METHOD

1A - SAMPLE AND VELOCITY TRAVERSES FOR STATIONARYSOURCES WITH SMALL STACKS OR

DUCTS

NOTE: This method does not include all of the

specifications (e.g.,

equipment and supplies) and procedures (e.g., sampling) essential to its performance.

Some material is incorporated by reference from other methods in this part.

Therefore, to obtain reliable results, persons using this method should have a

thorough knowledge of at least the following additional test method: Method 1.

6.0 Equipment and Supplies.

[Reserved]

7.0 Reagents and Standards.

[Reserved]

8.0 Sample Collection,

Preservation, Storage, and Transport. [Reserved]

9.0 Quality Control.

[Reserved]

10.0 Calibration and

Standardization. [Reserved]

11.1 Selection of Measurement

Site.

11.1.1 Particulate

Measurements Ð

11.1.2 PM Sampling (Steady

Flow) or Velocity (Steady or Unsteady Flow)

11.2 Determining the Number of

Traverse Points.

11.2.1 Particulate

Measurements (Steady or Unsteady Flow).

11.2.2 PM Sampling (Steady

Flow) or only Velocity (Non-Particulate) Measurements.

12.0 Data Analysis and

Calculations. [Reserved]

13.0 Method Performance.

[Reserved]

14.0 Pollution Prevention.

[Reserved]

15.0 Waste Management.

[Reserved]

17.0 Tables, Diagrams,

Flowcharts, and Validation Data.

1.0 Scope and Application.

1.1 Measured Parameters.

The purpose of the

method is to provide guidance for the selection of sampling ports and traverse

points at which sampling for air pollutants will be performed pursuant to

regulations set forth in this part.

1.2 Applicability.

The applicability

and principle of this method are identical to Method 1, except its

applicability is limited to stacks or ducts. This method is applicable to

flowing gas streams in ducts, stacks, and flues of less than about O.30 meter

(12 in.) in diameter, or 0.071 m2 (113 in.2) in cross-sectional area, but equal to or

greater than about O.10 meter (4 in.) in diameter, or 0.0081 m2 (12.57 in.2) in

cross-sectional area. This method cannot be used when the flow is cyclonic or

swirling.

1.3 Data Quality Objectives.

Adherence to the

requirements of this method will enhance the quality of the data obtained from

air pollutant sampling methods.

2.0 Summary of Method.

2.1 The method is

designed to aid in the representative measurement of pollutant emissions and/or

total volumetric flow rate from a stationary source. A measurement site or a

pair of measurement sites where the effluent stream is flowing in a known

direction is (are) selected. The cross-section of the stack is divided into a

number of equal areas. Traverse points are then located within each of these

equal areas.

2.2 In these small

diameter stacks or ducts, the conventional Method 5

stack assembly (consisting of a Type S pitot tube attached to a sampling probe,

equipped with a nozzle and thermocouple) blocks a significant portion of the

cross-section of the duct and causes inaccurate measurements. Therefore, for

particulate matter (PM) sampling in small stacks or ducts, the gas velocity is

measured using a standard pitot tube downstream of the actual emission sampling

site. The straight run of duct between the PM sampling and velocity measurement

sites allows the flow profile, temporarily disturbed by the presence of the

sampling probe, to redevelop and stabilize.

3.0 Definitions. [Reserved]

4.0 Interferences. [Reserved]

5.0 Safety.

5.1 Disclaimer.

This method may

involve hazardous materials, operations, and equipment. This test method may

not address all of the safety problems associated with its use. It is the

responsibility of the user of this test method to establish appropriate safety

and health practices and determine the applicability of regulatory limitations

prior to performing this test method.

6.0 Equipment and Supplies. [Reserved]

7.0 Reagents and Standards. [Reserved]

8.0 Sample Collection, Preservation, Storage, and Transport. [Reserved]

9.0 Quality Control. [Reserved]

10.0 Calibration and Standardization. [Reserved]

11.0 Procedure.

11.1 Selection of Measurement Site.

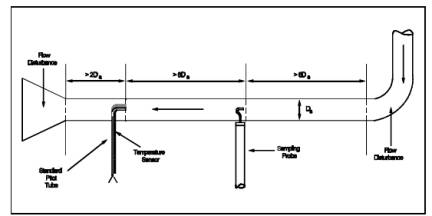

11.1.1 Particulate Measurements Ð

Steady or Unsteady

Flow. Select a particulate measurement site located preferably at least eight

equivalent stack or duct diameters downstream and 10 equivalent diameters

upstream from any flow disturbances such as bends, expansions, or contractions

in the stack, or from a visible flame. Next, locate the velocity measurement

site eight equivalent diameters downstream of the particulate measurement site

(see Figure 1A-1). If such locations are not available,

select an alternative particulate measurement location at least two equivalent

stack or duct diameters downstream and two and one-half diameters upstream from

any flow disturbance. Then, locate the velocity measurement site two equivalent

diameters downstream from the particulate measurement site. (See Section 12.2 of Method 1 for calculating

equivalent diameters for a rectangular cross-section.)

11.1.2 PM Sampling (Steady Flow) or Velocity (Steady or Unsteady Flow)

Measurements. For

PM sampling when the volumetric flow rate in a duct is constant with respect to

time, Section 11.1.1 of Method 1 may be

followed, with the PM sampling and velocity measurement performed at one

location. To demonstrate that the flow rate is constant (within 10 percent)

when PM measurements are made, perform complete velocity traverses before and

after the PM sampling run, and calculate the deviation of the flow rate derived

after the PM sampling run from the one derived before the PM sampling run. The

PM sampling run is acceptable if the deviation does not exceed 10 percent.

11.2 Determining the Number of Traverse Points.

11.2.1 Particulate Measurements (Steady or Unsteady Flow).

Use Figure 1-1 of Method 1 to determine the number of

traverse points to use at both the velocity measurement and PM sampling

locations. Before referring to the figure, however, determine the distances

between both the velocity measurement and PM sampling sites to the nearest

upstream and downstream disturbances. Then divide each distance by the stack

diameter or equivalent diameter to express the distances in terms of the number

of duct diameters. Then, determine the number of traverse points from Figure

1-1 of Method 1 corresponding to each of these four distances. Choose the

highest of the four numbers of traverse points (or a greater number) so that,

for circular ducts the number is a multiple of four; and for rectangular ducts,

the number is one of those shown in Table 1-1 of

Method 1. When the optimum duct diameter location criteria can be satisfied,

the minimum number of traverse points required is eight for circular ducts and

nine for rectangular ducts.

11.2.2 PM Sampling (Steady Flow) or only Velocity (Non-Particulate) Measurements.

Use Figure 1-2 of Method 1 to determine number of

traverse points, following the same procedure used for PM sampling as described

in Section 11.2.1 of Method 1. When the optimum duct diameter location criteria

can be satisfied, the minimum number of traverse points required is eight for

circular ducts and nine for rectangular ducts.

11.3 Cross-sectional Layout, Location of Traverse Points, and Verification of the Absence of Cyclonic Flow.

Same as Method 1,

Sections 11.3 and 11.4, respectively.

12.0 Data Analysis and Calculations. [Reserved]

13.0 Method Performance. [Reserved]

14.0 Pollution Prevention. [Reserved]

15.0 Waste Management. [Reserved]

16.0 References.

Same as Method 1, Section 16.0, References 1 through 6, with

the addition of the following:

1. Vollaro, Robert

F. Recommended Procedure for Sample Traverses in Ducts Smaller Than 12 Inches

in Diameter. U.S. Environmental Protection Agency, Emission Measurement Branch,

Research Triangle Park, North Carolina. January 1977.

17.0 Tables, Diagrams, Flowcharts, and Validation Data.

Figure

1A-1. Recommended sampling arrangement for small ducts