METHOD 25A -

DETERMINATION OF TOTAL GASEOUS ORGANIC CONCENTRATION USING A FLAME IONIZATION

ANALYZER

6.1.1 Organic

Concentration Analyzer.

6.1.4 Calibration Valve

Assembly.

7.1.3 Low-level

Calibration Gas.

7.1.4 Mid-level

Calibration Gas.

7.1.5 High-level

Calibration Gas.

8.0 Sample Collection,

Preservation, Storage, and Transport.

8.1 Selection of

Sampling Site.

8.3 Measurement System

Preparation.

8.6 Emission

Measurement Test Procedure.

10.0 Calibration and

Standardization.

12.0 Calculations and

Data Analysis.

14.0 Pollution

Prevention. [Reserved]

15.0 Waste Management.

[Reserved]

17.0 Tables, Diagrams,

Flowcharts, and Validation Data.

1.0 Scope and Application.

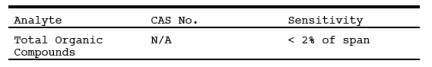

1.1 Analytes.

1.2 Applicability.

This method is applicable for the determination of total gaseous organic

concentration of vapors consisting primarily of alkanes, alkenes, and/or arenes

(aromatic hydrocarbons). The concentration is expressed in terms of propane (or

other appropriate organic calibration gas) or in terms of carbon.

1.3 Data Quality

Objectives. Adherence to the requirements of this method will enhance the

quality of the data obtained from air pollutant sampling methods.

2.0 Summary of Method.

2.1 A gas sample is extracted

from the source through a heated sample line and glass fiber filter to a flame

ionization analyzer (FIA). Results are reported as volume concentration

equivalents of the calibration gas or as carbon equivalents.

3.0 Definitions.

3.1 Calibration drift

Means the difference

in the measurement system response to a mid-level calibration gas before and

after a stated period of operation during which no unscheduled maintenance,

repair, or adjustment took place.

3.2 Calibration error

Means the difference

between the gas concentration indicated by the measurement system and the know

concentration of the calibration gas.

3.3 Calibration gas

Means a known

concentration of a gas in an appropriate diluent gas.

3.4 Measurement system

Means the total

equipment required for the determination of the gas concentration. The system

consists of the following major subsystems:

3.4.1 Sample interface

Means that portion of

a system used for one or more of the following: sample acquisition, sample

transportation, sample conditioning, or protection of the analyzer(s) from the

effects of the stack effluent.

3.4.2 Organic analyzer

Means that portion of

the measurement system that senses the gas to be measured and generates an

output proportional to its concentration.

3.5 Response time

Means the time

interval from a step change in pollutant concentration at the inlet to the

emission measurement system to the time at which 95 percent of the

corresponding final value is reached as displayed on the recorder.

3.6 Span Value

Means the upper limit

of a gas concentration measurement range that is specified for affected source

categories in the applicable part of the regulations. The span value is

established in the applicable regulation and is usually 1.5 to 2.5 times the

applicable emission limit. If no span value is provided, use a span value

equivalent to 1.5 to 2.5 times the expected concentration. For convenience, the

span value should correspond to 100 percent of the recorder scale.

3.7 Zero drift

Means the difference

in the measurement system response to a zero level calibration gas before or

after a stated period of operation during which no unscheduled maintenance,

repair, or adjustment took place.

4.0 Interferences. [Reserved]

5.0 Safety.

5.1 Disclaimer. This

method may involve hazardous materials, operations, and equipment. This test

method may not address all of the safety problems associated with its use. It

is the responsibility of the user of this test method to establish appropriate

safety and health practices and determine the applicability of regulatory

limitations prior to performing this test method. The analyzer users manual

should be consulted for specific precautions to be taken with regard to the

analytical procedure.

5.2 Explosive Atmosphere.

This method is often applied in highly explosive areas. Caution and care should

be exercised in choice of equipment and installation.

6.0 Equipment and Supplies

6.1 Measurement System.

Any measurement

system for total organic concentration that meets the specifications of this

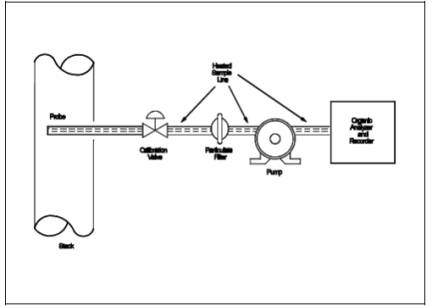

method. A schematic of an acceptable measurement system is shown in Figure 25A-1. All sampling components leading to the

analyzer shall be heated > 110¼C (220¼F) throughout the sampling period,

unless safety reasons are cited (Section 5.2). The essential components of the

measurement system are described below:

6.1.1 Organic Concentration Analyzer.

A flame ionization

analyzer (FIA) capable of meeting or exceeding the specifications of this

method. The flame ionization detector block shall be heated >120E¼C (250¼F).

6.1.2 Sample Probe.

Stainless steel, or

equivalent, three-hole rake type. Sample holes shall be 4 mm (0.16-in.) in

diameter or smaller and located at 16.7, 50, and 83.3 percent of the equivalent

stack diameter. Alternatively, a single opening probe may be used so that a gas

sample is collected from the centrally located 10 percent area of the stack

cross-section.

6.1.3 Heated Sample Line.

Stainless steel or

Teflon¨ tubing to transport the sample gas to the analyzer. The sample line

should be heated (>110 ¼C) to prevent any condensation.

6.1.4 Calibration Valve Assembly.

A three-way valve

assembly to direct the zero and calibration gases to the analyzers is

recommended. Other methods, such as quick-connect lines, to route calibration

gas to the analyzers are applicable.

6.1.5 Particulate Filter.

An in-stack or an

out-of-stack glass fiber filter is recommended if exhaust gas particulate

loading is significant. An out-of-stack filter should be heated to prevent any

condensation.

6.1.6 Recorder.

A strip-chart

recorder, analog computer, or digital recorder for recording measurement data.

The minimum data-recording requirement is one measurement value per minute.

7.0 Reagents and Standards.

7.1 Calibration Gases.

The calibration gases

for the gas analyzer shall be propane in air or propane in nitrogen.

Alternatively, organic compounds other than propane can be used; the

appropriate corrections for response factor must be made. Calibration gases

shall be prepared in accordance with the procedure listed in Citation 2 of Section 16. Additionally, the manufacturer of the

cylinder should provide a recommended shelf life for each calibration gas

cylinder over which the concentration does not change more than ± 2 percent

from the certified value. For calibration gas values not generally available (i.e., organics between 1 and 10 percent by volume),

alternative methods for preparing calibration gas mixtures, such as dilution

systems (Test Method 205, 40 CFR Part 51, Appendix M), may be used with prior

approval of the Administrator.

7.1.1 Fuel.

A 40 percent H2/60 percent N2

or He gas mixture is recommended to

avoid an oxygen synergism effect that reportedly occurs when oxygen

concentration varies significantly from a mean value.

7.1.2 Zero Gas.

High purity air with

less than 0.1 part per million by volume (ppmv) of organic material (propane or

carbon equivalent) or less than 0.1 percent of the span value, whichever is

greater.

7.1.3 Low-level Calibration Gas.

An organic

calibration gas with a concentration equivalent to 25 to 35 percent of the

applicable span value.

7.1.4 Mid-level Calibration Gas.

An organic

calibration gas with a concentration equivalent to 45 to 55 percent of the

applicable span value.

7.1.5 High-level Calibration Gas.

An organic

calibration gas with a concentration equivalent to 80 to 90 percent of the

applicable span value.

8.0 Sample Collection, Preservation, Storage, and

Transport.

8.1 Selection of Sampling Site.

The location of the

sampling site is generally specified by the applicable regulation or purpose of

the test (i.e., exhaust stack, inlet line, etc.). The sample port shall be

located to meet the testing requirements of Method 1.

8.2 Location of Sample Probe.

Install the sample

probe so that the probe is centrally located in the stack, pipe, or duct and is

sealed tightly at the stack port connection.

8.3 Measurement System Preparation.

Prior to the emission

test, assemble the measurement system by following the manufacturer's written

instructions for preparing sample interface and the organic analyzer. Make the

system operable (Section 10.1).

8.4 Calibration Error Test.

Immediately prior to

the test series (within 2 hours of the start of the test), introduce zero gas

and high-level calibration gas at the calibration valve assembly. Adjust the

analyzer output to the appropriate levels, if necessary. Calculate the

predicted response for the low-level and mid-level gases based on a linear

response line between the zero and high-level response. Then introduce

low-level and mid-level calibration gases successively to the measurement

system. Record the analyzer responses for low-level and mid-level calibration

gases and determine the differences between the measurement system responses

and the predicted responses. These differences must be less than 5 percent of

the respective calibration gas value. If not, the measurement system is not

acceptable and must be replaced or repaired prior to testing. No adjustments to

the measurement system shall be conducted after the calibration and before the

drift check (Section 8.6.2). If adjustments are necessary before the completion

of the test series, perform the drift checks prior to the required adjustments

and repeat the calibration following the adjustments. If multiple electronic

ranges are to be used, each additional range must be checked with a mid-level

calibration gas to verify the multiplication factor.

8.5 Response Time Test.

Introduce zero gas

into the measurement system at the calibration valve assembly. When the system

output has stabilized, switch quickly to the high-level calibration gas. Record

the time from the concentration change to the measurement system response

equivalent to 95 percent of the step change. Repeat the test three times and

average the results.

8.6 Emission Measurement Test Procedure.

8.6.1 Organic Measurement.

Begin sampling at the

start of the test period, recording time and any required process information

as appropriate. In particulate, note on the recording chart, periods of process

interruption or cyclic operation.

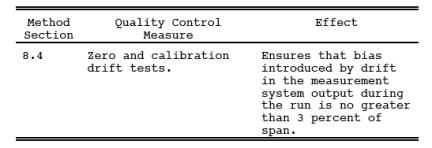

8.6.2 Drift Determination.

Immediately following

the completion of the test period and hourly during the test period,

reintroduce the zero and mid-level calibration gases, one at a time, to the

measurement system at the calibration valve assembly. (Make no adjustments to

the measurement system until both the zero and calibration drift checks are

made.) Record the analyzer response. If the drift values exceed the specified

limits, invalidate the test results preceding the check and repeat the test following

corrections to the measurement system. Alternatively, recalibrate the test

measurement system as in Section 8.4 and report the results using both sets of

calibration data (i.e., data determined prior to the test period and data

determined following the test period).

NOTE: Note on the recording chart periods of process

interruption or cyclic operation.

9.0 Quality Control

10.0 Calibration and Standardization.

10.1 FIA equipment can

be calibrated for almost any range of total organic concentrations. For high

concentrations of organics (> 1.0 percent by volume as propane),

modifications to most commonly available analyzers are necessary. One accepted

method of equipment modification is to decrease the size of the sample to the

analyzer through the use of a smaller diameter sample capillary. Direct and

continuous measurement of organic concentration is a necessary consideration

when determining any modification design.

11.0 Analytical Procedure.

The sample collection

and analysis are concurrent for this method (see Section

8.0).

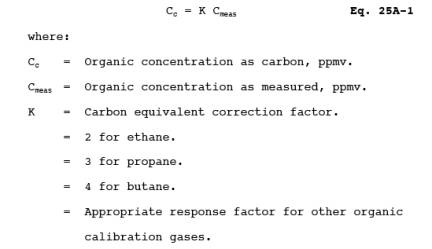

12.0 Calculations and Data Analysis.

12.1 Determine the

average organic concentration in terms of ppmv as propane or other calibration

gas. The average shall be determined by integration of the output recording

over the period specified in the applicable regulation. If results are required

in terms of ppmv as carbon, adjust measured concentrations using Equation

25A-1.

13.0 Method Performance.

13.1 Measurement

System Performance Specifications.

13.1.1 Zero Drift.

Less than ±3 percent of the span value.

13.1.2 Calibration

Drift. Less than ±3 percent of span value.

13.1.3 Calibration

Error. Less than ±5 percent of the calibration gas value.

14.0 Pollution Prevention. [Reserved]

15.0 Waste Management. [Reserved]

16.0 References.

1. Measurement of

Volatile Organic Compounds-Guideline Series. U.S. Environmental Protection Agency.

Research Triangle Park, NC. Publication No. EPA-450/2-78-041. June 1978. p.

46-54.

2. EPA Traceability

Protocol for Assay and Certification of Gaseous Calibration Standards. U.S.

Environmental Protection Agency, Quality Assurance and Technical Support

Division. Research Triangle Park, N.C. September 1993.

3. Gasoline Vapor

Emission Laboratory Evaluation-Part 2. U.S. Environmental Protection Agency,

Office of Air Quality Planning and Standards. Research Triangle Park, NC. EMB

Report No. 75-GAS-6. August 1975.

17.0 Tables, Diagrams, Flowcharts, and Validation Data.

Figure

25A-1. Organic Concentration Measurement System.