METHOD 111 - DETERMINATION OF POLONIUM-210 EMISSIONS

FROM STATIONARY SOURCES

NOTE: This method does not include all of the

specifications (e.g.,

equipment and supplies) and procedures (e.g., sampling and analytical) essential to its

performance. Some material is incorporated by reference from methods in

appendix A to 40 CFR Part 60. Therefore, to obtain reliable results, persons

using this method should have a thorough knowledge of at least the following

additional test methods: Method 1, Method 2, Method 3, and Method 5.

5.2.1 Hydrochloric Acid

(HCl).

5.2.4 Perchloric Acid

(HClO4).

8.0 Sample Collection,

Preservation, Transport, and Storage. [Reserved]

9.2 Miscellaneous

Quality Control Measures.

10.0 Calibration and

Standardization.

10.1 Standardization of

Alpha Spectrometry System.

10.2 Preparation of

Standardized Solution of Polonium-209.

10.3 Standardization of

Internal Proportional Counter

11.1 Determination of

Procedure Background.

11.2 Determination of

Instrument Background.

11.3 Quality Assurance

Audit Samples.

11.6 Preparation of

Silver Disc for Spontaneous Electro-deposition.

12.0 Data Analysis and

Calculations.

13.0 Method

Performance. [Reserved]

14.0 Pollution

Prevention. [Reserved]

15.0 Waste Management.

[Reserved]

17.0 Tables, Diagrams,

Flowcharts, and Validation Data. [Reserved]

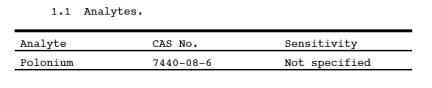

1.0 Scope and Application.

1.1 Analytes.

1.2 Applicability.

This method is

applicable for the determination of the polonium-210 content of particulate

matter samples collected from stationary source exhaust stacks, and for the use

of these data to calculate polonium-210 emissions from individual sources and

from all affected sources at a facility.

1.3 Data Quality Objectives.

Adherence to the

requirements of this method will enhance the quality of the data obtained from

air pollutant sampling methods.

2.0 Summary of Method.

A particulate

matter sample, collected according to Method 5, is analyzed for polonium-210

content: the polonium-210 in the sample is put in solution, deposited on a

metal disc, and the radioactive disintegration rate measured. Polonium in acid

solution spontaneously deposits on surfaces of metals that are more

electropositive than polonium. This principle is routinely used in the

radiochemical analysis of polonium-210. Data reduction procedures are provided,

allowing the calculation of polonium-210 emissions from individual sources and

from all affected sources at a facility, using data obtained from Methods 2 and

5 and from the analytical procedures herein.

3.0 Definitions. [Reserved]

4.0 Interferences. [Reserved]

5.0 Safety.

5.1 Disclaimer.

This method may

involve hazardous materials, operations, and equipment. This test method may

not address all of the safety problems associated with its use. It is the

responsibility of the user of this test method to establish appropriate safety

and health practices and determine the applicability of regulatory limitations

prior to performing this test method.

5.2 Corrosive Reagents.

The following

reagents are hazardous. Personal protective equipment and safe procedures are

useful in preventing chemical splashes. If contact occurs, immediately flush

with copious amounts of water at least 15 minutes. Remove clothing under shower

and decontaminate. Treat residual chemical burns as thermal burns.

5.2.1 Hydrochloric Acid (HCl).

Highly corrosive

liquid with toxic vapors. Vapors are highly irritating to eyes, skin, nose, and

lungs, causing severe damage. May cause bronchitis, pneumonia, or edema of

lungs. Exposure to concentrations of 0.13 to 0.2 percent can be lethal to

humans in a few minutes. Provide ventilation to limit exposure. Reacts with

metals, producing hydrogen gas.

5.2.2 Hydrofluoric Acid (HF).

Highly corrosive

to eyes, skin, nose, throat, and lungs. Reaction to exposure may be delayed by

24 hours or more. Provide ventilation to limit exposure.

5.2.3 Nitric Acid (HNO3).

Highly corrosive

to eyes, skin, nose, and lungs. Vapors cause bronchitis, pneumonia, or edema of

lungs. Reaction to inhalation may be delayed as long as 30 hours and still be

fatal. Provide ventilation to limit exposure. Strong oxidizer. Hazardous

reaction may occur with organic materials such as solvents.

5.2.4 Perchloric Acid (HClO4).

Corrosive to eyes,

skin, nose, and throat. Provide ventilation to limit exposure. Keep separate

from water and oxidizable materials to prevent vigorous evolution of heat,

spontaneous combustion, or explosion. Heat solutions containing HClO4 only in hoods specifically designed for HClO4.

6.0 Equipment and Supplies.

6.1 Alpha

Spectrometry System. Consisting of a multi-channel analyzer, biasing

electronics, silicon surface barrier detector, vacuum pump and chamber.

6.2 Constant

Temperature Bath at 85 ûC (185 ûF).

6.3 Polished

Silver Discs. 3.8 cm diameter, 0.4 mm thick with a small hole near the edge.

6.4 Glass Beakers.

400 ml, 150 ml.

6.5 Hot Plate,

Electric.

6.6 Fume Hood.

6.7 Teflon

Beakers, 150 ml.

6.8 Magnetic

Stirrer.

6.9 Stirring Bar.

6.10 Hooks. Plastic

or glass, to suspend plating discs.

6.11 Internal

Proportional Counter. For measuring alpha particles.

6.12 Nucleopore

Filter Membranes. 25 mm diameter, 0.2 micrometer pore size or equivalent.

6.13 Planchets.

Stainless steel, 32 mm diameter with 1.5 mm lip.

6.14 Transparent

Plastic Tape. 2.5 cm wide with adhesive on both sides.

6.15 Epoxy Spray

Enamel.

6.16 Suction

Filter Apparatus. For 25 mm diameter

filter.

6.17 Wash Bottles,

250 ml capacity.

6.18 Graduated Cylinder,

plastic, 25 ml capacity.

6.19 Volumetric

Flasks, 100 ml, 250 ml.

7.0 Reagents and Standards.

Unless otherwise

indicated, it is intended that all reagents conform to the specifications

established by the Committee on Analytical Reagents of the American Chemical

Society, where such specifications are available; otherwise, use the best

available grade.

7.1 Ascorbic Acid.

7.2 Ammonium

Hydroxide (NH4OH), 15 M.

7.3 Water.

Deionized distilled, to conform to ASTM D 1193-77 or 91 (incorporated by reference

- see ¤ 61.18), Type 3. Use in all dilutions requiring water.

7.4 Ethanol (C2H5OH),

95 percent.

7.5 Hydrochloric

Acid, 12 M.

7.6 Hydrochloric

Acid, 1 M. Dilute 83 ml of the 12 M HCl to 1 liter with distilled water.

7.7 Hydrofluoric

Acid, 29 M.

7.8 Hydrofluoric

Acid, 3 M. Dilute 52 ml of the 29 M HF to 500 ml with distilled water. Use a

plastic graduated cylinder and storage bottle.

7.9 Lanthanum

Carrier, 0.1 mg La+3/ml. Dissolve 0.078 gram lanthanum nitrate,

La(NO3)3á6H2O in 250 ml of 1 M HCl.

7.10 Nitric Acid,

16 M.

7.11 Perchloric

Acid, 12 M.

7.12 Polonium-209

Solution.

7.13 Silver

Cleaner. Any mild abrasive commercial silver cleaner.

7.14 Degreaser.

7.15 Standard Solution.

Standardized solution of an alpha-emitting actinide element, such as

plutonium-239 or americium-241.

8.0 Sample Collection, Preservation, Transport, and Storage. [Reserved]

9.0 Quality Control

9.1 General Requirement.

9.1.1 All analysts

using this method are required to demonstrate their ability to use the method

and to define their respective accuracy and precision criteria.

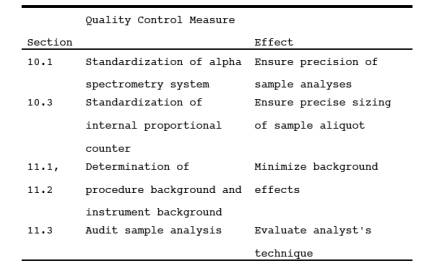

9.2 Miscellaneous Quality Control Measures.

10.0 Calibration and Standardization.

10.1 Standardization of Alpha Spectrometry System.

10.1.1 Add a

quantity of the actinide standard solution to a 100 ml volumetric flask so that

the final concentration when diluted to a volume of 100 ml will be

approximately 1 pCi/ml.

10.1.2 Add 10 ml

of 16 M HNO3 and dilute to 100 ml with water.

10.1.3 Add 20 ml

of 1 M HCl to each of six 150 ml beakers. Add 1.0 ml of lanthanum carrier, 0.1

mg lanthanum per ml, to the acid solution in each beaker.

10.1.4 Add 1.0 ml

of the 1 pCi/ml working solution (from Section 10.1.1) to each beaker. Add 5.0

ml of 3 M HF to each beaker.

10.1.5 Cover

beakers and allow solutions to stand for a minimum of 30 minutes. Filter the

contents of each beaker through a separate filter membrane using the suction

filter apparatus. After each filtration, wash the filter membrane with 10 ml of

distilled water and 5 ml of ethanol, and allow the filter membrane to air dry

on the filter apparatus.

10.1.6

Carefully remove the filter membrane and mount it, filtration side up, with

double-side tape on the inner surface of a planchet. Place planchet in an alpha

spectrometry system and count each planchet for 1000 minutes.

10.1.7 Calculate

the counting efficiency of the detector for each aliquot of the 1 pCi/ml

actinide working solution using Eq. 111-1 in Section

12.2.

10.1.8 Determine the average counting

efficiency of the detector, Ec, by calculating

the average of the six determinations.

10.2 Preparation of Standardized Solution of Polonium-209.

10.2.1 Add a quantity

of the Po-209 solution to a 100 ml volumetric flask so that the final

concentration when diluted to a 100 ml volume will be approximately 1 pCi/ml.

10.2.2 Follow the

procedures outlined in Sections 10.1.2 through 10.1.6, except substitute 1.0 ml

of polonium-209 tracer solution (Section 10.2.1) and 3.0 ml of 15 M ammonium

hydroxide for the 1 pCi/ml actinide working solution and the 3 M HF,

respectively.

10.2.3 Calculate

the activity of each aliquot of the polonium-209 tracer solution using Eq. 111-2 in Section 12.3.

10.2.4

Determine the average activity of the polonium-209 tracer solution, F, by

averaging the results of the six determinations.

10.3 Standardization of Internal Proportional Counter

10.3.1 Add a quantity

of the actinide standard solution to a 100 ml volumetric flask so that the

final concentration when diluted to a 100 ml volume will be approximately 100

pCi/ml.

10.3.2

Follow the procedures outlined in Sections 10.1.2 through 10.1.6, except

substitute the 100 pCi/ml actinide working solution for the 1 pCi/ml solution,

place the planchet in an internal proportional counter (instead of an alpha

spectrometry system), and count for 100 minutes (instead of 1000 minutes).

10.3.3 Calculate

the counting efficiency of the internal proportional counter for each aliquot

of the 100 pCi/ml actinide working solution using Eq.

111-3 in 12.4.

10.3.4 Determine

the average counting efficiency of the internal proportional counter, EI, by averaging the results of the six

determinations.

11.0 Analytical Procedure.

NOTE: Perform duplicate analyses of all samples,

including background counts, quality assurance audit samples, and Method 5

samples. Duplicate measurements are considered acceptable when the difference

between them is less than two standard deviations as described in EPA

600/4-77-001 or subsequent revisions.

11.1 Determination of Procedure Background.

Background counts

used in all equations are determined by performing the specific analysis

required using the analytical reagents only. All procedure background counts

and sample counts for the internal proportional counter should utilize a

counting time of 100 minutes; for the alpha spectrometry system, 1000 minutes.

These background counts should be performed no less frequently than once per 10

sample analyses.

11.2 Determination of Instrument Background.

Instrument

backgrounds of the internal proportional counter and the alpha spectrometry

system should be determined on a weekly basis. Instrument background should not

exceed procedure background. If this occurs, it may be due to a malfunction or

contamination, and should be corrected before use.

11.3 Quality Assurance Audit Samples.

An externally

prepared performance evaluation sample shall be analyzed no less frequently

than once per 10 sample analyses, and the results reported with the test

results.

11.4 Sample Preparation.

Treat the Method 5

samples [i.e., the glass

fiber filter (Container No. 1) and the acetone rinse (Container No. 2)] as

follows:

11.4.1 Container

No. 1. Transfer the filter and any loose particulate matter from the sample

container to a 150-ml Teflon beaker.

11.4.2 Container

No. 2. Note the level of liquid in the container, and confirm on the analysis

sheet whether leakage occurred during transport. If a noticeable amount of

leakage has occurred, either void the sample or use methods, subject to the

approval of the Administrator, to

correct the final results. Transfer the

contents to a 400-ml glass beaker. Add polonium-209 tracer solution to the

glass beaker in an amount approximately equal to the amount of polonium-210

expected in the total particulate sample. Record the activity of the tracer

solution added. Add 16 M nitric acid to the beaker to digest and loosen the

residue.

11.4.3 Transfer

the contents of the glass beaker to the Teflon beaker containing the glass

fiber filter. Rinse the glass beaker with 16 M HNO3. If necessary, reduce the volume in the

beaker by evaporation until all of the nitric acid HNO3 from the glass beaker has been transferred to

the Teflon beaker.

11.4.4 Add 30 ml

of 29 M HF to the Teflon beaker and evaporate to near dryness on a hot plate in

a properly operating hood.

NOTE: Do not allow the residue to go to dryness

and overheat; this will result in loss of polonium.

11.4.5 Repeat step

11.4.4 until the filter is dissolved.

11.4.6 Add 100 ml

of 16 M HNO3 to the residue in the Teflon beaker and evaporate

to near dryness.

NOTE: Do not allow the residue to go to dryness.

11.4.7 Add 50 ml

of 16 M HNO3 and 10 ml of 12 M perchloric acid to the

Teflon beaker and heat until dense fumes of perchloric acid are evolved.

11.4.8 Repeat steps

11.4.4 to 11.4.7 as necessary until sample is completely dissolved.

11.4.9 Add 10 ml

of 12 M HCl to the Teflon beaker and evaporate to dryness. Repeat additions and

evaporations several times.

11.4.10 Transfer

the sample to a 250-ml volumetric flask and dilute to volume with 3 M HCl.

11.5 Sample Screening.

To avoid

contamination of the alpha spectrometry system, check each sample as follows:

11.5.1 Add 20 ml

of 1 M HCl, 1 ml of the lanthanum carrier solution (0.1 mg La/ml), a 1 ml

aliquot of the sample solution from Section 11.4.10, and 3 ml of 15 M ammonium

hydroxide to a 250-ml beaker in the order listed. Allow this solution to stand

for a minimum of 30 minutes.

11.5.2 Filter the

solution through a filter membrane using the suction filter apparatus. Wash the

filter membrane with 10 ml of water and 5 ml of ethanol, and allow the filter

membrane to air dry on the filter apparatus.

11.5.3 Carefully

remove the filter membrane and mount it, filtration side up, with double-side

tape on the inner surface of a planchet. Place the planchet in an internal

proportional counter, and count for 100 minutes.

11.5.4 Calculate

the activity of the sample using Eq. 111-4 in Section

12.5.

11.5.5 Determine

the aliquot volume of the sample solution from Section 11.4.10 to be analyzed

for polonium-210 , such that the aliquot contains an activity between 1 and 4

picocuries. Use Eq. 111-5 in Section 12.6.

11.6 Preparation of Silver Disc for Spontaneous Electro-deposition.

11.6.1 Clean both

sides of the polished silver disc with silver cleaner and with degreaser.

11.6.2 Place disc

on absorbent paper and spray one side with epoxy spray enamel. This should be carried

out in a well-ventilated area, with the disc lying flat to keep paint on one

side only. Allow paint to dry for 24 hours before using disc for deposition.

11.7 Sample Analysis.

11.7.1 Add the

aliquot of sample solution from Section 11.4.10 to be analyzed for

polonium-210, the volume of which was determined in Section 11.5.5, to a

suitable 200-ml container to be placed in a constant temperature bath.

NOTE: Aliquot volume may require a larger

container.

11.7.2 If

necessary, bring the volume to 100 ml with 1 M HCl. If the aliquot volume

exceeds 100 ml, use total aliquot.

11.7.3 Add 200 mg

of ascorbic acid and heat solution to 85 ûC (185 ûF) in a constant temperature

bath.

11.7.4 Suspend a

silver disc in the heated solution using a glass or plastic rod with a hook

inserted through the hole in the disc. The disc should be totally immersed in

the solution, and the solution must be stirred constantly, at all times during

the plating operation. Maintain the disc in solution for 3 hours.

11.7.5 Remove the

silver disc, rinse with deionized distilled water, and allow to air dry at room

temperature.

11.7.6 Place the

disc, with deposition side (unpainted side) up, on a planchet and secure with

double-side plastic tape. Place the planchet with disc in alpha spectrometry

system and count for 1000 minutes.

12.0 Data Analysis and Calculations.

12.1 Nomenclature.

A = picocuries of

polonium-210 in the Method 5 sample (from Section 12.8).

AA = picocuries of actinide added.

AL = volume of sample aliquot used, in ml

(specified in Section 11.5.1 as 1 ml).

AS = aliquot to be analyzed, in ml.

BB = procedure background counts measured in

polonium-209 spectral region.

BT = polonium-209 tracer counts in sample.

CT = total counts in polonium-210 spectral

region.

D = decay

correction for time "t" (in days) from sample collection to sample

counting, given by: D=e-0.005t

EC = average counting efficiency of detector

(from Section 10.1.8), as counts per

disintegration.

ECi = counting efficiency of the detector for

aliquot i of the actinide working solution, counts per disintegration.

EI = average counting efficiency of the internal

proportional counter, as determined in Section 10.3.4, counts per

disintegration.

EIi = counting efficiency of the internal

proportional counter for aliquot i of the 100 pCi/ml actinide working solution,

counts per disintegration.

EY = the fraction of polonium-209 recovered on

the planchet (from Section 12.7).

F = average

activity of polonium-209 in sample (from Section

10.2.4), in pCi.

Fi = activity of aliquot i of the polonium-209

tracer solution, in pCi.

L = dilution

factor (unitless). This is the volume of sample solution prepared (specified as

250 ml in Section 11.1.10) divided by the volume of the aliquot of sample

solution analyzed for polonium-210 (from Section 11.7.1).

Mi = phosphorous rock processing rate of the

source being tested, during run i, Mg/hr.

Mk = phosphate rock processed annually by source

k, in Mg/yr.

n = number of

calciners at the elemental phosphorus plant.

P = total activity

of sample solution from Section 11.4.10, in pCi (see Eq. 111-4).

Qsd = volumetric flow rate of effluent stream, as

determined by Method 2, in dscm/hr.

S = annual

polonium-210 emissions from the entire facility, in curies/yr.

Vm(std) = volume of air sample, as determined by

Method 5, in dscm.

Xk = emission rate from source k, from Section 12.10, in curies/Mg.

10-12 = curies per picocurie.

2.22 =

disintegrations per minute per picocurie.

250 = volume of

solution from Section 11.4.10, in ml.

12.2

Counting Efficiency. Calculate the counting efficiency of the detector for each

aliquot of the 1 pCi/ml actinide working solution using Eq. 111-1.

where:

CB = background counts in same peak area as CS.

CS = gross counts in actinide peak.

T = counting time

in minutes, specified in Section 10.1.6 as 1000

minutes.

12.3

Polonium-209 Tracer Solution Activity. Calculate the activity of each aliquot

of the polonium-209 tracer solution using Eq. 111-2.

where:

CB = background counts in the 4.88 MeV region of

spectrum the in the counting time T.

CS = gross counts of polonium-209 in the 4.88

MeV region of the spectrum in the counting time T.

T = counting time,

specified in Section 10.1.6 as 1000 minutes.

12.4

Control Efficiency of Internal Proportional Counter. Calculate the counting

efficiency of the internal proportional counter for each aliquot of the 100

pCi/ml actinide working solution using Eq. 111-3.

where:

CB = gross counts of procedure background.

CS = gross counts of standard.

T = counting time

in minutes, specified in Section 10.3.2 as 100

minutes.

12.5

Calculate the activity of the sample using Eq. 111-4.

where:

CB = total counts of procedure background. (See Section 11.1).

CS = total counts of screening sample.

T = counting time

for sample and background (which must be equal), in minutes (specified in

Section 11.5.3 as 100 minutes).

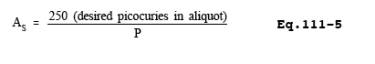

12.6

Aliquot Volume. Determine the aliquot volume of the sample solution from

Section 11.4.10 to be analyzed for polonium-210 , such that the aliquot

contains an activity between 1 and 4 picocuries using Eq. 111-5.

12.7 Polonium-209

Recovery. Calculate the fraction of polonium-209 recovered on the planchet, EY, using Eq. 111-6.

where:

T = counting time,

specified in Section 11.1 as 1000 minutes.

12.8

Polonium-210 Activity. Calculate the activity of polonium-210 in the Method 5

sample (including glass fiber filter and acetone rinse) using Eq. 111-7.

![]()

where:

CB = procedure background counts in polonium-210

spectral region.

T = counting time,

specified in Section 11.1 as 1000 minutes for all alpha spectrometry sample and

background counts.

12.9 Emission Rate

from Each Stack.

12.9.1 For each test

run, i, on a stack, calculate the measured polonium-210 emission rate, RSi, using Eq. 111-8.

12.9.2 Determine

the average polonium-210 emission rate from the stack, RS, by taking the sum of the measured emission

rates for all runs, and dividing by the number of runs performed.

12.9.3 Repeat

steps 12.9.1 and 12.9.2 for each stack of each calciner.

12.10

Emission Rate from Each Source. Determine the total polonium-210 emission rate,

Xk, from each source, k, by taking the sum of

the average emission rates from all stacks to which the source exhausts.

12.11 Annual

Polonium-210 Emission Rate from Entire Facility. Determine the annual elemental

phosphorus plant emissions of polonium-210, S, using Eq. 111-9.

13.0 Method Performance. [Reserved]

14.0 Pollution Prevention. [Reserved]

15.0 Waste Management. [Reserved]

16.0 References.

1. Blanchard, R.L.

"Rapid Determination of Lead-210 and Polonium-210 in Environmental Samples

by Deposition on Nickel." Anal. Chem., 38:189, pp. 189-192. February 1966.

17.0 Tables, Diagrams, Flowcharts, and Validation Data. [Reserved]