Method 6C - Determination of Sulfur Dioxide Emissions from Stationary Sources (Instrumental Analyzer Procedure)

1.

APPLICABILITY AND PRINCIPLE

3.4 Analyzer

Calibration Error.

4. MEASUREMENT SYSTEM

PERFORMANCE

4.1 Analyzer

Calibration Error.

5.1.4 Calibration Valve

Assembly.

5.1.5 Moisture Removal

System.

5.1.8 Sample Flow Rate

Control.

5.2 Method 6 Apparatus

and Reagents.

6. MEASUREMENT SYSTEM

PERFORMANCE TEST PROCEDURES

6.1 Calibration Gas

Concentration Verification.

6.2 Measurement System

Preparation.

6.3 Analyzer

Calibration Error.

6.4 Sampling System

Bias Check.

7.1 Selection of

Sampling Site and Sampling Points.

7.2 Interference Check

Preparation.

7.4 Zero and

Calibration Drift Tests.

7.5 Interference Check

(if performed).

1. APPLICABILITY AND PRINCIPLE

1.1 Applicability.

This

method is applicable to the determination of sulfur dioxide (SO2) concentrations in controlled and

uncontrolled emissions from stationary sources only when specified within the

regulations.

1.2 Principle.

A gas sample

is continuously extracted from a stack, and a portion of the sample is conveyed

to an instrumental analyzer for determination of SO2 gas concentration using an ultraviolet

(UV), non-dispersive infrared (NDIR), or fluorescence analyzer. Performance

specifications and test procedures are provided to ensure reliable data.

2. RANGE AND SENSITIVITY

2.1 Analytical Range.

The analytical

range is determined by the instrumental design. For this method, a portion of

the analytical range is selected by choosing the span of the monitoring system.

The span of the monitoring system shall be selected such that the pollutant gas

concentration equivalent to the emission standard is not less than 30 percent

of the span. If at any time during a run the measured gas concentration exceeds

the span, the run shall be considered invalid.

2.2 Sensitivity.

The minimum

detectable limit depends on the analytical range, span, and signal-to-noise

ratio of the measurement system. For a well-designed system, the minimum

detectable limit should be less than 2 percent of the span.

3. DEFINITIONS

3.1 Measurement System.

The total

equipment required for the determination of gas concentration. The measurement

system consists of the following major subsystems:

3.1.1 Sample Interface.

That portion

of a system used for one or more of the following: sample acquisition, sample

transport, sample conditioning, or protection of the analyzers from the effects

of the stack effluent.

3.1.2 Gas Analyzer.

That portion

of the system that senses the gas to be measured and generates an output

proportional to its concentration.

3.1.3 Data Recorder.

A strip chart

recorder, analog computer, or digital recorder for recording measurement data

from the analyzer output.

3.2 Span.

The upper

limit of the gas concentration measurement range displayed on the data

recorder.

3.3 Calibration Gas.

A known

concentration of a gas in an appropriate diluent gas.

3.4 Analyzer Calibration Error.

The difference

between the gas concentration exhibited by the gas analyzer and the known

concentration of the calibration gas when the calibration gas is introduced

directly to the analyzer.

3.5 Sampling System Bias.

The difference

between the gas concentrations exhibited by the measurement system when a known

concentration gas is introduced at the outlet of the sampling probe and when

the same gas is introduced directly to the analyzer.

3.6 Zero Drift.

The difference

in the measurement system output reading from the initial calibration response

at the zero concentration level after a stated period of operation during which

no unscheduled maintenance, repair, or adjustment took place.

3.7 Calibration Drift.

The difference

in the measurement system output reading from the initial calibration response

at a mid-range calibration value after a stated period of operation during

which no unscheduled maintenance, repair, or adjustment took place.

3.8 Response Time.

The amount of

time required for the measurement system to display 95 percent of a step change

in gas concentration on the data recorder.

3.9 Interference Check.

A method for

detecting analytical interferences and excessive biases through direct

comparison of gas concentrations provided by the measurement system and by a

modified Method 6 procedure. For this check, the

modified Method 6 samples are acquired at the sample by-pass discharge vent.

3.10 Calibration Curve.

A graph or

other systematic method of establishing the relationship between the analyzer

response and the actual gas concentration introduced to the analyzer.

4. MEASUREMENT SYSTEM PERFORMANCE SPECIFICATIONS

4.1 Analyzer Calibration Error.

Less than ±2

percent of the span for the zero, mid-range, and high-range calibration gases.

4.2 Sampling System Bias.

Less than ±5

percent of the span for the zero and mid-range calibration gases.

4.3 Zero Drift.

Less than ±3

percent of the span over the period of each run.

4.4 Calibration Drift.

Less than ±3

percent of the span over the period of each run.

4.5 Interference Check.

Less than ±7 percent

of the modified Method 6 result for each run.

5. APPARATUS AND REAGENTS

5.1 Measurement System.

Use any

measurement system for SO2 that meets the specifications of this

method. A schematic of an acceptable measurement system is shown in Figure 6C-1. The essential components of the measurement

system are described below:

5.1.1 Sample Probe.

Glass,

stainless steel, or equivalent, of sufficient length to traverse the sample

points. The sampling probe shall be heated to prevent condensation.

5.1.2 Sample Line.

Heated

(sufficient to prevent condensation) stainless steel or Teflon tubing, to

transport the sample gas to the moisture removal system.

5.1.3 Sample Transport Lines.

Stainless

steel or Teflon tubing, to transport the sample from the moisture removal

system to the sample pump, sample flow rate control, and sample gas manifold.

5.1.4 Calibration Valve Assembly.

A three-way

valve assembly, or equivalent, for blocking the sample gas flow and introducing

calibration gases to the measurement system at the outlet of the sampling probe

when in the calibration mode.

5.1.5 Moisture Removal System.

A

refrigerator-type condenser or similar device (e.g., permeation dryer), to

remove condensate continuously from the sample gas while maintaining minimal

contact between the condensate and the sample gas. The moisture removal system

is not necessary for analyzers that can measure gas concentrations on a wet

basis; for these analyzers, (1) heat the sample line and all interface

components up to the inlet of the analyzer sufficiently to prevent

condensation, and (2) determine the moisture content and correct the measured

gas concentrations to a dry basis using appropriate methods, subject to the

approval of the Administrator. The determination of sample moisture content is

not necessary for pollutant analyzers that measure concentrations on a wet

basis when (1) a wet basis CO2

analyzer operated according to Method 3A is used

to obtain simultaneous measurements, and (2) the pollutant/CO2 measurements are used to determine

emissions in units of the standard.

5.1.6 Particulate Filter.

An in-stack or

heated (sufficient to prevent water condensation) out-of-stack filter. The

filter shall be borosilicate or quartz glass wool, or glass fiber mat.

Additional filters at the inlet or outlet of the moisture removal system and

inlet of the analyzer may be used to prevent accumulation of particulate

material in the measurement system and extend the useful life of the

components. All filters shall be fabricated of materials that are nonreactive

to the gas being sampled.

5.1.7 Sample Pump.

A leak-free

pump, to pull the sample gas through the system at a flow rate sufficient to

minimize the response time of the measurement system. The pump may be

constructed of any material that is nonreactive to the gas being sampled.

5.1.8 Sample Flow Rate Control.

A sample flow

rate control valve and rotameter, or equivalent, to maintain a constant

sampling rate within 10 percent. (Note: The tester may elect to install a

back-pressure regulator to maintain the sample gas manifold at a constant

pressure in order to protect the analyzer(s) from over-pressurization, and to

minimize the need for flow rate adjustments.)

5.1.9 Sample Gas Manifold.

A sample gas

manifold, to divert a portion of the sample gas stream to the analyzer and the

remainder to the by-pass discharge vent. The sample gas manifold should also

include provisions for introducing calibration gases directly to the analyzer.

The manifold may be constructed of any material that is non-reactive to the gas

being sampled.

5.1.10 Gas Analyzer.

A UV or NDIR

absorption or fluorescence analyzer, to determine continuously the SO2 concentration in the sample gas stream.

The analyzer shall meet the applicable performance specifications of Section 4. A means of controlling the analyzer flow rate

and a device for determining proper sample flow rate (e.g., precision

rotameter, pressure gauge downstream of all flow controls, etc.) shall be

provided at the analyzer. (Note: Housing the analyzer(s) in a clean,

thermally-stable, vibration-free environment will minimize drift in the

analyzer calibration.)

5.1.11 Data Recorder.

A strip chart

recorder, analog computer, or digital recorder, for recording measurement data.

The data recorder resolution (i.e., readability) shall be 0.5 percent of span.

Alternatively, a digital or analog meter having a resolution of 0.5 percent of

span may be used to obtain the analyzer responses and the readings may be

recorded manually. If this alternative is used, the readings shall be obtained

at equally spaced intervals over the duration of the sampling run. For sampling

run durations of less than 1 hour, measurements at 1-minute intervals or a

minimum of 30 measurements, whichever is less restrictive, shall be obtained.

For sampling run durations greater than 1 hour, measurements at 2-minute

intervals or a minimum of 96 measurements, whichever is less restrictive, shall

be obtained.

5.2 Method 6 Apparatus and Reagents.

The apparatus

and reagents described in Method 6 and shown by the schematic of the sampling

train in Figure 6C-2 are used to conduct the

interference check.

5.3 SO2 Calibration Gases.

The

calibration gases for the gas analyzer shall be SO2 in N2

or SO2 in air. Alternatively, SO2/CO2,

SO2/O2,

or SO2/CO2/O2 gas mixtures in N2 may be used. For fluorescence-based

analyzers, the O2 and CO2 concentrations

of the calibration gases as introduced to the analyzer shall be within 1

percent (absolute) O2

and 1 percent (absolute) CO2 of the O2 and

CO2 concentrations

of the effluent samples introduced to the analyzer. Alternatively, for fluorescence-based

analyzers, use calibration blends of SO2 in

air and the nomographs provided by the vendor to determine the quenching

correction factor (the effluent O2 and

CO2 concentrations must be known). Use three

calibration gases as specified below:

5.3.1 High-Range Gas.

Concentration

equivalent to 80 to 100 percent of the span.

5.3.2 Mid-Range Gas.

Concentration

equivalent to 40 to 60 percent of the span.

5.3.3 Zero Gas.

Concentration

of less than 0.25 percent of the span. Purified ambient air may be used for the

zero gas by passing air through a charcoal filter or through one or more

impingers containing a solution of 3 percent H2O2 .

6. MEASUREMENT SYSTEM PERFORMANCE TEST PROCEDURES

Perform the

following procedures before measurement of emissions (Section

7).

6.1 Calibration Gas Concentration Verification.

There are two

alternatives for establishing the concentrations of calibration gases.

Alternative No. 1 is preferred.

6.1.1 Alternative No. 1Ñ

Use of

calibration gases that are analyzed following the Environmental Protection

Agency Traceability Protocol No. 1 (see Citation 1 in

Bibliography). Obtain a certification from the gas manufacturer that Protocol

No. 1 was followed.

6.1.2 Alternative No. 2Ñ

Use of

calibration gases not prepared according to Protocol No. 1. If this alternative

is chosen, obtain gas mixtures with a manufacturer's tolerance not to exceed ±2

percent of the tag value. Within 6 months before the emission test, analyze

each of the calibration gases in triplicate using Method 6. Citation

2 in the Bibliography describes procedures and techniques that may be used

for this analysis. Record the results on a data sheet (example is shown in Figure 6C-3). Each of the individual SO2 analytical results for each calibration

gas shall be within 5 percent (or 5 ppm, whichever is greater) of the

triplicate set average; otherwise, discard the entire set and repeat the

triplicate analyses. If the average of the triplicate analyses is within 5

percent of the calibration gas manufacturer's cylinder tag value, use the tag

value; otherwise, conduct at least three additional analyses until the results

of six consecutive runs agree within 5 percent (or 5 ppm, whichever is greater)

of the average. Then use this average for the cylinder value.

6.2 Measurement System Preparation.

Assemble the

measurement system by following the manufacturer's written instructions for

preparing and preconditioning the gas analyzer and, as applicable, the other

system components. Introduce the

calibration gases in any sequence, and make all necessary adjustments to

calibrate the analyzer and the data recorder. Adjust system components to

achieve correct sampling rates.

6.3 Analyzer Calibration Error.

Conduct the

analyzer calibration error check by introducing calibration gases to the

measurement system at any point upstream of the gas analyzer as follows:

6.3.1 After the measurement system has been

prepared for use, introduce the zero, mid-range, and high-range gases to the

analyzer. During this check, make no adjustments to the system except those

necessary to achieve the correct calibration gas flow rate at the analyzer.

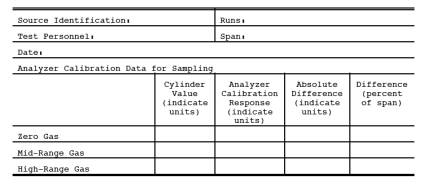

Record the analyzer responses to each calibration gas on a form similar to Figure 6C-4. Note: A calibration curve established prior to

the analyzer calibration error check may be used to convert the analyzer

response to the equivalent gas concentration introduced to the analyzer.

However, the same correction procedure shall be used for all effluent and

calibration measurements obtained during the test.

6.3.2 The analyzer calibration error check

shall be considered invalid if the gas concentration displayed by the analyzer

exceeds ±2 percent of the span for any of the calibration gases. If an invalid

calibration is exhibited, take corrective action and repeat the analyzer

calibration error check until acceptable performance is achieved.

6.4 Sampling System Bias Check.

Perform the

sampling system bias check by introducing calibration gases at the calibration

valve installed at the outlet of the sampling probe. A zero gas and either the

mid-range or high-range gas, whichever most closely approximates the effluent

concentrations, shall be used for this check as follows:

6.4.1 Introduce the upscale calibration gas,

and record the gas concentration displayed by the analyzer on a form similar to

Figure 6C-5. Then introduce zero gas, and record the gas

concentration displayed by the analyzer. During the sampling system bias check,

operate the system at the normal sampling rate, and make no adjustments to the

measurement system other than those necessary to achieve proper calibration gas

flow rates at the analyzer. Alternately introduce the zero and upscale gases

until a stable response is achieved. The tester shall determine the measurement

system response time by observing the times required to achieve a stable

response for both the zero and upscale gases. Note the longer of the two times

as the response time.

6.4.2 The sampling system bias check shall be considered

invalid if the difference between the gas concentrations displayed by the

measurement system for the analyzer calibration error check and for the

sampling system bias check exceeds ±5 percent of the span for either the zero

or upscale calibration gases. If

an invalid calibration is exhibited, take corrective action, and repeat the

sampling system bias check until acceptable performance is achieved. If

adjustment to the analyzer is required, first repeat the analyzer calibration

error check, then repeat the sampling system bias check.

7. EMISSION TEST PROCEDURE

7.1 Selection of Sampling Site and Sampling Points.

Select a

measurement site and sampling points using the same criteria that are

applicable to Method 6.

7.2 Interference Check Preparation.

For each

individual analyzer, conduct an interference check for at least three runs per

during the initial field test on a particular source category. Retain the

results, and report them with each test performed on that source category. If

an interference check is being performed, assemble the modified Method 6 train

(flow control valve, two midget impingers containing 3 percent H2O2,

and dry gas meter) as shown in Figure 6C-2. Install the sampling train to

obtain a sample at the measurement system sample by-pass discharge vent. Record

the initial dry gas meter reading.

7.3 Sample Collection.

Position the

sampling probe at the first measurement point, and begin sampling at the same

rate as used during the sampling system bias check. Maintain constant rate

sampling (i.e., ±10 percent) during the entire run. The sampling time per run

shall be the same as for Method 6 plus twice the average system response time.

For each run, use only those measurements obtained after twice the response

time of the measurement system has elapsed to determine the average effluent

concentration. If an interference check is being performed, open the flow

control valve on the modified Method 6 train concurrent with the initiation of

the sampling period, and adjust the flow to 1 liter per minute (±10 percent).

(Note: If a pump is not used in the modified Method 6 train, caution should be

exercised in adjusting the flow rate since over-pressurization of the impingers

may cause leakage in the impinger train, resulting in positively biased

results).

7.4 Zero and Calibration Drift Tests.

Immediately

preceding and following each run, or if adjustments are necessary for the

measurement system during the run, repeat the sampling system bias check procedure

described in Section 6.4. (Make no adjustments to the measurement system until

after the drift checks are completed.) Record the analyzer's responses on a

form similar to Figure 6C-5.

7.4.1 If either the zero or upscale calibration

value exceeds the sampling system bias specification, then the run is

considered invalid. Repeat both the analyzer calibration error check procedure

(Section 6.3) and the sampling system bias check procedure (Section 6.4) before

repeating the run.

7.4.2 If both the zero and upscale calibration

values are within the sampling system bias specification, then use the average

of the initial and final bias check values to calculate the gas concentration

for the run. If the zero or upscale calibration drift value exceeds the drift

limits, based on the difference between the sampling system bias check

responses immediately before and after the run, repeat both the analyzer

calibration error check procedure (Section 6.3) and the sampling system bias

check procedure (Section 6.4) before conducting additional runs.

7.5 Interference Check (if performed).

After

completing the run, record the final dry gas meter reading, meter temperature,

and barometric pressure. Recover and analyze the contents of the midget

impingers, and determine the SO2 gas

concentration using the procedures of Method 6. (It is not necessary to analyze

EPA performance audit samples for Method 6.) Determine the average gas

concentration exhibited by the analyzer for the run. If the gas concentrations

provided by the analyzer and the modified Method 6 differ by more than 7

percent of the modified Method 6 result, the run is invalidated.

8. EMISSION CALCULATION

The average

gas effluent concentration is determined from the average gas concentration

displayed by the gas analyzer and is adjusted for the zero and upscale sampling

system bias checks, as determined in accordance with Section 7.4. The average

gas concentration displayed by the analyzer may be determined by integration of

the area under the curve for chart recorders, or by averaging all of the

effluent measurements. Alternatively, the average may be calculated from

measurements recorded at equally spaced intervals over the entire duration of

the run. For sampling run durations of less than 1 hour, measurements at

1-minute intervals or a minimum of 30 measurements, whichever is less

restrictive, shall be used. For sampling run durations greater than 1 hour,

measurements at 2-minute intervals or a minimum of 96 measurements, whichever

is less restrictive, shall be used. Calculate the effluent gas concentration

using Equation 6C-1.

![]()

Where:

C gas = Effluent gas concentration, dry basis,

ppm.

C avg = Average gas concentration indicated by

gas analyzer, dry basis, ppm.

C o = Average of initial and final system

calibration bias check responses for the zero gas, ppm.

C m = Average of initial and final system

calibration bias check responses for the upscale calibration gas, ppm.

C ma = Actual concentration of the upscale

calibration gas, ppm.

1. Traceability Protocol for Establishing

True Concentrations of Gases Used for Calibrations and Audits of Continuous

Source Emission Monitors: Protocol Number 1. U. S. Environmental Protection

Agency, Quality Assurance Division. Research Triangle Park, N.C. June 1978.

2. Westlin, Peter R. and John W. Brown.

Methods for Collecting and Analyzing Gas Cylinder Samples. Source Evaluation

Society Newsletter. 3(3):5-15. September 1978.

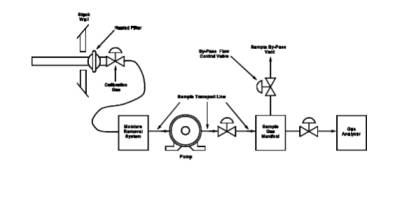

Figure

6C-1. Measurement System Schematic.

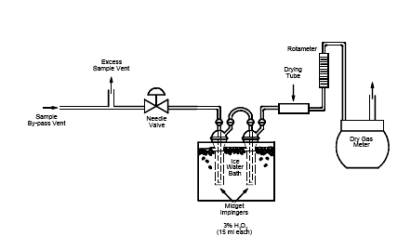

Figure

6C-2. Interference Check Sampling Train.

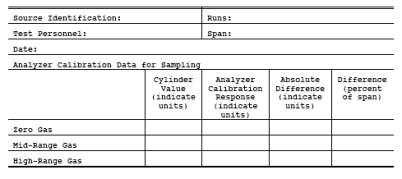

Figure

6C-3. Analysis of Calibration Gases.

Figure

6C-4. Analyzer Calibration Data.

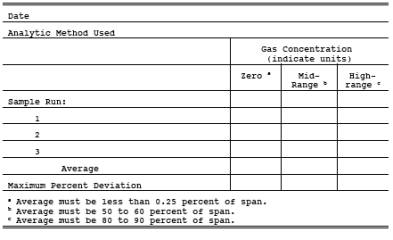

Figure

6C-5. System Calibration Bias and Drift Data.