Essex County Resource Recovery Facility

|

American Ref-Fuel Company of Essex County

183 Raymond Boulevard Newark, NJ 07105 973/344-0900 Constraints Safety:

Environmental: Profit: Carbon usage - Through-Put:

Innovation: Quality: Partnershipping:

Employee Quality of Life: Partner Employee Quality of Life:

|

Key FactsPrimary Service Area: Essex County Owner: American Ref-Fuel Company of Essex County which is wholly owned by AIG Contract Term: 25 years with provisions for extensions Financing Method: Tax-exempt Revenue Bonds plus private equity Waste Supply: County municipalities guarantee to deliver a combined minimum of 680,000 tons per year. Energy Market: Electricity generation for plant use and export to Public Service Electric and Gas Capacity: 2,800 tons per day Number of Process Lines: Three @ 933 tons per day Type of Stoker Grate: Duesseldorf Roller Grate System Steam Conditions at Boiler Outlet: 211,000 lbs/hr @ 650 psia/7500F Turbine-Generators: Two 35 nominal megawatt units Air Quality Control: Three DBA electrostatic precipitators and three spray dry scrubber systems Stack Height: 279 feet Bunker Capacity: 14,000 tons Secondary Materials Recovery: Recovery of ferrous materials from post-incinerated ash

New Jerseyís largest waste-to-energy facility, owned and operated by American Ref-Fuel Company of Essex County, serves the refuse disposal needs of 22 municipalities in Essex County and the surrounding region.

The Essex County Resource Recovery Facility opened in 1990, boasting one of the smoothest plant start-ups in industry history. Today the facility combusts 2,800 tons per day of municipal solid waste and generates approximately 65 megawatts of electricity for sale. Essex County, New Jersey, sponsored the facility developed by the Port Authority of New York and New Jersey and constructed by American Ref-Fuel. The projectís design and construction employed the largest Minority Business Enterprise Plan in New Jersey history. The reduction of the countyís landfill requirements and the recovery of energy from the Essex County solid waste stream in an environmentally sound manner are among the benefits the facility brings to the community. The Essex Resource Recovery Facility received its OSHA Star facility designation in 1995. Plant Personnel: Plant Manager - Environmental Engineer - Safety Supervisor - Operations Manager -

Strategy & Philosophy Aim & Purpose - Policy - Environment Plant Goals & Targets Bonus Targets - Award Targets - Projections -

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

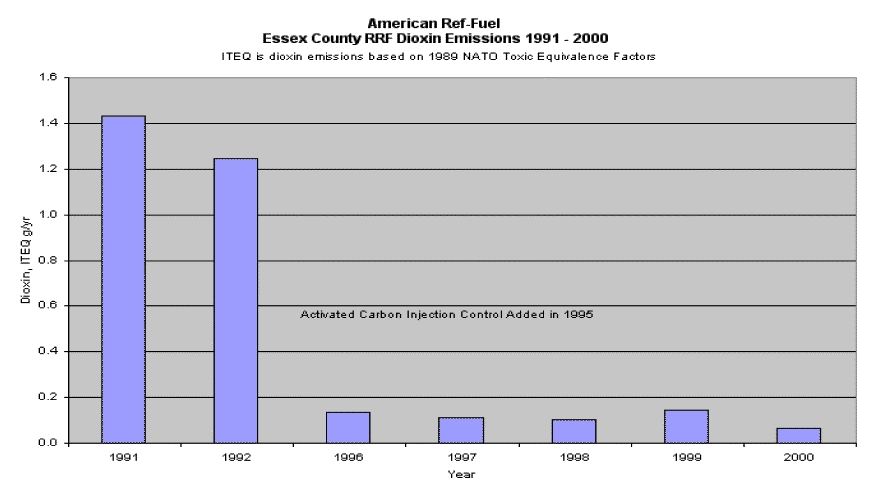

1. CleanAir has determined that a major operational problem at Essex is the need to inject a very large quantity of activated carbon into the APC to capture and remove mercury. This carbon is a high non-value added cost and increases the volume of toxic waste. It would be ideal to reduce both the toxic equivalent emissions and activated carbon costs. ARC has estimated that a 50% reduction in the need for this carbon would result in a NPV of $100,000. CleanAir has committed to brainstorming on possible alternatives, being on the lookout for creative technologies and providing an annual update on progress. 2. New Jersey has a special requirement that requires |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Historical Summary

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||