METHOD 22 - VISUAL

DETERMINATION OF FUGITIVE EMISSIONS FROM MATERIAL SOURCES AND SMOKE EMISSIONS

FROM FLARES

NOTE: This method is not inclusive with respect to

observer certification. Some material is incorporated by reference from Method 9.

7.0 Reagents and

Supplies. [Reserved]

8.0 Sample Collection,

Preservation, Storage, and Transfer. [Reserved]

9.0 Quality Control. [Reserved]

10.0 Calibration and

Standardization. [Reserved]

11.1 Selection of

Observation Location.

11.3 Indoor Lighting

Requirements.

12.0 Data Analysis and

Calculations.

13.0 Method

Performance. [Reserved]

14.0 Pollution

Prevention. [Reserved]

15.0 Waste Management.

[Reserved]

17.0 Tables, Diagrams,

Flowcharts, and Validation Data.

1.0 Scope and Application.

This method is

applicable for the determination of the frequency of fugitive emissions from

stationary sources, only as specified in an applicable subpart of the

regulations. This method also is applicable for the determination of the

frequency of visible smoke emissions from flares.

2.0 Summary of Method.

2.1 Fugitive

emissions produced during material processing, handling, and transfer

operations or smoke emissions from flares are visually determined by an

observer without the aid of instruments.

2.2 This method is

used also to determine visible smoke emissions from flares used for combustion

of waste process materials.

2.3 This method

determines the amount of time that visible emissions occur during the

observation period (i.e.,

the accumulated emission time.) This method does not require that the opacity

of emissions be determined. Since this procedure requires only the

determination of whether visible emissions occur and does not require the

determination of opacity levels, observer certification according to the

procedures of Method 9 is not required. However, it is necessary that the

observer is knowledgeable with respect to the general procedures for

determining the presence of visible emissions. At a minimum, the observer must

be trained and knowledgeable regarding the effects of background contrast,

ambient lighting, observer position relative to lighting, wind, and the

presence of uncombined water (condensing water vapor) on the visibility of

emissions. This training is to be obtained from written materials found in References 1 and 2 or from the lecture portion of the

Method 9 certification course.

3.0 Definitions.

3.1 Emission frequency

Means the percentage

of time that emissions are visible during the observation period.

3.2 Emission time

Means the accumulated

amount of time that emissions are visible during the observation period.

3.3 Fugitive emissions

Means emissions

generated by an affected facility which is not collected by a capture system

and is released to the atmosphere. This includes emissions that (1) escape

capture by process equipment exhaust hoods; (2) are emitted during material

transfer; (3) are emitted from buildings housing material processing or

handling equipment; or (4) are emitted directly from process equipment.

3.4 Observation period

Means the accumulated

time period during which observations are conducted, not to be less than the

period specified in the applicable regulation.

3.5 Smoke emissions

Means a pollutant

generated by combustion in a flare and occurring immediately downstream of the

flame. Smoke occurring within the flame, but not downstream of the flame, is

not considered a smoke emission.

4.0 Interferences.

4.1 Occasionally,

fugitive emissions from sources other than the affected facility (e.g., road dust) may prevent a clear view of the

affected facility. This may particularly be a problem during periods of high wind.

If the view of the potential emission points is obscured to such a degree that

the observer questions the validity of continuing observations, then the

observations shall be terminated, and the observer shall clearly note this fact

on the data form.

5.0 Safety.

5.1 Disclaimer. This

method may involve hazardous materials, operations, and equipment. This test

method may not address all of the safety problems associated with its use. It

is the responsibility of the user of this test method to establish appropriate

safety and health practices and determine the applicability of regulatory

limitations prior to performing this test method.

6.0 Equipment.

6.1 Stopwatches

(two). Accumulative type with unit divisions of at least 0.5 seconds.

6.2 Light Meter.

Light meter capable of measuring illuminance in the 50 to 200 lux range,

required for indoor observations only.

7.0 Reagents and Supplies. [Reserved]

8.0 Sample Collection, Preservation, Storage, and Transfer. [Reserved]

9.0 Quality Control. [Reserved]

10.0 Calibration and Standardization. [Reserved]

11.0 Analytical Procedure.

11.1 Selection of Observation Location.

Survey the affected

facility, or the building or structure housing the process to be observed, and

determine the locations of potential emissions. If the affected facility is

located inside a building, determine an observation location that is consistent

with the requirements of the applicable regulation (i.e., outside observation of emissions escaping the

building/structure or inside observation of emissions directly emitted from the

affected facility process unit). Then select a position that enables a clear

view of the potential emission point(s) of the affected facility or of the

building or structure housing the affected facility, as appropriate for the

applicable subpart. A position at least 4.6 m (15 feet), but not more than 400

m (0.25 miles), from the emission source is recommended. For outdoor locations,

select a position where the sunlight is not shining directly in the observer's

eyes.

11.2 Field Records.

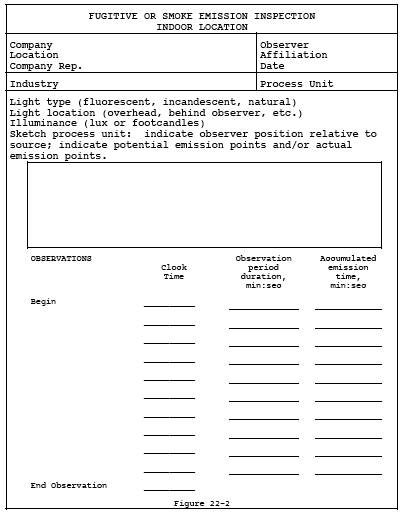

11.2.1 Outdoor Location.

Record the following

information on the field data sheet (Figure 22-1):

Company name, industry, process unit, observer's name, observer's affiliation,

and date. Record also the estimated wind speed, wind direction, and sky

condition. Sketch the process unit being observed, and note the observer

location relative to the source and the sun. Indicate the potential and actual

emission points on the sketch.

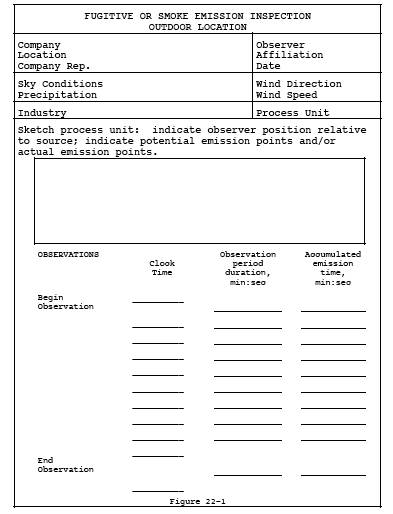

11.2.2 Indoor Location.

Record the following

information on the field data sheet (Figure 22-2):

Company name, industry, process unit, observer's name, observer's affiliation,

and date. Record as appropriate the type, location, and intensity of lighting

on the data sheet. Sketch the process unit being observed, and note the

observer location relative to the source. Indicate the potential and actual

fugitive emission points on the sketch.

11.3 Indoor Lighting Requirements.

For indoor locations,

use a light meter to measure the level of illumination at a location as close

to the emission source(s) as is feasible. An illumination of greater than 100

lux (10 foot candles) is considered necessary for proper application of this

method.

11.4 Observations.

11.4.1 Procedure.

Record the clock time

when observations begin. Use one stopwatch to monitor the duration of the

observation period. Start this stopwatch when the observation period begins. If

the observation period is divided into two or more segments by process

shutdowns or observer rest breaks (see Section 11.4.3),

stop the stopwatch when a break begins and restart the stopwatch without

resetting it when the break ends. Stop the stopwatch at the end of the observation

period. The accumulated time indicated by this stopwatch is the duration of

observation period. When the observation period is completed, record the clock

time. During the observation period, continuously watch the emission source.

Upon observing an emission (condensed water vapor is not considered an

emission), start the second accumulative stopwatch; stop the watch when the

emission stops. Continue this procedure for the entire observation period. The

accumulated elapsed time on this stopwatch is the total time emissions were

visible during the observation period (i.e., the emission time.)

11.4.2 Observation Period.

Choose an observation

period of sufficient length to meet the requirements for determining compliance

with the emission standard in the applicable subpart of the regulations. When

the length of the observation period is specifically stated in the applicable

subpart, it may not be necessary to observe the source for this entire period

if the emission time required to indicate noncompliance (based on the specified

observation period) is observed in a shorter time period. In other words, if the regulation

prohibits emissions for more than 6 minutes in any hour, then observations may (optional) be stopped after an emission

time of 6 minutes is exceeded. Similarly, when the regulation is expressed as

an emission frequency and the regulation prohibits emissions for greater than

10 percent of the time in any hour, then observations may (optional) be

terminated after 6 minutes of emission are observed since 6 minutes is 10

percent of an hour. In any case, the observation period shall not be less than

6 minutes in duration. In some cases, the process operation may be intermittent

or cyclic. In such cases, it may be convenient for the observation period to

coincide with the length of the process cycle.

11.4.3 Observer Rest Breaks.

Do not observe

emissions continuously for a period of more than 15 to 20 minutes without

taking a rest break. For sources requiring observation periods of greater than

20 minutes, the observer shall take a break of not less than 5 minutes and not

more than 10 minutes after every 15 to 20 minutes of observation. If continuous

observations are desired for extended time periods, two observers can alternate

between making observations and taking breaks.

11.5 Recording Observations.

Record the

accumulated time of the observation period on the data sheet as the observation

period duration. Record the accumulated time emissions were observed on the

data sheet as the emission time. Record the clock time the observation period

began and ended, as well as the clock time any observer breaks began and ended.

12.0 Data Analysis and Calculations.

If the applicable

subpart requires that the emission rate be expressed as an emission frequency

(in percent), determine this value as follows: Divide the accumulated emission

time (in seconds) by the duration of the observation period (in seconds) or by

any minimum observation period required in the applicable subpart, if the

actual observation period is less than the required period, and multiply this

quotient by 100.

13.0 Method Performance. [Reserved]

14.0 Pollution Prevention. [Reserved]

15.0 Waste Management. [Reserved]

16.0 References.

1. Missan, R., and A.

Stein. Guidelines for Evaluation of Visible Emissions Certification, Field

Procedures, Legal Aspects, and Background Material. EPA Publication No.

EPA-340/1-75-007. April 1975.

2. Wohlschlegel, P.,

and D.E. Wagoner. Guideline for Development of a Quality Assurance Program: Volume

IX--Visual Determination of Opacity Emissions from Stationary Sources. EPA

Publication No. EPA-650/4-74-005i. November.

17.0 Tables, Diagrams, Flowcharts, and Validation Data.

Figure

22-1 Ð Fugitive or Smoke Emission Inspection Outdoor Location

Figure

22-2 Ð Fugitive or Smoke Emission Inspection Indoor Location