METHOD 2C -

DETERMINATION OF GAS VELOCITY AND VOLUMETRIC FLOW RATE IN SMALL STACKS OR DUCTS

(STANDARD PITOT TUBE)

NOTE: This method does not include all of the

specifications (e.g.,

equipment and supplies) and procedures (e.g., sampling) essential to its performance.

Some material is incorporated by reference from other methods in this part.

Therefore, to obtain reliable results, persons using this method should also

have a thorough knowledge of at least the following additional test methods: Method 1, Method 2.

6.1 Standard Pitot Tube

(instead of Type S).

7.0 Reagents and Standards.

[Reserved]

8.0 Sample Collection and

Analysis.

10.0 Calibration and

Standardization.

12.0 Calculations and Data

Analysis.

13.0 Method Performance.

[Reserved]

14.0 Pollution Prevention.

[Reserved]

15.0 Waste Management.

[Reserved]

17.0 Tables, Diagrams,

Flowcharts, and Validation Data.

1.0 Scope and Application.

1.1 This

method is applicable for the determination of average velocity and volumetric

flow rate of gas streams in small stacks or ducts. Limits on the applicability

of this method are identical to those set forth in Method 2, Section 1.0,

except that this method is limited to stationary source stacks or ducts less

than about 0.30 meter (12 in.) in diameter, or 0.071 m2 (113 in.2)

in cross-sectional area, but equal to or greater than about 0.10 meter (4 in.)

in diameter, or 0.0081 m2

(12.57 in.2) in cross-sectional area.

1.2 Data

Quality Objectives. Adherence to the requirements of this method will enhance

the quality of the data obtained from air pollutant sampling methods.

2.0 Summary of Method.

2.1 The

average gas velocity in a stack or duct is determined from the gas density and

from measurement of velocity heads with a standard pitot tube.

3.0 Definitions. [Reserved]

4.0 Interferences. [Reserved]

5.0 Safety.

5.1 This

method may involve hazardous materials, operations, and equipment. This test

method may not address all of the safety problems associated with its use. It is

the responsibility of the user of this test method to establish appropriate

safety and health practices and determine the applicability of regulatory

limitations prior to performing this test method.

6.0 Equipment and Supplies.

Same as Method 2, Section 6.0, with the exception of the

following:

6.1 Standard Pitot Tube (instead of Type S).

A standard

pitot tube which meets the specifications of Section

6.7 of Method 2. Use a coefficient of O.99 unless it is calibrated against

another standard pitot tube with a NIST-traceable coefficient (see Section 10.2 of Method 2).

6.2 Alternative Pitot Tube.

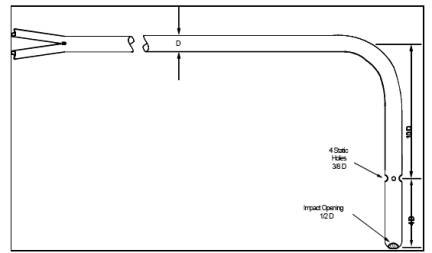

A modified

hemispherical-nosed pitot tube (see Figure 2C-1), which

features a shortened stem and enlarged impact and static pressure holes. Use a

coefficient of 0.99 unless it is calibrated as mentioned in Section 6.1 above.

This pitot tube is useful in particulate liquid droplet-laden gas streams when

a "back purge" is ineffective.

7.0 Reagents and Standards. [Reserved]

8.0 Sample Collection and Analysis.

8.1 Follow the

general procedures in Section 8.0 of Method 2,

except conduct the measurements at the traverse points specified in Method 1A. The static and impact pressure holes of

standard pitot tubes are susceptible to plugging in particulate-laden gas

streams. Therefore, adequate proof that the openings of the pitot tube have not

plugged during the traverse period must be furnished; this can be done by

taking the velocity head (Ąp) heading at the final traverse point, cleaning out

the impact and static holes of the standard pitot tube by

"back-purging" with pressurized air, and then taking another Ąp

reading. If the Ąp readings made before and after the air purge are the same

(within ±5 percent) the traverse is acceptable. Otherwise, reject the run. Note

that if the Ąp at the final traverse point is unsuitably low, another point may

be selected. If "back purging" at regular intervals is part of the

procedure, then take comparative Ąp readings, as above, for the last two back

purges at which suitably high Ąp readings are observed.

9.0 Quality Control.

10.0 Calibration and Standardization.

Same as Method

2, Sections 10.2 through 10.4.

11.0 Analytical Procedure.

Sample

collection and analysis are concurrent for this method (see Section 8.0).

12.0 Calculations and Data Analysis.

Same as Method

2, Section 12.0.

13.0 Method Performance. [Reserved]

14.0 Pollution Prevention. [Reserved]

15.0 Waste Management. [Reserved]

16.0 References.

Same as Method

2, Section 16.0.

17.0 Tables, Diagrams, Flowcharts, and Validation Data.

Figure

2C-1. Modified Hemispherical-Nosed Pitot Tube.