Tip of the Week

Click HERE for Adobe version of this Tip

Successful Mercury Testing

Successful Mercury Testing

With EPA’s Clean Air Mercury Rule looming

over utility boilers, we can expect to be doing a lot of mercury testing in the

next year or so. Utilities will be

particularly interested in understanding how the different

forms of mercury change as the flue gas passes through existing air

pollution control equipment. A mercury

mass balance around the plant and each individual control device will become a

standard request. This may involve not

only simultaneous gas sampling at five or more locations, but extensive fuel

and ash sampling as well.

The

Ontario-Hydro method published under ASTM-D6784-02

is currently considered the “standard” for speciated

mercury measurements. This method has

few known biases when determining total mercury concentrations. However, there are some well-documented

biases in the method’s ability to speciate mercury in

high dust loadings (e.g., inlets) and at entrained moisture locations (e.g.,

scrubber outlets). Here are a few tips

to reduce these biases, as well as some more general tips to help ensure a

successful mercury testing program.

·

In

high particulate loadings, use the in-stack filtration option. This will help reduce the contact time of the

gas and the particulate matter, and hopefully reduce the potential adsorption

or catalytic oxidation of elemental mercury.

·

In

a flue gas saturated with moisture, water droplets in the nozzle and probe may

affect the oxidation state of the mercury.

The following actions are recommended after wet scrubbers:

Ř

Point

the nozzle opposite the flow. The resulting

sub-isokinetic sampling will reduce the capture of larger water droplets. Since PM is expected to consist of relatively

small particle sizes in these locations, the error on the particulate capture

should be minimal.

Ř Heat the probe to 350°F to ensure

complete re-vaporization of any water droplets.

·

Do

not start a test series until the plant is at steady state. Allow at least 2 to 3 hours after any process

changes for line-out of plant conditions.

·

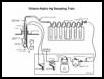

Plan

for a good & complete coal and residue sampling program (see example).

·

Coordinate

solid sampling with gas sampling.

·

Pay

attention to soot blowing cycles.

·

Consider

installing a continuous O2 monitor on each meter box exhaust.

·

Make

sure the laboratory understands that the samples must be analyzed within an

hour of digestion. Otherwise, low

mercury recoveries may result.

·

For

coal and ash mercury analysis, use ASTM D6722, which is a direct combustion

method. Other methods such as ASTM D6414

and D3684 are indirect and not as accurate.