METHOD 5E -

DETERMINATION OF PARTICULATE MATTER EMISSIONS FROM THE WOOL FIBERGLASS

INSULATION MANUFACTURING INDUSTRY

NOTE: This method does not include all of the

specifications (e.g.,

equipment and supplies) and procedures (e.g., sampling and analytical) essential to its

performance. Some material is incorporated by reference from other methods in

this part. Therefore, to obtain reliable results, persons using this method

should have a thorough knowledge of at least the following additional test

methods: Method 1, Method 2,

Method 3, and Method 5.

5.2.1 Hydrochloric Acid

(HCl). Highly toxic.

5.2.2 Sodium Hydroxide

(NaOH).

8.0 Sample Collection,

Preservation, Storage, and

8.1 Pretest Preparation

and Preliminary Determinations.

8.2 Preparation of

Sampling Train.

8.3 Leak-Check

Procedures, Sampling Train Operation, Calculation of Percent Isokinetic.

9.1 Miscellaneous

Quality Control Measures.

9.2 Volume Metering

System Checks.

10.0 Calibration and

Standardization.

10.1 Preparation of

Organic Carbon Standard Curve.

10.2 Preparation of

Inorganic Carbon Standard Curve.

12.0 Data Analysis and

Calculations.

12.2 Concentration of

Condensed TOC in Liquid Sample.

12.3 Mass of Condensed

TOC Collected.

12.4 Concentration of

Condensed Particulate Material.

12.5 Total Particulate

Concentration.

13.0 Method

Performance. [Reserved]

14.0 Pollution

Prevention. [Reserved]

15.0 Waste Management.

[Reserved]

17.0 Tables, Diagrams,

Flowcharts, and Validation Data.

[Reserved]

1.0 Scope and Applications.

1.1 Analyte. Particulate

matter (PM). No CAS number assigned.

1.2 Applicability.

This method is applicable for the determination of PM emissions from wool fiberglass insulation manufacturing

sources.

2.0 Summary of Method.

Particulate matter is

withdrawn isokinetically from the source and is collected either on a glass

fiber filter maintained at a temperature in the range of 120 ± 14 ¡C (248 ± 25

¡F) and in impingers in solutions of 0.1 N sodium hydroxide (NaOH). The

filtered particulate mass, which includes any material that condenses at or

above the filtration temperature,

is determined gravimetrically after the removal of uncombined water. The

condensed PM collected in the impinger solutions is determined as total organic

carbon (TOC) using a nondispersive infrared type of analyzer. The sum of the

filtered PM mass and the condensed PM is reported as the total PM mass.

3.0 Definitions. [Reserved]

4.0 Interferences. [Reserved]

5.0 Safety.

5.1 Disclaimer.

This method may

involve hazardous materials, operations, and equipment. This test method may

not address all of the safety problems associated with its use. It is the

responsibility of the user of this test method to establish appropriate safety

and health practices and to determine the applicability of regulatory limitations

prior to performing this test method.

5.2 Corrosive Reagents.

The following

reagents are hazardous. Personal

protective equipment and safe procedures are useful in preventing chemical

splashes. If contact occurs, immediately flush with copious amounts of water at

least 15 minutes. Remove clothing under shower and decontaminate. Treat

residual chemical burn as thermal burn.

5.2.1 Hydrochloric Acid (HCl). Highly toxic.

Vapors are highly

irritating to eyes, skin, nose,

and lungs, causing severe damage.

May cause bronchitis, pneumonia,

or edema of lungs. Exposure to concentrations of 0.13 to 0.2 percent in

air can be lethal in minutes. Will react with metals, producing hydrogen.

5.2.2 Sodium Hydroxide (NaOH).

Causes severe damage

to eye tissues and to skin. Inhalation causes irritation to nose, throat, and

lungs. Reacts exothermically with limited amounts of water.

6.0 Equipment and Supplies.

6.1 Sample Collection.

Same as Method 5, Section 6.1, with the exception of the

following:

6.1.1 Probe Liner.

Same as described in Section 6.1.1.2 of Method 5 except use only borosilicate

or quartz glass liners.

6.1.2 Filter Holder.

Same as described in Section 6.1.1.5 of Method 5 with the addition of a

leak-tight connection in the rear half of the filter holder designed for

insertion of a temperature sensor used for measuring the sample gas exit

temperature.

6.2 Sample Recovery.

Same as Method 5, Section 6.2, except three wash

bottles are needed instead of two and only glass storage bottles and funnels

may be used.

6.3 Sample Analysis.

Same as Method 5, Section 6.3, with the additional

equipment for TOC analysis as described below:

6.3.1 Sample Blender

or Homogenizer. Waring type or ultrasonic.

6.3.2 Magnetic

Stirrer.

6.3.3 Hypodermic

Syringe. 0- to 100-µl capacity.

6.3.4 Total Organic

Carbon Analyzer. Rosemount Model 2100A analyzer or equivalent and a recorder.

6.3.5 Beaker. 30-ml.

6.3.6 Water Bath.

Temperature controlled.

6.3.7 Volumetric

Flasks. 1000-ml and 500-ml.

7.0 Reagents and Standards.

Unless otherwise

indicated, it is intended that all reagents conform to the specifications

established by the Committee on Analytical Reagents of the American Chemical

Society, where such specifications are available; otherwise, use the best

available grade.

7.1 Sample Collection.

Same as Method 5, Section 7.1, with the addition of 0.1 N NaOH (Dissolve 4 g

of NaOH in water and dilute to 1 liter).

7.2 Sample Recovery.

Same as Method 5, Section 7.2, with the addition of the

following:

7.2.1 Water.

Deionized distilled to conform to ASTM Specification D 1193-77 or 91 Type 3

(incorporated by reference - see ¤60.17). The potassium permanganate (KMnO4) test for oxidizable organic matter may be omitted when high

concentrations of organic matter are not expected to be present.

7.2.2 Sodium

Hydroxide. Same as described in Section 7.1.

7.3 Sample Analysis.

Same as Method 5,

Section 7.3, with the addition of the following:

7.3.1 Carbon

Dioxide-Free Water. Distilled or deionized water that has been freshly boiled

for 15 minutes and cooled to room temperature while preventing exposure to

ambient air by using a cover vented with an Ascarite tube.

7.3.2 Hydrochloric

Acid. HCl, concentrated, with a dropper.

7.3.3 Organic Carbon

Stock Solution. Dissolve 2.1254 g of dried potassium biphthalate (HOOCC6H4COOK) in CO2-free

water, and dilute to 1 liter in a volumetric flask. This solution contains 1000

mg/L organic carbon.

7.3.4 Inorganic

Carbon Stock Solution. Dissolve 4.404 g anhydrous sodium carbonate (Na2CO3) in about 500 ml of CO2-free water in a 1-liter volumetric flask. Add 3.497 g anhydrous

sodium bicarbonate (NaHCO3) to the flask, and dilute to 1 liter with CO2-free water. This solution contains 1000 mg/L inorganic carbon.

7.3.5 Oxygen Gas. CO2-free.

8.0 Sample Collection, Preservation, Storage, and Transport.

8.1 Pretest Preparation and Preliminary Determinations.

Same as Method 5, Sections 8.1 and 8.2, respectively.

8.2 Preparation of Sampling Train.

Same as Method 5,

Section 8.3, except that 0.1 N NaOH

is used in place of water in the impingers. The volumes of the solutions are

the same as in Method 5.

8.3 Leak-Check Procedures, Sampling Train Operation, Calculation of Percent Isokinetic.

Same as Method 5, Sections 8.4 through 8.6,

respectively.

8.4 Sample Recovery.

Same as Method 5, Sections 8.7.1 through 8.7.4, with

the addition of the following:

8.4.1 Save portions

of the water, acetone, and 0.1 N NaOH used for cleanup as blanks. Take 200 ml

of each liquid directly from the wash bottles being used, and place in glass

sample containers labeled "water blank," "acetone blank,"

and "NaOH blank," respectively.

8.4.2 Inspect the

train prior to and during disassembly, and note any abnormal conditions. Treat

the samples as follows:

8.4.2.1 Container No.

1. Same as Method 5, Section 8.7.6.1.

8.4.2.2 Container No.

2. Use water to rinse the sample nozzle, probe, and front half of the filter

holder three times in the manner described in Section 8.7.6.2 of Method 5

except that no brushing is done. Put all the water wash in one container, seal,

and label.

8.4.2.3 Container No.

3. Rinse and brush the sample nozzle, probe, and front half of the filter

holder with acetone as described for Container No. 2 in Section 8.7.6.2 of

Method 5.

8.4.2.4 Container No.

4. Place the contents of the silica gel impinger in its original container as

described for Container No. 3 in Section 8.7.6.3 of Method 5.

8.4.2.5 Container No.

5. Measure the liquid in the first three impingers and record the volume or

weight as described for the Impinger Water in Section 8.7.6.4 of Method 5. Do

not discard this liquid, but place it in a sample container using a glass

funnel to aid in the transfer from the impingers or graduated cylinder (if

used) to the sample container. Rinse each impinger thoroughly with 0.1 N NaOH

three times, as well as the graduated cylinder (if used) and the funnel, and

put these rinsings in the same sample container. Seal the container and label

to clearly identify its contents.

8.5 Sample Transport.

Whenever possible,

containers should be shipped in such a way that they remain upright at all

times.

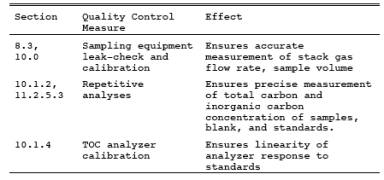

9.0 Quality Control.

9.1 Miscellaneous Quality Control Measures.

9.2 Volume Metering System Checks.

Same as Method 5, Section 9.2.

10.0 Calibration and Standardization.

Same as Method 5, Section 10.0, with the addition of

the following procedures for calibrating the total organic carbon analyzer:

10.1 Preparation of Organic Carbon Standard Curve.

10.1.1 Add 10 ml, 20

ml, 30 ml, 40 ml, and 50 ml of the organic carbon stock solution to a series of

five 1000-ml volumetric flasks. Add 30 ml, 40 ml, and 50 ml of the same

solution to a series of three 500-ml volumetric flasks. Dilute the contents of

each flask to the mark using CO2-free water. These

flasks contain 10, 20, 30, 40, 50, 60, 80, and 100 mg/L organic carbon,

respectively.

10.1.2 Use a

hypodermic syringe to withdraw a 20- to 50-µl aliquot from the 10 mg/L standard

solution and inject it into the total carbon port of the analyzer. Measure the

peak height. Repeat the injections until three consecutive peaks are obtained

within 10 percent of their arithmetic mean. Repeat this procedure for the

remaining organic carbon standard solutions.

10.1.3 Calculate the

corrected peak height for each standard by deducting the blank correction (see Section 11.2.5.3) as follows:

Corrected Peak Height = A - B Eq.

5E-1

where:

A = Peak height of

standard or sample, mm or other appropriate unit.

B = Peak height of

blank, mm or other appropriate unit.

10.1.4 Prepare a linear

regression plot of the arithmetic mean of the three consecutive peak heights

obtained for each standard solution against the concentration of that solution.

Calculate the calibration factor as the inverse of the slope of this curve. If

the product of the arithmetic mean peak height for any standard solution and

the calibration factor differs from the actual concentration by more than 5

percent, remake and reanalyze that standard.

10.2 Preparation of Inorganic Carbon Standard Curve.

Repeat the procedures

outlined in Sections 10.1.1 through 10.1.4, substituting the inorganic carbon

stock solution for the organic carbon stock solution, and the inorganic carbon

port of the analyzer for the total carbon port.

11.0 Analytical Procedure.

11.1 Record the data

required on a sheet such as the one shown in Figure

5-6 of Method 5.

11.2 Handle each

sample container as follows:

11.2.1 Container No.

1. Same as Method 5, Section 11.2.1, except

that the filters must be dried at 20 ± 6 ¡C (68 ± 10 ¡F) and ambient pressure.

11.2.2 Containers No.

2 and No. 3. Same as Method 5, Section 11.2.2, except that evaporation of the

samples must be at 20 ± 6 ¡C (68 ± 10 ¡F) and ambient pressure.

11.2.3 Container No.

4. Same as Method 5, Section 11.2.3.

11.2.4 "Water

Blank" and "Acetone Blank" Containers. Determine the water and

acetone blank values following the procedures for the "Acetone Blank"

container in Section 11.2.4 of Method 5. Evaporate the samples at ambient

temperature [20 ± 6 ¡C (68 ± 10 ¡F)] and pressure.

11.2.5 Container No.

5. For the determination of total organic carbon, perform two analyses on

successive identical samples, i.e.,

total carbon and inorganic carbon. The desired quantity is the difference

between the two values obtained. Both analyses are based on conversion of

sample carbon into carbon dioxide for measurement by a nondispersive infrared

analyzer. Results of analyses register as peaks on a strip chart recorder.

11.2.5.1 The

principal differences between the operating parameters for the two channels

involve the combustion tube packing material and temperature. In the total

carbon channel, a high temperature [950 ¡C (1740 ¡F)] furnace heats a Hastelloy

combustion tube packed with cobalt oxide-impregnated asbestos fiber. The oxygen

in the carrier gas, the elevated temperature, and the catalytic effect of the

packing result in oxidation of both organic and inorganic carbonaceous material

to CO2 and steam. In the inorganic carbon channel, a

low temperature [150 ¡C (300 ¡F)] furnace heats a glass tube containing quartz

chips wetted with 85 percent phosphoric acid. The acid liberates CO2 and steam from inorganic carbonates. The operating temperature is

below that required to oxidize organic matter. Follow the manufacturer's

instructions for assembly, testing, calibration, and operation of the analyzer.

11.2.5.2 As samples

collected in 0.1 N NaOH often contain a high measure of inorganic carbon that

inhibits repeatable determinations of TOC, sample pretreatment is necessary.

Measure and record the liquid volume of each sample (or impinger contents). If

the sample contains solids or immiscible liquid matter, homogenize the sample

with a blender or ultrasonics until satisfactory repeatability is obtained.

Transfer a representative portion of 10 to 15 ml to a 30-ml beaker, and acidify

with about 2 drops of concentrated HCl to a pH of 2 or less. Warm the acidified

sample at 50 ¡C (120 ¡F) in a water bath for 15 minutes.

11.2.5.3 While stirring the sample with a magnetic stirrer, use a

hypodermic syringe to withdraw a 20- to 50-µl aliquot from the beaker. Analyze

the sample for total carbon and calculate its corrected mean peak height

according to the procedures outlined in Sections 10.1.2 and 10.1.3. Similarly

analyze an aliquot of the sample for inorganic carbon. Repeat the analyses for

all the samples and for the 0.1 N NaOH blank.

11.2.5.4 Ascertain

the total carbon and inorganic carbon concentrations (CTC and CIC,

respectively) of each sample and blank by comparing the corrected mean peak

heights for each sample and blank to the appropriate standard curve.

NOTE: If samples must be diluted for analysis, apply

an appropriate dilution factor.

12.0 Data Analysis and Calculations.

Same as Method 5, Section 12.0, with the addition of the

following:

12.1 Nomenclature.

Cc = Concentration of condensed particulate matter in stack gas, gas dry

basis, corrected to standard conditions, g/dscm (gr/dscf).

CIC = Concentration of condensed TOC in the liquid

sample, from Section 11.2.5, mg/L.

Ct = Total particulate concentration, dry basis, corrected to standard

conditions, g/dscm (gr/dscf).

CTC = Concentration of condensed TOC in the liquid

sample, from Section 11.2.5, mg/L.

CTOC = Concentration of condensed TOC in the liquid

sample, mg/L.

mTOC = Mass of condensed TOC collected in the

impingers, mg.

Vm(std) = Volume of gas sample measured by the dry gas

meter, corrected to standard conditions, from Section 12.3 of Method 5, dscm

(dscf).

Vs = Total volume of liquid sample, ml.

12.2 Concentration of Condensed TOC in Liquid Sample.

![]()

12.3 Mass of Condensed TOC Collected.

![]()

where:

0.001 = Liters per

milliliter.

12.4 Concentration of Condensed Particulate Material.

![]()

where:

K4 = 0.001 g/mg for metric units.

= 0.0154 gr/mg for

English units.

12.5 Total Particulate Concentration.

![]()

13.0 Method Performance. [Reserved]

14.0 Pollution Prevention. [Reserved]

15.0 Waste Management. [Reserved]

16.0 References.

Same as Section 17.0 of Method 5, with the addition of

the following:

1. American Public

Health Association, American Water Works Association, Water Pollution Control

Federation. Standard Methods for the Examination of Water and Wastewater.

Fifteenth Edition. Washington, D.C. 1980.