METHOD 24A - DETERMINATION OF VOLATILE MATTER CONTENT AND DENSITY OF PUBLICATION ROTOGRAVURE INKS AND RELATED PUBLICATION ROTOGRAVURE COATINGS

8.0 Sample Collection,

Preservation, Storage, and Transport.

9.0 Quality Control.

[Reserved]

10.0 Calibration and

Standardization. [Reserved]

11.2 Ink or Related

Coating Density.

12.0 Calculations and

Data Analysis.

13.0 Method

Performance. [Reserved]

14.0 Pollution

Prevention. [Reserved]

15.0 Waste Management.

[Reserved]

17.0 Tables, Diagrams,

Flowcharts, and Validation Data. [Reserved]

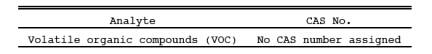

1.0 Scope and Application.

1.1 Analytes.

1.2 Applicability.

This method is applicable for the determination of the VOC content and density

of solvent-borne (solvent-reducible) publication rotogravure inks and related

publication rotogravure coatings.

2.0 Summary of Method.

2.1 Separate

procedures are used to determine the VOC weight fraction and density of the ink

or related coating and the density of the solvent in the ink or related

coating. The VOC weight fraction is determined by measuring the weight loss of

a known sample quantity which has been heated for a specified length of time at

a specified temperature. The density of both the ink or related coating and

solvent are measured by a standard procedure. From this information, the VOC

volume fraction is calculated.

3.0 Definitions. [Reserved]

4.0 Interferences. [Reserved]

5.0 Safety.

5.1 Disclaimer.

This method may

involve hazardous materials, operations, and equipment. This test method does

not purport to address all of the safety problems associated with its use. It

is the responsibility of the user of this test method to establish appropriate

safety and health practices and to determine the applicability of regulatory

limitations prior to performing this test method.

5.2 Hazardous Components.

Some of the compounds

that may be contained in the inks or related coatings analyzed by this method

may be irritating or corrosive to tissues or may be toxic. Nearly all are fire

hazards. Appropriate precautions can be found in reference documents, such as

Reference 6 of Section 16.0.

6.0 Equipment and Supplies.

The following

equipment and supplies are required for sample analysis:

6.1 Weighing Dishes.

Aluminum foil, 58 mm (2.3 in.) in diameter by 18 mm (0.7 in.) high, with a flat

bottom. There must be at least three weighing dishes per sample.

6.2 Disposable

Syringe. 5 ml.

6.3 Analytical

Balance. To measure to within 0.1 mg.

6.4 Oven. Vacuum oven

capable of maintaining a temperature of 120 ± 2 ûC (248 ± 4 ûF) and an absolute

pressure of 510 ± 51 mm Hg (20 ± 2 in. Hg) for 4 hours. Alternatively, a forced draft oven capable of maintaining

a temperature of 120 ± 2 ûC (248 ± 4 ûF) for 24 hours.

6.5 The equipment and

supplies specified in ASTM D 1475- 60, 80, or 90 (incorporated by reference -

see ¤60.17).

7.0 Reagents and Standards.

7.1 The reagents and standards

specified in ASTM D 1475-60, 80, or 90 are required.

8.0 Sample Collection, Preservation, Storage, and Transport.

8.1 Follow the sample

collection, preservation, storage, and transport procedures described in

Reference 4 of Section 16.0.

9.0 Quality Control. [Reserved]

10.0 Calibration and Standardization. [Reserved]

11.0 Analytical Procedure.

Additional guidance

can be found in Reference 5 of Section 16.0.

11.1 VOC Weight Fraction.

Shake or mix the ink

or related coating sample thoroughly to assure that all the solids are

completely suspended. Label and weigh to the nearest 0.1 mg a weighing dish and

record this weight (Mx1). Using a 5 ml syringe, without a needle,

extract an aliquot from the ink or related coating sample. Weigh the syringe

and aliquot to the nearest 0.1 mg and record this weight (Mcy1). Transfer 1 to 3 g of the aliquot to the tared

weighing dish. Reweigh the syringe and remaining aliquot to the nearest 0.1 mg

and record this weight (Mcy2). Heat the weighing dish with the transferred

aliquot in a vacuum oven at an absolute pressure of 510 ± 51 mm Hg (20 ± 2 in.

Hg) and a temperature of 120 ± 2 ûC (248 ± 4 ûF) for 4 hours. Alternatively,

heat the weighing dish with the transferred aliquot in a forced draft oven at a

temperature of 120 ± 2 ûC for 24 hours. After the weighing dish has cooled,

reweigh it to the nearest 0.1 mg and record the weight (Mx2). Repeat this procedure two times for each ink or related coating

sample, for a total of three samples.

11.2 Ink or Related Coating Density.

Determine the density

of the ink or related coating (Dc) according to the

procedure outlined in ASTM D 1475. Make a total of three determinations for

each ink or related coating sample. Report the ink or related coating density

as the arithmetic average (øDc) of the three

determinations.

11.3 Solvent Density.

Determine the density

of the solvent (Do) according to the procedure outlined in ASTM D

1475. Make a total of three determinations for each ink or related coating

sample. Report the solvent density as the arithmetic average (øDo) of the three determinations.

12.0 Calculations and Data Analysis.

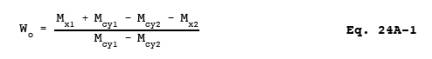

12.1 VOC Weight

Fraction. For each determination, calculate the volatile organic content weight

fraction (Wo) using the following equation: Make a total of

three determinations. Report the VOC weight fraction as the arithmetic average

(øWo) of the three determinations.

12.2 VOC Volume

Fraction. Calculate the volume fraction volatile organic content (Vo) using the following equation:

13.0 Method Performance. [Reserved]

14.0 Pollution Prevention. [Reserved]

15.0 Waste Management. [Reserved]

16.0 References.

1. Standard Test

Method for Density of Paint, Varnish, Lacquer, and Related Products. ASTM Designation

D 1475.

2. Teleconversation.

Wright, Chuck, Inmont Corporation with Reich, R., A., Radian Corporation.

September 25, 1979, Gravure Ink Analysis.

3. Teleconversation.

Oppenheimer, Robert, Gravure Research Institute with Burt, Rick, Radian Corporation,

November 5, 1979, Gravure Ink Analysis.

4. Standard Procedure

for Collection of Coating and Ink Samples for Analysis by Reference Methods 24

and 24A. EPA-340/1-91-010. U.S. Environmental Protection Agency, Stationary

Source Compliance Division, Washington, D.C. September 1991.

5. Standard Operating

Procedure for Analysis of Coating and Ink Samples by Reference Methods 24 and

24A. EPA-340/1-91-011. U.S. Environmental Protection Agency, Stationary Source

Compliance Division, Washington, D.C. September 1991.

6. Handbook of

Hazardous Materials: Fire, Safety, Health. Alliance of American Insurers.

Schaumberg, IL. 1983.

17.0 Tables, Diagrams, Flowcharts, and Validation Data. [Reserved]