, subject to the approval of the Administrator, to correct

the final results.

11.1.2.2 Add the

rinse from Container No. 1 to Container No. 2 and measure the liquid in this

container either volumetrically to ±1 ml or gravimetrically to ±0.5 g. Check to

see whether there is any appreciable quantity of condensed water present in the

TCE rinse (look for a boundary layer or phase separation). If the volume of

condensed water appears larger than 5 ml, separate the oil- TCE fraction from

the water fraction using a separatory funnel. Measure the volume of the water

phase to the nearest ml; adjust the stack gas moisture content, if necessary

(see Sections 12.3 and 12.4). Next, extract the water phase with several 25-ml

portions of TCE until, by visual observation, the TCE does not remove any

additional organic material. Transfer the remaining water fraction to a tared

beaker and evaporate to dryness at 93 ¡C (200 ¡F), desiccate for 24 hours, and

weigh to the nearest 0.1 mg.

11.1.2.3 Treat the

total TCE fraction (including TCE from the filter container rinse and water

phase extractions) as follows: Transfer the TCE and oil to a tared beaker, and

11.1.3 Container No.

3 (Silica Gel). This step may be conducted in the field. Weigh the spent silica

gel (or silica gel plus impinger) to the nearest 0.5 g using a balance.

11.1.4 "TCE

Blank" Container. Measure TCE in this container either volumetrically or

gravimetrically. Transfer the TCE to a tared 250-ml beaker, and evaporate to

dryness at ambient temperature and pressure. Desiccate for 24 hours, and weigh

to a constant weight. Report the results to the nearest 0.1 mg.

NOTE: In order to facilitate the evaporation of TCE

liquid samples, these samples may be dried in a controlled temperature oven at

temperatures up to 38 ¡C (100 ¡F) until the liquid is evaporated.

12.0 Data Analysis and Calculations.

Carry out

calculations, retaining at least one extra significant figure beyond that of

the acquired data. Round off figures after the final calculation. Other forms of

the equations may be used as long as they give equivalent results.

12.1 Nomenclature.

Same as Method 5, Section 12.1, with the following

additions:

Ct = TCE blank residue concentration, mg/g.

mt = Mass of residue of TCE blank after evaporation, mg.

Vpc = Volume of water collected in precollector, ml.

Vt = Volume of TCE blank, ml.

Vtw = Volume of TCE used in wash, ml.

Wt = Weight of residue in TCE wash, mg.

¥ t = Density of TCE (see label on bottle), g/ml.

12.2 Dry Gas Meter Temperature, Orifice Pressure Drop, and Dry Gas Volume.

Same as Method 5,

Sections 12.2 and 12.3, except use data obtained in performing this test.

12.3 Volume of Water Vapor.

![]()

where:

K2 = 0.001333 m3/ml for metric units.

= 0.04706 ft3/ml for English units.

12.4 Moisture Content.

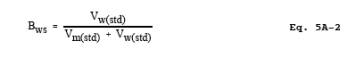

NOTE: In saturated or water droplet-laden gas streams,

two calculations of the moisture content of the stack gas shall be made, one

from the impinger and precollector analysis (Equations 5A-1 and 5A-2) and a

second from the assumption of saturated conditions. The lower of the two values

of moisture content shall be considered correct. The procedure for determining

the moisture content based upon assumption of saturated conditions is given in Section 4.0 of Method 4. For the purpose of this

method, the average stack gas temperature from Figure

5-3 of Method 5 may be used to make this determination, provided that the

accuracy of the in-stack temperature sensor is within 1 ¡C (2 ¡F).

12.5 TCE Blank Concentration.

NOTE: In no case shall a blank value of greater than 0.001

percent of the weight of TCE used be subtracted from the sample weight.

12.6 TCE Wash Blank.

![]()

12.7 Total PM Weight.

Determine the total

PM catch from the sum of the weights obtained from Containers 1 and 2, less the

TCE blank.

12.8 PM Concentration.

where: K3 = 0.001 g/mg for metric units

= 0.0154 gr/mg for English units

12.9 Isokinetic Variation.

Same as in Method 5, Section 12.11.

13.0 Method Performance. [Reserved]

14.0 Pollution Prevention. [Reserved]

15.0 Waste Management. [Reserved]

16.0 References.

Same as Method 5, Section 17.0.

17.0 Tables, Diagrams, Flowcharts, and Validation Data.