Method 318 -

Extractive FTIR Method for the Measurement of

Emissions from the

Mineral Wool and Wool Fiberglass Industries

APPENDIX

A TO PART 63--TEST METHOD

1.3 Method Range and Sensitivity.

4.1 Analytical (or

Spectral) Interferences.

4.2 Sampling System

Interferences.

8.0 Sample Collection,

Preservation, and Storage.

8.1 Pretest

Preparations and Evaluations.

8.2 Sampling System

Leak-check.

8.3 Analytical System

Leak-check.

8.5 Pre-Test Calibration

Transfer Standard.

8.7 Sampling QA, Data

Storage and Reporting.

10.0 Calibration and

Standardization.

10.1 Signal-to-Noise

Ratio (S/N).

12.0 Data Analysis and

Calculations.

13.0 Reporting and

Recordkeeping.

15.0 Pollution

Prevention. [Reserved]

1.0 Scope and Application.

This method has been

validated and approved for mineral wool and wool fiberglass sources. This

method may not be applied to other source categories without validation and

approval by the Administrator according to the procedures in Test Method 301,

40 CFR Part 63, Appendix A. For sources seeking to apply FTIR to other source

categories, Test Method 320 (40 CFR Part 63, Appendix A) may be utilized.

1.1 Scope.

The analytes measured

by this method and their CAS numbers are:

Carbon Monoxide

630-08-0

Carbonyl Sulfide

463-58-1

Formaldehyde 50-00-0

Methanol 1455-13-6

Phenol 108-95-2

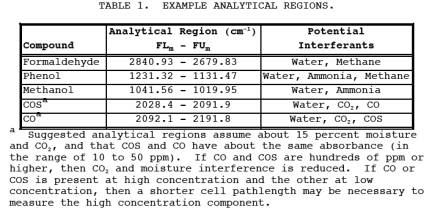

1.2 Applicability.

1.2.1 This method is

applicable for the determination of formaldehyde, phenol, methanol, carbonyl

sulfide (COS) and carbon monoxide (CO) concentrations in controlled and

uncontrolled emissions from manufacturing processes using phenolic resins. The

compounds are analyzed in the mid-infrared spectral region (about 400 to 4000

cm-1 or 25 to 2.5 Fm). Suggested analytical regions

are given below (Table 1). Slight deviations from these recommended regions may

be necessary due to variations in moisture content and ammonia concentration

from source to source.

1.2.2 This method

does not apply when: (a) polymerization of formaldehyde occurs, (b) moisture

condenses in either the sampling system or the instrumentation, and (c) when

moisture content of the gas stream is so high relative to the analyte

concentrations that it causes severe spectral interference.

1.3 Method Range and Sensitivity.

1.3.1 The analytical

range is a function of instrumental design and composition of the gas stream.

Theoretical detection limits depend, in part, on (a) the absorption coefficient

of the compound in the analytical frequency region, (b) the spectral

resolution, (c) interferometer sampling time, (d) detector sensitivity and

response, and (e) absorption path-length.

1.3.2 Practically,

there is no upper limit to the range. The practical lower detection limit is

usually higher than the theoretical value, and depends on (a) moisture content

of the flue gas, (b) presence of interferants, and (c) losses in the sampling

system. In general, a 22 meter path-length cell in a suitable sampling system

can achieve practical detection limits of 1.5 ppm for three compounds

(formaldehyde, phenol, and methanol) at moisture levels up to 15 percent by

volume. Sources with uncontrolled emissions of CO and COS may require a 4 meter

path-length cell due to high concentration levels. For these two compounds,

make sure absorbance of highest concentration component is <1.0.

1.4 Data Quality Objectives.

1.4.1 In designing or

configuring the system, the analyst first sets the data quality objectives,

i.e., the desired lower detection limit (DLi) and the

desired analytical uncertainty (AUi) for each

compound. The instrumental parameters (factors b, c, d, and e in Section 1.3.1)

are then chosen to meet these requirements, using Appendix D of the FTIR

Protocol.

1.4.2 Data quality

for each application is determined, in part, by measuring the RMS (Root Mean

Square) noise level in each analytical spectral region (Appendix C of the FTIR

Protocol). The RMS noise is

defined as the RMSD (Root Mean Square Deviation) of the absorbance values in an

analytical region from the mean absorbance value of the region. Appendix D of

the FTIR Protocol defines

the MAUim (minimum analyte uncertainty of the ith analyte in the mth analytical

region). The MAU is the minimum analyte concentration for which the analytical

uncertainty limit (AUi) can be maintained: if the measured analyte

concentration is less than MAUi, then data quality is

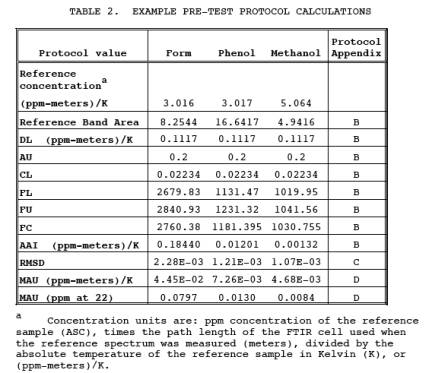

unacceptable. Table 2 gives some

2.0 Summary of Method.

2.1 Principle.

2.1.1 Molecules are

composed of chemically bonded atoms, which are in constant motion. The atomic

motions result in bond deformations (bond stretching and bond-angle bending).

The number of fundamental (or independent) vibrational motions depends on the

number of atoms (N) in the molecule. At typical testing temperatures, most

molecules are in the ground-state vibrational state for most of their

fundamental vibrational motions. A molecule can undergo a transition from its

ground state (for a particular vibration) to the first excited state by

absorbing a quantum of light at a frequency characteristic of the molecule and

the molecular motion. Molecules also undergo rotational transitions by

absorbing energies in the far-infrared or microwave spectral regions.

Rotational transition absorbencies are superimposed on the vibrational

absorbencies to give a characteristic shape to each rotational-vibrational

absorbance "band."

2.1.2 Most molecules

exhibit more than one absorbance band in several frequency regions to produce

an infrared spectrum (a characteristic pattern of bands or a

"fingerprint") that is unique to each molecule. The infrared spectrum

of a molecule depends on its structure (bond lengths, bond angles, bond

strengths, and atomic masses). Even small differences in structure can produce

significantly different spectra.

2.1.3 Spectral band

intensities vary with the concentration of the absorbing compound. Within

constraints, the relationship between absorbance and sample concentration is

linear. Sample spectra are compared to reference spectra to determine the

species and their concentrations.

2.2 Sampling and Analysis.

2.2.1 Flue gas is

continuously extracted from the source, and the gas or a portion of the gas is

conveyed to the FTIR gas cell, where a spectrum of the flue gas is recorded.

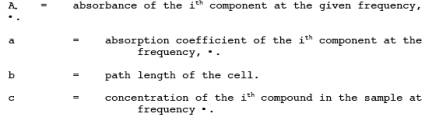

Absorbance band intensities are related to sample concentrations by Beer's Law.

![]()

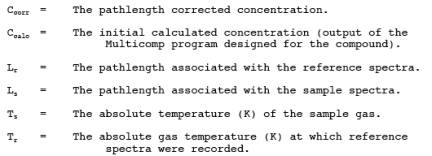

where:

2.2.2 After identifying

a compound from the infrared spectrum, its concentration is determined by

comparing band intensities in the sample spectrum to band intensities in

"reference spectra" of the formaldehyde, phenol, methanol, COS and

CO. These reference spectra are available in a permanent soft copy from the EPA

spectral library on the EMTIC bulletin board. The source may also prepare

reference spectra according to Section 4.5 of the FTIR Protocol. (Note: Reference spectra not prepared

according to the FTIR Protocol are not acceptable for use in this test method.

Documentation detailing the FTIR Protocol steps used in preparing any non-EPA

reference spectra shall be included in each test report submitted by the

source.)

2.3 Operator Requirements.

The analyst must have

some knowledge of source sampling and of infrared spectral patterns to operate

the sampling system and to choose a suitable instrument configuration. The

analyst should also understand FTIR instrument operation well enough to choose

an instrument configuration consistent with the data quality objectives.

3.0 Definitions.

See Appendix A of the

FTIR Protocol.

4.0 Interferences.

4.1 Analytical (or Spectral) Interferences.

Water vapor. High

concentrations of ammonia (hundreds of ppm) may interfere with the analysis of

low concentrations of methanol (1 to 5 ppm). For CO, carbon dioxide and water

may be interferants. In cases where COS levels are low relative to CO levels,

CO and water may be interferants.

4.2 Sampling System Interferences.

Water, if it condenses,

and ammonia, which reacts with formaldehyde.

5.0 Safety.

5.1 Formaldehyde is a

suspected carcinogen; therefore, exposure to this compound must be limited.

Proper monitoring and safety precautions must be practiced in any atmosphere

with potentially high concentrations of CO.

5.2 This method may

involve sampling at locations having high positive or negative pressures, high

temperatures, elevated heights, high concentrations of hazardous or toxic

pollutants, or other diverse sampling conditions. It is the responsibility of

the tester(s) to ensure proper safety and health practices, and to determine

the applicability of regulatory limitations before performing this test method.

6.0 Equipment and Supplies.

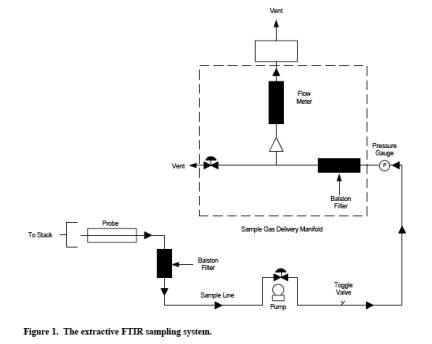

The equipment and

supplies are based on the schematic of a sampling train shown in Figure 1.

Either the evacuated or purged sampling technique may be used with this

sampling train. Alternatives may be used, provided that the data quality

objectives of this method are met.

6.1 Sampling Probe.

Glass, stainless steel, or other appropriate material of sufficient length and

physical integrity to sustain heating, prevent adsorption of analytes, and to

reach gas sampling point.

6.2 Particulate

Filters. A glass wool plug (optional) inserted at the probe tip (for large

particulate removal) and a filter rated at 1-micron (e.g., Balstonª) for fine particulate removal, placed immediately after the heated

probe.

6.3 Sampling

Line/Heating System. Heated (maintained at 250 ± 25 degrees F) stainless steel,

TeflonTM, or other inert material that does not adsorb

the analytes, to transport the sample to analytical system.

6.4 Stainless Steel

Tubing. Type 316, e.g., 3/8 in. diameter, and appropriate length for heated

connections.

6.5 Gas Regulators.

Appropriate for individual gas cylinders.

6.6 TeflonTM Tubing. Diameter (e.g., 3/8 in.) and length

suitable to connect cylinder regulators.

6.7 Sample Pump. A

leak-free pump (e.g., KNFª), with by-pass valve, capable of pulling sample

through entire sampling system at a rate of about 10 to 20 L/min. If placed

before the analytical system, heat the pump and use a pump fabricated from

materials non-reactive to the target pollutants. If the pump is located after

the instrument, systematically record the sample pressure in the gas cell.

6.8 Gas Sample

Manifold. A heated manifold that diverts part of the sample stream to the

analyzer, and the rest to the by-pass discharge vent or other analytical

instrumentation.

6.9 Rotameter. A

calibrated 0 to 20 L/min range rotameter.

6.10 FTIR Analytical

System. Spectrometer and detector, capable of measuring formaldehyde, phenol,

methanol, COS and CO to the predetermined minimum detectable level. The system

shall include a personal computer with compatible software that provides

real-time updates of the spectral profile during sample collection and spectral

collection.

6.11 FTIR Cell Pump.

Required for the evacuated sampling technique, capable of evacuating the FTIR

cell volume within 2 minutes. The FTIR cell pump should allow the operator to

obtain at least 8 sample spectra in 1 hour.

6.12 Absolute

Pressure Gauge. Heatable and capable of measuring pressure from 0 to 1000 mmHg

to within ±2.5 mmHg (e.g., Baratronª).

6.13 Temperature

Gauge. Capable of measuring the cell temperature to within ±2¡C.

7.0 Reagents and Standards.

7.1 Ethylene

(Calibration Transfer Standard). Obtain NIST traceable (or Protocol) cylinder

gas.

7.2 Nitrogen. Ultra

high purity (UHP) grade.

7.3 Reference

Spectra. Obtain reference spectra for the target pollutants at concentrations

that bracket (in ppm-meter/K) the emission source levels. Also, obtain

reference spectra for SF6

and ethylene. Suitable

concentrations are 0.0112 to 0.112 (ppm-meter)/K for SF6 and 5.61 (ppm-meter)/K or less for ethylene. The reference spectra

shall meet the criteria for acceptance outlined in Section 2.2.2. The optical

density (ppm-meters/K) of the reference spectrum must match the optical density

of the sample spectrum within (less than) 25 percent.

8.0 Sample Collection, Preservation, and Storage.

Sampling should be

performed in the following sequence: Collect background, collect CTS spectrum,

collect samples, collect post-test CTS spectrum, verify that two copies of all

data were stored on separate computer media.

8.1 Pretest Preparations and Evaluations.

Using the procedure

in Section 4.0 of the FTIR Protocol,

determine the optimum sampling system configuration for sampling the target

pollutants. Table 2 gives some example values for AU, DL, and MAU. Based on a

study (Reference 1), an FTIR system using 1 cm-1 resolution,

22 meter path length, and a broad band MCT detector was suitable for meeting

the requirements in Table 2. Other factors that must be determined are:

a. Test requirements:

AUi, CMAXi, DLi, OFUi, and tAN for

each.

b. Inteferants: See

Table 1.

c. Sampling system: LS', Pmin, PS', TS', tSS, VSS;

fractional error, MIL.

d. Analytical

regions: 1 through Nm, FLm, FCm, and FUm, plus interferants, FFUm, FFLm, wave number range FNU to FNL. See Tables 1 and

2.

8.1.1 If necessary,

sample and acquire an initial spectrum. Then determine the proper operational

path-length of the instrument to obtain non-saturated absorbances of the target

analytes.

8.1.2 Set up the

sampling train as shown in Figure 1.

8.2 Sampling System Leak-check.

Leak-check from the

probe tip to pump outlet as follows: Connect a 0- to 250-mL/min rate meter

(rotameter or bubble meter) to the outlet of the pump. Close off the inlet to

the probe, and note the leakage rate. The leakage rate shall be < 200

mL/min.

8.3 Analytical System Leak-check.

8.3.1 For the

evacuated sample technique, close the valve to the FTIR cell, and evacuate the

absorption cell to the minimum absolute pressure Pmin. Close the valve to the pump, and determine the

change in pressure ¥Pv

after 2 minutes.

8.3.2 For both the

evacuated sample and purging techniques, pressurize the system to about 100

mmHg above atmospheric pressure. Isolate the pump and determine the change in

pressure ¥Pp after 2 minutes.

8.3.3 Measure the

barometric pressure, Pb

in mmHg.

8.3.4 Determine the

percent leak volume %VL

for the signal integration time tSS and for ¥Pmax, i.e.,

the larger of ¥Pv or ¥Pp, as

follows:

![]()

where:

50 = 100% divided by

the leak-check time of 2 minutes.

8.3.5 Leak volumes in

excess of 4 percent of the sample system volume VSS are

unacceptable.

8.4 Background Spectrum.

Evacuate the gas cell

to <5 mmHg, and fill with dry nitrogen gas to ambient pressure.

Verify that no significant amounts of absorbing species (for example water

vapor and CO2) are present. Collect a background spectrum,

using a signal averaging period equal to or greater than the averaging period

for the sample spectra. Assign a unique file name to the background spectrum.

Store the spectra of the background interferogram and processed single-beam

background spectrum on two separate computer media (one is used as the backup).

If continuous sampling will be used during sample collection, collect the

background spectrum with nitrogen gas flowing through the cell at the same

pressure and temperature as will be used during sampling.

8.5 Pre-Test Calibration Transfer Standard.

Evacuate the gas cell

to <5 mmHg absolute pressure, and fill the FTIR cell to atmospheric

pressure with the CTS gas. Or, purge the cell with 10 cell volumes of CTS gas.

Record the spectrum. If continuous sampling will be used during sample

collection, collect the CTS spectrum with CTS gas flowing through the cell at

the same pressure and temperature as will be used during sampling.

8.6 Samples.

8.6.1 Evacuated Samples.

Evacuate the

absorbance cell to <5 mmHg absolute pressure. Fill the cell with flue

gas to ambient pressure and record the spectrum. Before taking the next sample,

evacuate the cell until no further evidence of absorption exists. Repeat this

procedure to collect at least 8 separate spectra (samples) in 1 hour.

8.6.2 Purge Sampling.

Purge the FTIR cell

with 10 cell volumes of flue gas and at least for about 10 minutes. Discontinue

the gas cell purge, isolate the cell, and record the sample spectrum and the

pressure. Before taking the next sample, purge the cell with 10 cell volumes of

flue gas.

8.6.3 Continuous Sampling.

Spectra can be

collected continuously while the FTIR cell is being purged. The sample

integration time, tss, the sample flow rate through the FTIR gas

cell, and the total run time must be chosen so that the collected data consist

of at least 10 spectra with each spectrum being of a separate cell volume of

flue gas. More spectra can be collected over the run time and the total run

time (and number of spectra) can be extended as well.

8.7 Sampling QA, Data Storage and Reporting.

8.7.1 Sample

integration times should be sufficient to achieve the required signal-to-noise

ratios. Obtain an absorbance spectrum by filling the cell with nitrogen.

Measure the RMSD in each analytical region in this absorbance spectrum. Verify

that the number of scans is sufficient to achieve the target MAU (Table 2).

8.7.2 Identify all

sample spectra with unique file names.

8.7.3 Store on two

separate computer media a copy of sample interferograms and processed spectra.

The data shall be available to the Administrator on request for the length of

time specified in the applicable regulation.

8.7.4 For each sample

spectrum, document the sampling conditions, the sampling time (while the cell

was being filled), the time the spectrum was recorded, the instrumental

conditions (path length, temperature, pressure, resolution, integration time),

and the spectral file name. Keep a hard copy of these data sheets.

8.8 Signal Transmittance.

While sampling,

monitor the signal transmittance through the instrumental system. If signal

transmittance (relative to the background) drops below 95 percent in any

spectral region where the sample does not absorb infrared energy, obtain a new

background spectrum.

8.9 Post-run CTS.

After each sampling

run, record another CTS spectrum.

8.10 Post-test QA.

8.10.1 Inspect the

sample spectra immediately after the run to verify that the gas matrix

composition was close to the expected (assumed) gas matrix.

8.10.2 Verify that

the sampling and instrumental parameters were appropriate for the conditions

encountered. For example, if the moisture is much greater than anticipated, it

will be necessary to use a shorter path length or dilute the sample.

8.10.3 Compare the

pre- and post-run CTS spectra. They shall agree to within ±5 percent. See FTIR

Protocol, Appendix E.

9.0 Quality Control.

Follow the quality

assurance procedures in the method, including the analysis of pre- and post-run

calibration transfer standards (Sections 8.5 and 8.9) and the post-test quality

assurance procedures in Section 8.10.

10.0 Calibration and Standardization.

10.1 Signal-to-Noise Ratio (S/N).

The S/N shall be

sufficient to meet the MAU in each analytical region.

10.2 Absorbance Path-length.

Verify the absorbance

path length by comparing CTS spectra to reference spectra of the calibration

gas(es). See FTIR Protocol,

Appendix E.

10.3 Instrument Resolution.

Measure the line

width of appropriate CTS band(s) and compare to reference CTS spectra to verify

instrumental resolution.

10.4 Apodization Function.

Choose appropriate

apodization function. Determine any appropriate mathematical transformations

that are required to correct instrumental errors by measuring the CTS. Any

mathematical transformations must be documented and reproducible.

10.5 FTIR Cell Volume.

Evacuate the cell to <5

mmHg. Measure the initial absolute temperature (Ti)

and absolute pressure (Pi). Connect a wet test meter (or a calibrated dry

gas meter), and slowly draw room air into the cell. Measure the meter volume (Vm), meter absolute temperature (Tm), and

meter absolute pressure (Pm), and the cell final absolute temperature (Tf) and absolute pressure (Pf).

Calculate the FTIR cell volume VSS, including that of

the connecting tubing, as follows:

As an alternative to

the wet test meter/calibrated dry gas meter procedure, measure the inside

dimensions of the cell cylinder and calculate its volume.

11.0 Procedure.

Refer to Sections 4.6

- 4.11, Sections 5, 6, and 7, and the appendices of the FTIR Protocol.

12.0 Data Analysis and Calculations.

a. Data analysis is

performed using appropriate reference spectra whose concentrations can be

verified using CTS spectra. Various analytical programs are available to relate

sample absorbance to a concentration standard. Calculated concentrations should

be verified by analyzing spectral baselines after mathematically subtracting

scaled reference spectra from the sample spectra. A full description of the

data analysis and calculations may be found in the FTIR Protocol (Sections 4.0, 5.0, 6.0 and appendices).

b. Correct the

calculated concentrations in sample spectra for differences in absorption

path-length between the reference and sample spectra by:

where:

13.0 Reporting and Recordkeeping.

All interferograms

used in determining source concentration shall be stored for the period of time

required in the applicable regulation. The Administrator has the option of

requesting the interferograms recorded during the test in electronic form as

part of the test report.

14.0 Method Performance.

Refer to the FTIR

Protocol.

15.0 Pollution Prevention. [Reserved]

16.0 Waste Management.

Laboratory standards

prepared from the formaldehyde and phenol are handled according to the

instructions in the materials safety data sheets (MSDS).

17.0 References.

(1) "Field

Validation Test Using Fourier Transform Infrared (FTIR) Spectrometry To Measure

Formaldehyde, Phenol and Methanol at a Wool Fiberglass Production

Facility." Draft. U.S. Environmental Protection Agency Report, Entropy,

Inc., EPA Contract No. 68D20163, Work Assignment I-32, December 1994 (docket

item II-A-13).

(2) "Method 301

- Field Validation of Pollutant Measurement Methods from Various Waste

Media," 40 CFR part 63, appendix A.