METHOD

101 - DETERMINATION OF PARTICULATE AND GASEOUS MERCURY EMISSIONS FROM

CHLOR-ALKALI PLANTS (AIR STREAMS)

NOTE: This method does not include all of the

specifications (e.g.,

equipment and supplies) and procedures (e.g., sampling and analytical) essential to its

performance. Some material is incorporated by reference from methods in

Appendix A to 40 CFR Part 60. Therefore, to obtain reliable results, persons

using this method should have a thorough knowledge of at least the following

additional test methods: Method 1, Method 2, Method 3, and Method 5.

5.2.1 Hydrochloric Acid

(HCl).

6.3 Sample Preparation

and Analysis.

7.2 Sample Preparation

and Analysis.

8.0 Sample Collection,

Preservation, Transport, and Storage.

8.2 Preliminary

Determinations.

8.3 Preparation of

Sampling Train.

8.6 Calculation of

Percent Isokinetic.

10.0 Calibration and

Standardizations.

10.3 Aeration System

Flow Rate Meter.

10.4 Optical Cell

Heating System.

10.5 Spectrophotometer

and Recorder.

11.4 Container No. 2

(Silica Gel).

12.0 Data Analysis and

Calculations.

14.0 Pollution

Prevention. [Reserved]

15.0 Waste Management.

[Reserved]

17.0 Tables, Diagrams,

Flowcharts, and Validation Data.

1.0 Scope and Application.

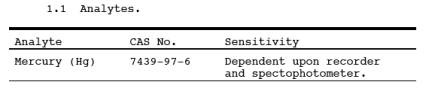

1.1 Analytes.

1.2 Applicability.

This method is

applicable for the determination of Hg emissions, including both particulate

and gaseous Hg, from chlor-alkali plants and other sources (as specified in the

regulations) where the carrier-gas stream in the duct or stack is principally

air.

1.3 Data Quality Objectives.

Adherence to the

requirements of this method will enhance the quality of the data obtained from

air pollutant sampling methods.

2.0 Summary of Method.

Particulate and

gaseous Hg emissions are withdrawn isokinetically from the source and collected

in acidic iodine monochloride (ICl) solution. The Hg collected (in the mercuric

form) is reduced to elemental Hg, which is then aerated from the solution into

an optical cell and measured by atomic absorption spectrophotometry.

3.0 Definitions. [Reserved]

4.0 Interferences.

4.1 Sample Collection.

Sulfur dioxide (SO2) reduces ICl and causes premature depletion of the ICl solution.

4.2 Sample Analysis.

4.2.1 ICl

concentrations greater than 10-4 molar inhibit the

reduction of the Hg (II) ion in the aeration cell.

4.2.2 Condensation of

water vapor on the optical cell windows causes a positive interference.

5.0 Safety.

5.1 Disclaimer.

This method may

involve hazardous materials, operations, and equipment. This test method does

not purport to address all of the safety problems associated with its use. It

is the responsibility of the user of this test method to establish appropriate

safety and health practices and determine the applicability of regulatory

limitations prior to performing this test method.

5.2 Corrosive Reagents.

The following

reagents are hazardous. Personal protective equipment and safe procedures are

useful in preventing chemical splashes. If contact occurs, immediately flush

with copious amounts of water for at least 15 minutes. Remove clothing under

shower and decontaminate. Treat residual chemical burn as thermal burn.

5.2.1 Hydrochloric Acid (HCl).

Highly toxic and

corrosive. Causes severe damage to tissues. Vapors are highly irritating to

eyes, skin, nose, and lungs, causing severe damage. May cause bronchitis,

pneumonia, or edema of lungs. Exposure to concentrations of 0.13 to 0.2 percent

can be lethal to humans in a few minutes. Provide ventilation to limit

exposure. Reacts with metals, producing hydrogen gas.

5.2.2 Nitric Acid (HNO3).

Highly corrosive to

eyes, skin, nose, and lungs. Vapors cause bronchitis, pneumonia, or edema of

lungs. Reaction to inhalation may be delayed as long as 30 hours and still be

fatal. Provide ventilation to limit exposure. Strong oxidizer. Hazardous

reaction may occur with organic materials such as solvents.

5.2.3 Sulfuric Acid (H2SO4).

Rapidly destructive

to body tissue. Will cause third degree burns. Eye damage may result in

blindness. Inhalation may be fatal from spasm of the larynx, usually within 30

minutes. 3 mg/m3 will cause lung damage. 1 mg/m3 for 8 hours will cause lung damage or, in higher concentrations,

death. Provide ventilation to limit inhalation. Reacts violently with metals

and organics.

6.0 Equipment and Supplies.

6.1 Sample Collection.

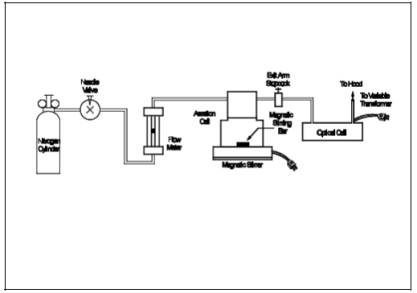

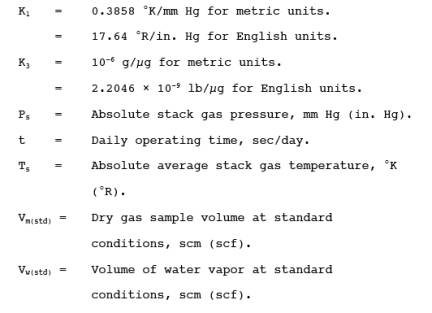

A schematic of the

sampling train used in performing this method is shown in

Figure 101-1; it is similar to the Method 5 sampling train. The following

items are required for sample collection:

6.1.1 Probe Nozzle,

Pitot Tube, Differential Pressure Gauge, Metering System, Barometer, and Gas

Density Determination Equipment. Same as Method 5, Sections 6.1.1.1, 6.1.1.3,

6.1.1.4, 6.1.1.9, 6.1.2, and 6.1.3, respectively.

6.1.2 Probe Liner.

Borosilicate or quartz glass tubing. A heating system capable of maintaining a

gas temperature of 120 ± 14 ¼C (248 ± 25 ¼F) at the probe exit during sampling

may be used to prevent water condensation.

NOTE: Do not use metal probe liners.

6.1.3 Impingers. Four

Greenburg-Smith impingers connected in series with leak-free ground glass

fittings or any similar leak-free non-contaminating fittings. For the

first, third, and

fourth impingers, impingers that are modified by replacing the tip with a 13-mm

ID (0.5-in.) glass tube extending to 13 mm (0.5 in.) from the bottom of the

flask may be used.

6.1.4 Acid Trap. Mine

Safety Appliances air line filter, Catalog number 81857, with acid absorbing

cartridge and suitable connections, or equivalent.

6.2 Sample Recovery.

The following items

are needed for sample recovery:

6.2.1 Glass Sample

Bottles. Leakless, with Teflon-lined caps, 1000- and 100-ml.

6.2.2 Graduated

Cylinder. 250-ml.

6.2.3 Funnel and

Rubber Policeman. To aid in transfer of silica gel to container; not necessary

if silica gel is weighed in the field.

6.2.4 Funnel. Glass,

to aid in sample recovery.

6.3 Sample Preparation and Analysis.

The following items

are needed for sample preparation and analysis:

6.3.1 Atomic

Absorption Spectrophotometer. Perkin-Elmer 303, or equivalent, containing a

hollow-cathode mercury lamp and the optical cell described in Section 6.3.2.

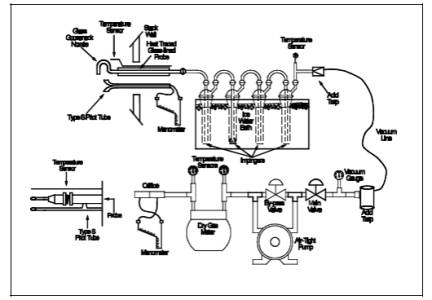

6.3.2 Optical Cell.

Cylindrical shape with quartz end windows and having the dimensions shown in Figure 101-2. Wind the cell with approximately 2 meters (6

ft) of 24-gauge Nichrome wire, or equivalent, and wrap with fiberglass

insulation tape, or equivalent; do not let the wires touch each other.

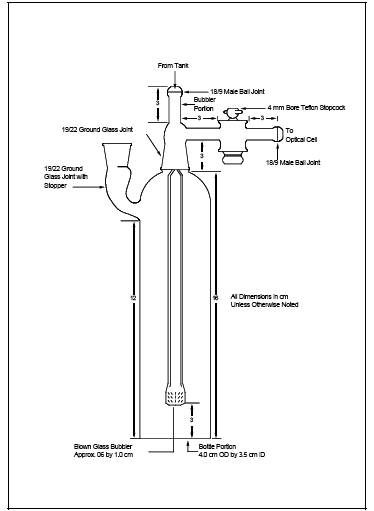

6.3.3 Aeration Cell.

Constructed according to the specifications in Figure 101-3.

Do not use a glass frit as a substitute for the blown glass bubbler tip shown

in Figure 101-3.

6.3.4 Recorder. Matched

to output of the spectrophotometer described in Section 6.3.1.

6.3.5 Variable

Transformer. To vary the voltage on the optical cell from 0 to 40 volts.

6.3.6 Hood. For

venting optical cell exhaust.

6.3.7 Flow Metering

Valve.

6.3.8 Rate Meter. Rotameter,

or equivalent, capable of measuring to within 2 percent a gas flow of 1.5

liters/min (0.053 cfm).

6.3.9 Aeration Gas

Cylinder. Nitrogen or dry, Hg-free air, equipped with a single-stage regulator.

6.3.10 Tubing. For

making connections. Use glass tubing (ungreased ball and socket connections are

recommended) for all tubing connections between the solution cell and the

optical cell; do not use Tygon tubing, other types of flexible tubing, or metal

tubing as substitutes. Teflon, steel, or copper tubing may be used between the

nitrogen tank and flow metering valve (Section 6.3.7), and Tygon, gum, or

rubber tubing between the flow metering valve and the aeration cell.

6.3.11 Flow Rate

Calibration Equipment. Bubble flow meter or wet-test meter for measuring a gas

flow rate of 1.5 ± 0.1 liters/min (0.053 ± 0.0035 cfm).

6.3.12 Volumetric

Flasks. Class A with penny head standard taper stoppers; 100-, 250-, 500-, and

1000-ml.

6.3.13 Volumetric

Pipets. Class A; 1-, 2-, 3-, 4-, and 5-ml.

6.3.14 Graduated Cylinder.

50-ml.

6.3.15 Magnetic

Stirrer. General-purpose laboratory type.

6.3.16 Magnetic

Stirring Bar. Teflon-coated.

6.3.17 Balance.

Capable of weighing to ± 0.5 g

6.3.18 Alternative Analytical

Apparatus. Alternative systems are allowable as long as they meet the following

criteria:

6.3.18.1 A linear

calibration curve is generated and two consecutive samples of the same aliquot

size and concentration agree within 3 percent of their average.

6.3.18.2 A minimum of

95 percent of the spike is recovered when an aliquot of a source sample is

spiked with a known concentration of Hg (II) compound.

6.3.18.3 The reducing

agent should be added after the aeration cell is closed.

6.3.18.4 The aeration

bottle bubbler should not contain a frit.

6.3.18.5 Any Tygon

tubing used should be as short as possible and conditioned prior to use until

blanks and standards yield linear and reproducible results.

6.3.18.6 If manual

stirring is done before aeration, it should be done with the aeration cell

closed.

6.3.18.7 A drying

tube should not be used unless it is conditioned as the Tygon tubing above.

7.0 Reagents and Standards.

Unless otherwise

indicated, all reagents must conform to the specifications established by the

Committee on Analytical Reagents of the American Chemical Society; where such

specifications are not available, use the best available grade.

7.1 Sample Collection.

The following

reagents are required for sample collection:

7.1.1 Water.

Deionized distilled, to conform to ASTM D 1193-77 or 91 (incorporated by

reference - see ¤ 61.18), Type 1. If high concentrations of organic matter are

not expected to be present, the analyst may eliminate the KMnO4 test for oxidizable organic matter. Use this water in all dilutions

and solution preparations.

7.1.2 Nitric Acid, 50

Percent (v/v). Mix equal volumes of concentrated HNO3 and water, being careful to add the acid to the water slowly.

7.1.3 Silica Gel.

Indicating type, 6- to 16-mesh. If previously used, dry at 175 ¼C (350 ¼F) for

2 hours. The tester may use new silica gel as received.

7.1.4 Potassium

Iodide (KI) Solution, 25 Percent. Dissolve 250 g of KI in water, and dilute to

1 liter.

7.1.5 Iodine Monochloride

Stock Solution, 1.0 M. To 800 ml of 25 percent KI solution, add 800 ml of

concentrated HCl. Cool to room temperature. With vigorous stirring, slowly add

135 g of potassium iodate (KIO3), and stir until all

free iodine has dissolved. A clear orange-red solution occurs when all the KIO3 has been added. Cool to room temperature, and dilute to 1800 ml

with water. Keep the solution in amber glass bottles to prevent degradation.

7.1.6 Absorbing

Solution, 0.1 M ICl. Dilute 100 ml of the 1.0 M ICl stock solution to 1 liter

with water. Keep the solution in amber glass bottles and in darkness to prevent

degradation. This reagent is stable for at least two months.

7.2 Sample Preparation and Analysis.

The following

reagents and standards are required for sample preparation and analysis:

7.2.1 Reagents

7.2.1.1 Tin (II)

Solution. Prepare fresh daily, and keep sealed when not being used. Completely

dissolve 20 g of tin (II) chloride [or 25 g of tin (II) sulfate] crystals

(Baker Analyzed reagent grade or any other brand that will give a clear

solution) in 25 ml of concentrated HCl. Dilute to 250 ml with water. Do not

substitute HNO3, H2SO4, or other strong acids for the HCl.

7.2.1.2 Sulfuric

Acid, 5 Percent (v/v). Dilute 25 ml of concentrated H2SO4 to 500 ml with water.

7.2.2 Standards

7.2.2.1 Hg Stock

Solution, 1 mg Hg/ml. Prepare and store all Hg standard solutions in

borosilicate glass containers. Completely dissolve 0.1354 g of Hg (II) chloride

in 75 ml of water in a 100-ml glass volumetric flask. Add 10 ml of concentrated

HNO3, and adjust the volume to exactly 100 ml with

water. Mix thoroughly. This solution is stable for at least one month.

7.2.2.2 Intermediate

Hg Standard Solution, 10 µg Hg/ml. Prepare fresh weekly. Pipet 5.0 ml of the Hg

stock solution (Section 7.2.2.1) into a 500-ml glass volumetric flask, and add

20 ml of the 5 percent H2SO4 solution.

Dilute to exactly 500 ml with water. Thoroughly mix the solution.

7.2.2.3 Working Hg

Standard Solution, 200 ng Hg/ml. Prepare fresh daily. Pipet 5.0 ml of the

intermediate Hg standard solution (Section 7.2.2.2) into a 250-ml volumetric

glass flask. Add 10 ml of the 5 percent H2SO4 and 2 ml of the 0.1 M ICl absorbing solution taken as a blank (Section 8.7.4.3), and dilute to 250 ml with water.

Mix thoroughly.

8.0 Sample Collection, Preservation, Transport, and

Storage.

Because of the

complexity of this method, testers should be trained and experienced with the

test procedures to ensure reliable results. Since the amount of Hg that is

collected generally is small, the method must be carefully applied to prevent

contamination or loss of sample.

8.1 Pretest Preparation.

Follow the general

procedure outlined in Method 5, Section 8.1,

except omit Sections 8.1.2 and 8.1.3.

8.2 Preliminary Determinations.

Follow the general

procedure outlined in Method 5, Section 8.2,

with the exception of the following:

8.2.1 Select a nozzle

size based on the range of velocity heads to assure that it is not necessary to

change the nozzle size in order to maintain isokinetic sampling rates below 28

liters/min (1.0 cfm).

8.2.2 Perform test

runs such that samples are obtained over a period or periods that accurately

determine the maximum emissions that occur in a 24-hour period. In the case of

cyclic operations, run sufficient tests for the accurate determination of the

emissions that occur over the duration of the cycle. A minimum sample time of 2

hours is recommended. In some instances, high Hg or high SO2 concentrations make it impossible to sample for the desired minimum

time. This is indicated by reddening (liberation of free iodine) in the first

impinger. In these cases, the sample run may be divided into two or more

sub-runs to ensure that the absorbing solution is not depleted.

8.3 Preparation of Sampling Train.

8.3.1 Clean all

glassware (probe, impingers, and connectors) by rinsing with 50 percent HNO3, tap water, 0.1 M ICl, tap water, and finally deionized distilled

water. Place 100 ml of 0.1 M ICl in each of the first three impingers. Take

care to prevent the absorbing solution from contacting any greased surfaces.

Place approximately 200 g of pre-weighed silica gel in the fourth impinger.

More silica gel may be used, but care should be taken to ensure that it is not

entrained and carried out from the impinger during sampling. Place the silica

gel container in a clean place for later use in the sample recovery.

Alternatively, determine and record the weight of the silica gel plus impinger

to the nearest 0.5 g.

8.3.2 Install the

selected nozzle using a Viton A O-ring when stack temperatures are less than

260 ¼C (500 ¼F). Use a fiberglass string gasket if temperatures are higher. See

APTD-0576 (Reference 3 in Method 5) for

details. Other connecting systems using either 316 stainless steel or Teflon

ferrules may be used. Mark the probe with heat-resistant tape or by some other

method to denote the proper distance into the stack or duct for each sampling

point.

8.3.3 Assemble the

train as shown in Figure 101-1, using (if necessary) a very light coat of

silicone grease on all ground glass joints. Grease only the outer portion (see

APTD-0576) to avoid the possibility of contamination by the silicone grease.

NOTE: An empty impinger may be inserted between the

third impinger and the silica gel to remove excess moisture from the sample

stream.

8.3.4 After the

sampling train has been assembled, turn on and set the probe heating system, if

applicable, at the desired operating temperature. Allow time for the

temperatures to stabilize. Place crushed ice around the impingers.

8.4 Leak-Check Procedures.

Follow the leak-check

procedures outlined in Method 5, Section 8.4.

8.5 Sampling Train Operation.

Follow the general

procedure outlined in Method 5, Section 8.5.

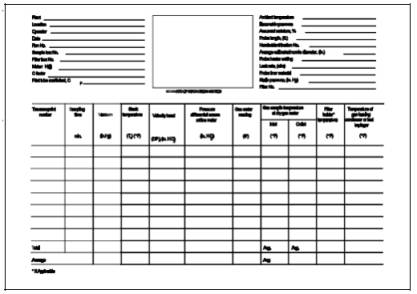

For each run, record the data required on a data sheet such as the one shown in

Figure 101-4.

8.6 Calculation of Percent Isokinetic.

Same as Method 5, Section 8.6.

8.7 Sample Recovery.

Begin proper cleanup

procedure as soon as the probe is removed from the stack at the end of the

sampling period.

8.7.1 Allow the probe

to cool. When it can be safely handled, wipe off any external particulate

matter near the tip of the probe nozzle, and place a cap over it. Do not cap

off the probe tip tightly while the sampling train is cooling. Capping would

create a vacuum and draw liquid out from the impingers.

8.7.2 Before moving the

sampling train to the cleanup site, remove the probe from the train, wipe off

the silicone grease, and cap the open outlet of the probe. Be careful not to

lose any condensate that might be present. Wipe off the silicone grease from

the impinger. Use either ground-glass stoppers, plastic caps, or serum caps to

close these openings.

8.7.3 Transfer the

probe and impinger assembly to a cleanup area that is clean, protected from the

wind, and free of Hg contamination. The ambient air in laboratories located in

the immediate vicinity of Hg-using facilities is not normally free of Hg

contamination.

8.7.4 Inspect the

train before and during disassembly, and note any abnormal conditions. Treat

the samples as follows.

8.7.4.1 Container No.

1 (Impingers and Probe).

8.7.4.1.1 Using a

graduated cylinder, measure the liquid in the first three impingers to within 1

ml. Record the volume of liquid present (e.g., see Figure 5-6 of

Method 5). This information is needed to calculate the moisture content of

the effluent gas. (Use only glass storage bottles and graduated cylinders that

have been precleaned as in Section 8.3.1) Place the contents of the first three

impingers into a 1000-ml glass sample bottle.

8.7.4.1.2 Taking care

that dust on the outside of the probe or other exterior surfaces does not get

into the sample, quantitatively recover the Hg (and any condensate) from the

probe nozzle, probe fitting, and probe liner as follows: Rinse these components

with two 50-ml portions of 0.1 M ICl. Next, rinse the probe nozzle, fitting and

liner, and each piece of connecting glassware between the probe liner and the

back half of the third impinger with a maximum of 400 ml of water. Add all washings to the 1000-ml glass

sample bottle containing the liquid from the first three impingers.

8.7.4.1.3 After all

washings have been collected in the sample container, tighten the lid on the

container to prevent leakage during shipment to the laboratory. Mark the height

of the liquid to determine later whether leakage occurred during transport.

Label the container to identify clearly its contents.

8.7.4.2 Container No.

2 (Silica Gel). Same as Method 5, Section

8.7.6.3.

8.7.4.3 Container No. 3 (Absorbing Solution Blank). Place 50 ml of

the 0.1 M ICl absorbing solution in a 100-ml sample bottle. Seal the container.

Use this blank to prepare the working Hg standard solution (Section 7.2.2.3).

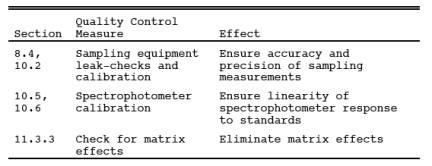

9.0 Quality Control.

9.1 Miscellaneous

Quality Control Measures.

9.2 Volume Metering

System Checks. Same as Method 5, Section 9.2.

10.0 Calibration and Standardizations.

NOTE: Maintain a laboratory log of all calibrations.

10.1 Before Use

Before use, clean all

glassware, both new and used, as follows: brush with soap and tap water,

liberally rinse with tap water, soak for 1 hour in 50 percent HNO3, and then rinse with deionized distilled water.

10.2 Sampling Equipment.

Calibrate the

sampling equipment according to the procedures outlined in the following

sections of Method 5: Section 10.1 (Probe

Nozzle), Section 10.2 (Pitot Tube Assembly), Section 10.3 (Metering System),

Section 10.5 (Temperature Sensors), Section 10.6 (Barometer).

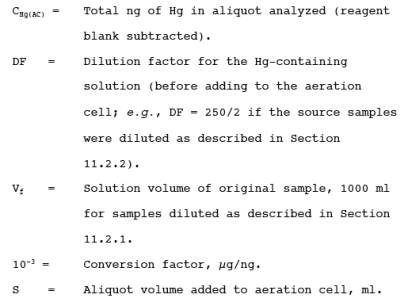

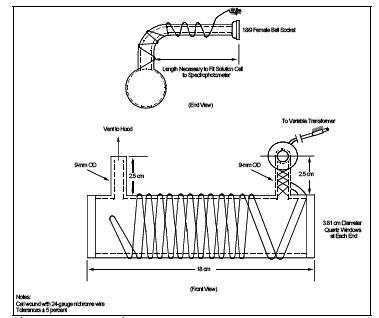

10.3 Aeration System Flow Rate Meter.

Assemble the aeration

system as shown in Figure 101-5. Set the outlet

pressure on the aeration gas cylinder regulator to a minimum pressure of 500 mm

Hg (10 psi), and use the flowmetering valve and a bubble flowmeter or wet-test

meter to obtain a flow rate of 1.5 ± 0.1 liters/min (0.053 ± 0.0035 cfm)

through the aeration cell. After the calibration of the aeration system flow

rate meter is complete, remove the bubble flowmeter from the system.

10.4 Optical Cell Heating System.

Using a 50-ml

graduated cylinder, add 50 ml of water to the bottle section of the aeration

cell, and attach the bottle section to the bubbler section of the cell. Attach

the aeration cell to the optical cell and while aerating at 1.5 ± 0.1

liters/min (0.053 ± 0.0035 cfm), determine the minimum variable transformer

setting necessary to prevent condensation of moisture in the optical cell and

in the connecting tubing. (This setting should not exceed 20 volts.)

10.5 Spectrophotometer and Recorder.

10.5.1 The Hg

response may be measured by either peak height or peak area.

NOTE: The temperature of the solution affects the rate

at which elemental Hg is released from a solution and, consequently, it affects

the shape of the absorption curve (area) and the point of maximum absorbance

(peak height). Therefore, to

obtain reproducible results, bring all solutions to room temperature before

use.

10.5.2 Set the

spectrophotometer wavelength at 253.7 nm, and make certain the optical cell is

at the minimum temperature that will prevent water condensation. Then set the

recorder scale as follows: Using a 50-ml graduated cylinder, add 50 ml of water

to the aeration cell bottle. Add three drops of Antifoam B to the bottle, and

then pipet 5.0 ml of the working Hg standard solution into the aeration cell.

NOTE: Always add the Hg-containing solution to the

aeration cell after the 50 ml of water.

10.5.3 Place a

Teflon-coated stirring bar in the bottle. Before attaching the bottle section

to the bubbler section of the aeration cell, make certain that (1) the aeration

cell exit arm stopcock (Figure 101-3) is closed (so

that Hg will not prematurely enter the optical cell when the reducing agent is

being added) and (2) there is no flow through the bubbler. If conditions (1)

and (2) are met, attach the bottle section to the bubbler section of the

aeration cell. Pipet 5 ml of tin (II) reducing solution into the aeration cell

through the side arm, and immediately stopper the side arm. Stir the solution

for 15 seconds, turn on the recorder, open the aeration cell exit arm stopcock,

and immediately initiate aeration with continued stirring. Determine the

maximum absorbance of the standard, and set this value to read 90 percent of

the recorder full scale.

10.6 Calibration Curve.

10.6.1 After setting

the recorder scale, repeat the procedure in Section 10.5 using 0.0-, 1.0-,

2.0-, 3.0-, 4.0-, and 5.0-ml aliquots of the working standard solution (final

amount of Hg in the aeration cell is 0, 200, 400, 600, 800, and 1000 ng,

respectively). Repeat this procedure on each aliquot size until two consecutive

peaks agree within 3 percent of their average value.

NOTE: To prevent Hg carryover from one sample to

another, do not close the aeration cell from the optical cell until the

recorder pen has returned to the baseline.) 10.6.2 It should not be necessary

to disconnect the aeration gas inlet line from the aeration cell when changing

samples. After separating the bottle and bubbler sections of the aeration cell,

place the bubbler section into a 600-ml beaker containing approximately 400 ml

of water. Rinse the bottle section of the aeration cell with a stream of water

to remove all traces of the tin (II) reducing agent. Also, to prevent the loss

of Hg before aeration, remove all traces of the reducing agent between samples

by washing with water. It will be necessary, however, to wash the aeration cell

parts with concentrated HCl if any of the following conditions occur: (1) A

white film appears on any inside surface of the aeration cell, (2) the

calibration curve changes suddenly, or (3) the replicate samples do not yield

reproducible results.

10.6.3 Subtract the

average peak height (or peak area) of the blank (0.0-ml aliquot) - which must

be less than 2 percent of recorder full scale - from the averaged peak heights

of the 1.0-, 2.0-, 3.0-, 4.0-, and 5.0-ml aliquot standards. If the blank

absorbance is greater than 2 percent of full-scale, the probable cause is Hg

contamination of a reagent or carry-over of Hg from a previous sample. Prepare

the calibration curve by plotting the corrected peak height of each standard

solution versus the corresponding final total Hg weight in the aeration cell

(in ng), and draw the best fit straight line. This line should either pass

through the origin or pass through a point no further from the origin than ± 2

percent of the recorder full scale. If the line does not pass through or very

near to the origin, check for nonlinearity of the curve and for incorrectly

prepared standards.

11.0 Analytical Procedure.

11.1 Sample Loss Check.

Check the liquid

level in each container to see whether liquid was lost during transport. If a

noticeable amount of leakage occurred, either void the sample or use methods

subject to the approval of the Administrator to account for the losses.

11.2 Sample Preparation.

Treat each sample as

follows:

11.2.1 Container No.

1 (Impingers and Probe). Carefully transfer the contents of Container No. 1

into a 1000-ml volumetric flask, and adjust the volume to exactly 1000 ml with

water.

11.2.2 Dilutions. Pipet

a 2-ml aliquot from the diluted sample from Section 11.2.1 into a 250-ml

volumetric flask. Add 10 ml of 5 percent H2SO4, and adjust the volume to exactly 250 ml with water. This solution

is stable for at least 72 hours.

NOTE: The dilution factor will be 250/2 for this

solution.

11.3 Analysis.

Calibrate the

analytical equipment and develop a calibration curve as outlined in Sections

10.3 through 10.6.

11.3.1 Mercury

Samples. Repeat the procedure used to establish the calibration curve with an

appropriately sized aliquot (1 to 5 ml) of the diluted sample (from Section

11.2.2) until two consecutive peak heights agree within 3 percent of their

average value. The peak maximum of an aliquot (except the 5-ml aliquot) must be

greater than 10 percent of the recorder full scale. If the peak maximum of a

1.0-ml aliquot is off scale on the recorder, further dilute the original source

sample to bring the Hg concentration into the calibration range of the

spectrophotometer.

11.3.2 Run a blank

and standard at least after every five samples to check the spectrophotometer

calibration. The peak height of the blank must pass through a point no further

from the origin than ±2 percent of the recorder full scale. The difference

between the measured concentration of the standard (the product of the

corrected peak height and the reciprocal of the least squares slope) and the

actual concentration of the standard must be less than 7 percent, or

recalibration of the analyzer is required.

11.3.3

Check for Matrix Effects (optional). Use the Method of Standard Additions as

follows to check at least one sample from each source for matrix effects on the

Hg results. The Method of Standard Additions procedures described on pages 9-4

and 9-5 of the section entitled "General Information" of the Perkin

Elmer Corporation Atomic Absorption Spectrophotometry Manual, Number 303-0152

(Reference 16 in Section 16.0) are recommended. If the results of the Method of

Standard Additions procedure used on the single source sample do not agree to

within ±5 percent of the value obtained by the routine atomic absorption

analysis, then reanalyze all samples from the source using the Method of

Standard Additions procedure.

11.4 Container No. 2 (Silica Gel).

Weigh the spent

silica gel (or silica gel plus impinger) to the nearest 0.5 g using a balance.

(This step may be conducted in the field.)

12.0 Data Analysis and Calculations.

Carry out

calculations, retaining at least one extra decimal significant figure beyond

that of the acquired data. Round off figures only after the final calculation.

Other forms of the equations may be used as long as they give equivalent

results.

12.1 Average Dry Gas

Meter Temperature and Average Orifice Pressure Drop, Dry Gas Volume, Volume of

Water Vapor Condensed, Moisture Content, and Isokinetic Variation. Same as Method 5, Sections 12.2 through 12.5 and 12.11,

respectively.

12.2 Stack Gas

Velocity. Using the data from this test and Equation

2-9 of Method 2, calculate the average stack gas velocity vs.

12.3.1 For each

source sample, correct the average maximum absorbance of the two consecutive

samples whose peak heights agree within 3 percent of their average for the

contribution of the solution blank (see Section 10.6.3). Use the calibration

curve and these corrected averages to determine the final total weight of Hg in

ng in the aeration cell for each source sample.

12.3.2 Correct for

any dilutions made to bring the sample into the working range of the

spectrophotometer. Then calculate the Hg in the original solution, mHg, as follows:

![]()

where:

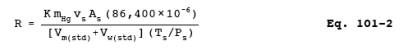

12.4 Mercury Emission

Rate. Calculate the daily Hg emission rate, R, using Equation 101-2. For

continuous operations, the operating time is equal to 86,400 seconds per day.

For cyclic operations, use only the time per day each stack is in operation.

The total Hg emission rate from a source will be the summation of results from

all stacks.

where:

12.5 Determination of

Compliance. Each performance test consists of three repetitions of the

applicable test method. For the purpose of determining compliance with an

applicable national emission standard, use the average of the results of all

repetitions.

13.0 Method Performance.

The following

estimates are based on collaborative tests, wherein 13 laboratories performed

duplicate analyses on two Hg-containing samples from a chlor-alkali plant and

on one laboratory-prepared sample of known Hg concentration. The sample concentrations

ranged from 2 to 65 µg Hg/ml.

13.1 Precision. The

estimated intra-laboratory and inter-laboratory standard deviations are 1.6 and

1.8 µg Hg/ml, respectively.

13.2 Accuracy. The participating

laboratories that analyzed a 64.3 µg Hg/ml (in 0.1 M ICl) standard obtained a

mean of 63.7 µg Hg/ml.

13.3 Analytical

Range. After initial dilution, the range of this method is 0.5 to 120 µg Hg/ml.

The upper limit can be extended by further dilution of the sample.

14.0 Pollution Prevention. [Reserved]

15.0 Waste Management. [Reserved]

16.0 References.

Same as Method 5, Section 17.0, References 1-3, 5, and 6,

with the addition of the following:

1. Determining Dust

Concentration in a Gas Stream. ASME Performance Test Code No. 27. New York, NY.

1957.

2. DeVorkin, Howard,

et al. Air Pollution Source Testing Manual. Air Pollution Control District. Los

Angeles, CA. November 1963.

3. Hatch, W.R., and

W.I. Ott. Determination of Sub-Microgram Quantities of Mercury by Atomic

Absorption Spectrophotometry. Anal. Chem. 40:2085-87. 1968.

4. Mark, L.S.

Mechanical Engineers' Handbook. McGraw-Hill Book Co., Inc. New York, NY. 1951.

5. Western

Precipitation Division of Joy Manufacturing Co. Methods for Determination of

Velocity, Volume, Dust and Mist Content of Gases. Bulletin WP-50. Los Angeles,

CA. 1968.

6. Perry, J.H.

Chemical Engineers' Handbook. McGraw-Hill Book Co., Inc. New York, NY. 1960.

7. Shigehara, R.T.,

W.F. Todd, and W.S. Smith. Significance of Errors in Stack Sampling

Measurements. Stack Sampling News. 1(3):6-18. September 1973.

8. Smith, W.S., R.T.

Shigehara, and W.F. Todd. A Method of Interpreting Stack Sampling Data. Stack

Sampling News. 1(2):8-17. August 1973.

9. Standard Method

for Sampling Stacks for Particulate Matter. In: 1971 Annual Book of ASTM

Standards, Part 23. ASTM Designation D 2928-71. Philadelphia, PA 1971.

10. Vennard, J.K. Elementary

Fluid Mechanics. John Wiley and Sons, Inc. New York. 1947.

11. Mitchell, W.J.

and M.R. Midgett. Improved Procedure for Determining Mercury Emissions from

Mercury Cell Chlor-Alkali Plants. J. APCA. 26:674-677. July 1976.

12. Shigehara, R.T.

Adjustments in the EPA Nomograph for Different Pitot Tube Coefficients and Dry

Molecular Weights. Stack Sampling News. 2:4-11. October 1974.

13. Vollaro, R.F.

Recommended Procedure for Sample Traverses in Ducts Smaller than 12 Inches in

Diameter. U.S. Environmental Protection Agency, Emission Measurement Branch.

Research Triangle Park, NC. November 1976.

14. Klein, R. and C.

Hach. Standard Additions: Uses and Limitation in Spectrophotometric

Measurements. Amer. Lab. 9:21. 1977.

15. Perkin Elmer

Corporation. Analytical Methods for Atomic Absorption Spectrophotometry.

Norwalk, Connecticut. September 1976.

17.0 Tables, Diagrams, Flowcharts, and Validation Data.

Figure

101-1. Mercury Sampling Train.

Figure

101-4. Mercury Field Data.

Figure

101-5. Schematic of Aeration System.