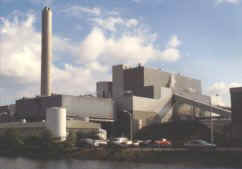

SEMASS Resource Recovery Facility

|

American Ref-Fuel

Company of SEMASS, L.P. Plant Tour

Information Contact: Plant Tour Information Form Directions to Facility Materials Separation Plan (691kB MS Word document) The SEMASS Resource Recovery Facility provides southeastern Massachusetts communities with an alternative to landfilling their municipal solid waste. Since opening in 1989, the facility has employed a shred-and-burn process developed by Energy Answers Corporation (EAC), the SEMASS facility?s developer, enabling the plant?s processing of approximately one million tons of solid waste each year. The resulting electricity meets the needs of more than 75,000 homes. The facility also recovers nearly 20,000 tons of recyclable metals from bottom ash annually. American Ref-Fuel Company acquired controlling interest in SEMASS Partnership, the facility?s owner, in 1996. Energy Answers Corporation and ESI Energy, Inc. previously composed the SEMASS Partnership. Among the numerous operational and environmental prizes awarded to the SEMASS facility is the American Academy of Environmental Engineers? Honor Award for EAC?s ash technology. The SEMASS Resource Recovery Facility received its OSHA Star facility designation in 2000 and was recertified as a VPP Star in 2003. |

Key Project FactsService Area: Southeastern Massachusetts, Cape Cod and Boston vicinity Owner: SEMASS Partnership, which is 90 percent owned by American Ref-Fuel Company of SEMASS, L.P. Financing Method: Private financing Waste Supply: Participating municipalities and private haulers to deliver approximately one million tons per year Energy Market: Electricity generation for plant use and export to Commonwealth Electric Co. Capacity: 3,000 tons per day Number of Process Lines: Three Riley-Stoker boilers. Steam Conditions at Boiler Outlet: 300,000 lbs/hr @ 650 psia/750Śr Turbine-Generator: One 54-megawatt nominal condensing unit and one 30-megawatt condensing unit Air Quality Control: Units 1 and 2 have dry scrubbers with a 5-field electrostatic precipitator and COHPAC baghouse, along with carbon injection. Unit 3 uses a dry scrubber and baghouse. Stack Height: 345 feet Secondary Materials Recovery: Recovery of ferrous and non-ferrous metals |

Company Information | Contact Information | Special Waste Services | Plant Locations | Energy Marketing | Our Process | Employment | Site Map | Links