GE Remote Services

Abstract

As deregulation becomes a reality for the power generation

industry and as competitive power production becomes standard operating

procedure, the quality of power a company produces becomes the measure of its

success. This requires the utility, independent power producer (IPP), and/or

industrial power producer to bid power competitively at current market rates.

The power producer that operates at the lowest cost per kilowatt-hour will

thrive in this challenging environment.

GE Power Systems and its Energy Services business offer an

abundance of products aimed at increasing the availability and reducing the

cost of plant operation. These include long-term service agreements (LTSA);

operation and maintenance (O&M) contracts; inventory-management programs;

life-extension services; refurbished turbine parts offerings; and remote

services (RS), an integrated management tool that helps customers meet their

plant life-cycle objectives. This paper is focused on new developments in RS over

the past four years.

Introduction

Increasing competition has caused power plants to switch

from traditional time-based maintenance strategies to those based on a plantÕs

operating condition. In order to stay competitive, power producers such as

utilities, IPPs and industrials have focused their efforts on improving the

availability of plant equipment, reducing maintenance costs and becoming the

lowest- cost producer. To meet this need, GEÕs Monitoring and Diagnostic Center

(M&DC) developed RS, which provides real-time data assessments and

recommendations from remote locations to improve the availability and

performance of equipment, systems and plants. The main elements of the RS

process are monitoring and communication, on-site data acquisition and monitoring

system, and communication vehicles such as the satellite, the Internet, the

telephone and the LAN.

GE has designed, manufactured or commissioned more than

50% of the worldÕs installed base of power generation equipment and maintains

the largest field sales and service workforce in the industry. The M&DCÕs

RS strategy combines GEÕs considerable practical experience in O&M with the

M&DCÕs expertise in remote diagnostics gained through the deployment of

over 150 units with RS features. This allows customers to respond quickly to a

rapidly changing environment by extending the intervals between maintenance

outages, reducing the duration of scheduled outages, maximizing plant

performance, predicting life cycles, optimizing plant output, reducing unplanned

outage events and managing the timing of those which do occur, as well as

providing operating recommendations that maximize the revenue stream and

decrease plant life-cycle costs. The critical components of RS and their

functions are:

- Monitoring

and communication

On-site data acquisition and monitoring system

Communication vehicles such as the satellite, the

Internet, telephone and the LAN

- Data

infrastructure and collection

Measurement and analysis of equipment condition and

performance

Comparison of conditions to fleet and equipment baselines, design specification and experience

Communication of relevant data to the M&DC

- Technical

advice

Identification and isolation of problems

Root-cause analysis and experience-based learning

Problem reporting and corrective action

recommendation

Data archiving and unit/fleet analysis

A broad range of service modules are available to cover

equipment at component, system or plant level.

- Service

program modules

(Telediagnostics) gas turbine generator health report

(GTD) gas turbine diagnostics

(GD) generator diagnostics

(Enter) online heat balance analysis.

GE Energy ServicesÕ RS Solution

GEÕs RS solution provides the ability to collect, validate

and analyze operational data from a customerÕs equipment. Operational data is

reviewed at different frequencies, depending on the RS modules supplied. The

review can take place on an as-needed or a continuous basis. Concurrent

analysis is performed on site in real time and at the M&DC. This

methodology is designed to identify operating anomalies (symptoms and/or

indications) or incipient problems and, thus, provide validated solutions. If

an anomaly is detected on site, the system automatically notifies diagnostic

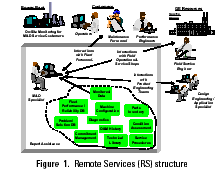

specialists at the M&DC. Figure 1 outlines

the design, organizational structure and functionality of the M&DC.

Diagnostic specialists are able to connect to equipment

remotely to examine its operation and performance or investigate the nature of

a problem in addition to providing online site consulting to customers. When

warranted, the diagnostic specialist is able to generate recommendations on

plant operations and/or maintenance actions. The recommendations are designed

to maximize the equipment's performance, reliability and availability and,

potentially, extend its outage interval cycle. This process is designed to

occur as a complement to normal plant operating procedures and will allow the

plant manager and operator to use GE's RS as a resource for better-informed

and, thus, higher-quality maintenance and operating decisions.

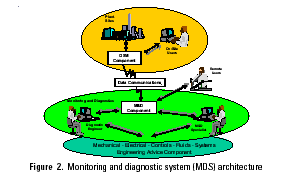

The monitoring and diagnostic system (MDS) architecture

provides networking among a site component (referred to

as the on-site monitor, or OSM), the M&DC, GE expert engineers and a data

communication component (Figure 2).

Plant Monitoring and Diagnostics Concept and Architecture

The concept of a remote monitoring and diagnostic (M&D)

service that provides ready access to operating data, transmits it to a central

location, performs diagnostic evaluation through a combination of automation

and experts, and reports on a plantÕs operating condition has existed for some

time. Numerous technical papers have been written about monitoring and

diagnostics, each of which is specific in nature and often deals with a single

issue such as vibration or performance of a single piece of equipment.

Very few publications describe a detailed approach to

monitoring a fleet of similar machines with variable features. This paper

should fill that void by describing various technologies that were developed

over the past decade for monitoring such a fleet. A power plant fleet consists

of gas turbines, steam turbines, generators and balance of plant (BOP). The

infrastructure needed to diagnose an entire range of issues that affect a fleet

of turbines is presented here, and only examples of only GEÕs gas turbine fleet

will be cited to reduce the paper's scope.

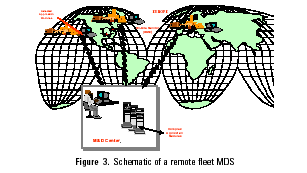

Figure 3 provides a pictorial summary of the remote fleet-monitoring concept. Two functional components, an MDS and a central M&DC, monitor a fleet of turbines. The MDS consists of an OSM; a computer that logs data from the power plantÕs control system; various telecommunication technologies; and a network of computer systems, located at a central M&DC, that archive fleet operating data and perform diagnostics and reporting functions. The OSM measures and analyzes large amounts of data, detects anomalous conditions and then transmits information to the M&DC for further analysis on the condition of equipment; compares conditions to equipment baselines, design specifications and experience; and communicates the relevant information to customer personal.

The M&DC can additionally interpret fleet data and

provide advice to the remote operators regarding plant operations as and when

needed. This includes commissioning and startup support, optimizing plant

operations and critical shutdown scenarios that are not handled by the plant

control systems. The M&DC performs these functions by using modules

(querying and archiving the data periodically), trend analysis, problem

identification and isolation, root-cause analysis and experience-based

learning, problem reporting, and recommendations for corrective action.

Although a variety of equipment needs to be monitored, the

principles of M&D are similar and common tools and processes are used where

practical. Special and highly engineered software is also used to detect unique

anomalies and aids the diagnostic team in reporting and recommendations. GEÕs

Energy Services M&DC is a single M&DC monitoring different types of

turbomachinery applications. It is located in Atlanta, GA.

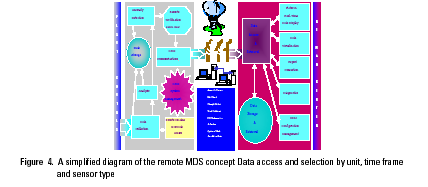

A simple diagram of the remote monitoring and diagnostics

(M&D) concept of regularly transferring operational data to determine the

current operating condition of a plant is depicted in Figure 4. All operational data collected is validated through

advanced mathematical algorithms before it is used. Transient and steadystate

(startup, shutdown, load-change) data are utilized in problem diagnosis. Also,

past and current data and relevant baselines are utilized in discovering

operational anomalies, which are detected on the OSM and at the M&DC.

Anomalies detected on the OSM are usually operational or unusual equipment

problems that have not been detected by the control system and require immediate

attention by the M&DC. Thus, detection of a first-level deviation is

performed on site by the OSM. Detection of anomalies that develop over several

hours or days is performed at the M&DC. Methods and approaches for

detecting anomalies include the following:

- Time

trending of sensor data, individually or in a group

- Cross

correlation and regression analysis of operational data

- Time-series

analysis to identify periodic discrepancies

- Comparison

with fleetwide operational data and design specification

Many of the well-understood root-cause algorithms have been

catalogued and automated using advanced mathematical and computational

techniques to resolve operational problems quickly. Root-cause assessments of

all operational anomalies, deviations in performance and abnormalities in

maintenance condition are used as a basis for determining whether operational

and maintenance recommendations are required.

Trend monitoring is performed at the M&DC to identify

long-term deviations in condition and performance. This provides a means to

highlight and detect emerging problems well in advance of actual failures and

identify subtle deviations in performance that may be indicators of emerging

problems. Thus, although mature anomaly-detection algorithms are deployed on the

OSM, when necessary, more detailed root-cause analyses and diagnostic functions

are performed by experts at the M&DC.

The M&D Viewer

Many specialists and engineers employ the M&D systemÕs

user interface to display archived operational data for diagnostic assessments

and associated preliminary recommendations. It manages periodic assessment

functions, performs selected assessments on demand, carries out hypothetical

assessments, conducts remote OSM administrative functions and displays real

time operational data (up to a one-secondupdate rate).

A variety of on-site and remote clients use the M&D

viewer to access diagnostic results and operational data. A flexible and open

system with Internet data access capabilities is provided to satisfy this need.

Diagnostics Functionality

The M&D system provides detection, notification and

diagnoses of automated and manual anomalies to assist the diagnostic specialist

in making assessments and determining operational and maintenance

recommendations.

Validated Sensor Data

All operational data collected is validated by thresholding

and cross checking, as appropriate. The validation is complementary to but more

detailed than the range checking carried out on the OSM. Support is provided for both

transient and steady-state operating conditions. Transient conditions include

startup, shutdown and load change. In steady-state operations, trending and

rate-of-change monitoring is provided. Invalid sensor data would be flagged and

highlighted in any analysis or report.

Trend Unit Health and Performance

The trending of equipment and system health and performance

is accomplished by using operational data collected from the OSM as well as

historical operating data. The operational data includes monitored sensors

(pressure and temperature) as well as derived sensors (enthalpy). Manual entry

of operational observations (e.g., visual, NDE, meteorological) will be

recorded as needed.

Assessment of a unit's health and performance calculations

(e.g., its efficiency and thermal performance) is carried out periodically to

track the condition of each monitored unit over time and to build up its health

and performance history. All performance data and results are normalized to ISO

conditions as appropriate to facilitate comparison of unit-specific data over

time. This will also facilitate comparisons between similar units and

comparison of unit data to design specifications.

Detection of Anomalies

The M&D system utilizes a unitÕs current and historical

health and performance data and applicable baseline data to detect anomalies

(e.g., higher-than-expected vibration levels or significant deviation in

performance from what is expected). Detection of an anomaly is composed of two

components: real-time assessment within the OSM (minutes to hours) and data

evaluation over an extended time frame (12 hours or more).

- Methods

for and approaches to detecting anomalies include the following:

- Data

access and selection by unit, time frame or sensor type

- Time

trending of individual datum or data groups

- Consultation

with symptom/cause database using indicators computed from the operational

data

- Comparison

with fleetwide data and design specifications

The relevant baselines to be used as benchmarks include the

historical performance of the unit, fleet averages for similar units and the

design-specification performance of the given unit and its subcomponents.

Maintenance and operation logs will be consulted (Figure 4).

Root-Cause Analysis

Root-cause analysis is aided by an automated diagnostic

system that includes cause-and-effect knowledge of equipment-specific failure,

equipment design knowledge, past problem/solution information and the

site-specific configuration. Its key purpose is to provide the necessary

technical input for determining appropriate maintenance or operating

recommendations.

Once a problem is defined, its root cause must be

determined. To do that, a cause-and-effect diagram is constructed that relates

each problem to its underlying cause. It also shows the hierarchical nature of

the process because problems often have causes that can themselves be

considered problems with causes. Take, for example, a low turbine efficiency

that is caused by low compressor efficiency that is caused by aerodynamic

losses due to deposits.

Recommendations for Operators

The M&D specialists and diagnostic engineers develop

short-term operation recommendations (such as Run at reduced power levels or Adjust

operating settings) and long-term

data-collection or maintenance recommendations (such as Plan for a

shutdown within two weeks to further assess the unitÕs condition or Perform a gas turbine water wash on-line

or off-line) as appropriate to a unit's

health anomalies. The diagnostics engineer will also consider measures that can

be taken while a unit is operating (e.g., on-line against off-line actions).

The M&D diagnostic engineer will, upon determination of

a problem, provide recommendations for avoiding unplanned outages, minimizing

possible secondary damage, enhancing the reliability and availability of the

units, maintaining the intended level of performance and optimizing unit

performance.

Product

Functionality

Although power plant rotating

machines are carefully designed with high levels of safety and exceptional

performance, operating flaws can still occur. The M&D system has been

designed to predict these deviations and provide recommendations so operators

can prevent serious failures or deviations from peak performance. Typical

evaluations that the M&D system is able to make on the steam turbine, gas

turbine and generator are listed below.

Steam Turbine, Gas Turbine and Generator Assessment:

- Performance

Monitoring turbine and generator

performance parameters (baseline predictions) Detecting performance deviations

Discovering and identifying causes

of performance problems early on

- Vibration

Assessment

Rotor train vibration monitoring

Remote access analysis programs

Engineering-advised vibration

diagnostics

The OSM

The OSM is an assembly of electronic components that incorporate

microprocessor technology. It is designed and fabricated to perform integrated

monitoring, data analysis and communication to a centralized M&D data

server. The OSM is installed on site and receives data from plant systems.

Primary OSM functions are acquisition of operational data

from plant equipment, performance of anomaly detection for deviations from

baseline and buffering the data for subsequent transmission to the M&DC.

The OSM can interface with various devices (e.g., the unit

control system, DCS and thirdparty systems) and collect operational data from

them. In addition, it will perform analysis on the data, provide temporary

storage of operational data and communicate data remotely. The OSM provides a

first level of anomaly detection and notification, which alerts on-site

personnel and the M&DC to developing problems or potential issues. The OSM

allows the diagnostic specialist remote access to the customerÕs equipment to

allow real-time viewing of the operating data.

The OSM's functions are performed independently. Data

collection, processing and buffering, deviation detection and notification are

performed as needed for the unit-monitored equipment. Detected events and trips

will not impair the OSM's real-time data-collection performance, nor will

M&DC or engineering-initiated interactions and local-user-initiated

interactions.

A calculation engine aboard the OSM uses high-fidelity data

to produce calculations of the equipmentÕs operating mode, performance,

vibration and equipment-specific parameters. Within its architecture is an

action engine that can trigger remote notification when anomalies are detected.

A single OSM can monitor multiple pieces of equipment

installed at a plant site. The OSM software is standardized but highly configurable

so that together with the flexible data interfaces, the OSM can be tailored to

the needs of the site-specific installation to be monitored. The OSM also

provides local and remote capability for RS system configuration. In addition

to providing notification of an anomaly, the OSM is an Internet interface that

provides on-line access to selected portions of the operating data archives.

Gas Turbine Diagnostics

Module (GTDM)

The GTDM is a monitoring strategy that focuses on specific

equipment behaviors and monitors them on a nearly continuous basis. Failure

modes are detected and managed through an OSM and M&DC experience

procedures. Specifically, avoiding gas turbine rotor and combustion operation

issues have been key to assuring that customers maximize turbine run times.

M&D specialists and M&D engineering work closely to understand the

plant operating characteristics by monitoring vibration and combustion

parameters. Plant operation is then understood by using these data profiles,

and a monitoring strategy is developed with techniques and software to detect

gas turbine rotor or combustion anomalies.

Gas Turbine Generator

Health Report (GTHR)

The GTHR is a monitoring and diagnosis module that allows

the customer to send stored data to the M&DC for analysis and

interpretation. A modem connection lets GE's diagnostic specialists view the

plant in real time for collaborative troubleshooting. Up to 14 different

systems can be monitored, depending on a unit's complexity and a customerÕs

needs, resulting in a description of trends and abnormalities as well as

recommendations for corrective action.

The GTHR module automatically records data from the

three-hour period before a trip, startup or shutdown. Next, this data can be

sent to the M&DC by way of modem for analysis. Data files are transmitted

to the M&DC each month, leading to generation of reports that provide an

overview of the plant's health and recommendations for O&M.

The GTHR determines aspects of plant performance such as

turbine performance and compressor efficiency, which can be used to schedule

water washes. The monthly data analysis allows a GE diagnostic specialist to

detect deviation from normal behavior and to prescribe corrective action.

Generator Diagnostics

Module (GDM)

The GDM is a generator-monitoring module that detects

developing problems and utilizes structured analysis processes and engineering

experience to provide detailed diagnoses and real-time operational

recommendations for corrective action. The recommendations are based on the

monitoring of all relevant data, which is analyzed by the GDMÕs expert

knowledge base and checked by generator engineers. Its dynamic tracking

capabilities allow the GDM to detect incipient problems as they develop, often

long before alarm conditions are reached. If followed, these recommendations

will help the customer avoid generator-operating conditions that could cause

damage to the equipment. The diagnosis also will assist maintenance and outage

planning, and the GDMÕs information will help the customer to assess a unit's

condition and plan future operation accordingly.

The GDM is a highly capable module. It monitors eight

generator subsystems: core, excitation, hydrogen cooling, lubricating oil, seal

oil, rotor, stator and stator water cooling. Within each of these subsystems

are numerous specific diagnoses; some examples are high core-end temperature,

overfluxing core, reduced hydrogen cooler efficiency, blocked lubricating oil

flow, rotor shorted turns, rotor winding ventilation problems, seal oil vacuum

treatment malfunction, fouled or plugged stator bar coolant path or high stator

cooling-water conductivity.

The GDM provides multimode diagnostics under the following

operating conditions: turning gear, run up, full-speed, no-load and no

excitation, normal-loaded, run down. It performs online sensor data trending

and displays information on multiple Internet screens.

On-line Heat Balance

Analysis Module (HBM)

The HBM uses EfficiencyMapª, GEÕs power plant optimization

and performance-monitoring software. It assists the plant's operational staff

in predicting the most profitable way to run the plant and measuring and

tracking changes in plant performance. The HBM tells operators where to set

controllable parameters to maximize profitability. It reduces degradation to

0.5% per year, and it also identifies sensors with poor accuracy and retrieves

and shows results quickly.

The HBM has many useful features. It optimizes plant

operation to maximize profitability while evaluating performance and

determining degradation, validates measurements using model-based plant mass

and energy balances and acquires real-time measurements, and archives data for

easy retrieval and viewing.

Diagnostics Engineering Team

The diagnostics engineering team provides additional

customer contact for technical support on combustion, mechanical, electrical,

performance, vibration, systems and controls expertise. It provides consistent,

high-quality responses to customers' queries and is available seven days a week,

24 hours a day. The technical advice structure allows it to direct O&M

questions rapidly to the proper GE engineer. When the GE engineer receives a

question, a case documenting the situation is opened. The diagnostics

engineering commitment tracking system allows for team utilization of the case

as a problem- solving vehicle. The case is recorded in the technical advice

database as a part of the site history and equipment profile.

There are three tools that help the diagnostics engineering

team provide quick, accurate, experience-based responses: the problem-solution

database, the reference library database and the

reliability/availability/maintenance (RAM) database.

Problem-Solution Database

The problem solution database stores all previous problems

and causes by class for GE and non-GE fleets. Once potential causes are

defined, validation/testing of symptoms of the causes begin. Validation is

conducted by a review of current relevant conditions, similar fleet problems

and solutions, and expert team assessment and advice. A diagnostic engineer is

the overall owner of the specific fleetwide component in question and validates

each problem and solution before it is entered into the database.

Reference Library Database

The reference library database contains the full scope of

technical documents for equipment and system design. It also contains the

design and operating specifications for optimal performance. An example in the

case of a gas tur- bine would be pressure drops across the HRSG and inlet exhaust

systems, including the performance excursions as the unit sees an ambient

temperature change.

Reliability/Availability/Maintenance

This tool gives the diagnostic specialist immediate

reference to monthly RAM data provided by the plant operator. This data

identifies the specific start-and-stop times of plant outages. It also computes

reliability and availability calculations; in addition, it documents plant

outage caused by a specific component. This allows for a model of plant

availability as a function of mode of operation, design, fuel type and other

common parameters. The results of the modeling used in conjunction with M&D

data will be used in making recommendations for configuration and/or operating

changes.

Experience

GE Energy Services has deployed RS

modules on over 150 units around the world and uses M&D as a tool to

manage, analyze and resolve potential equipment problems. Real-time access and

continuous on-line evaluation of turbine condition is available to our

engineers for problem resolution. Several benefits were derived during customer

application.

For example, an IPP partner operating during peak demand was

alerted to a slight deviation from baseline rotor dynamic characteristics.

Shutting down the plant meant up to $1 million in lost revenue per day.

Immediately, GE engineers were online, assessing the signature to identify risk

in continued operation of the turbine. The evaluation resulted in a realization

that this rotor signature suggested a shutdown and machine inspection. The inspection,

combined with the data analysis and prior analysis history, caught the

condition before significant rotor and other system damage took place.

Detecting this incipient failure quickly and correctly allowed for the

equipment's rapid repair and return to service. The estimated saving to the

customer through generation of revenue exceeded $150 million.

Another example of the demonstrated value of M&D

occurred during the normal data review process at the M&DC when it was

noted the combustion exhaust profile of a gas turbine was beginning to change.

The monitoring frequency of this gas turbine was increased from four hour to

one-hour intervals. The unit was placed on M&D combustion alert and the

customer was notified that a potential combustion issue was developing. Exhaust

combustion profiles continued to indicate that a combustion issue indeed had

developed. Using the M&D GTDM monitoring strategy, the customer w-s able to

operate safely for an additional 13 days to a non-critical production time

before the gas turbine was shut down and a combustion inspection focusing on

specific combustion hardware was performed. This recommendation was preceded by

a technical review with the customer to explain what the data indicated.

Results of an inspection revealed that the specific hardware had experienced

cracking, making continued operation of the unit no longer prudent. The unit

was back in operation two days after the unit was shut down for inspection and

subsequent replacement of hardware.

Conclusion

GEÕs RS system is part of GE Power

Systems- Energy Services offerings to increase output, performance and

availability. The system consists of modularized functionality, which can

provide a full scope service that will:

- Improve

overall availability and reliability of plant equipment

- Extend

intervals between maintenance outages

- Reduce

the duration of scheduled and forced outages

- Predict

product life cycles

- Optimize

plant output (thermal performance and heat rate)

RS provides the ability to access, transmit, analyze and

report on the operating conditions of a wide range of customer equipment.

Through learning experiences and key technological developments and

acquisitions, RS gives customer operators, managers and diagnostic experts the

proper tools to make equipment, plant and/or fleet-operating decisions.

References

Makansi, J., ÒOutage/Maintenance

Management Puts Information Technology to Work,Ó Power, pp. 41-49, January

1994.

Madej, J. et al., ÒMonitoring and Diagnostics Service Delivery System,Ó GER 3956, GE Company, 1996.