Tip of the Week††††††††††††††††††††

Click HERE for Adobe version of this Tip

Making Peace with Your Meter

Making Peace with Your Meter

Everyone knows that EPA Method 5 requires the

calibration of the metering system after each field use.† We do this either in the field with a

critical orifice, or we send it back to the shop for a check against a wet test

meter.†

It is

preferable to do the orifice check in the field for obvious reasons, not the

least of which is to eliminate the specter of having to remobilize a job if the

meter comes back to the shop out of spec.†

However, since we donít normally do an orifice calibration until the end

of the job, we still risk having to repeat a lot of runs and maybe several days

of work if this calibration check fails.†

So what can we do to monitor our meterís performance on an on-going

basis?

There is a

way and it requires practically no effort.†

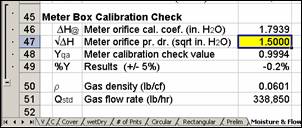

This is the Yqa check, which is described in the ALTERNATIVE METHOD 5 POST-TEST

CALIBRATION (ALT-009), found on the EPA website*.

The trick

is to use the Meter Box Calibration Check section found in lines 45-49 of the

Moisture and Flow tab in the FPS field workbook.† Essentially, all you need to do is calculate

the average of the square roots of DH and plug this value into line

47.† The workbook will calculate a value

for Yqa (Line 48) and compare this with the Yd of the meter.† A deviation of 5% or less between the two is

required (Line 49).

It is a

good idea to keep track of the meter performance during a job by doing this Yqa

check after each run.† This will alert

you to potential calibration issues with the meter.† Any check that is close to or above the 5%

criteria should be dealt with by either repairing or replacing the meter before

proceeding with additional tests.

*Although the EPA prescribes this as

an alternative calibration procedure, CleanAirís policy is to always post-test

calibrate our meters using either a critical orifice or a wet test meter.† The Yqa-check described here is intended only

to be used as a means of evaluating on-going performance of the metering

system, and is not a replacement of an orifice or bench calibration.