METHOD

26 - DETERMINATION OF HYDROGEN HALIDE AND HALOGEN EMISSIONS FROM STATIONARY

SOURCES NON-ISOKINETIC METHOD

5.2.1 Sodium Hydroxide

(NaOH).

6.1.4 Drying Tube or

Impinger.

6.1.6 Filter Holder and

Support.

6.1.9 Purge Pump, Purge

Line, Drying Tube, Needle Valve, and Rate Meter.

6.1.10 Stopcock Grease,

Valve, Pump, Volume Meter, Barometer, and Vacuum Gauge.

6.1.11 Temperature

Measuring Devices.

6.3 Sample Preparation

and Analysis.

7.1.3 Acidic Absorbing

Solution, 0.1 N Sulfuric Acid (H2SO4).

7.1.5 Alkaline

Adsorbing Solution, 0.1 N Sodium Hydroxide (NaOH).

7.1.6 Sodium

Thiosulfate (Na2S2O3 .5 H2O)

7.2 Sample Preparation

and Analysis.

7.2.2 Absorbing

Solution Blanks.

7.2.3 Halide Salt Stock

Standard Solutions.

7.3 Quality Assurance

Audit Samples.

8.0 Sample Collection,

Preservation, Storage, and Transport.

8.1.1 Preparation of

Collection Train.

8.1.2 Adjust the probe

temperature and the temperature of the filter and the stopcock

8.3 Sample Preparation

for Analysis.

10.0 Calibration and

Standardization.

10.1 Volume Metering

System, Temperature Sensors, Rate Meter, and Barometer.

12.0 Data Analysis and

Calculations.

12.2 Calculate the

exact Cl-, Br-, and F- concentration

12.3 Sample Volume, Dry

Basis, Corrected to Standard Conditions.

12.4 Total µg HCl, HBr,

or HF Per Sample.

12.5 Total µg Cl2 or

Br2 Per Sample.

12.6 Concentration of

Hydrogen Halide or Halogen in Flue Gas.

14.0 Pollution

Prevention. [Reserved]

15.0 Waste Management.

[Reserved]

17.0 Tables, Diagrams,

Flowcharts, and Validation Data.

1.0 Scope and Application.

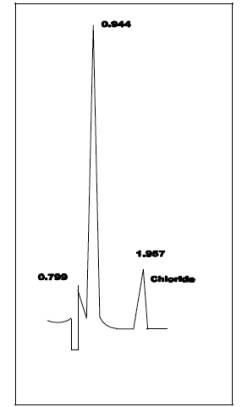

1.1 Analytes.

1.2 Applicability.

This method is

applicable for determining emissions of hydrogen halides (HX) [HCl, HBr, and

HF] and halogens (X2) [Cl2 and Br2] from stationary sources when specified by the applicable subpart.

Sources, such as those controlled by wet scrubbers, that emit acid particulate

matter must be sampled using Method 26A.

1.3 Data Quality Objectives.

Adherence to the

requirements of this method will enhance the quality of the data obtained from

air pollutant sampling methods.

2.0 Summary of Method.

2.1 An integrated

sample is extracted from the source and passed through a pre-purged heated

probe and filter into dilute sulfuric acid and dilute sodium hydroxide

solutions which collect the gaseous hydrogen halides and halogens, respectively.

The filter collects articulate matter including halide salts but is not

routinely recovered and analyzed. The hydrogen halides are solubilized in the

acidic solution and form chloride (Cl-), bromide

(Br-), and fluoride (F-)

ions. The halogens have a very low solubility in the acidic solution and pass

through to the alkaline solution where they are hydrolyzed to form a proton (H+), the halide ion, and the hypohalous acid (HClO or HBrO). Sodium

thiosulfate is added in excess to the alkaline solution to assure reaction with

the hypohalous acid to form a second halide ion such that 2 halide ions are

formed for each molecule of halogen gas. The halide ions in the separate

solutions are measured by ion chromatography (IC).

3.0 Definitions. [Reserved]

4.0 Interferences.

4.1 Volatile

materials, such as chlorine dioxide (ClO2) and

ammonium chloride (NH4Cl), which produce halide ions upon dissolution

during sampling are potential interferents. Interferents for the halide

measurements are the halogen gases which disproportionate to a hydrogen halide

and a hydrohalous acid upon dissolution in water. However, the use of acidic

rather than neutral or basic solutions for collection of the hydrogen halides

greatly reduces the dissolution of any halogens passing through this solution.

4.2 The simultaneous

presence of HBr and CL2

may cause a positive bias in the

HCL result with a corresponding negative bias in the Cl2 result as well as affecting the HBr/Br2 split.

4.3 High

concentrations of nitrogen oxides (NOx) may

produce sufficient nitrate (NO3-) to interfere with

measurements of very low Br- levels.

4.4 A glass wool plug

should not be used to remove particulate matter since a negative bias in the

data could result.

4.5 There is anecdotal

evidence that HF may be out-gassed from new Teflon components. If HF is a

target analyte, then preconditioning of new Teflon components, by heating

should be considered.

5.0 Safety

5.1 Disclaimer.

This method may

involve hazardous materials, operations, and equipment. This test method may

not address all of the safety problems associated with its use. It is the

responsibility of the user to establish appropriate safety and health practices

and determine the applicability of regulatory limitations before performing

this test method.

5.2 Corrosive Reagents.

The following

reagents are hazardous. Personal protective equipment and safe procedures are

useful in preventing chemical splashes. If contact occurs, immediately flush

with copious amounts of water for at least 15 minutes. Remove clothing under

shower and decontaminate. Treat residual chemical burns as thermal burns.

5.2.1 Sodium Hydroxide (NaOH).

Causes severe damage

to eyes and skin. Inhalation causes irritation to nose, throat, and lungs. Reacts

exothermically with limited amounts of water.

5.2.2 Sulfuric Acid (H2SO4).

Rapidly destructive

to body tissue. Will cause third degree burns. Eye damage may result in

blindness. Inhalation may be fatal from spasm of the larynx, usually within 30

minutes. May cause lung tissue damage with edema. 1 mg/m3 for 8 hours will cause lung damage or, in higher concentrations,

death. Provide ventilation to limit inhalation. Reacts violently with metals

and organics.

6.0 Equipment and Supplies.

NOTE: Mention of trade names or specific products does

not constitute endorsement by the Environmental Protection Agency.

6.1 Sampling.

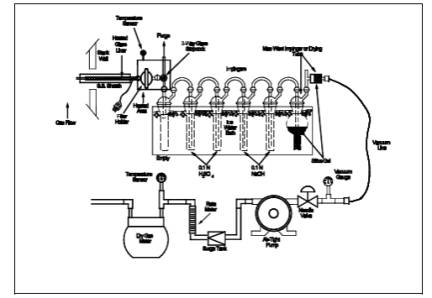

The sampling train is

shown in Figure 26-1, and component parts are discussed

below.

6.1.1 Probe.

Borosilicate glass,

approximately 3/8-in. (9-mm) I.D. with a heating system to prevent moisture

condensation. A Teflon-glass filter in a mat configuration should be installed

to remove particulate matter from the gas stream (see Section 6.1.6).

6.1.2 Three-way Stopcock.

A borosilicate-glass

three-way stopcock with a heating system to prevent moisture condensation. The

heated stopcock should connect to the outlet of the heated filter and the inlet

of the first impinger. The heating system should be capable of preventing

condensation up to the inlet of the first impinger. Silicone grease may be

used, if necessary, to prevent leakage.

6.1.3 Impingers.

Four 30-ml midget

impingers with leak-free glass connectors. Silicone grease may be used, if

necessary, to prevent leakage. For sampling at high moisture sources or for

sampling times greater than one hour, a midget impinger with a shortened stem

(such that the gas sample does not bubble through the collected condensate)

should be used in front of the first impinger.

6.1.4 Drying Tube or Impinger.

Tube or impinger, of

Mae West design, filled with 6- to 16-mesh indicating type silica gel, or

equivalent, to dry the gas sample and to protect the dry gas meter and pump. If

the silica gel has been used previously, dry at 175ûC (350ûF) for 2 hours. New

silica gel may be used as received. Alternatively, other types of desiccants

(equivalent or better) may be used.

6.1.5 Heating System.

Any heating system

capable of maintaining a temperature around the probe and filter holder greater

than 120ûC (248ûF) during sampling, or such other temperature as specified by

an applicable subpart of the standards or approved by the Administrator for a

particular application.

6.1.6 Filter Holder and Support.

The filter holder

shall be made of Teflon or quartz. The filter support shall be made of Teflon.

All Teflon filter holders and supports are available from Savillex Corp., 5325

Hwy 101, Minnetonka, MN 55345.

6.1.7 Sample Line.

Leak-free, with compatible

fittings to connect the last impinger to the needle valve.

6.1.8 Rate Meter.

Rotameter, or

equivalent, capable of measuring flow rate to within 2 percent of the selected

flow rate of 2 liters/min (0.07 ft3/min).

6.1.9 Purge Pump, Purge Line, Drying Tube, Needle Valve, and Rate Meter.

Pump capable of

purging the sampling probe at 2 liters/min, with drying tube, filled with

silica gel or equivalent, to protect pump, and a rate meter capable of

measuring 0 to 5 liters/min (0.2 ft3/min).

6.1.10 Stopcock Grease, Valve, Pump, Volume Meter, Barometer, and Vacuum Gauge.

Same as in Method 6, Sections 6.1.1.4, 6.1.1.7,

6.1.1.8, 6.1.1.10, 6.1.2, and 6.1.3.

6.1.11 Temperature Measuring Devices.

Temperature sensors

to monitor the temperature of the probe and to monitor the temperature of the

sampling system from the outlet of the probe to the inlet of the first

impinger.

6.1.12 Ice Water Bath.

To minimize loss of

absorbing solution.

6.2 Sample Recovery.

6.2.1 Wash Bottles.

Polyethylene or

glass, 500-ml or larger, two.

6.2.2 Storage

Bottles. 100- or 250-ml, high-density polyethylene bottles with Teflon screw

cap liners to store impinger samples.

6.3 Sample Preparation and Analysis.

The materials

required for volumetric dilution and chromatographic analysis of samples are

described below.

6.3.1 Volumetric

Flasks. Class A, 100-ml size.

6.3.2 Volumetric

Pipets. Class A, assortment. To dilute samples to the calibration range of the

ion chromatograph.

6.3.3 Ion Chromatograph

(IC). Suppressed or non-suppressed, with a conductivity detector and electronic

integrator operating in the peak area mode. Other detectors, strip chart

recorders, and peak height measurements may be used.

7.0 Reagents and Standards.

NOTE: Unless otherwise indicated, all reagents must

conform to the specifications established by the Committee on Analytical

Reagents of the American Chemical Society (ACS reagent grade). When such

specifications are not available, the best available grade shall be used.

7.1 Sampling.

7.1.1 Filter.

A 25-mm (1 in)(or

other size) Teflon glass mat, Pallflex TX40HI75 (Pallflex Inc., 125 Kennedy

Drive, Putnam, CT 06260). This filter is in a mat configuration to prevent fine

particulate matter from entering the sampling train. Its composition is 75%

Teflon/25% borosilicate glass. Other filters may be used, but they must be in a

mat (as opposed to a laminate) configuration and contain at least 75% Teflon.

For practical rather than scientific reasons, when the stack gas temperature

exceeds 210ûC (410ûF) and the HCl concentration is greater than 20 ppm, a

quartz-fiber filter may be used since Teflon becomes unstable above this

temperature.

7.1.2 Water.

Deionized, distilled

water that conforms to American Society of Testing and Materials (ASTM)

Specification D 1193-77 or 91, Type 3 (incorporated by reference - see ¤60.17).

7.1.3 Acidic Absorbing Solution, 0.1 N Sulfuric Acid (H2SO4).

To prepare 100 ml of

the absorbing solution for the front impinger pair, slowly add 0.28 ml of

concentrated H2SO4 to about

90 ml of water while stirring, and adjust the final volume to 100 ml using

additional water. Shake well to mix the solution.

7.1.4 Silica Gel.

Indicating type, 6 to

16 mesh. If previously used, dry at 180 ûC (350 ûF) for 2 hours. New silica gel

may be used as received. Alternatively, other types of desiccants may be used,

subject to the approval of the Administrator.

7.1.5 Alkaline Adsorbing Solution, 0.1 N Sodium Hydroxide (NaOH).

To prepare 100 ml of

the scrubber solution for the third and fourth impinger, dissolve 0.40 g of

solid NaOH in about 90 ml of water, and adjust the final solution volume to 100

ml using additional water. Shake well to mix the solution.

7.1.6 Sodium Thiosulfate (Na2S2O3 .5 H2O)

7.2 Sample Preparation and Analysis.

7.2.1 Water.

Same as in Section

7.1.2.

7.2.2 Absorbing Solution Blanks.

A separate blank

solution of each absorbing reagent should be prepared for analysis with the

field samples. Dilute 30 ml of each absorbing solution to approximately the

same final volume as the field samples using the blank sample of rinse water.

7.2.3 Halide Salt Stock Standard Solutions.

Prepare concentrated

stock solutions from reagent grade sodium chloride (NaCl), sodium bromide

(NaBr), and sodium fluoride (NaF). Each must be dried at 110ûC (230ûF) for two

or more hours and then cooled to room temperature in a desiccator immediately

before weighing. Accurately weigh 1.6 to 1.7 g of the dried NaCl to within 0.1

mg, dissolve in water, and dilute to 1 liter. Calculate the exact Cl- concentration using Equation 26-1 in Section 12.2. In a similar

manner, accurately weigh and solubilize 1.2 to 1.3 g of dried NaBr and 2.2 to

2.3 g of NaF to make 1-liter solutions. Use Equations

26-2 and 26-3 in Section 12.2, to calculate the Br- and F- concentrations. Alternately, solutions

containing a nominal certified concentration of 1000 mg/l NaCl are commercially

available as convenient stock solutions from which standards can be made by

appropriate volumetric dilution. Refrigerate the stock standard solutions and

store no longer than one month.

7.2.4 Chromatographic Eluent.

Effective eluents for

nonsuppressed IC using a resin- or silica-based weak ion exchange column are a

4 mM potassium hydrogen phthalate solution, adjusted to pH 4.0 using a

saturated sodium borate solution, and a 4 mM 4-hydroxy benzoate solution,

adjusted to pH 8.6 using 1 N NaOH. An effective eluent for suppressed ion

chromatography is a solution containing 3 mM sodium bicarbonate and 2.4 mM

sodium carbonate. Other dilute solutions buffered to a similar pH and

containing no interfering ions may be used. When using suppressed ion

chromatography, if the "water dip" resulting from sample injection

interferes with the chloride peak, use a 2 mM NaOH/2.4 mM sodium bicarbonate

eluent.

7.3 Quality Assurance Audit Samples.

When making

compliance determinations, and upon availability, audit samples may be obtained

from the appropriate EPA regional Office or from the responsible enforcement

authority.

NOTE: The responsible enforcement authority should be

notified at least 30 days prior to the test date to allow sufficient time for

sample delivery.

8.0 Sample Collection, Preservation, Storage, and Transport.

NOTE: Because of the complexity of this method,

testers and analyst should be trained and experienced with the procedure to

ensure reliable results.

8.1 Sampling.

8.1.1 Preparation of Collection Train.

Prepare the sampling

train as follows: Pour 15 ml of the acidic absorbing solution into each one of

the first pair of impingers, and 15 ml of the alkaline absorbing solution into

each one of the second pair of impingers. Connect the impingers in series with

the knockout impinger first, if used, followed by the two impingers containing

the acidic absorbing solution and the two impingers containing the alkaline

absorbing solution. Place a fresh charge of silica gel, or equivalent, in the

drying tube or impinger at the end of the impinger train.

8.1.2 Adjust the probe temperature and the temperature of the filter and the stopcock

Adjust the probe

temperature and the temperature of the filter and the stopcock, i.e., the

heated area in Figure 26-1 to a temperature sufficient to prevent water

condensation. This temperature should be at least 20ûC (68ûF) above the source

temperature, and greater than 120ûC (248ûF). The temperature should be

monitored throughout a sampling run to ensure that the desired temperature is

maintained. It is important to maintain a temperature around the probe and

filter of greater than 120ûC (248ûF) since it is extremely difficult to purge

acid gases off these components. (These components are not quantitatively

recovered and hence any collection of acid gases on these components would

result in potential undereporting of these emissions. The applicable subparts

may specify alternative higher temperatures.)

8.1.3 Leak-Check Procedure.

8.1.3.1 Sampling Train.

A leak-check prior to

the sampling run is optional; however, a leak-check after the sampling run is

mandatory. The leak-check procedure is as follows: Temporarily attach a

suitable [e.g., 0-40 cc/min (0-2.4 in3/min)]

rotameter to the outlet of the dry gas meter and place a vacuum gauge at or

near the probe inlet. Plug the probe inlet, pull a vacuum of at least 250 mm Hg

(10 in. Hg), and note the flow rate as indicated by the rotameter. A leakage

rate not in excess of 2 percent of the average sampling rate is acceptable. (NOTE:

Carefully release the probe

inlet plug before turning off the pump.)

8.1.3.2 Pump.

It is suggested (not

mandatory) that the pump be leak-checked separately, either prior to or after

the sampling run. If done prior to the sampling run, the pump leak-check shall

precede the leak-check of the sampling train described immediately above; if

done after the sampling run, the pump leak-check shall follow the train

leak-check. To leak-check the pump, proceed as follows: Disconnect the drying

tube from the probe-impinger assembly. Place a vacuum gauge at the inlet to

either the drying tube or pump, pull a vacuum of 250 mm (10 in) Hg, plug or

pinch off the outlet of the flow meter, and then turn off the pump. The vacuum

should remain stable for at least 30 sec. Other leak-check procedures may be

used, subject to the approval of the Administrator, U.S. Environmental

Protection Agency.

8.1.4 Purge Procedure.

Immediately before

sampling, connect the purge line to the stopcock, and turn the stopcock to

permit the purge pump to purge the probe (see Figure 1A of Figure 26-1). Turn

on the purge pump, and adjust the purge rate to 2 liters/min (0.07 ft3/min). Purge for at least 5 minutes before sampling.

8.1.5 Sample Collection.

Turn on the sampling

pump, pull a slight vacuum of approximately 25 mm Hg (1 in Hg) on the impinger

train, and turn the stopcock to permit stack gas to be pulled through the

impinger train (see Figure 1C of Figure 26-1). Adjust the sampling rate to 2

liters/min, as indicated by the rate meter, and maintain this rate to within 10

percent during the entire sampling run. Take readings of the dry gas meter

volume and temperature, rate meter, and vacuum gauge at least once every five

minutes during the run. A sampling time of one hour is recommended. Shorter

sampling times may introduce a significant negative bias in the HCl

concentration. At the conclusion of the sampling run, remove the train from the

stack, cool, and perform a leak-check as described in Section 8.1.3.1.

8.2 Sample Recovery.

8.2.1 Disconnect the

impingers after sampling. Quantitatively transfer the contents of the acid

impingers and the knockout impinger, if used, to a leak-free storage bottle.

Add the water rinses of each of these impingers and connecting glassware to the

storage bottle.

8.2.2 Repeat this procedure

for the alkaline impingers and connecting glassware using a separate storage

bottle. Add 25 mg of sodium thiosulfate per the product of ppm of halogen

anticipated to be in the stack gas times the volume (dscm) of stack gas sampled

(0.7 mg per ppm-dscf).

[NOTE: This amount of sodium thiosulfate includes a

safety factor of approximately 5 to assure complete reaction with the

hypohalous acid to form a second Cl- ion in

the alkaline solution.]

8.2.3 Save portions

of the absorbing reagents (0.1 N H2SO4 and 0.1 N NaOH) equivalent to the amount used in the sampling train

(these are the absorbing solution blanks described in Section 7.2.2); dilute to

the approximate volume of the corresponding samples using rinse water directly

from the wash bottle being used. Add the same amount of sodium thiosulfate

solution to the 0.1 N NaOH absorbing solution blank. Also, save a portion of

the rinse water used to rinse the sampling train. Place each in a separate,

prelabeled storage bottle. The sample storage bottles should be sealed, shaken

to mix, and labeled. Mark the fluid level.

8.3 Sample Preparation for Analysis.

Note the liquid

levels in the storage bottles and confirm on the analysis sheet whether or not

leakage occurred during transport. If a noticeable leakage has occurred, either

void the sample or use methods, subject to the approval of the Administrator,

to correct the final results. Quantitatively transfer the sample solutions to

100-ml volumetric flasks, and dilute to 100 ml with water.

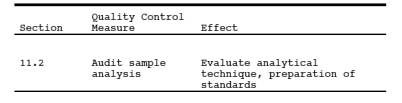

9.0 Quality Control.

10.0 Calibration and Standardization.

NOTE: Maintain a laboratory log of all calibrations.

10.1 Volume Metering System, Temperature Sensors, Rate Meter, and Barometer.

Same as in Method 6,

Sections 10.1, 10.2, 10.3, and 10.4.

10.2 Ion Chromatograph.

10.2.1 To prepare the

calibration standards, dilute given amounts (1.0 ml or greater) of the stock

standard solutions to convenient volumes, using 0.1 N H2SO4 or 0.1 N NaOH, as appropriate. Prepare at least

four calibration standards for each absorbing reagent containing the

appropriate stock solutions such that they are within the linear range of the

field samples.

10.2.2 Using one of

the standards in each series, ensure adequate baseline separation for the peaks

of interest.

10.2.3 Inject the appropriate

series of calibration standards, starting with the lowest concentration

standard first both before and after injection of the quality control check

sample, reagent blanks, and field samples. This allows compensation for any

instrument drift occurring during sample analysis. The values from duplicate

injections of these calibration samples should agree within 5 percent of their

mean for the analysis to be valid.

10.2.4 Determine the

peak areas, or heights, for the standards and plot individual values versus

halide ion concentrations in µg/ml.

10.2.5 Draw a smooth

curve through the points. Use linear regression to calculate a formula

describing the resulting linear curve.

11.0 Analytical Procedures.

11.1 Sample Analysis.

11.1.1 The IC conditions

will depend upon analytical column type and whether suppressed or

non-suppressed IC is used. An example chromatogram from a non-suppressed system

using a 150-mm Hamilton PRP-X100 anion column, a 2 ml/min flow rate of a 4 mM

4-hydroxy benzoate solution adjusted to a pH of 8.6 using 1 N NaOH, a 50 µl

sample loop, and a conductivity detector set on 1.0 µS full scale is shown in Figure 26-2.

11.1.2 Before sample

analysis, establish a stable baseline. Next, inject a sample of water, and

determine if any Cl-, Br-, or F- appears in the chromatogram. If any of these ions are present,

repeat the load/injection procedure until they are no longer present. Analysis

of the acid and alkaline absorbing solution samples requires separate standard

calibration curves; prepare each according to Section 10.2. Ensure adequate

baseline separation of the analyses.

11.1.3 Between

injections of the appropriate series of calibration standards, inject in

duplicate the reagent blanks, quality control sample, and the field samples.

Measure the areas or heights of the Cl-, Br-, and F-

peaks. Use the mean response of the

duplicate injections to determine the concentrations of the field samples and

reagent blanks using the linear calibration curve. The values from duplicate

injections should agree within 5 percent of their mean for the analysis to be

valid. If the values of duplicate injections are not within 5 percent of the

mean, the duplicate injections shall be repeated and all four values used to

determine the average response. Dilute any sample and the blank with equal

volumes of water if the concentration exceeds that of the highest standard.

11.2 Audit Sample Analysis.

11.2.1 When the

method is used to analyze samples to demonstrate compliance with a source

emission regulation, a set of two EPA audit samples must be analyzed, subject

to availability.

11.2.2 Concurrently

analyze the audit samples and the compliance samples in the same manner to

evaluate the technique of the analyst and the standards preparation.

11.2.3 The same

analyst, analytical reagents, and analytical system shall be used for the

compliance samples and the EPA audit samples. If this condition is met,

duplicate auditing of subsequent compliance analyses for the same enforcement

agency within a 30-day period is waived. An audit sample set may not be used to

validate different sets of compliance samples under the jurisdiction of

separate enforcement agencies, unless prior arrangements have been made with

both enforcement agencies.

11.3 Audit Sample Results.

11.3.1 Calculate the

concentrations in mg/L of audit sample and submit results following the

instructions provided with the audit samples.

11.3.2 Report the

results of the audit samples and the compliance determination samples along

with their identification numbers, and the analyst's name to the responsible

enforcement authority. Include this information with reports of any subsequent

compliance analyses for the same enforcement authority during the 30-day

period.

11.3.3 The

concentrations of the audit samples obtained by the analyst shall agree within

10 percent of the actual concentrations. If the 10 percent specification is not

met, reanalyze the compliance and audit samples, and include initial and

reanalysis values in the test report.

11.3.4 Failure to

meet the 10 percent specification may require retests until the audit problems

are resolved. However, if the audit results do not affect the compliance or noncompliance

status of the affected facility, the Administrator may waive the reanalysis

requirement, further audits, or retests and accept the results of the

compliance test. While steps are being taken to resolve audit analysis

problems, the Administrator may also choose to use the data to determine the

compliance or noncompliance status of the affected facility.

12.0 Data Analysis and Calculations.

NOTE: Retain at least one extra decimal figure beyond

those contained in the available data in intermediate calculations, and round

off only the final answer appropriately.

12.1 Nomenclature.

BX- = Mass concentration of applicable absorbing

solution blank, µg halide ion (Cl-, Br-, F-) /ml, not to exceed 1 µg/ml which is 10 times the

published analytical detection limit of 0.1 µg/ml.

C = Concentration of

hydrogen halide (HX) or halogen (X2), dry

basis, mg/dscm.

K = 10-3 mg/µg.

KHCl = 1.028 (µg HCl/µg-mole)/(µg Cl-/µg-mole).

KHBr = 1.013 (µg HBr/µg-mole)/(µg Br-/µg-mole).

KHF = 1.053 (µg HF/µg-mole)/(µg F-/µg-mole).

mHX = Mass of HCl, HBr, or HF in sample, µg.

mX2 = Mass of Cl2 or Br2 in sample, µg.

SX- = Analysis of sample, µg halide ion (Cl-, Br-, F-)/ml.

Vm(std)= Dry gas volume measured by the dry gas meter,

corrected to standard conditions, dscm.

Vs = Volume of filtered and diluted sample, ml.

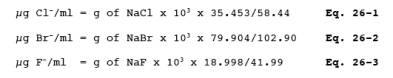

12.2 Calculate the exact Cl-, Br-, and F- concentration

Calculate the exact

Cl-, Br-, and F-

concentration in the halide salt stock standard solutions using the following

equations.

12.3 Sample Volume, Dry Basis, Corrected to Standard Conditions.

Calculate the sample

volume using Eq. 6-1 of Method 6.

12.4 Total µg HCl, HBr, or HF Per Sample.

![]()

12.5 Total µg Cl2 or Br2 Per Sample.

![]()

12.6 Concentration of Hydrogen Halide or Halogen in Flue Gas.

![]()

13.0 Method Performance.

13.1 Precision and Bias.

The within-laboratory

relative standard deviations are 6.2 and 3.2 percent at Hcl concentrations of

3.9 and 15.3 ppm, respectively. The method does not exhibit a bias to Cl2 when sampling at concentrations less than 50 ppm.

13.2 Sample Stability.

The collected Cl- samples can be stored for up to 4 weeks.

13.3 Detection Limit.

A typical IC

instrumental detection limit for Cl- is 0.2

µg/ml. Detection limits for the other analyses should be similar. Assuming 50

ml liquid recovered from both the acidified impingers, and the basic impingers,

and 0.06 dscm of stack gas sampled, then the analytical detection limit in the

stack gas would be about 0.1 ppm for HCl and Cl2,

respectively.

14.0 Pollution Prevention. [Reserved]

15.0 Waste Management. [Reserved]

16.0 References.

1. Steinsberger, S.

C. and J. H. Margeson, "Laboratory and Field Evaluation of a Methodology

for Determination of Hydrogen Chloride Emissions from Municipal and Hazardous

Waste Incinerators," U.S. Environmental Protection Agency, Office of

Research and Development, Report No. 600/3-89/064, April 1989. Available from

the National Technical Information Service, Springfield, VA 22161 as PB89220586/AS.

2. State of

California, Air Resources Board, Method 421, "Determination of

Hydrochloric Acid Emissions from Stationary Sources," March 18, 1987.

3. Cheney, J.L. and

C.R. Fortune. Improvements in the Methodology for Measuring Hydrochloric Acid

in Combustion Source Emissions. J. Environ. Sci. Health. A19(3): 337-350. 1984.

4. Stern, D. A., B.

M. Myatt, J. F. Lachowski, and K. T. McGregor. Speciation of Halogen and

Hydrogen Halide Compounds in Gaseous Emissions. In: Incineration and Treatment

of Hazardous Waste: Proceedings of the 9th Annual Research Symposium,

Cincinnati, Ohio, May 2-4, 1983. Publication No. 600/9-84-015. July 1984.

Available from National Technical Information Service, Springfield, VA 22161 as

PB84-234525.

5. Holm, R. D. and S.

A. Barksdale. Analysis of Anions in Combustion Products. In: Ion

Chromatographic Analysis of Environmental Pollutants. E. Sawicki, J. D. Mulik,

and E. Wittgenstein (eds.). Ann Arbor, Michigan, Ann Arbor Science Publishers.

1978. pp. 99-110.

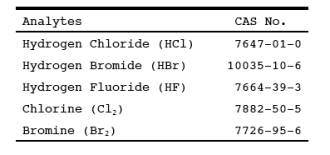

17.0 Tables, Diagrams, Flowcharts, and Validation Data.

Figure

26-2. Example Chromatogram.