METHOD 306 -

DETERMINATION OF CHROMIUM EMISSIONS FROM DECORATIVE AND HARD CHROMIUM

ELECTROPLATING AND CHROMIUM ANODIZING OPERATIONS - ISOKINETIC METHOD

Note: This method does not include all of the

specifications (e.g., equipment

and supplies) and procedures (e.g., sampling and analytical) essential to its performance. Some

material is incorporated by reference from other methods in 40 CFR Part 60,

Appendix A. Therefore, to obtain reliable results, persons using this method

should have a thorough knowledge of at least Method 5.

3.8 Calibration

Reference Standards

3.12 Inter-element

Correction Factors

3.13 Duplicate Sample

Analysis

4.1.1 ICP Spectral

Interferences.

4.1.2 ICP Physical

Interferences.

4.1.3 ICP Chemical

Interferences.

4.2.1 GFAAS Chemical

Interferences.

4.2.2 GFAAS Cyanide

Band Interferences.

4.2.3 GFAAS Spectral

Interferences.

4.2.4 GFAAS Background

Interferences.

4.3.1 IC/PCR Chemical

Interferences.

4.3.2 IC/PCR Background

Interferences.

7.3 Sample Preparation

and Analysis.

7.4 Glassware Cleaning

Reagents.

7.5 Quality Assurance

Audit Samples.

8.0 Sample Collection,

Preservation, Holding Times, Storage, and Transport.

8.3 Sample

Preservation, Storage, and Transport.

9.1.1 ICP Calibration

Reference Standards.

9.1.2 ICP Continuing

Check Standard.

9.1.5 ICP Duplicate

Sample Analysis.

9.1.7 ICP Field Reagent

Blank.

9.2.1 GFAAS Calibration

Reference Standards.

9.2.2 GFAAS Continuing

Check Standard.

9.2.3 GFAAS Calibration

Blank.

9.2.4 GFAAS Duplicate

Sample Analysis.

9.2.6 GFAAS Method of

Standard Additions.

9.2.7 GFAAS Field

Reagent Blank.

9.3.1 IC/PCR

Calibration Reference Standards.

9.3.2 IC/PCR Continuing

Check Standard and Calibration Blank.

9.3.3 IC/PCR Duplicate

Sample Analysis.

9.3.5 IC/PCR Field

Reagent Blank.

10.0 Calibration and

Standardization.

10.1 Sampling Train

Calibration.

11.2.1 The ICP analysis

is applicable for the determination of total chromium only.

11.2.3 ICP Instrument

Adjustment.

11.2.4 ICP Instrument

Calibration.

11.2.5 ICP Operational

Quality Control Procedures.

11.3 GFAAS Sample

Preparation.

11.4.1 The GFAAS

analysis is applicable for the determination of total chromium only.

11.4.3 GFAAS Instrument

Adjustment.

11.4.4 Furnace

Operational Parameters.

11.4.5 GFAAS

Operational Quality Control Procedures.

11.4.7 Reporting

Analytical Results.

11.5 IC/PCR Sample

Preparation.

11.5.3 Sample

Preconcentration (older instruments).

11.6.1 The IC/PCR

analysis is applicable for hexavalent chromium measurements only.

11.6.5 IC/PCR

Instrument Calibration.

11.6.6 IC/PCR

Instrument Operation.

11.6.7 IC/PCR

Operational Quality Control Procedures.

11.6.8 IC/PCR Sample

Dilution.

11.6.9 Reporting

Analytical Results.

12.0 Data Analysis and

Calculations.

12.1.1 Pretest Protocol

(Site Test Plan).

12.1.2 Post Test

Calculations.

17.0 Tables, Diagrams,

Flowcharts, and Validation Data.

1.0 Scope and Application.

1.1 Analytes.

1.2 Applicability.

This method applies to the determination of chromium (Cr) in emissions from

decorative and hard chrome electroplating facilities, chromium anodizing

operations, and continuous chromium plating operations at iron and steel

facilities.

1.3 Data Quality

Objectives. [Reserved]

2.0 Summary of Method.

2.1 Sampling.

An emission sample

is extracted isokinetically from the source using an unheated Method 5 sampling

train (40 CFR Part 60, Appendix A), with a glass nozzle and probe liner, but

with the filter omitted. The sample time shall be at least two hours. The Cr

emissions are collected in an alkaline solution containing 0.1 N sodium

hydroxide (NaOH) or 0.1 N sodium bicarbonate (NaHCO3). The collected samples are recovered using

an alkaline solution and are then transported to the laboratory for analysis.

2.2 Analysis.

2.2.1 Total

chromium samples with high chromium concentrations (>35 µg/L) may be

analyzed using inductively coupled plasma emission spectrometry (ICP) at 267.72

nm.

NOTE: The ICP analysis is applicable for this

method only when the solution analyzed has a Cr concentration greater than or

equal to 35 µg/L or five times the method detection limit as determined

according to Appendix B in 40 CFR Part 136.

2.2.2

Alternatively, when lower total chromium concentrations (<35 µg/L) are

encountered, a portion of the alkaline sample solution may be digested with

nitric acid and analyzed by graphite furnace atomic absorption spectroscopy

(GFAAS) at 357.9 nm.

2.2.3 If it is

desirable to determine hexavalent chromium (Cr+6)

emissions, the samples may be analyzed using an ion chromatograph equipped with

a post-column reactor (IC/PCR) and a visible wavelength detector. To increase

sensitivity for trace levels of Cr+6, a

preconcentration system may be used in conjunction with the IC/PCR.

3.0 Definitions.

3.1 Total Chromium

Measured chromium

content that includes both major chromium oxidation states (Cr+3, Cr+6).

3.2 May

Implies an

optional operation.

3.3 Digestion

The analytical

operation involving the complete (or nearly complete) dissolution of the sample

in order to ensure the complete solubilization of the element (analyte) to be

measured.

3.4 Interferences

Physical,

chemical, or spectral phenomena that may produce a high or low bias in the

analytical result.

3.5 Analytical System

All components of

the analytical process including the sample digestion and measurement

apparatus.

3.6 Sample Recovery

The quantitative

transfer of sample from the collection apparatus to the sample preparation

(digestion, etc.) apparatus. This term should not be confused with analytical

recovery.

3.7 Matrix Modifier

A chemical modification

to the sample during GFAAS determinations to ensure that the analyte is not

lost during the measurement process (prior to the atomization stage)

3.8 Calibration Reference Standards

Quality control

standards used to check the accuracy of the instrument calibration curve prior

to sample analysis.

3.9 Continuing Check Standard

Quality control

standards used to verify that unacceptable drift in the measurement system has

not occurred.

3.10 Calibration Blank

A blank used to

verify that there has been no unacceptable shift in the baseline either

immediately following calibration or during the course of the analytical

measurement.

3.11 Interference Check

An

analytical/measurement operation that ascertains whether a measurable

interference in the sample exists.

3.12 Inter-element Correction Factors

Factors used to

correct for interfering elements that produce a false signal (high bias).

3.13 Duplicate Sample Analysis

Either the repeat

measurement of a single solution or the measurement of duplicate preparations

of the same sample. It is important to be aware of which approach is required

for a particular type of measurement. For example, no digestion is required for

the ICP determination and the duplicate instrument measurement is therefore

adequate whereas duplicate digestion/instrument measurements are required for

GFAAS.

3.14 Matrix Spiking

Analytical spikes

that have been added to the actual sample matrix either before (Section

9.2.5.2) or after (Section 9.1.6). Spikes added to the sample prior to a

preparation technique (e.g., digestion) allow for the assessment of an overall

method accuracy while those added after only provide for the measurement

accuracy determination.

4.0 Interferences.

4.1 ICP Interferences.

4.1.1 ICP Spectral Interferences.

Spectral

interferences are caused by: overlap of a spectral line from another element;

unresolved overlap of molecular band spectra; background contribution from

continuous or recombination phenomena; and, stray light from the line emission

of high-concentrated elements. Spectral overlap may be compensated for by

correcting the raw data with a computer and measuring the interfering element.

At the 267.72 nm Cr analytical wavelength, iron, manganese, and uranium are

potential interfering elements. Background and stray light interferences can

usually be compensated for by a background correction adjacent to the

analytical line. Unresolved overlap requires the selection of an

alternative chromium wavelength.

Consult the instrument manufacturer's

operation manual

for interference correction procedures.

4.1.2 ICP Physical Interferences.

High levels of

dissolved solids in the samples may cause significant inaccuracies due to salt

buildup at the nebulizer and torch tips. This problem can be controlled by

diluting the sample or by extending the rinse times between sample analyses.

Standards shall be prepared in the same solution matrix as the samples (i.e.,

0.1 N NaOH or 0.1 N NaHCO3).

4.1.3 ICP Chemical Interferences.

These include

molecular compound formation, ionization effects and solute vaporization

effects, and are usually not significant in the ICP procedure, especially if

the standards and samples are matrix matched.

4.2 GFAAS Interferences.

4.2.1 GFAAS Chemical Interferences.

Low concentrations

of calcium and/or phosphate may cause interferences; at concentrations above

200 µg/L, calcium's effect is constant and eliminates the effect of phosphate.

Calcium nitrate is therefore added to the concentrated analyte to ensure a

known constant effect. Other matrix modifiers recommended by the instrument

manufacturer may also be considered.

4.2.2 GFAAS Cyanide Band Interferences.

Nitrogen should

not be used as the purge gas due to cyanide band interference.

4.2.3 GFAAS Spectral Interferences.

Background correction

may be required because of possible significant levels of nonspecific

absorption and scattering at the 357.9 nm analytical wavelength.

4.2.4 GFAAS Background Interferences.

Zeeman or

Smith-Hieftje background correction is recommended for interferences resulting

from high levels of dissolved solids in the alkaline impinger solutions.

4.3 IC/PCR Interferences.

4.3.1 IC/PCR Chemical Interferences.

Components in the

sample matrix may cause Cr+6

to convert to trivalent chromium

(Cr+3) or cause Cr+3 to

convert to Cr+6. The chromatographic separation of Cr+6 using ion chromatography reduces the

potential for other metals to interfere with the post column reaction. For the

IC/PCR analysis, only compounds that coelute with Cr+6 and affect the diphenylcarbazide reaction

will cause interference.

4.3.2 IC/PCR Background Interferences.

Periodic analyses

of reagent water blanks are used to demonstrate that the analytical system is

essentially free of contamination. Sample cross-contamination can occur when high-level

and low-level samples or standards are analyzed alternately and can be

eliminated by thorough purging of the sample loop. Purging of the sample can

easily be achieved by increasing the injection volume to ten times the size of

the sample loop.

5.0 Safety.

5.1 Disclaimer.

This method may involve hazardous materials, operations, and equipment. This

test method may not address all of the safety problems associated with its use.

It is the responsibility of the user to establish appropriate safety and health

practices and to determine the applicability of regulatory limitations prior to

performing this test method.

5.2 Hexavalent

chromium compounds have been listed as carcinogens although chromium (III)

compounds show little or no toxicity. Chromium can be a skin and respiratory

irritant.

6.0 Equipment and Supplies.

6.1 Sampling Train.

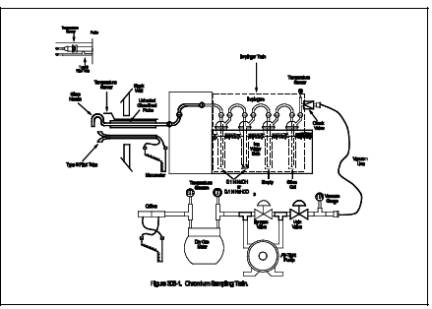

6.1.1 A schematic

of the sampling train used in this method is shown in Figure 306-1. The train

is the same as shown in Method 5, Section 6.0 (40 CFR Part 60, Appendix A)

except that the probe liner is unheated, the particulate filter is omitted, and

quartz or borosilicate glass must be used for the probe nozzle and liner in

place of stainless steel.

6.1.2 Probe

fittings of plastic such as Teflon, polypropylene, etc. are recommended over

metal fittings to prevent contamination. If desired, a single combined probe

nozzle and liner may be used, but such a single glass assembly is not a

requirement of this methodology.

6.1.3 Use 0.1 N

NaOH or 0.1 N NaHCO3

in the impingers in place of

water.

6.1.4 Operating

and maintenance procedures for the sampling train are described in APTD-0576 of

Method 5. Users should read the APTD-0576 document and adopt the outlined

procedures.

6.1.5 Similar

collection systems which have been approved by the Administrator may be used.

6.2 Sample Recovery.

Same as Method 5,

[40 CFR Part 60, Appendix A], with the following exceptions:

6.2.1 Probe-Liner

and Probe-Nozzle Brushes. Brushes are not necessary for sample recovery. If a

probe brush is used, it must be non-metallic.

6.2.2 Sample

Recovery Solution. Use 0.1 N NaOH or 0.1 N NaHCO3,

whichever is used as the impinger absorbing solution, in place of acetone to

recover the sample.

6.2.3 Sample

Storage Containers. Polyethylene, with leak-free screw cap, 250 mL, 500 mL or

1,000 mL.

6.3 Analysis.

6.3.1 General.

For analysis, the

following equipment is needed.

6.3.1.1 Phillips

Beakers. (Phillips beakers are preferred, but regular beakers may also be

used.)

6.3.1.2 Hot Plate.

6.3.1.3 Volumetric

Flasks. Class A, various sizes as appropriate.

6.3.1.4 Assorted

Pipettes.

6.3.2 Analysis by ICP.

6.3.2.1 ICP

Spectrometer. Computer-controlled emission spectrometer with background

correction and radio frequency generator.

6.3.2.2 Argon Gas

Supply. Welding grade or better.

6.3.3 Analysis by GFAAS.

6.3.3.1 Chromium

Hollow Cathode Lamp or Electrodeless Discharge Lamp.

6.3.3.2 Graphite

Furnace Atomic Absorption Spectrophotometer.

6.3.3.3 Furnace

Autosampler

6.3.4 Analysis by IC/PCR.

6.3.4.1 IC/PCR

System. High performance liquid chromatograph pump, sample injection valve,

post-column reagent delivery and mixing system, and a visible detector, capable

of operating at 520 nm-540 nm, all with a nonmetallic (or inert) flow path. An

electronic peak area mode is recommended, but other recording devices and

integration techniques are acceptable provided the repeatability criteria and

the linearity criteria for the calibration curve described in Section 10.4 can

be satisfied. A sample loading system is required if preconcentration is

employed.

6.3.4.2 Analytical

Column. A high performance ion chromatograph (HPIC) non-metallic column with

anion separation characteristics and a high loading capacity designed for

separation of metal chelating compounds to prevent metal interference.

Resolution described in Section 11.6 must be obtained. A non-metallic guard

column with the same ion-exchange material is recommended.

6.3.4.3

Preconcentration Column (for older instruments). An HPIC non-metallic column

with acceptable anion retention characteristics and sample loading rates must

be used as described in Section 11.6.

6.3.4.4 Filtration

Apparatus for IC/PCR.

6.3.4.4.1 Teflon,

or equivalent, filter holder to accommodate 0.45-µm acetate, or equivalent,

filter, if needed to remove insoluble particulate matter.

6.3.4.4.2 0.45-µm

Filter Cartridge. For the removal of insoluble material. To be used just prior

to sample injection/analysis.

7.0 Reagents and Standards.

NOTE: Unless otherwise indicated, all reagents

should conform to the specifications established by the Committee on Analytical

Reagents of the American Chemical Society (ACS reagent grade). Where such

specifications are not available, use the best available grade. Reagents should

be checked by the appropriate analysis prior to field use to assure that

contamination is below the analytical detection limit for the ICP or GFAAS

total chromium analysis; and that contamination is below the analytical

detection limit for Cr+6

using IC/PCR for direct

injection or, if selected, preconcentration.

7.1 Sampling.

7.1.1 Water.

Reagent water that conforms to ASTM Specification D1193-77 or 91 Type II

(incorporated by reference see ¤63.14). All references to water in the method

refer to reagent water unless otherwise specified. It is recommended that water

blanks be checked prior to preparing the sampling reagents to ensure that the

Cr content is less than three (3) times the anticipated detection limit of the

analytical method.

7.1.2 Sodium

Hydroxide (NaOH) Absorbing Solution, 0.1 N. Dissolve 4.0 g of sodium hydroxide

in 1 liter of water to obtain a pH of approximately 8.5.

7.1.3 Sodium

Bicarbonate (NaHCO3) Absorbing Solution, 0.1 N. Dissolve

approximately 8.5 g of sodium bicarbonate in 1 liter of water to obtain a pH of

approximately 8.3.

7.1.4 Chromium

Contamination.

7.1.4.1 The

absorbing solution shall not exceed the QC criteria noted in Section 7.1.1 (<

3 times the instrument detection limit).

7.1.4.2 When the

Cr+6 content in the field samples exceeds the

blank concentration by at least a factor of ten (10), Cr+6 blank concentrations < 10 times the

detection limit will be allowed.

NOTE: At sources with high concentrations of acids

and/or SO2, the concentration of NaOH or NaHCO3 should be > 0.5 N to insure that

the pH of the solution remains at or above 8.5 for NaOH and 8.0 for NaHCO3 during and after sampling.

7.1.5 Silica Gel.

Same as in Method 5.

7.2 Sample Recovery.

7.2.1 0.1 N NaOH

or 0.1 N NaHCO3. Use the same solution for the sample

recovery that is used for the impinger absorbing solution.

7.2.2 pH Indicator

Strip, for IC/PCR. pH indicator capable of determining the pH of solutions

between the pH range of 7 and 12, at 0.5 pH increments.

7.3 Sample Preparation and Analysis.

7.3.1 Nitric Acid

(HNO3), Concentrated, for GFAAS. Trace metals

grade or better HNO3

must be used for reagent

preparation. The ACS reagent grade HNO3 is

acceptable for cleaning glassware.

7.3.2 HNO3, 1.0% (v/v), for GFAAS. Prepare, by slowly

stirring, 10 mL of concentrated HNO3 into

800 mL of reagent water. Dilute to 1,000 mL with reagent water. The solution

shall contain less than 0.001 mg Cr/L.

7.3.3 Calcium

Nitrate Ca(NO3)2 Solution

(10 µg Ca/mL) for GFAAS analysis. Prepare the solution by weighing 40.9 mg of

Ca(NO3)2 into

a 1 liter volumetric flask. Dilute with reagent water to 1 liter.

7.3.4 Matrix

Modifier, for GFAAS. See instrument manufacturer's manual for suggested matrix

modifier.

7.3.5

Chromatographic Eluent, for IC/PCR. The eluent used in the analytical system is

ammonium sulfate based.

7.3.5.1 Prepare by

adding 6.5 mL of 29 percent ammonium hydroxide (NH4OH) and 33 g of ammonium sulfate ((NH4)2SO4) to 500 mL of reagent water. Dilute to 1

liter with reagent water and mix well.

7.3.5.2 Other

combinations of eluents and/or columns may be employed provided peak

resolution, repeatability,

linearity, and analytical sensitivity as described in Sections 9.3 and

11.6 are acceptable.

7.3.6 Post-Column

Reagent, for IC/PCR. An effective post-column reagent for use with the

chromatographic eluent described in Section 7.3.5 is a diphenylcarbazide

(DPC)-based system. Dissolve 0.5 g of 1,5-diphenylcarbazide in 100 mL of ACS

grade methanol. Add 500 mL of reagent water containing 50 mL of 96 percent

spectrophotometric grade sulfuric acid. Dilute to 1 liter with reagent water.

7.3.7 Chromium

Standard Stock Solution (1000 mg/L). Procure a certified aqueous standard or

dissolve 2.829 g of potassium dichromate (K2Cr2O7),

in reagent water and dilute to 1 liter.

7.3.8 Calibration

Standards for ICP or IC/PCR. Prepare calibration standards for ICP or IC/PCR by

diluting the Cr standard stock solution (Section 7.3.7) with 0.1 N NaOH or 0.1

N NaHCO3, whichever is used as the impinger absorbing

solution, to achieve a matrix similar to the actual field samples. Suggested

levels are 0, 50, 100, and 200 µg Cr/L for ICP, and 0, 1, 5, and 10 µg Cr+6/L for IC/PCR.

7.3.9 Calibration

Standards for GFAAS. Chromium solutions for GFAAS calibration shall contain 1.0

percent (v/v) HNO3. The zero standard shall be 1.0 percent

(v/v) HNO3. Calibration standards should be prepared

daily by diluting the Cr standard stock solution (Section 7.3.7) with 1.0

percent HNO3. Use at least four standards to make the

calibration curve. Suggested levels are 0, 10, 50, and 100 µg Cr/L.

7.4 Glassware Cleaning Reagents.

7.4.1 HNO3, Concentrated. ACS reagent grade or

equivalent.

7.4.2 Water.

Reagent water that conforms to ASTM Specification D1193-77 or 91 Type II.

7.4.3 HNO3, 10 percent (v/v). Add by stirring 500 mL of

concentrated HNO3

into a flask containing

approximately 4,000 mL of reagent water. Dilute to 5,000 mL with reagent water.

Mix well. The reagent shall contain less than 2 µg Cr/L.

7.5 Quality Assurance Audit Samples.

7.5.1 When making

compliance determinations, and upon availability, audit samples shall be

obtained from the appropriate EPA regional Office or from the responsible

enforcement authority and analyzed in conjunction with the field samples.

7.5.2 If EPA or

National Institute of Standards and Technology (NIST) reference audit sample

are not available, a mid-range standard, prepared from an independent

commercial source, may be used.

NOTE: To order audit samples, contact the

responsible enforcement authority at least 30 days prior to the test date to

allow sufficient time for the audit sample to be delivered.

8.0 Sample Collection, Preservation, Holding Times, Storage, and Transport.

NOTE: Prior to sample collection, consideration

should be given to the type of analysis (Cr+6 or

total Cr) that will be performed. Which analysis option(s) will be performed

will determine which sample recovery and storage procedures will be required to

process the sample (See Figures 306-3 and 306-4).

8.1 Sample Collection.

Same as Method 5

(40 CFR Part 60, Appendix A), with the following exceptions.

8.1.1 Omit the

particulate filter and filter holder from the sampling train. Use a glass

nozzle and probe liner instead of stainless steel. Do not heat the probe. Place

100 mL of 0.1 N NaOH or 0.1 N NaHCO3 in

each of the first two impingers, and record the data for each run on a data

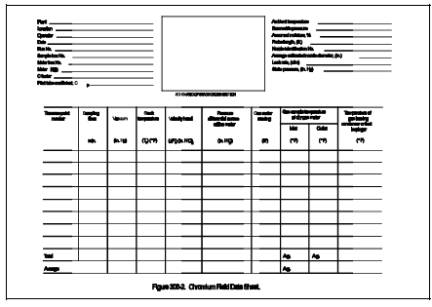

sheet such as shown in Figure 306-2.

8.1.2 Clean all

glassware prior to sampling in hot soapy water designed for laboratory cleaning

of glassware. Next, rinse the glassware three times with tap water, followed by

three additional rinses with reagent water. Then soak the glassware in 10%

(v/v) HNO3 solution for a minimum of 4 hours, rinse

three times with reagent water, and allow to air dry. Cover all glassware

openings where contamination can occur with Parafilm, or equivalent, until the

sampling train is assembled for sampling.

8.1.3 Train

Operation. Follow the basic procedures outlined in Method 5 in conjunction with

the following instructions. Train sampling rate shall not exceed 0.030 m3/min (1.0 cfm) during a run.

8.2 Sample Recovery.

Follow the basic

procedures of Method 5, with the exceptions noted.

8.2.1 A

particulate filter is not recovered from this train.

8.2.2 Tester shall

select either the total Cr or Cr+6 sample

recovery option.

8.2.3 Samples to

be analyzed for both total Cr and Cr+6,

shall be recovered using the Cr+6 sample option

(Section 8.2.6).

8.2.4 A field

reagent blank shall be collected for either of the Cr or the Cr+6 analysis. If both analyses (Cr and Cr+6) are to be conducted on the samples, collect

separate reagent blanks for each analysis.

NOTE: Since particulate matter is not usually

present at chromium electroplating and/or chromium anodizing operations, it is

not necessary to filter the Cr+6 samples unless

there is observed sediment in the collected solutions. If it is necessary to

filter the Cr+6 solutions, please refer to Method 0061,

Determination of Hexavalent Chromium Emissions From Stationary Sources, Section

7.4, Sample Preparation in SW-846 (see Reference 1).

8.2.5 Total Cr

Sample Option.

8.2.5.1 Container

No. 1. Measure the volume of the liquid in the first, second, and third

impingers and quantitatively transfer into a labeled sample container.

8.2.5.2 Use

approximately 200 to 300 mL of the 0.1 N NaOH or 0.1 N NaHCO3 absorbing solution to rinse the probe nozzle,

probe liner, three impingers, and connecting glassware; add this rinse to

Container No. 1.

8.2.6 Cr+6 Sample Option.

8.2.6.1 Container

No. 1. Measure and record the pH of the absorbing solution contained in the

first impinger at the end of the sampling run using a pH indicator strip. The

pH of the solution must be >8.5 for NaOH and >8.0 for NaHCO3. If it is not, discard the collected sample,

increase the normality of the NaOH or NaHCO3 impinger

absorbing solution to 0.5 N or to a solution normality approved by the

Administrator and collect another air emission sample.

8.2.6.2 After

determining the pH of the first impinger solution, combine and measure the

volume of the liquid in the first, second, and third impingers and

quantitatively transfer into the labeled sample container. Use approximately

200 to 300 mL of the 0.1 N NaOH or 0.1 N NaHCO3 absorbing

solution to rinse the probe nozzle, probe liner, three impingers, and

connecting glassware; add this rinse to Container No. 1.

8.2.7 Field

Reagent Blank.

8.2.7.1 Container

No. 2.

8.2.7.2 Place

approximately 500 mL of the 0.1 N NaOH or 0.1 N NaHCO3 absorbing solution into a labeled sample

container.

8.3 Sample Preservation, Storage, and Transport.

8.3.1 Total Cr

Sample Option. Samples to be

analyzed for total Cr need not be refrigerated.

8.3.2 Cr+6 Sample Option. Samples to be analyzed for Cr+6 must be shipped and stored at 4NC. Allow Cr+6 samples to return to ambient temperature

prior to analysis.

8.4 Sample Holding Times.

8.4.1 Total Cr

Sample Option. Samples to be

analyzed for total Cr shall be analyzed within 60 days of collection.

8.4.2 Cr+6 Sample Option. Samples to be analyzed for Cr+6 shall be analyzed within 14 days of

collection.

9.0 Quality Control.

9.1 ICP Quality Control.

9.1.1 ICP Calibration Reference Standards.

Prepare a

calibration reference standard using the same alkaline matrix as the

calibration standards; it should be at least 10 times the instrumental

detection limit.

9.1.1.1 This

reference standard must be prepared from a different Cr stock solution source

than that used for preparation of the calibration curve standards.

9.1.1.2 Prior to

sample analysis, analyze at least one reference standard.

9.1.1.3 The

calibration reference standard must be measured within 10 percent of it's true

value for the curve to be considered valid.

9.1.1.4 The curve

must be validated before sample analyses are performed.

9.1.2 ICP Continuing Check Standard.

9.1.2.1 Perform

analysis of the check standard with the field samples as described in Section

11.2 (at least after every 10 samples, and at the end of the analytical run).

9.1.2.2 The check

standard can either be the mid-range calibration standard or the reference

standard. The results of the check standard shall agree within 10 percent of

the expected value; if not, terminate the analyses, correct the problem,

recalibrate the instrument, and rerun all samples analyzed subsequent to the

last acceptable check standard analysis.

9.1.3 ICP Calibration Blank.

9.1.3.1 Perform

analysis of the calibration blank with the field samples as described in

Section 11.2 (at least after every 10 samples, and at the end of the analytical

run).

9.1.3.2 The

results of the calibration blank shall agree within three standard deviations

of the mean blank value. If not, analyze the calibration blank two more times

and average the results. If the average is not within three standard deviations

of the background mean, terminate the analyses, correct the problem,

recalibrate, and reanalyze all samples analyzed subsequent to the last

acceptable calibration blank analysis.

9.1.4 ICP Interference Check.

Prepare an

interference check solution that contains known concentrations of interfering

elements that will provide an adequate test of the correction factors in the

event of potential spectral interferences.

9.1.4.1 Two

potential interferences, iron and manganese, may be prepared as 1000 µg/mL and

200 µg/mL solutions, respectively. The solutions should be prepared in dilute

HNO3 (1-5 percent). Particular care must be used

to ensure that the solutions and/or salts used to prepare the solutions are of

ICP grade purity (i.e., that no measurable Cr contamination exists in the

salts/solutions). Commercially prepared interfering element check standards are

available.

9.1.4.2 Verify the

interelement correction factors every three months by analyzing the

interference check solution. The correction factors are calculated according to

the instrument manufacturer's directions. If the interelement correction

factors are used properly, no false Cr should be detected.

9.1.4.3 Negative

results with an absolute value greater than three (3) times the detection limit

are usually the results of the background correction position being set

incorrectly. Scan the spectral region to ensure that the correction position

has not been placed on an interfering peak.

9.1.5 ICP Duplicate Sample Analysis.

Perform one

duplicate sample analysis for each compliance sample batch (3 runs).

9.1.5.1 As there

is no sample preparation required for the ICP analysis, a duplicate analysis is

defined as a repeat analysis of one of the field samples. The selected sample

shall be analyzed using the same procedures that were used to analyze the

original sample.

9.1.5.2 Duplicate

sample analyses shall agree within 10 percent of the original measurement

value.

9.1.5.3 Report the

original analysis value for the sample and report the duplicate analysis value

as the QC check value. If agreement is not achieved, perform the duplicate

analysis again. If agreement is not achieved the second time, perform

corrective action to identify and correct the problem before analyzing the

sample for a third time.

9.1.6 ICP Matrix Spiking.

Spiked samples

shall be prepared and analyzed daily to ensure that there are no matrix

effects, that samples and standards have been matrix-matched, and that the

laboratory equipment is operating properly.

9.1.6.1 Spiked

sample recovery analyses should indicate a recovery for the Cr spike of between

75 and 125 percent.

9.1.6.2 Cr levels

in the spiked sample should provide final solution concentrations that are

within the linear portion of the calibration curve, as well as, at a

concentration level at least: equal to that of the original sample; and, ten

(10) times the detection limit.

9.1.6.3 If the

spiked sample concentration meets the stated criteria but exceeds the linear

calibration range, the spiked sample must be diluted with the field absorbing

solution.

9.1.6.4 If the

recoveries for the Cr spiked samples do not meet the specified criteria,

perform corrective action to identify and correct the problem prior to

reanalyzing the samples.

9.1.7 ICP Field Reagent Blank.

9.1.7.1 Analyze a

minimum of one matrix-matched field reagent blank (Section 8.2.4) per sample

batch to determine if contamination or memory effects are occurring.

9.1.7.2 If

contamination or memory effects are observed, perform corrective action to

identify and correct the problem before reanalyzing the samples.

9.1.8 Audit Sample Analysis.

9.1.8.1 When the

method is used to analyze samples to demonstrate compliance with a source

emission regulation, an audit sample must be analyzed, subject to availability.

9.1.8.2

Concurrently analyze the audit sample and the compliance samples in the same

manner to evaluate the technique of the analyst and the standards preparation.

9.1.8.3 The same

analyst, analytical reagents, and analytical system shall be used for the

compliance samples and the audit sample. If this condition is met, duplicate

auditing of subsequent compliance analyses for the same enforcement agency

within a 30-day period is waived. An audit sample set may not be used to

validate different sets of compliance samples under the jurisdiction of

separate enforcement agencies, unless prior arrangements have been made with

both enforcement agencies.

9.1.9 Audit Sample Results.

9.1.9.1 Calculate

the audit sample concentrations and submit results using the instructions

provided with the audit samples.

9.1.9.2 Report the

results of the audit samples and the compliance determination samples along

with their identification numbers, and the analyst's name to the responsible

enforcement authority. Include this information with reports of any subsequent

compliance analyses for the same enforcement authority during the 30-day

period.

9.1.9.3 The

concentrations of the audit samples obtained by the analyst shall agree within

the values specified by the compliance auditor. If the specified range is not

met, reanalyze the compliance and audit samples, and include initial and

reanalysis values in the test report.

9.1.9.4 Failure to

meet the specified range may require retests unless the audit problems are

resolved. However, if the audit results do not affect the compliance or noncompliance

status of the affected facility, the Administrator may waive the reanalysis

requirement, further audits, or retests and accept the results of the

compliance test. While steps are being taken to resolve audit analysis

problems, the Administrator may also choose to use the data to determine the

compliance or noncompliance status of the affected facility.

9.2 GFAAS Quality Control.

9.2.1 GFAAS Calibration Reference Standards.

The calibration

curve must be verified by using at least one calibration reference standard

(made from a reference material or other independent standard material) at or

near the mid-range of the calibration curve.

9.2.1.1 The

calibration curve must be validated before sample analyses are performed.

9.2.1.2 The

calibration reference standard must be measured within 10 percent of its true

value for the curve to be considered valid.

9.2.2 GFAAS Continuing Check Standard.

9.2.2.1 Perform

analysis of the check standard with the field samples as described in Section

11.4 (at least after every 10 samples, and at the end of the analytical run).

9.2.2.2 These

standards are analyzed, in part, to monitor the life and performance of the

graphite tube. Lack of reproducibility or a significant change in the signal

for the check standard may indicate that the graphite tube should be replaced.

9.2.2.3 The check

standard may be either the mid-range calibration standard or the reference

standard.

9.2.2.4 The

results of the check standard shall agree within 10 percent of the expected

value.

9.2.2.5 If not,

terminate the analyses, correct the problem, recalibrate the instrument, and

reanalyze all samples analyzed subsequent to the last acceptable check standard

analysis.

9.2.3 GFAAS Calibration Blank.

9.2.3.1 Perform

analysis of the calibration blank with the field samples as described in

Section 11.4 (at least after every 10 samples, and at the end of the analytical

run).

9.2.3.2 The

calibration blank is analyzed to monitor the life and performance of the

graphite tube as well as the existence of any memory effects. Lack of

reproducibility or a significant change in the signal, may indicate that the

graphite tube should be replaced.

9.2.3.3 The

results of the calibration blank shall agree within three standard deviations

of the mean blank value.

9.2.3.4 If not,

analyze the calibration blank two more times and average the results. If the

average is not within three standard deviations of the background mean,

terminate the analyses, correct the problem, recalibrate, and reanalyze all

samples analyzed subsequent to the last acceptable calibration blank analysis.

9.2.4 GFAAS Duplicate Sample Analysis.

Perform one

duplicate sample analysis for each compliance sample batch (3 runs).

9.2.4.1 A digested

aliquot of the selected sample is processed and analyzed using the identical

procedures that were used for the whole sample preparation and analytical

efforts.

9.2.4.2 Duplicate

sample analyses results incorporating duplicate digestions shall agree within

20 percent for sample results exceeding ten (10) times the detection limit.

9.2.4.3 Report the

original analysis value for the sample and report the duplicate analysis value

as the QC check value.

9.2.4.4 If

agreement is not achieved, perform the duplicate analysis again. If agreement

is not achieved the second time, perform corrective action to identify and

correct the problem before analyzing the sample for a third time.

9.2.5 GFAAS Matrix Spiking.

9.2.5.1 Spiked

samples shall be prepared and analyzed daily to ensure that (1) correct procedures

are being followed, (2) there are no matrix effects and (3) all equipment is

operating properly.

9.2.5.2 Cr spikes

are added prior to any sample preparation.

9.2.5.3 Cr levels

in the spiked sample should provide final solution concentrations that are

within the linear portion of the calibration curve, as well as, at a

concentration level at least: equal to that of the original sample; and, ten

(10) times the detection limit.

9.2.5.4 Spiked

sample recovery analyses should indicate a recovery for the Cr spike of between

75 and 125 percent.

9.2.5.5 If the

recoveries for the Cr spiked samples do not meet the specified criteria,

perform corrective action to identify and correct the problem prior to

reanalyzing the samples.

9.2.6 GFAAS Method of Standard Additions.

9.2.6.1 Method of

Standard Additions. Perform procedures in Section 5.4 of Method 12 (40 CFR Part

60, Appendix A)

9.2.6.2 Whenever

sample matrix problems are suspected and standard/sample matrix matching is not

possible or whenever a new sample matrix is being analyzed, perform referenced

procedures to determine if the method of standard additions is necessary.

9.2.7 GFAAS Field Reagent Blank.

9.2.7.1 Analyze a

minimum of one matrix-matched field reagent blank (Section 8.2.4) per sample batch

to determine if contamination or memory effects are occurring. 9.2.7.2 If

contamination or memory effects are observed, perform corrective action to

identify and correct the problem before reanalyzing the samples.

9.2.8 Audit Sample Analysis.

9.2.8.1 When the

method is used to analyze samples to demonstrate compliance with a source

emission regulation, an audit sample must be analyzed, subject to availability.

9.2.8.2

Concurrently analyze the audit sample and the compliance samples in the same

manner to evaluate the technique of the analyst and the standards preparation.

9.2.8.3 The same

analyst, analytical reagents, and analytical system shall be used for the

compliance samples and the audit sample. If this condition is met, duplicate

auditing of subsequent compliance analyses for the same enforcement agency

within a 30-day period is waived. An audit sample set may not be used to

validate different sets of compliance samples under the jurisdiction of

separate enforcement agencies, unless prior arrangements have been made with

both enforcement agencies.

9.2.9 Audit Sample Results.

9.2.9.1 Calculate

the audit sample concentrations and submit results using the instructions

provided with the audit samples.

9.2.9.2 Report the

results of the audit samples and the compliance determination samples along

with their identification numbers, and the analyst's name to the responsible

enforcement authority. Include this information with reports of any subsequent

compliance analyses for the same enforcement authority during the 30-day

period.

9.2.9.3 The

concentrations of the audit samples obtained by the analyst shall agree within

the values specified by the compliance auditor. If the specified range is not

met, reanalyze the compliance and audit samples, and include initial and

reanalysis values in the test report.

9.2.9.4 Failure to

meet the specified range may require retests unless the audit problems are

resolved. However, if the audit results do not affect the compliance or

noncompliance status of the affected facility, the Administrator may waive the

reanalysis requirement, further audits, or retests and accept the results of

the compliance test. While steps are being taken to resolve audit analysis

problems, the Administrator may also choose to use the data to determine the

compliance or noncompliance status of the affected facility.

9.3 IC/PCR Quality Control.

9.3.1 IC/PCR Calibration Reference Standards.

9.3.1.1 Prepare a

calibration reference standard at a concentration that is at or near the

mid-point of the calibration curve using the same alkaline matrix as the

calibration standards. This reference standard should be prepared from a

different Cr stock solution than that used to prepare the calibration curve

standards. The reference standard is used to verify the accuracy of the

calibration curve.

9.3.1.2 The curve

must be validated before sample analyses are performed. Prior to sample

analysis, analyze at least one reference standard with an expected value within

the calibration range.

9.3.1.3 The

results of this reference standard analysis must be within 10 percent of the

true value of the reference standard for the calibration curve to be considered

valid.

9.3.2 IC/PCR Continuing Check Standard and Calibration Blank.

9.3.2.1 Perform

analysis of the check standard and the calibration blank with the field samples

as described in Section 11.6 (at least after every 10 samples, and at the end

of the analytical run).

9.3.2.2 The result

from the check standard must be within 10 percent of the expected value.

9.3.2.3 If the 10

percent criteria is exceeded, excessive drift and/or instrument degradation may

have occurred, and must be corrected before further analyses can be performed.

9.3.2.4 The

results of the calibration blank analyses must agree within three standard

deviations of the mean blank value.

9.3.2.5 If not,

analyze the calibration blank two more times and average the results.

9.3.2.6 If the

average is not within three standard deviations of the background mean,

terminate the analyses, correct the problem, recalibrate, and reanalyze all

samples analyzed subsequent to the last acceptable calibration blank analysis.

9.3.3 IC/PCR Duplicate Sample Analysis.

9.3.3.1 Perform

one duplicate sample analysis for each compliance sample batch (3 runs).

9.3.3.2 An aliquot

of the selected sample is prepared and analyzed using procedures identical to

those used for the emission samples (for example, filtration and/or, if

necessary, preconcentration).

9.3.3.3 Duplicate

sample injection results shall agree within 10 percent for sample results

exceeding ten (10) times the detection limit.

9.3.3.4 Report the

original analysis value for the sample and report the duplicate analysis value

as the QC check value.

9.3.3.5 If

agreement is not achieved, perform the duplicate analysis again.

9.3.3.6 If

agreement is not achieved the second time, perform corrective action to

identify and correct the problem prior to analyzing the sample for a third

time.

9.3.4 ICP/PCR Matrix Spiking.

Spiked samples

shall be prepared and analyzed with each sample set to ensure that there are no

matrix effects, that samples and standards have been matrix-matched, and that

the equipment is operating properly.

9.3.4.1 Spiked

sample recovery analysis should indicate a recovery of the Cr+6 spike between 75 and 125 percent.

9.3.4.2 The spiked

sample concentration should be within the linear portion of the calibration

curve and should be equal to or greater than the concentration of the original

sample. In addition, the spiked sample concentration should be at least ten

(10) times the detection limit.

9.3.4.3 If the

recoveries for the Cr+6

spiked samples do not meet the

specified criteria, perform corrective action to identify and correct the

problem prior to reanalyzing the samples.

9.3.5 IC/PCR Field Reagent Blank.

9.3.5.1 Analyze a

minimum of one matrix-matched field reagent blank (Section 8.2.4) per sample

batch to determine if contamination or memory effects are occurring.

9.3.5.2 If

contamination or memory effects are observed, perform corrective action to

identify and correct the problem before reanalyzing the samples.

9.3.6 Audit Sample Analysis.

9.3.6.1 When the

method is used to analyze samples to demonstrate compliance with source

emission regulation, an audit sample must be analyzed, subject to availability.

9.3.6.2

Concurrently analyze the audit sample and the compliance samples in the same

manner to evaluate the technique of the analyst and the standards preparation.

9.3.6.3 The same

analyst, analytical reagents, and analytical system shall be used for the

compliance samples and the audit sample. If this condition is met, duplicate

auditing of subsequent compliance analyses for the same enforcement agency

within a 30-day period is waived. An audit sample set may not be used to

validate different sets of compliance samples under the jurisdiction of

separate enforcement agencies, unless prior arrangements have been made with

both enforcement agencies.

9.3.7 Audit Sample Results.

9.3.7.1 Calculate

the audit sample concentrations and submit results using the instructions

provided with the audit samples.

9.3.7.2 Report the

results of the audit samples and the compliance determination samples along

with their identification numbers, and the analyst's name to the responsible enforcement

authority. Include this information with reports of any subsequent compliance

analyses for the same enforcement authority during the 30-day period.

9.3.7.3 The

concentrations of the audit samples obtained by the analyst shall agree within

the values specified by the compliance auditor. If the specified range is not

met, reanalyze the compliance and audit samples, and include initial and

reanalysis values in the test report.

9.3.7.4 Failure to

meet the specified range may require retests unless the audit problems are

resolved. However, if the audit results do not affect the compliance or

noncompliance status of the affected facility, the Administrator may waive the

reanalysis requirement, further audits, or retests and accept the results of

the compliance test. While steps are being taken to resolve audit analysis

problems, the Administrator may also choose to use the data to determine the

compliance or noncompliance status of the affected facility.

10.0 Calibration and Standardization.

10.1 Sampling Train Calibration.

Perform

calibrations described in Method 5, (40 CFR Part 60, Appendix A). The alternate

calibration procedures described in Method 5, may also be used.

10.2 ICP Calibration.

10.2.1 Calibrate

the instrument according to the instrument manufacturer's recommended

procedures, using a calibration blank and three standards for the initial

calibration.

10.2.2 Calibration

standards should be prepared fresh daily, as described in Section 7.3.8. Be

sure that samples and calibration standards are matrix matched. Flush the

system with the calibration blank between each standard.

10.2.3 Use the

average intensity of multiple exposures (3 or more) for both standardization

and sample analysis to reduce random error.

10.2.4 Employing

linear regression, calculate the correlation coefficient .

10.2.5 The

correlation coefficient must equal or exceed 0.995.

10.2.6 If

linearity is not acceptable, prepare and rerun another set of calibration

standards or reduce the range of the calibration standards, as necessary.

10.3 GFAAS Calibration.

10.3.1 For

instruments that measure directly in concentration, set the instrument software

to display the correct concentration, if applicable.

10.3.2 Curve must

be linear in order to correctly perform the method of standard additions which

is customarily performed automatically with most instrument computer-based data

systems.

10.3.3 The

calibration curve (direct calibration or standard additions) must be prepared

daily with a minimum of a calibration blank and three standards that are

prepared fresh daily.

10.3.4 The

calibration curve acceptance criteria must equal or exceed 0.995.

10.3.5 If

linearity is not acceptable, prepare and rerun another set of calibration

standards or reduce the range of calibration standards, as necessary.

10.4 IC/PCR Calibration.

10.4.1 Prepare a

calibration curve using the calibration blank and three calibration standards

prepared fresh daily as described in Section 7.3.8.

10.4.2 The

calibration curve acceptance criteria must equal or exceed 0.995.

10.4.3 If

linearity is not acceptable, remake and/or rerun the calibration standards. If

the calibration curve is still unacceptable, reduce the range of the curve.

10.4.4 Analyze the

standards with the field samples as described in Section 11.6.

11.0 Analytical Procedures.

NOTE: The method determines the chromium

concentration in µg Cr/mL. It is important that the analyst measure the field

sample volume prior to analyzing the sample. This will allow for conversion of

µg Cr/mL to µg Cr/sample.

11.1 ICP Sample Preparation.

11.1.1 The ICP

analysis is performed directly on the alkaline impinger solution; acid

digestion is not necessary, provided the samples and standards are matrix

matched.

11.1.2 The ICP

analysis should only be employed when the solution analyzed has a Cr

concentration greater than 35 µg/L or five times the method detection limit as

determined according to Appendix B in 40 CFR Part 136 or by other commonly

accepted analytical procedures.

11.2 ICP Sample Analysis.

11.2.1 The ICP analysis is applicable for the determination of total chromium only.

11.2.2 ICP Blanks.

Two types of

blanks are required for the ICP analysis.

11.2.2.1

Calibration Blank. The calibration blank is used in establishing the

calibration curve. For the calibration blank, use either 0.1 N NaOH or 0.1 N

NaHCO3, whichever is used for the impinger

absorbing solution. The calibration blank can be prepared fresh in the

laboratory; it does not have to be prepared from the same batch of solution

that was used in the field. A sufficient quantity should be prepared to flush

the system between standards and samples.

11.2.2.2 Field

Reagent Blank. The field reagent blank is collected in the field during the

testing program. The field reagent blank (Section 8.2.4) is an aliquot of the

absorbing solution prepared in Section 7.1.2. The reagent blank is used to

assess possible contamination resulting from sample processing.

11.2.3 ICP Instrument Adjustment.

11.2.3.1 Adjust

the ICP instrument for proper operating parameters including wavelength,

background correction settings (if necessary), and interfering element

correction settings (if necessary).

11.2.3.2 The

instrument must be allowed to become thermally stable before beginning

measurements (usually requiring at least 30 min of operation prior to

calibration). During this warmup period, the optical calibration and torch

position optimization may be performed (consult the operator's manual).

11.2.4 ICP Instrument Calibration.

11.2.4.1 Calibrate

the instrument according to the instrument manufacturer's recommended

procedures, and the procedures specified in Section 10.2.

11.2.4.2 Prior to

analyzing the field samples, reanalyze the highest calibration standard as if

it were a sample.

11.2.4.3

Concentration values obtained should not deviate from the actual values or from

the established control limits by more than 5 percent, whichever is lower (see

Sections 9.1 and 10.2).

11.2.4.4 If they

do, follow the recommendations of the instrument manufacturer to correct the

problem.

11.2.5 ICP Operational Quality Control Procedures.

11.2.5.1 Flush the

system with the calibration blank solution for at least 1 min before the

analysis of each sample or standard.

11.2.5.2 Analyze

the continuing check standard and the calibration blank after each batch of 10

samples.

11.2.5.3 Use the

average intensity of multiple exposures for both standardization and sample

analysis to reduce random error.

11.2.6 ICP Sample Dilution.

11.2.6.1 Dilute

and reanalyze samples that are more concentrated than the linear calibration

limit or use an alternate, less sensitive Cr wavelength for which quality

control data have already been established.

11.2.6.2 When

dilutions are performed, the appropriate factors must be applied to sample

measurement results.

11.2.7 Reporting

Analytical Results. All analytical results should be reported in µg Cr/mL using

three significant figures. Field sample volumes (mL) must be reported also.

11.3 GFAAS Sample Preparation.

11.3.1 GFAAS Acid

Digestion. An acid digestion of the alkaline impinger solution is required for

the GFAAS analysis.

11.3.1.1 In a

beaker, add 10 mL of concentrated HNO3 to

a 100 mL sample aliquot that has been well mixed. Cover the beaker with a watch

glass. Place the beaker on a hot plate and reflux the sample to near dryness.

Add another 5 mL of concentrated HNO3 to

complete the digestion. Again, carefully reflux the sample volume to near

dryness. Rinse the beaker walls and watch glass with reagent water.

11.3.1.2 The final

concentration of HNO3

in the solution should be 1

percent (v/v).

11.3.1.3 Transfer

the digested sample to a 50-mL volumetric flask. Add 0.5 mL of concentrated HNO3 and 1 mL of the 10 µg/mL of Ca(NO3)2.

Dilute to 50 mL with reagent water.

11.3.2 HNO3 Concentration. A different final volume may

be used based on the expected Cr concentration, but the HNO3 concentration must be maintained at 1 percent

(v/v).

11.4 GFAAS Sample Analysis.

11.4.1 The GFAAS analysis is applicable for the determination of total chromium only.

11.4.2 GFAAS Blanks.

Two types of

blanks are required for the GFAAS analysis.

11.4.2.1

Calibration Blank. The 1.0 percent HNO3 is

the calibration blank which is used in establishing the calibration curve.

11.4.2.2 Field

Reagent Blank. An aliquot of the 0.1 N NaOH solution or the 0.1 N NaHCO3 prepared in Section 7.1.2 is collected for

the field reagent blank. The field reagent blank is used to assess possible

contamination resulting from processing the sample.

11.4.2.2.1 The

reagent blank must be subjected to the entire series of sample preparation and

analytical procedures, including the acid digestion.

11.4.2.2.2 The

reagent blank's final solution must contain the same acid concentration as the

sample solutions.

11.4.3 GFAAS Instrument Adjustment.

11.4.3.1 The 357.9

nm wavelength line shall be used.

11.4.3.2 Follow

the manufacturer's instructions for all other spectrophotometer operating

parameters.

11.4.4 Furnace Operational Parameters.

Parameters

suggested by the manufacturer should be employed as guidelines.

11.4.4.1

Temperature-sensing mechanisms and temperature controllers can vary between

instruments and/or with time; the validity of the furnace operating parameters

must be periodically confirmed by systematically altering the furnace parameters

while analyzing a standard. In this manner, losses of analyte due to

higher-than-necessary temperature settings or losses in sensitivity due to less

than optimum settings can be minimized.

11.4.4.2 Similar

verification of furnace operating parameters may be required for complex sample

matrices (consult instrument manual for additional information). Calibrate the

GFAAS system following the procedures specified in Section 10.3.

11.4.5 GFAAS Operational Quality Control Procedures.

11.4.5.1 Introduce

a measured aliquot of digested sample into the furnace and atomize.

11.4.5.2 If the

measured concentration exceeds the calibration range, the sample should be

diluted with the calibration blank solution (1.0 percent HNO3) and reanalyzed.

11.4.5.3 Consult the

operator's manual for suggested injection volumes. The use of multiple

injections can improve accuracy and assist in detecting furnace pipetting

errors.

11.4.5.4 Analyze a

minimum of one matrix-matched reagent blank per sample batch to determine if

contamination or any memory effects are occurring.

11.4.5.5 Analyze a

calibration blank and a continuing check standard after approximately every

batch of 10 sample injections.

11.4.6 GFAAS Sample Dilution.

11.4.6.1 Dilute

and reanalyze samples that are more concentrated than the instrument

calibration range.

11.4.6.2 If

dilutions are performed, the appropriate factors must be applied to sample

measurement results.

11.4.7 Reporting Analytical Results.

11.4.7.1 Calculate

the Cr concentrations by the method of standard additions (see operator's

manual) or, from direct calibration. All dilution and/or concentration factors

must be used when calculating the results.

11.4.7.2

Analytical results should be reported in µg Cr/mL using three significant

figures. Field sample volumes (mL) must be reported also.

11.5 IC/PCR Sample Preparation.

11.5.1 Sample pH.

Measure and record

the sample pH prior to analysis.

11.5.2 Sample Filtration.

Prior to

preconcentration and/or analysis, filter all field samples through a 0.45-µm

filter. The filtration step should be conducted just prior to sample

injection/analysis.

11.5.2.1 Use a

portion of the sample to rinse the syringe filtration unit and acetate filter

and then collect the required volume of filtrate.

11.5.2.2 Retain

the filter if total Cr is to be determined also.

11.5.3 Sample Preconcentration (older instruments).

11.5.3.1 For older

instruments, a preconcentration system may be used in conjunction with the

IC/PCR to increase sensitivity for trace levels of Cr+6.

11.5.3.2 The

preconcentration is accomplished by selectively retaining the analyte on a

solid absorbent, followed by removal of the analyte from the absorbent (consult

instrument manual).

11.5.3.3 For a

manual system, position the injection valve so that the eluent displaces the

concentrated Cr+6

sample, transferring it from the

preconcentration column and onto the IC anion separation column.

11.6 IC/PCR Sample Analyses.

11.6.1 The IC/PCR analysis is applicable for hexavalent chromium measurements only.

11.6.2 IC/PCR Blanks.

Two types of

blanks are required for the IC/PCR analysis.

11.6.2.1

Calibration Blank. The calibration blank is used in establishing the analytical

curve. For the calibration blank, use either 0.1 N NaOH or 0.1 N NaHCO3, whichever is used for the impinger

solution. The calibration blank can be prepared fresh in the laboratory; it

does not have to be prepared from the same batch of absorbing solution that is

used in the field.

11.6.2.2 Field

Reagent Blank. An aliquot of the 0.1 N NaOH solution or the 0.1 N NaHCO3 solution prepared in Section 7.1.2 is

collected for the field reagent blank. The field reagent blank is used to

assess possible contamination resulting from processing the sample.

11.6.3 Stabilized Baseline.

Prior to sample

analysis, establish a stable baseline with the detector set at the required

attenuation by setting the eluent and post-column reagent flow rates according

to the manufacturers recommendations.

NOTE: As long as the ratio of eluent flow rate to

PCR flow rate remains constant, the standard curve should remain linear. Inject

a sample of reagent water to ensure that no Cr+6 appears

in the water blank.

11.6.4 Sample Injection Loop.

Size of injection

loop is based on standard/sample concentrations and the selected attenuator

setting.

11.6.4.1 A 50-µL

loop is normally sufficient for most higher concentrations.

11.6.4.2 The

sample volume used to load the injection loop should be at least 10 times the

loop size so that all tubing in contact with the sample is thoroughly flushed

with the new sample to prevent cross contamination.

11.6.5 IC/PCR Instrument Calibration.

11.6.5.1 First,

inject the calibration standards prepared, as described in Section 7.3.8 to

correspond to the appropriate concentration range, starting with the lowest

standard first.

11.6.5.2 Check the

performance of the instrument and verify the calibration using data gathered

from analyses of laboratory blanks, calibration standards, and a quality

control sample.

11.6.5.3 Verify

the calibration by analyzing a calibration reference standard. If the measured

concentration exceeds the established value by more than 10 percent, perform a

second analysis. If the measured concentration still exceeds the established

value by more than 10 percent, terminate the analysis until the problem can be

identified and corrected.

11.6.6 IC/PCR Instrument Operation.

11.6.6.1 Inject

the calibration reference standard (as described in Section 9.3.1), followed by

the field reagent blank (Section 8.2.4), and the field samples.

11.6.6.1.1

Standards (and QC standards) and samples are injected into the sample loop of

the desired size (use a larger size loop for greater sensitivity). The Cr+6 is collected on the resin bed of the column.

11.6.6.1.2 After

separation from other sample components, the Cr+6 forms

a specific complex in the post-column reactor with the DPC reaction solution,

and the complex is detected by visible absorbance at a maximum wavelength of

540 nm.

11.6.6.1.3 The

amount of absorbance measured is proportional to the concentration of the Cr+6 complex formed.

11.6.6.1.4 The IC

retention time and the absorbance of the Cr+6 complex

with known Cr+6 standards analyzed under identical conditions

must be compared to provide both qualitative and quantitative analyses.

11.6.6.1.5 If a

sample peak appears near the expected retention time of the Cr+6 ion, spike the sample according to Section

9.3.4 to verify peak identity.

11.6.7 IC/PCR Operational Quality Control Procedures.

11.6.7.1 Samples

should be at a pH >8.5 for NaOH and >8.0 if using NaHCO3; document any discrepancies.

11.6.7.2

Refrigerated samples should be allowed to equilibrate to ambient temperature

prior to preparation and analysis.

11.6.7.3 Repeat

the injection of the calibration standards at the end of the analytical run to

assess instrument drift. Measure areas or heights of the Cr+6/DPC complex chromatogram peaks.

11.6.7.4 To ensure

the precision of the sample injection (manual or autosampler), the response for

the second set of injected standards must be within 10 percent of the average

response.

11.6.7.5 If the 10

percent criteria duplicate injection cannot be achieved, identify the source of

the problem and rerun the calibration standards.

11.6.7.6 Use peak

areas or peak heights from the injections of calibration standards to generate

a linear calibration curve. From the calibration curve, determine the

concentrations of the field samples.

11.6.8 IC/PCR Sample Dilution.

11.6.8.1 Samples

having concentrations higher than the established calibration range must be

diluted into the calibration range and re-analyzed.

11.6.8.2 If

dilutions are performed, the appropriate factors must be applied to sample

measurement results.

11.6.9 Reporting Analytical Results.

Results should be

reported in µg Cr+6/mL using three significant figures. Field

sample volumes (mL) must be reported also.

12.0 Data Analysis and Calculations.

12.1 Pretest Calculations.

12.1.1 Pretest Protocol (Site Test Plan).

12.1.1.1 The

pretest protocol should define and address the test data quality objectives

(DQOs), with all assumptions, that will be required by the end user

(enforcement authority); what data are needed? why are the data needed? how

will the data be used? what are method

detection limits?

and what are estimated target analyte levels for the following test parameters.

12.1.1.1.1

Estimated source concentration for total chromium and/or Cr+6.

12.1.1.1.2

Estimated minimum sampling time and/or volume required to meet method detection

limit requirements (Appendix B 40 CFR Part 136) for measurement of total

chromium and/or Cr+6.

12.1.1.1.3

Demonstrate that planned sampling parameters will meet DQOs. The protocol must

demonstrate that the planned sampling parameters calculated by the tester will

meet the needs of the source and the enforcement authority.

12.1.1.2 The

pre-test protocol should include information on equipment, logistics,

personnel, process operation, and other resources necessary for an efficient

and coordinated test.

12.1.1.3 At a

minimum, the pre-test protocol should identify and be approved by the source,

the tester, the analytical laboratory, and the regulatory enforcement

authority. The tester should not proceed with the compliance testing before

obtaining approval from the enforcement authority.

12.1.2 Post Test Calculations.

12.1.2.1 Perform

the calculations, retaining one extra decimal figure beyond that of the

acquired data. Round off figures after final calculations.

12.1.2.2

Nomenclature.

CS = Concentration of Cr in sample solution, µg

Cr/mL.

Ccr = Concentration of Cr in stack gas, dry

basis, corrected to standard conditions, mg/dscm.

D = Digestion

factor, dimension less.

F = Dilution

factor, dimension less.

MCr = Total Cr in each sample, µg.

Vad = Volume of sample aliquot after digestion,

mL.

Vaf = Volume of sample aliquot after dilution,

mL.

Vbd = Volume of sample aliquot submitted to

digestion, mL.

Vbf = Volume of sample aliquot before dilution,

mL.

VmL = Volume of impinger contents plus rinses,

mL.

Vm(std) = Volume of gas sample measured by the dry

gas meter, corrected to standard conditions, dscm.

12.1.2.3 Dilution

Factor. The dilution factor is the ratio of the volume of sample aliquot after

dilution to the volume before dilution. This ratio is given by the following

equation:

12.1.2.4 Digestion

Factor. The digestion factor is the ratio of the volume of sample aliquot after

digestion to the volume before digestion. This ratio is given by Equation

306-2.

12.1.2.5 Total Cr

in Sample. Calculate MCr, the total µg Cr in each sample, using the

following equation:

![]()

12.1.2.6 Average

Dry Gas Meter Temperature and Average Orifice Pressure Drop. Same as Method 5.

12.1.2.7 Dry Gas

Volume, Volume of Water Vapor, Moisture Content. Same as Method 5.

12.1.2.8 Cr

Emission Concentration (CCr). Calculate CCr,

the Cr concentration in the stack gas, in mg/dscm on a dry basis, corrected to

standard conditions using the following equation:

12.1.2.9

Isokinetic Variation, Acceptable Results. Same as Method 5.

13.0 Method Performance.

13.1 Range.

The recommended

working range for all of the three analytical techniques starts at five times

the analytical detection limit (see also Section 13.2.2). The upper limit of

all three techniques can be extended indefinitely by appropriate dilution.

13.2 Sensitivity.

13.2.1 Analytical

Sensitivity. The estimated instrumental detection limits listed are provided as

a guide for an instrumental limit. The actual method detection limits are

sample and instrument dependent and may vary as the sample matrix varies.

13.2.1.2 ICP

Analytical Sensitivity. The minimum estimated detection limits for ICP, as

reported in Method 6010A and the recently revised Method 6010B of SW-846

(Reference 1), are 7.0 µg Cr/L and 4.7 µg Cr/L, respectively.

13.2.1.3 GFAAS

Analytical Sensitivity. The minimum estimated detection limit for GFAAS, as

reported in Methods 7000A and 7191 of SW-846 (Reference 1), is 1 µg Cr/L.

13.2.1.4 IC/PCR

Analytical Sensitivity. The minimum detection limit for IC/PCR with a

preconcentrator, as reported in Methods 0061 and 7199 of SW-846 (Reference 1),

is 0.05 µg Cr+6/L.

1.3.2.1.5

Determination of Detection Limits. The laboratory performing the Cr+6 measurements must determine the method

detection limit on a quarterly basis using a suitable procedure such as that

found in 40 CFR, Part 136, Appendix B. The determination should be made on

samples in the appropriate alkaline matrix. Normally this involves the

preparation (if applicable) and consecutive measurement of seven (7) separate

aliquots of a sample with a concentration <5 times the expected detection

limit. The detection limit is 3.14 times the standard deviation of these

results.

13.2.2 In-stack

Sensitivity. The in-stack sensitivity depends upon the analytical detection

limit, the volume of stack gas sampled, the total volume of the impinger

absorbing solution plus the rinses, and, in some cases, dilution or

concentration factors from sample preparation. Using the analytical detection

limits given in Sections 13.2.1.1, 13.2.1.2, and 13.2.1.3; a stack gas sample

volume of 1.7 dscm; a total liquid sample volume of 500 mL; and the digestion

concentration factor of 1/2 for the GFAAS analysis; the corresponding in-stack

detection limits are 0.0014 mg Cr/dscm to 0.0021 mg Cr/dscm for ICP, 0.00015 mg Cr/dscm for GFAAS, and 0.000015 mg Cr+6/dscm for IC/PCR with preconcentration.

NOTE: It is recommended that the concentration of

Cr in the analytical solutions be at least five times the analytical detection

limit to optimize sensitivity in the analyses. Using this guideline and the

same assumptions for impinger sample volume, stack gas sample volume, and the

digestion concentration factor for the GFAAS analysis (500 mL,1.7 dscm, and

1/2, respectively), the recommended minimum stack concentrations for optimum sensitivity

are 0.0068 mg Cr/dscm to 0.0103 mg Cr/dscm for ICP, 0.00074 mg Cr/dscm for

GFAAS, and 0.000074 mg Cr+6/dscm

for IC/PCR with preconcentration.

If required, the in-stack detection limits can be improved by either increasing

the stack gas sample volume, further reducing the volume of the digested sample

for GFAAS, improving the analytical detection limits, or any combination of the

three.

13.3 Precision.

13.3.1 The

following precision data have been reported for the three analytical methods.

In each case, when the sampling precision is combined with the reported

analytical precision, the resulting overall precision may decrease.

13.3.2 Bias data

is also reported for GFAAS.

13.4 ICP Precision.

13.4.1 As reported

in Method 6010B of SW-846 (Reference 1), in an EPA round-robin Phase 1 study,

seven laboratories applied the ICP technique to acid/distilled water matrices

that had been spiked with various metal concentrates. For true values of 10,

50, and 150 µg Cr/L; the mean reported values were 10, 50, and 149 µg Cr/L; and

the mean percent relative standard deviations were 18, 3.3, and 3.8 percent,

respectively.

13.4.2 In another

multi laboratory study cited in Method 6010B, a mean relative standard of 8.2

percent was reported for an aqueous sample concentration of approximately 3750

µg Cr/L.

13.5 GFAAS Precision.

As reported in

Method 7191 of SW-846 (Reference 1), in a single laboratory (EMSL), using

Cincinnati, Ohio tap water spiked at concentrations of 19, 48, and 77 µg Cr/L,

the standard deviations were ±0.1, ±0.2, and ±0.8, respectively. Recoveries at

these levels were 97 percent, 101 percent, and 102 percent, respectively.

13.6 IC/PCR Precision.

As reported in

Methods 0061 and 7199 of SW-846 (Reference 1), the precision of IC/PCR with

sample preconcentration is 5 to 10 percent. The overall precision for sewage

sludge incinerators emitting 120 ng/dscm of Cr+6 and

3.5 µg/dscm of total Cr was 25 percent and 9 percent, respectively; and for

hazardous waste incinerators emitting 300 ng/dscm of Cr+6 the precision was 20 percent.

14.0 Pollution Prevention.

14.1 The only

materials used in this method that could be considered pollutants are the

chromium standards used for instrument calibration and acids used in the

cleaning of the collection and measurement containers/labware, in the

preparation of standards, and in the acid digestion of samples. Both reagents