|

Merom

Generating Station in Merom, Indiana (near Sullivan, Indiana) Merom

Generating Station in Merom, Indiana (near Sullivan, Indiana)

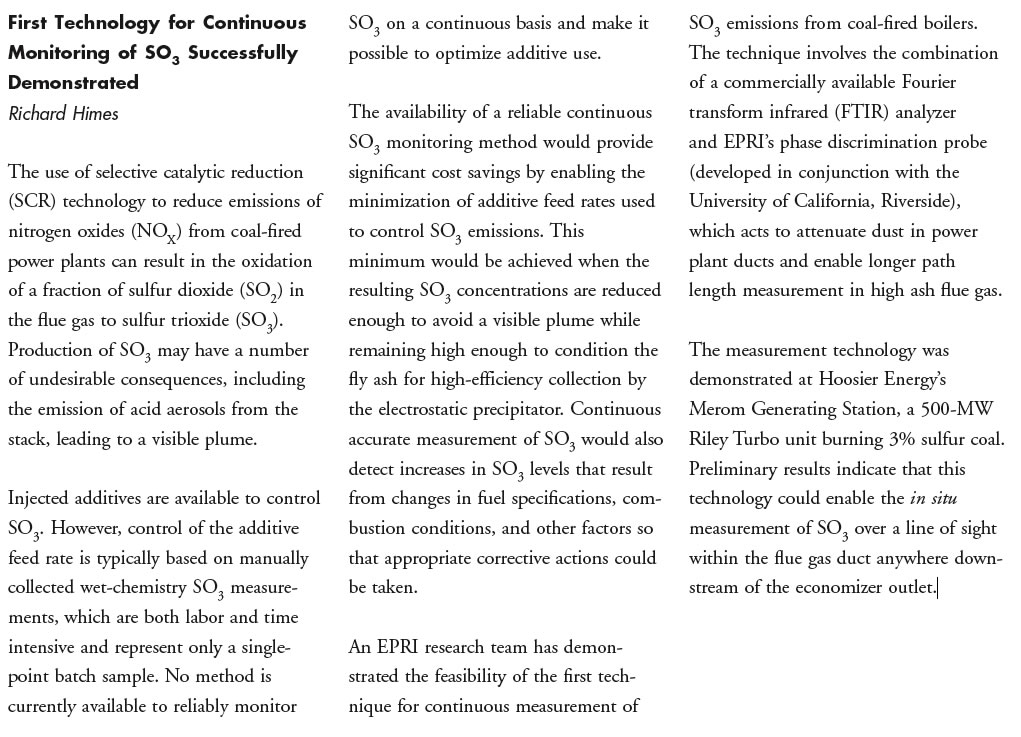

With a production capacity of more than 1,000 megawatts, Hoosier Energy's Merom Generating Station in Sullivan County provides dependable baseload power at the lowest possible cost for central and southern Indiana member distribution cooperatives.

The station is equipped with more than a quarter-of-a-billion dollars in environmental protection equipment and meets all Clean Air Act standards. The plant is outfitted with electrostatic precipitators for flyash removal, and a flue gas desulfurization system, or scrubber, to remove sulfur dioxide from the coal combustion process.

In 2003, a $73 million environmental project was completed that added selective catalytic reduction (SCR) technology to reduce nitrogen oxide emissions at the plant.

At full load levels, the power plant's two generating units use more than 10,000 tons a day of coal from southwestern Indiana mines. Trucks and trains deliver coal to the plant.

To provide cooling water for the power facility's operation,

Hoosier Energy developed the adjacent 1,550-acre Turtle Creek Reservoir. The reservoir is a popular destination for fishing and waterfowl hunting, and is the site of an education center for students and other groups to study energy, the environment and science.

Plans for the Merom project were announced in 1977 as the most favorable option for meeting the future power requirements of central and southern Indiana's growing electric cooperatives.

Groundbreaking ceremonies for the facility were held November 3, 1977. More than 20 environmental permits were obtained from a dozen state and federal agencies prior to construction.

Built at a cost of approximately $850 million, the power plant's two generating units began commercial operation in 1982-83, providing electricity to Indiana homes, farms, businesses and industries.

Download a fact sheet about the Merom Station.

CleanAir Projects ~ 1987-1990 including SO3 study #4529

- #4533 - #4189 - #4189.1 - #5161

SCR Background - 2003 - #9437 & 2004 -

#9581

Value Opportunity Data

Future Opportunities

Hoosier Merom

Feb 17, 2005 - Conversation with Matthew Mabrey

Feedback on our Proposal 32872 for AIG Tuning

Generally confirmed what we already knew on pricing

On

base bid all 3 bids were very close but we were low.

When

re-bid with second mobilization to tune after outage

we were 2nd and FERCO was higher.

SCR

Tech seems to have a preferred status since they have been

working at the plant to identify the problems. They

did an internal inspection and also “pulled” 2

coupons. Matthew was impressed by all the problems SCR

Tech found inside the SCR. He did not know that SCR-Tech

was “A Catalytica

Energy Systems' Company”. He thought they were

just a couple of guys who got early experience working

on SCRs in Europe. I said I though they were connected,

he said they are just friends.

Update on SCR Problems

His comment “we took too long to tune” . They

are not meeting the expected NOX removal and are wasting

their banked credits. This has corporate attention. They

need to get above “.09#/MMBtu. I questioned

why above and not below. He said above, could be

the removal rate.

Hoosier Vendor Partnering

Matt said they have a vendor partnering program. We

should look into this.

AE – Burns & McDonald

They use Burns and MAC as their engineers for spec writing.

Matthews Mabrey’s Career

Matt worked 1st for US Gypsum. One of his projects was

making wallboard out of a blend of synthetic(flyash) and

mined material.

He also worked in the medical devise facility management

and with an aggregate plant or aggregate equipment construction.

Other consultants

He mentioned AWH or KWH and also Rob Moser for SO3 work

SO3 Mitigation Study

He would welcome a Webx on SO3 and Mercury. He

would set it up with corporate.

I mentioned the SO3 study we did in 1988 and he was

interested in getting a copy. Caleb will find

it.

I also ask if he would be willing to look at our SCR

benefits list and provide feedback on what has value

to them. He said he would be glad to do it. I

will send it with the SO3 study.

March 14 2007 Conversation with Bill Harding

Bill Harding called about Feb 6, 2007 and asked if we

could provide a crew to find the cause of their ID fan

capacity loss. Apparently the megawatt output has

been dropping since they install SCR's on both units in

2003. They are de-rated 50 MW on each boiler. We

offered to do it with people from Knoxville since Palatine

was booked at the time. Ricky Mull was the project manager

and field team leader for CleanAIr, Scott Lehman assisted.

Bill Harding called about Feb 6, 2007 and asked if we

could provide a crew to find the cause of their ID fan

capacity loss. Apparently the megawatt output has

been dropping since they install SCR's on both units in

2003. They are de-rated 50 MW on each boiler. We

offered to do it with people from Knoxville since Palatine

was booked at the time. Ricky Mull was the project manager

and field team leader for CleanAIr, Scott Lehman assisted.

On March 14, 2007 Bill & Walker drove to Washington,

IN and took Bill & Maryanne Harding to dinner. The

following is some of what was learned.

Prior to Bill taking over as Superintendent at Merom

he was Superintendent of the Ratt Generating where he

improves operations. Merom was being operated with

minimum reinvestment over a 15 yeqr period and the equipment

was not being well maintained. There were several problems

which occurred before Bill took over Merom including:

• 3 people died when they were gassed inside the

stack.

• 1 additional death

• 6 month outage when turbine generator bearings

lost oil

• ~100 MW de-rating due to seal and damper leakage

and/or air header plugging

Bill talked about how his plant management style differs

fromt eh previous. Bill wears work clothes and spends

many hours in the plant. Previous people were suits and

tie people and seldom ventured into the plant. Bill

is now trying to get union and leadership people to work

closer together.

Bill said they hired 2 summer interns. I told him about

our success using the intern career fair at Illinois and

suggested he also attend. He plans to do this next February

(2008).

I suggested we offer interns an opportunity to exchange

with Hoosier. One summer with CleanAir next with Hoosier

then CleanAir. He is interested in trying it.

EPRI SO3 Study at Merom

|