METHOD 27 -

DETERMINATION OF VAPOR TIGHTNESS OF GASOLINE DELIVERY TANK USING PRESSURE

VACUUM TEST

3.1 Allowable pressure

change (¥p)

3.2 Allowable vacuum

change (¥v)

3.5 Delivery tank vapor

collection equipment

3.9 Time period of the

pressure or vacuum test (t)

7.0 Reagents and

Standards. [Reserved]

8.0 Sample Collection,

Preservation, Storage, and Transport.

10.0 Calibration and

Standardization. [Reserved]

11.0 Analytical

Procedures. [Reserved]

12.0 Data Analysis and

Calculations. [Reserved]

14.0 Pollution

Prevention. [Reserved]

15.0 Waste Management.

[Reserved]

18.0 Tables, Diagrams,

Flowcharts, and Validation Data.

[Reserved]

1.0 Scope and Application.

1.1 Applicability. This

method is applicable for the determination of vapor tightness of a gasoline

delivery tank which is equipped with vapor collection equipment.

2.0 Summary of Method.

2.1 Pressure and

vacuum are applied alternately to the compartments of a gasoline delivery tank

and the change in pressure or vacuum is recorded after a specified period of

time.

3.0 Definitions.

3.1 Allowable pressure change (¥p)

Means the allowable

amount of decrease in pressure during the static pressure test, within the time

period t, as specified in the appropriate regulation, in mm H2O.

3.2 Allowable vacuum change (¥v)

Means the allowable

amount of decrease in vacuum during the static vacuum test, within the time

period t, as specified in the appropriate regulation, in mm H2O.

3.3 Compartment

Means a liquid-tight

division of a delivery tank.

3.4 Delivery tank

Means a container,

including associated pipes and fittings, that is attached to or forms a part of

any truck, trailer, or railcar used for the transport of gasoline.

3.5 Delivery tank vapor collection equipment

Means any piping,

hoses, and devices on the delivery tank used to collect and route gasoline

vapors either from the tank to a bulk terminal vapor control system or from a

bulk plant or service station into the tank.

3.6 Gasoline

Means a petroleum

distillate or petroleum distillate/alcohol blend having a Reid vapor pressure

of 27.6 kilopascals or greater which is used as a fuel for internal combustion

engines.

3.7 Initial pressure (Pi)

Means the pressure

applied to the delivery tank at the beginning of the static pressure test, as

specified in the appropriate regulation, in mm H2O.

3.8 Initial vacuum (Vi)

Means the vacuum

applied to the delivery tank at the beginning of the static vacuum test, as

specified in the appropriate regulation, in mm H2O.

3.9 Time period of the pressure or vacuum test (t)

Means the time period

of the test, as specified in the appropriate regulation, during which the

change in pressure or vacuum is monitored, in minutes.

4.0 Interferences. [Reserved]

5.0 Safety.

5.1 Gasoline contains

several volatile organic compounds (e.g. benzene and hexane) which presents a

potential for fire and/or explosions. It is advisable to take appropriate

precautions when testing a gasoline vessel's vapor tightness, such as

refraining from smoking and using explosion-proof equipment.

5.2 This method may

involve hazardous materials, operations, and equipment. This test method my not

address all of the safety problems associated with its use. It is the

responsibility of the user of this test method to establish appropriate safety

and health practices and determine the applicability of regulatory limitations

prior to performing this test method

6.0 Equipment and Supplies.

The following

equipment and supplies are required for testing:

6.1 Pressure Source.

Pump or compressed gas cylinder of air or inert gas sufficient to pressurize

the delivery tank to 500 mm (20 in.) H2O above

atmospheric pressure.

6.2 Regulator. Low

pressure regulator for controlling pressurization of the delivery tank.

6.3 Vacuum Source.

Vacuum pump capable of evacuating the delivery tank to 250 mm (10 in.) H2O below atmospheric pressure.

6.4 Pressure-Vacuum

Supply Hose.

6.5 Manometer. Liquid

manometer, or equivalent instrument, capable of measuring up to 500 mm (20 in.)

H2O gauge pressure with ± 2.5 mm (0.1 in.) H2O precision.

6.6 Pressure-Vacuum

Relief Valves. The test apparatus shall be equipped with an inline

pressure-vacuum relief valve set to activate at 675 mm (26.6 in.) H2O above atmospheric pressure or 250 mm (10 in.) H2O below atmospheric pressure, with a capacity equal to the

pressurizing or evacuating pumps.

6.7 Test Cap for

Vapor Recovery Hose. This cap shall have a tap for manometer connection and a fitting

with shutoff valve for connection to the pressure-vacuum supply hose.

6.8 Caps for Liquid

Delivery Hoses.

7.0 Reagents and Standards. [Reserved]

8.0 Sample Collection, Preservation, Storage, and Transport.

8.1 Pretest Preparations.

8.1.1 Summary.

Testing problems may occur due to the presence of volatile vapors and/or

temperature fluctuations inside the delivery tank. Under these conditions, it

is often difficult to obtain a stable initial pressure at the beginning of a

test, and erroneous test results may occur. To help prevent this, it is

recommended that prior to testing, volatile vapors be removed from the tank and

the temperature inside the tank be allowed to stabilize. Because it is not

always possible to completely attain these pretest conditions, a provision to

ensure reproducible results is included. The difference in results for two

consecutive runs must meet the criteria in Sections 8.2.2.5 and 8.2.3.5.

8.1.2 Emptying of

Tank. The delivery tank shall be emptied of all liquid.

8.1.3 Purging of

Vapor. As much as possible the delivery tank shall be purged of all volatile

vapors by any safe, acceptable method. One method is to carry a load of

non-volatile liquid fuel, such as diesel or heating oil, immediately prior to

the test, thus flushing out all the volatile gasoline vapors. A second method

is to remove the volatile vapors by blowing ambient air into each tank

compartment for at least 20 minutes. This second method is usually not as

effective and often causes stabilization problems, requiring a much longer time

for stabilization during the testing.

8.1.4 Temperature

Stabilization. As much as possible, the test shall be conducted under

isothermal conditions. The temperature of the delivery tank should be allowed

to equilibrate in the test environment. During the test, the tank should be

protected from extreme environmental and temperature variability, such as

direct sunlight.

8.2 Test Procedure.

8.2.1 Preparations.

8.2.1.1 Open and

close each dome cover.

8.2.1.2 Connect static

electrical ground connections to the tank. Attach the liquid delivery and vapor

return hoses, remove the liquid delivery elbows, and plug the liquid delivery

fittings.

NOTE: The purpose of testing the liquid delivery hoses

is to detect tears or holes that would allow liquid leakage during a delivery.

Liquid delivery hoses are not considered to be possible sources of vapor

leakage, and thus, do not have to be attached for a vapor leakage test.

Instead, a liquid delivery hose could be either visually inspected, or filled

with water to detect any liquid leakage.

8.2.1.3 Attach the

test cap to the end of the vapor recovery hose.

8.2.1.4 Connect the

pressure-vacuum supply hose and the pressure-vacuum relief valve to the

shut-off valve. Attach a manometer to the pressure tap.

8.2.1.5 Connect

compartments of the tank internally to each other if possible. If not possible,

each compartment must be tested separately, as if it were an individual

delivery tank.

8.2.2 Pressure Test.

8.2.2.1 Connect the pressure

source to the pressure vacuum supply hose.

8.2.2.2 Open the

shut-off valve in the vapor recovery hose cap. Apply air pressure slowly,

pressurize the tank to Pi, the initial pressure specified in the

regulation.

8.2.2.3 Close the

shut-off and allow the pressure in the tank to stabilize, adjusting the

pressure if necessary to maintain pressure of Pi.

When the pressure stabilizes, record the time and initial pressure.

8.2.2.4 At the end of

the time period (t) specified in the regulation, record the time and final

pressure.

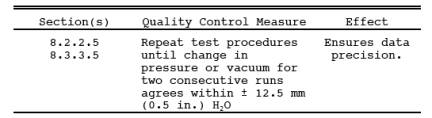

8.2.2.5 Repeat steps

8.2.2.2 through 8.2.2.4 until the change in pressure for two consecutive runs

agrees within 12.5 mm (0.5 in.) H2O.

Calculate the arithmetic average of the two results.

8.2.2.6 Compare the

average measured change in pressure to the allowable pressure change, ¥ p,

specified in the regulation. If the delivery tank does not satisfy the vapor

tightness criterion specified in the regulation, repair the sources of leakage,

and repeat the pressure test until the criterion is met.

8.2.2.7 Disconnect

the pressure source from the pressure-vacuum supply hose, and slowly open the

shut-off valve to bring the tank to atmospheric pressure.

8.2.3 Vacuum Test.

8.2.3.1 Connect the

vacuum source to the pressure vacuum supply hose.

8.2.3.2 Open the

shut-off valve in the vapor recovery hose cap. Slowly evacuate the tank to Vi, the initial vacuum specified in the regulation.

8.2.3.3 Close the

shut-off valve and allow the pressure in the tank to stabilize, adjusting the

pressure if necessary to maintain a vacuum of Vi.

When the pressure stabilizes, record the time and initial vacuum.

8.2.3.4 At the end of

the time period specified in the regulation (t), record the time and final

vacuum.

8.2.3.5 Repeat steps 8.2.3.2

through 8.2.3.4 until the change in vacuum for two consecutive runs agrees

within 12.5 mm (0.5 in.) H2O. Calculate the arithmetic average of the two

results.

8.2.3.6 Compare the

average measured change in vacuum to the allowable vacuum change, ¥ v, as specified in the regulation. If

the delivery tank does not satisfy the vapor tightness criterion specified in

the regulation, repair the sources of leakage, and repeat the vacuum test until

the criterion is met.

8.2.3.7 Disconnect

the vacuum source from the pressure-vacuum supply hose, and slowly open the

shut-off valve to bring the tank to atmospheric pressure.

8.2.4 Post-Test

Clean-up. Disconnect all test equipment and return the delivery tank to its

pretest condition.

9.0 Quality Control.

10.0 Calibration and Standardization. [Reserved]

11.0 Analytical Procedures. [Reserved]

12.0 Data Analysis and Calculations. [Reserved]

13.0 Method Performance.

13.1 Precision. The

vapor tightness of a gasoline delivery tank under positive or negative pressure,

as measured by this method, is precise within 12.5 mm (0.5 in.) H2O.

13.2 Bias. No bias

has been identified.

14.0 Pollution Prevention. [Reserved]

15.0 Waste Management. [Reserved]

16.0 Alternative Procedures.

16.1 The pumping of water

into the bottom of a delivery tank is an acceptable alternative to the pressure

source described above. Likewise, the draining of water out of the bottom of a

delivery tank may be substituted for the vacuum source. Note that some of the

specific step-by-step procedures in the method must be altered slightly to

accommodate these different pressure and vacuum sources.

16.2 Techniques other

than specified above may be used for purging and pressurizing a delivery tank,

if prior approval is obtained from the Administrator. Such approval will be

based upon demonstrated equivalency with the above method.

17.0 References. [Reserved]

18.0 Tables, Diagrams, Flowcharts, and Validation Data. [Reserved]