Method 23 -

Determination of Polychlorinated Dibenzo-p-dioxins and Polychlorinated

Dibenzofurans from Municipal Waste Combustors

1.

APPLICABILITY AND PRINCIPLE

3.1.6 Chromic Acid

Cleaning Solution.

5.2 Sample Cleanup and

Fractionation.

7.1 Sampling Train

Collection Efficiency Check.

7.2 Internal Standard

Percent Recoveries.

7.3 Surrogate Standard

Recoveries.

8.3 Audit Sample

Availability.

1. APPLICABILITY AND PRINCIPLE

1.1 Applicability.

This method is

applicable to the determination of emissions of polychlorinated

dibenzo-p-dioxins (PCDD's) and polychlorinated dibenzofurans (PCDF's) from

stationary sources.

1.2 Principle.

A sample is

withdrawn isokinetically from the gas stream and collected in the sample probe,

on a glass fiber filter, and on a packed column of adsorbent material. The

sample cannot be separated into a particle and vapor fraction. The PCDD's and

PCDF's are extracted from the sample, separated by high resolution gas chromatography

(HRGC), and measured by high resolution mass spectrometry (HRMS).

2. APPARATUS

2.1 Sampling.

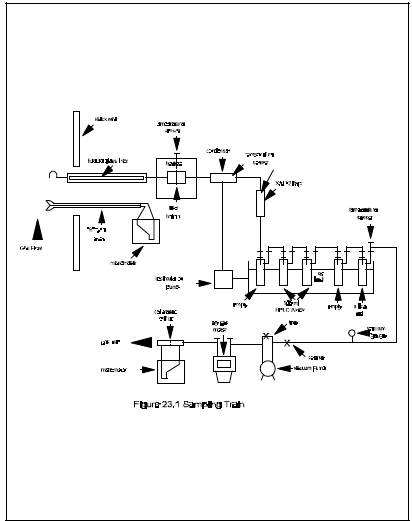

A schematic of the

sampling train is shown in Figure 23-1. Sealing greases may

not be used in assembling

the train. The train is identical to that described in Section 2.1 of Method 5 of this appendix with the following

additions:

2.1.1 Nozzle. The nozzle shall be made of nickel,

nickel-plated stainless steel, quartz, or borosilicate glass.

2.1.2 Sample

Transfer Lines. The sample

transfer lines, if needed, shall be heat traced, heavy walled TFE (1/2 in. OD

with 1/8 in. wall) with connecting fittings that are capable of forming leak

free, vacuum-tight connections without using sealing greases. The line shall be

as short as possible and must be maintained at 120¡C.

2.1.3 Filter

Support. Teflon or

Teflon-coated wire.

2.1.4

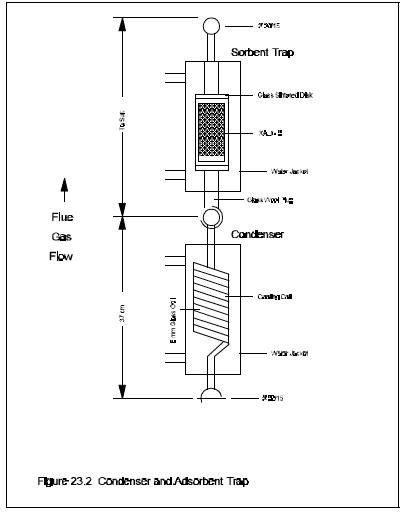

Condenser. Glass, coil type

with compatible fittings. A schematic diagram is shown in Figure

23-2.

2.1.5 Water

Bath. Thermostatically

controlled to maintain the gas temperature exiting the condenser at 20¡C

(68¡F).

2.1.6 Adsorbent

Module. Glass container to

hold the solid adsorbent. A schematic diagram is shown in Figure 23-2. Other

physical configurations of the resin trap/condenser assembly are acceptable.

The connecting fittings shall form leak-free, vacuum tight seals. No sealant

greases shall be used in the sampling train. A coarse glass frit is included to

retain the adsorbent.

2.2 Sample Recovery.

2.2.1 Fitting

Caps. Ground glass, Teflon

tape, or aluminum foil (Section 2.2.6) to cap off the sample exposed sections

of the train and sorbent module.

Figure

23.2. Condenser and Absorbent Trap

2.2.2 Wash

Bottles. Teflon, 500-mL.

2.2.3 Probe Liner, Probe Nozzle, and Filter Holder

Brushes. Inert bristle brushes with pre-cleaned stainless steel or Teflon

handles. The probe brush shall have extensions of stainless steel or Teflon, at

least as long as the probe. The brushes shall be properly sized and shaped to

brush out the nozzle, probe liner, and transfer line, if used.

2.2.4 Filter

Storage Container. Sealed

filter holder, wide-mouth amber glass jar with Teflon-lined cap, glass Petri

dish.

2.2.5 Balance. Triple beam.

2.2.6 Aluminum

Foil. Heavy duty,

hexane-rinsed.

2.2.7 Metal

Storage Container. Air tight

container to store silica gel.

2.2.8 Graduated

Cylinder. Glass, 250-mL with

2-mL graduations.

2.2.9 Glass

Sample Storage Containers. Amber

glass bottles for sample glassware washes, 500- or 1000-mL, with leak free

Teflon-lined caps.

2.3 Analysis.

2.3.1 Sample

Containers. 125- and 250-mL

flint glass bottles with Teflon-lined caps.

2.3.2 Test

Tubes. Glass.

2.3.3 Soxhlet

Extraction Apparatus. Capable

of holding 43 x 123 mm extraction thimbles.

2.3.4

Extraction Thimble. Glass,

pre-cleaned cellulosic, or glass fiber.

2.3.5 Pasteur

Pipettes. For preparing

liquid chromatographic columns.

2.3.6

Reacti-vials. Amber glass, 2-mL,

silanized prior to use.

2.3.7 Rotary

Evaporator. Buchi/Brinkman

RF-121 or equivalent.

2.3.8

Nitrogen Evaporative Concentrator. N-Evap

Analytical Evaporator Model III or equivalent.

2.3.9

Separatory Funnels. Glass,

2-liter.

2.3.10 Gas Chromatograph.

Consisting of the following

components:

2.3.10.1 Oven. Capable of maintaining the separation column

at the proper operating temperature +10¡C and performing programmed

increases in temperature at rates of at least 40¡C/min.

2.3.10.2 Temperature

Gauges. To monitor column

oven, detector, and exhaust temperatures +1¡C.

2.3.10.3 Flow

Systems. Gas metering system

to measure sample, fuel, combustion gas, and carrier gas flows.

2.3.10.4

Capillary Columns. A fused

silica column, 60 x 0.25 mm inside diameter (ID), coated with DB-5 and a fused

silica column, 30 m x 0.25 mm ID coated with DB-225. Other column systems may

be substituted provided that the user is able to demonstrate, using calibration

and performance checks, that the column system is able to meet the

specifications of Section 6.1.2.2.

2.3.11 Mass

Spectrometer. Capable of

routine operation at a resolution of 1:10000 with a stability of +5 ppm.

2.3.12 Data

System. Compatible with the

mass spectrometer and capable of monitoring at least five groups of 25 ions.

2.3.13

Analytical Balance. To

measure within 0.1 mg.

3. REAGENTS

3.1 Sampling.

3.1.1 Filters.

Glass fiber

filters, without organic binder, exhibiting at least 99.95 percent efficiency

(<0.05 percent penetration) on 0.3-micron dioctyl phthalate smoke particles.

The filter efficiency test shall be conducted in accordance with ASTM Standard

Method D 2986-71 (Reapproved 1978) (incorporated by reference - see ¤60.17).

3.1.1.1

Pre-cleaning. All filters

shall be cleaned before their initial use. Place a glass extraction thimble and

1 g of silica gel and a plug of glass wool into a Soxhlet apparatus, charge the

apparatus with toluene, and reflux for a minimum of 3 hours. Remove the toluene

and discard it, but retain the silica gel. Place no more than 50 filters in the

thimble onto the silica gel bed and top with the cleaned glass wool. Charge the

Soxhlet with toluene and reflux for 16 hours. After extraction, allow the

Soxhlet to cool, remove the filters, and dry them under a clean nitrogen (N2) stream. Store the filters in a glass Petri

dish sealed with Teflon tape.

3.1.2 Adsorbent Resin.

Amberlite XAD-2

resin. Thoroughly cleaned before initial use.

3.1.2.1

Cleaning. Procedure may be

carried out in a giant Soxhlet extractor. An all-glass filter thimble

containing an extra-coarse frit is used for extraction of XAD-2. The frit is

recessed 10-15 mm above a crenellated ring at the bottom of the thimble to

facilitate drainage. The resin must be carefully retained in the extractor cup

with a glass wool plug and a stainless steel ring because it floats on

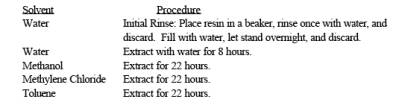

methylene chloride. This process involves sequential extraction in the

following order.

3.1.2.2 Drying.

3.1.2.2.1

Drying Column. Pyrex pipe,

10.2 cm ID by 0.6 m long, with suitable retainers.

3.1.2.2.2

Procedure. The adsorbent

must be dried with clean inert gas. Liquid nitrogen from a standard commercial

liquid nitrogen cylinder has proven to be a reliable source for large volumes

of gas free from organic contaminants. Connect the liquid nitrogen cylinder to

the column by a length of cleaned copper tubing, 0.95 cm ID, coiled to pass

through a heat source. A convenient heat source is a water-bath heated from a

steam line. The final nitrogen temperature should only be warm to the touch and

not over 40¡C. Continue flowing nitrogen through the adsorbent until all the

residual solvent is removed. The flow rate should be sufficient to gently

agitate the particles, but not so excessive as to cause the particles to

fracture.

3.1.2.3 Quality

Control Check. The adsorbent

must be checked for residual toluene prior to use.

3.1.2.3.1

Extraction. Weigh a 1.0 g

sample of dried resin into a small vial, add 3 mL of toluene, cap the vial, and

shake it well.

3.1.2.3.2

Analysis. Inject a 2 ¥ l

sample of the extract into a gas chromatograph operated under the following

conditions:

Column: 6 ft

x 1/8 in stainless steel containing 10 percent OV-101ª on 100/120 Supelcoport.

Carrier Gas:

Helium at a rate of 30 mL/min.

Detector:

Flame ionization detector operated at a sensitivity of 4 x 10-11 A/mV.

Injection

Port Temperature: 250¡C.

Detector

Temperature: 305¡C.

Oven

Temperature: 30¡C for 4 min; programmed to rise at 40¡C/min until it reaches

250¡C; return to 30¡C after 17 minutes.

Compare the

results of the analysis to the results from the reference solution. Prepare the

reference solution by injecting 2.5 ¥ l

of methylene chloride into 100 mL of toluene. This corresponds to 100 ¥ g of methylene chloride per g of adsorbent.

The maximum acceptable concentration is 1000 ¥ g/g

of adsorbent. If the adsorbent exceeds this level, drying must be continued

until the excess methylene chloride is removed.

3.1.2.4

Storage. The adsorbent must

be used within 4 weeks of cleaning. After cleaning, the adsorbent may be stored

in a wide mouth amber glass container with a Teflon-lined cap or placed in

glass adsorbent modules tightly sealed with glass stoppers. If pre-cleaned

adsorbent is purchased in sealed containers, it must be used within 4 weeks

after the seal is broken.

3.1.3 Glass Wool.

Cleaned by

sequential immersion in three aliquots of methylene chloride, dried in a 110¡C

oven, and stored in a methylene chloride-washed glass container with a

Teflon-lined screw cap.

3.1.4 Water.

Deionized

distilled and stored in a methylene chloride-rinsed glass container with a

Teflon-lined screw cap.

3.1.5 Silica Gel.

Indicating type, 6

to 16 mesh. If previously used, dry at 175¡ C (350¡F) for two hours. New silica

gel may be used as received. Alternatively, other types of desiccants

(equivalent or better) may be used, subject to the approval of the

Administrator.

3.1.6 Chromic Acid Cleaning Solution.

Dissolve 20 g of

sodium dichromate in 15 mL of water, and then carefully add 400 mL of concentrated

sulfuric acid.

3.2 Sample Recovery.

3.2.1 Acetone. Pesticide quality.

3.2.2 Methylene

Chloride. Pesticide quality.

3.2.3 Toluene. Pesticide quality.

3.3 Analysis.

3.3.1 Potassium

Hydroxide. ACS grade,

2-percent (weight/volume) in water.

3.3.2 Sodium

Sulfate. Granulated, reagent

grade. Purify prior to use by rinsing with methylene chloride and oven drying.

Store the cleaned material in a glass container with a Teflon-lined screw cap.

3.3.3 Sulfuric

Acid. Reagent grade.

3.3.4 Sodium

Hydroxide. 1.0 N. Weigh 40 g

of sodium hydroxide into a 1-liter volumetric flask. Dilute to 1 liter with

water.

3.3.5 Hexane. Pesticide grade.

3.3.6 Methylene

Chloride. Pesticide grade.

3.3.7 Benzene. Pesticide grade.

3.3.8 Ethyl

Acetate.

3.3.9 Methanol.

Pesticide grade.

3.3.10 Toluene.

Pesticide grade.

3.3.11 Nonane. Pesticide grade.

3.3.12

Cyclohexane. Pesticide

Grade.

3.3.13 Basic

Alumina. Activity grade 1,

100-200 mesh. Prior to use, activate the alumina by heating for 16 hours at

130¡C. Store in a desiccator. Pre-activated alumina may be purchased from a

supplier and may be used as received.

3.3.14 Silica

Gel. Bio-Sil A, 100-200

mesh. Prior to use, activate the silica gel by heating for at least 30 minutes at

180¡C. After cooling, rinse the silica gel sequentially with methanol and

methylene chloride. Heat the rinsed silica gel at 50¡C for 10 minutes, then

increase the temperature gradually to 180¡C over 25 minutes and maintain it at

this temperature for 90 minutes. Cool at room temperature and store in a glass

container with a Teflon-lined screw cap.

3.3.15 Silica

Gel Impregnated with Sulfuric Acid. Combine

100 g of silica gel with 44 g of concentrated sulfuric acid in a screw capped

glass bottle and agitate thoroughly. Disperse the solids with a stirring rod

until a uniform mixture is obtained. Store the mixture in a glass container

with a Teflon-lined screw cap.

3.3.16 Silica

Gel Impregnated with Sodium Hydroxide. Combine 39 g of 1 N sodium hydroxide with 100 g of silica gel in

a screw capped glass bottle and agitate thoroughly. Disperse solids with a

stirring rod until a uniform mixture is obtained. Store the mixture in glass

container with a Teflon-lined screw cap.

3.3.17

Carbon/Celite. Combine 10.7

g of AX-21 carbon with 124 g of Celite 545 in a 250- mL glass bottle with a

Teflon-lined screw cap. Agitate the mixture thoroughly until a uniform mixture

is obtained. Store in the glass container.

3.3.18

Nitrogen. Ultra high purity.

3.3.19

Hydrogen. Ultra high purity.

3.3.20

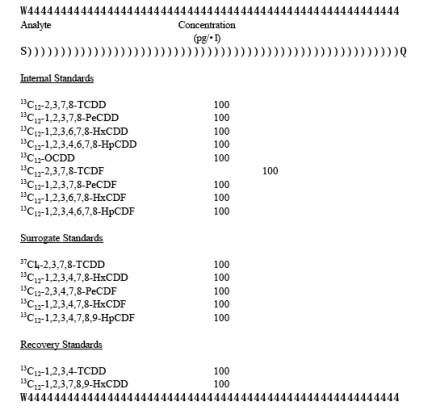

Internal Standard Solution. Prepare

a stock standard solution containing the isotopic ally labeled PCDD's and

PCDF's at the concentrations shown in Table 1 under the heading "Internal

Standards" in 10 mL of nonane.

3.3.21

Surrogate Standard Solution. Prepare

a stock standard solution containing the isotopic ally labeled PCDD's and

PCDF's at the concentrations shown in Table 1 under the heading "Surrogate

Standards" in 10 mL of nonane.

3.3.22 Recovery

Standard Solution. Prepare a

stock standard solution containing the isotopic ally labeled PCDD's and PCDF's

at the concentrations shown in Table 1 under the heading "Recovery

Standards" in 10 mL of nonane.

4. PROCEDURE

4.1 Sampling.

The complexity of

this method is such that, in order to obtain reliable results, testers and

analysts should be trained and experienced with the procedures.

4.1.1 Pretest

Preparation.

4.1.1.1

Cleaning Glassware. All

glass components of the train upstream of and including the adsorbent module,

shall be cleaned as described in Section 3A of the "Manual of Analytical

Methods for the Analysis of Pesticides in Human and Environmental

Samples." Special care shall be devoted to the removal of residual

silicone grease sealants on ground glass connections of used glassware. Any

residue shall be removed by soaking the glassware for several hours in a

chromic acid cleaning solution prior to cleaning as described above.

4.1.1.2

Adsorbent Trap. The traps

must be loaded in a clean area to avoid contamination. They may not be loaded

in the field. Fill a trap with 20 to 40 g of XAD-2. Follow the XAD-2 with glass

wool and tightly cap both ends of the trap. Add 100 ¥ l of the surrogate standard solution (Section

3.3.21) to each trap.

4.1.1.3

Sampling Train. It is suggested

that all components be maintained according to the procedure described in

APTD-0576.

4.1.1.4 Silica

Gel. Weigh several 200 to

300 g portions of silica gel in airtight containers to the nearest 0.5 g.

Record the total weight of the silica gel plus container, on each container. As

an alternative, the silica gel may be weighed directly in its impinger or

sampling holder just prior to sampling.

4.1.1.5 Filter.

Check each filter against

light for irregularities and flaws or pinhole leaks. Pack the filters flat in a

clean glass container.

4.1.2

Preliminary Determinations. Same

as Section 4.1.2 of Method 5.

4.1.3

Preparation of Collection Train.

4.1.3.1 During preparation and assembly of the

sampling train, keep all train openings where contamination can enter, sealed

until sampling is about to begin.

4.1.3.2 Place approximately 100 mL of water in the

second and third impingers, leave the first and fourth impingers empty, and

transfer approximately 200 to 300 g of pre-weighed silica gel from its container

to the fifth impinger.

4.1.3.3 Place the silica gel container in a clean

place for later use in the sample recovery. Alternatively, the weight of the

silica gel plus the fifth impinger may be determined to the nearest 0.5 g and

recorded.

4.1.3.4 Assemble the sampling train as shown in Figure 23-1.

4.1.3.5 Turn on the adsorbent module and condenser

coil recirculating pump and begin monitoring the adsorbent module gas entry

temperature. Ensure proper sorbent gas entry temperature before proceeding and

before sampling is initiated. It is extremely important that the XAD-2

adsorbent resin temperature never exceed 50¡C because thermal decomposition

will occur. During testing, the XAD-2 temperature must not exceed 20¡C for efficient

capture of the PCDD's and PCDF's.

4.1.4

Leak-Check Procedure. Same

as Method 5, Section 4.1.4.

4.1.5 Sampling

Train Operation. Same as

Method 5, Section 4.1.5.

4.2 Sample Recovery.

Proper cleanup

procedure begins as soon as the probe is removed from the stack at the end of

the sampling period. Seal the nozzle end of the sampling probe with Teflon tape

or aluminum foil. When the probe can be safely handled, wipe off all external

particulate matter near the tip of the probe. Remove the probe from the train

and close off both ends with aluminum foil. Seal off the inlet to the train

with Teflon tape, a ground glass cap, or aluminum foil. Transfer the probe and

impinger assembly to the cleanup area. This area shall be clean and enclosed so

that the chances of losing or contaminating the sample are minimized. Smoking,

which could contaminate the sample, shall not be allowed in the cleanup area.

Inspect the train prior to and during disassembly and note any abnormal

conditions, e.g., broken filters, colored impinger liquid, etc. Treat the

samples as follows:

4.2.1 Container

No. 1. Either seal the

filter holder or carefully remove the filter from the filter holder and place

it in its identified container. Do not place the filter in aluminum foil. Use a

pair of cleaned tweezers to handle the filter. If it is necessary to fold the

filter, do so such that the particulate cake is inside the fold. Carefully

transfer to the container any particulate matter and filter fibers which adhere

to the filter holder gasket, by using a dry inert bristle brush and a

sharp-edged blade. Seal the container.

4.2.2 Adsorbent

Module. Remove the module

from the train, tightly cap both ends, label it, and store it on ice for

transport to the laboratory.

4.2.3 Container

No. 2. Quantitatively

recover material deposited in the nozzle, probe transfer lines, the front half

of the filter holder, and the cyclone, if used, first, by brushing while

rinsing three times with acetone and then, by rinsing the probe three times

with methylene chloride. Collect all the rinses in Container No. 2. Rinse the

back half of the filter holder three times with acetone. Rinse the connecting

line between the filter and the condenser three times with acetone. Soak the

connecting line with three separate portions of methylene chloride for 5

minutes each. If using a separate condenser and adsorbent trap, rinse the

condenser in the same manner as the connecting line. Collect all the rinses in

Container No. 2 and mark the level of the liquid on the container.

4.2.4 Container

No. 3. Repeat the methylene

chloride-rinsing described in Section 4.2.3 using toluene as the rinse solvent.

Collect the rinses in Container No. 3 and mark the level of the liquid on the

container.

4.2.5 Impinger

Water. Measure the liquid in

the first four impingers to within 1 mL by using a graduated cylinder or by

weighing it to within 0.5 g by using a balance. Record the volume or weight of

liquid present. This information is required to calculate the moisture content

of the effluent gas. Discard the liquid after measuring and recording the

volume or weight.

4.2.7 Silica

Gel. Note the color of the

indicating silica gel to determine if it has been completely spent and make a mention

of its condition. Transfer the silica gel from the fifth impinger to its

original container and seal.

5. ANALYSIS

All glassware

shall be cleaned as described in Section 3A of the "Manual of Analytical

Methods for the Analysis of Pesticides in Human and Environmental

Samples." All samples must be extracted within 30 days of collection and

analyzed within 45 days of extraction.

5.1 Sample Extraction.

5.1.1

Extraction System. Place an

extraction thimble (Section 2.3.4), 1 g of silica

gel, and a plug of glass wool into the Soxhlet apparatus, charge the apparatus

with toluene, and reflux for a minimum of 3 hours. Remove the toluene and

discard it, but retain the silica gel. Remove the extraction thimble from the

extraction system and place it in a glass beaker to catch the solvent rinses.

5.1.2 Container

No. 1 (Filter). Transfer the

contents directly to the glass thimble of the extraction system and extract

them simultaneously with the XAD-2 resin.

5.1.3 Adsorbent

Cartridge. Suspend the

adsorbent module directly over the extraction thimble in the beaker (See

Section 5.1.1). The glass frit of the module should be in the up position.

Using a Teflon squeeze bottle containing toluene, flush the XAD-2 into the

thimble onto the bed of cleaned silica gel. Thoroughly rinse the glass module

catching the rinsings in the beaker containing the thimble. If the resin is

wet, effective extraction can be accomplished by loosely packing the resin in

the thimble. Add the XAD-2 glass wool plug to the thimble.

5.1.4 Container

No. 2 (Acetone and Methylene Chloride). Concentrate the sample to a volume of about 1-2 mL using the

rotary evaporator apparatus at a temperature of less than 37¡C. Rinse the

sample container three times with small portions of methylene chloride and add

these to the concentrated solution and concentrate further to near dryness.

This residue contains particulate matter removed in the rinse of the sampling

train probe and nozzle. Add the concentrate to the filter and the AD-2 resin in

the Soxhlet apparatus described in Section 5.1.1.

5.1.5

Extraction. Add100 ¥ l of the internal standard solution (Section 3.3.20) to the extraction thimble containing

the contents of the adsorbent cartridge, the contents of Container No. 1, and

the concentrate from Section 5.1.4. Cover the contents of the extraction

thimble with the cleaned glass wool plug to prevent the XAD-2 resin from

floating into the solvent reservoir of the extractor. Place the thimble in the

extractor, and add the toluene contained in the beaker to the solvent

reservoir. Pour additional toluene to fill the reservoir approximately 2/3

full. Add Teflon boiling chips and assemble the apparatus. Adjust the heat

source to cause the extractor to cycle three times per hour. Extract the sample

for 16 hours. After extraction, allow the Soxhlet to cool. Transfer the toluene

extract and three 10-mL rinses to the rotary evaporator. Concentrate the

extract to approximately 10 mL. At this point the analyst may choose to split

the sample in half. If so, split the sample, store one half for future use, and

analyze the other half according to the procedures in Sections 5.2 and 5.3. In

either case, use a nitrogen evaporative concentrator to reduce the volume of

the sample being analyzed to near dryness. Dissolve the residue in 5 mL of

hexane.

5.1.6 Container

No. 3 (Toluene Rinse). Add

100 ¥ l of the internal standard solution (Section

3.3.20) to the contents of the container. Concentrate the sample to a volume of

about 1-5 mL using the rotary evaporator apparatus at a temperature of less

than 37¡C. Rinse the sample container three times with small portions of

toluene and add these to the concentrated solution and concentrate further to

near dryness. Analyze the extract separately according to the procedures in

Sections 5.2 and 5.3, but concentrate the solution in a rotary evaporator

apparatus rather than a nitrogen evaporative concentrator.

5.2 Sample Cleanup and Fractionation.

5.2.1 Silica Gel

Column. Pack one end of a

glass column, 20 mm x 230 mm, with glass wool. Add in sequence, 1 g silica gel,

2 g of sodium hydroxide impregnated silica gel, 1 g silica gel, 4 g of

acid-modified silica gel, and 1 g of silica gel. Wash the column with 30 mL of

hexane and discard. Add the sample extract, dissolved in 5 mL of hexane to the

column with two additional 5-mL rinses. Elute the column with an additional 90

mL of hexane and retain the entire eluate. Concentrate this solution to a

volume of about 1 mL using the nitrogen evaporative concentrator (Section 2.3.8).

5.2.2 Basic

Alumina Column. Shorten a

25-mL disposable Pasteur pipette to about 16 mL. Pack the lower section with

glass wool and 12 g of basic alumina. Transfer the concentrated extract from

the silica gel column to the top of the basic alumina column and elute the

column sequentially with 120 mL of 0.5 percent methylene chloride in hexane

followed by 120 mL of 35 percent methylene chloride in hexane. Discard the

first 120 mL of eluate. Collect the second 120 mL of eluate and concentrate it

to about 0.5 mL using the nitrogen evaporative concentrator.

5.2.3 AX-21

Carbon/Celite 545 Column. Remove

the bottom 0.5 in. from the tip of a 9-mL disposable Pasteur pipette. Insert a

glass fiber filter disk or glass wool plug in the top of the pipette 2.5 cm

from the constriction. Add sufficient carbon/Celiteª mixture to form a 2 cm

column (the 0.6 mL mark column. Top with a glass wool plug. In some cases AX-21

carbon fines may wash through the glass wool plug and enter the sample. This

may be prevented by adding a celite plug to the exit end of the column. Rinse

the column in sequence with 2 mL of 50 percent benzene in ethyl acetate, 1 mL

of a 50 percent methylene chloride in cyclohexane mixture, and 2 mL of hexane.

Discard these rinses. Transfer, the concentrate in 1 mL hexane from the basic

alumina column to the carbon/celite along with 1 ml of hexane rinse. Elute the

column sequentially with 2 mL of 50 percent methylene chloride in hexane and 2

mL of 50 percent benzene in ethyl acetate and discard the eluates. Invert the

column and elute in the reverse direction with 13 mL of toluene. Collect this

eluate. Concentrate the eluate in a rotary evaporator at 50¡C to about 1 mL.

Transfer the concentrate to a Reacti-vial using a toluene rinse and concentrate

to a volume of 200 µl using a stream of N2.

Store extracts at room temperature, shielded from light, until the analysis is

performed.

5.3 Analysis.

Analyze the sample

with a gas chromatograph coupled to a mass spectrometer (GC/MS) using the

instrumental parameters in Sections 5.3.1 and 5.3.2. Immediately prior to

analysis, add a 20 ¥

l aliquot of the recovery

standard solution from Table 1 to each sample. A 2 ¥ l aliquot of the extract is injected into the

GC. Sample extracts are first analyzed using the DB-5 capillary column to

determine the concentration of each isomer of PCDD's and PCDF's (tetra-through

octa-). If tetrachlorinated dibenzofurans are detected in this analysis, then

analyze another aliquot of the sample in a separate run, using the DB-225

column to measure the 2,3,7,8 tetra-chloro dibenzofuran isomer. Other column

systems may be used, provided that the user is able to demonstrate using

calibration and performance checks that the column system is able to meet the

specifications of Section 6.1.2.2.

5.3.1 Gas

Chromatograph Operating Conditions.

5.3.1.1

Injector. Configured for

capillary column, splitless, 250 ¡C.

5.3.1.2 Carrier

Gas. Helium, 1-2 ml/min.

5.3.1.3 Oven. Initially at 150 ¡C. Raise by at least 40

¡C/min to 190 ¡C and then by ¡C/min up to 300 ¡C.

5.3.2 High

Resolution Mass Spectrometer.

5.3.2.1

Resolution. 10,000 m/e.

5.3.2.2

Ionization Mode. Electron

impact.

5.3.2.3 Source

Temperature 250¡C.

5.3.2.4

Monitoring Mode. Selected

ion monitoring. A list of the various ions to be monitored is presented in

Table 3.

5.3.2.5

Identification Criteria. The

following identification criteria shall be used for the characterization of

polychlorinated dibenzodioxins and dibenzofurans.

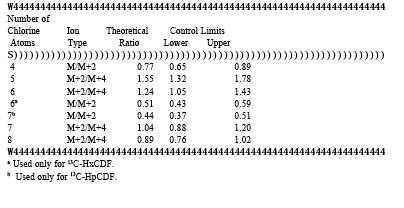

1. The integrated

ion-abundance ratio (M/M+2 or M+2/M+4) shall be within 15 percent of the

theoretical value. The acceptable ion-abundance ratio ranges (+15%) for

the identification of chlorine-containing compounds are given in Table 4.

2. The retention

time for the analytes must be within 3 seconds of the corresponding 13C-labeled internal standard or surrogate

standard.

3. The monitored

ions, shown in Table 3 for a given analyte, shall reach

their maximum within 2 seconds of each other.

4. The

identification of specific isomers that do not have corresponding 13C-labeled standards is done by comparison of

the relative retention time (RRT) of the analyte to the nearest internal

standard retention time with reference (i.e., within 0.005 RRT units) to the

comparable RRT's found in the continuing calibration.

5. The signal to

noise ratio for all monitored ions must be greater than 2.5.

6. The

confirmation of 2, 3, 7, 8-TCDF shall satisfy all of the above identification

criteria.

7. For the

identification of PCDFÕs, no signal may be found in the corresponding PCDPE channels.

5.3.2.6

Quantification. The peak

areas for the two ions monitored for each analyte are summed to yield the total

response for each analyte. Each internal standard is used to quantify the

indigenous PCDD's or PCDF's in its homologous series. For example, the 13C12-2,3,7,8-tetra

chlorinated dibenzodioxin is used to calculate the concentrations of all other

tetra chlorinated isomers. Recoveries of the tetra- and penta- internal

standards are calculated using the 13C12-1,2,3,4-TCDD. Recoveries of the hexa-

through octa- internal standards are calculated using 13C12-1,2,3,7,8,9-HxCDD.

Recoveries of the surrogate standards are calculated using the corresponding

homolog from the internal standard.

6. CALIBRATION

Same as Method 5

with the following additions.

6.1 GC/MS System.

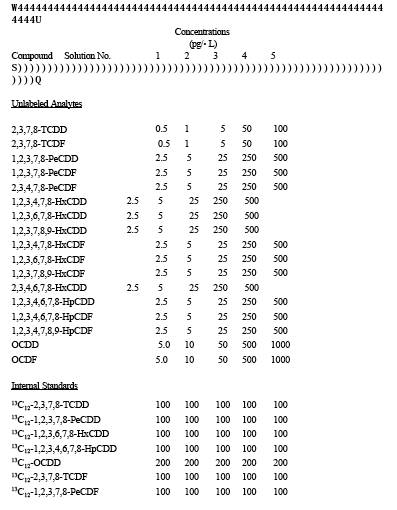

6.1.1 Initial

Calibration. Calibrate the

GC/MS system using the set of five standards shown in Table

2. The relative standard deviation for the mean response factor from each

of the unlabeled analytes (Table 2) and of the internal and surrogate standards

shall be less than or equal to the values in Table 5.

The signal to noise ratio for the GC signal present in every selected ion

current profile shall be greater than or equal to 2.5. The ion abundance ratios

shall be within the control limits in Table 4.

6.1.2 Daily

Performance Check.

6.1.2.1

Calibration Check. Inject

one ¥ l of solution Number 3 from Table 2. Calculate

the relative response factor (RRF) for each compound and compare each RRF to

the corresponding mean RRF obtained during the initial calibration. The

analyzer performance is acceptable if the measured RRF's for the labeled and

unlabeled compounds for the daily run are within the limits of the mean values

shown in Table 5. In addition, the ion-abundance ratios shall be within the

allowable control limits shown in Table 4.

6.1.2.2

Column Separation Check. Inject

a solution of a mixture of PCDD's and PCDF's that documents resolution between

2,3,7,8-TCDD and other TCDD isomers. Resolution is defined as a valley between

peaks that is less than 25 percent of the lower of the two peaks. Identify and

record the retention time windows for each homologous series. Perform a similar

resolution check on the confirmation column to document the resolution between

2,3,7,8 TCDF and other TCDF isomers.

6.2 Lock Channels.

Set mass

spectrometer lock channels as specified in Table 3. Monitor the quality control

check channels specified in Table 3 to verify instrument stability during the

analysis.

7. QUALITY CONTROL

7.1 Sampling Train Collection Efficiency Check.

Add 100 ¥ l of the surrogate standards in Table 1 to

the adsorbent cartridge of each train before collecting the field samples.

7.2 Internal Standard Percent Recoveries.

A group of nine

carbon-labeled PCDDs and PCDFs representing the tetra- through octachlorinated

homologues, is added to every sample prior to extraction. The role of the

internal standards is to quantify the native PCDD's and PCDF's present in the

sample as well as to determine the overall method efficiency. Recoveries of the

internal standards must be between 40 to 130 percent for the tetra- through

hexachlorinated compounds while the range is 25 to 130 percent for the hepta-

and octachlorinated homologues.

7.3 Surrogate Standard Recoveries.

The five surrogate

compounds in Table 2 are added to the resin in the adsorbent sampling cartridge

before the sample is collected. The surrogate recoveries are measured relative

to the internal standards and are a measure of the collection efficiency. They

are not used to measure the native PCDD's and PCDF's. All recoveries shall be

between 70 and 130 percent. Poor recoveries for all the surrogates may be an

indication of breakthrough in the sampling train. If the recovery of all

standards is below 70 percent, the sampling runs must be repeated. As an

alternative, the sampling runs do not have to be repeated if the final results

are divided by the fraction of surrogate recovery. Poor recoveries of isolated

surrogate compounds should not be grounds for rejecting an entire set of

samples.

7.4 Toluene QA Rinse.

Report the results

of the toluene QA rinse separately from the total sample catch. Do not add it

to the total sample.

8. QUALITY ASSURANCE

8.1 Applicability.

When the method is

used to analyze samples to demonstrate compliance with a source emission

regulation, an audit sample must be analyzed, subject to availability.

8.2 Audit Procedure.

Analyze an audit

sample with each set of compliance samples. The audit sample contains tetra

through octa isomers of PCDD and PCDF. Concurrently analyze the audit sample

and a set of compliance samples in the same manner to evaluate the technique of

the analyst and the standards preparation. The same analyst, analytical

reagents, and analytical system shall be used both for the compliance samples

and the EPA audit sample.

8.3 Audit Sample Availability.

Audit samples will

be supplied only to enforcement agencies for compliance tests. Audit samples

may be obtained by writing:

Source Test

Audit Coordinator (MD-77B)

Quality

Assurance Division

Atmospheric

Research and Exposure Assessment Laboratory

U.S.

Environmental Protection Agency

Research

Triangle Park, NC 27711

or by calling the

Source Test Audit Coordinator (STAC) at (919) 541-7834. The audit sample

request must be made at least 30 days prior to the scheduled compliance sample

analysis.

8.4 Audit Results.

Calculate the

audit sample concentration according to the calculation procedure provided in

the audit instructions included with the audit sample. Fill in the audit sample

concentration and the analyst's name on the audit response form included with

the audit instructions. Send one copy to the EPA Regional Office or the

appropriate enforcement agency and a second copy to the STAC. The EPA Regional

office or the appropriate enforcement agency will report the results of the

audit to the laboratory being audited. Include this response with the results

of the compliance samples in relevant reports to the EPA Regional Office or the

appropriate enforcement agency.

9. CALCULATIONS

Same as Method 5, Section 6 with the following

additions.

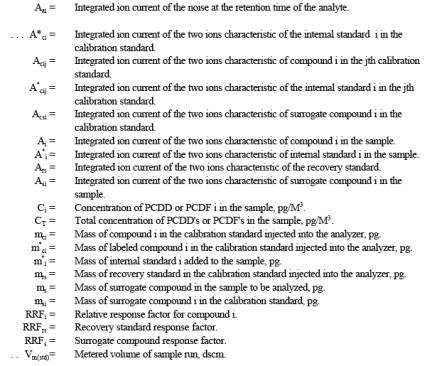

9.1

Nomenclature.

9.2 Average

Relative Response Factor.

9.3

Concentration of the PCDD's and PCDF's.

9.4 Recovery

Standard Response Factor.

9.5 Recovery of

Internal Standards (R*).

9.6 Surrogate

Compound Response Factor.

9.7 Recovery of

Surrogate Compounds (Rs).

9.8 Minimum

Detectable Limit (DL).

9.9 Total

Concentration of PCDD's and PCDF's in the Sample.

Any PCDDs or PCDFs

that are reported as nondetected (below the DL) shall be counted as zero for

the purpose of calculating the total concentration of PCDDs and PCDFs in the

sample.

10. BIBLIOGRAPHY

1. American

Society of Mechanical Engineers. Sampling for the Determination of Chlorinated

Organic Compounds in Stack Emissions. Prepared for U.S. Department of Energy

and U.S. Environmental Protection Agency. Washington DC. December 1984. 25 p.

2. American

Society of Mechanical Engineers. Analytical Procedures to Assay Stack Effluent

Samples and Residual Combustion Products for Polychlorinated Dibenzo-p-Dioxins

(PCDD) and Polychlorinated Dibenzofurans (PCDF). Prepared for the U.S.

Department of Energy and U.S. Environmental Protection Agency. Washington, DC.

December 1984. 23 p.

3. Thompson, J. R.

(ed.). Analysis of Pesticide Residues in Human and Environmental Samples. U.S. Environmental

Protection Agency. Research Triangle Park, NC. 1974.

4. Triangle

Laboratories. Case Study: Analysis of Samples for the Presence of Tetra Through

Octachloro-p-Dibenzodioxins and Dibenzofurans. Research Triangle Park, NC.

1988. 26 p.

5. U.S. Environmental

Protection Agency. Method 8290 - The Analysis of Polychlorinated

Dibenzo-p-dioxin and Polychlorinated Dibenzofurans by High-Resolution Gas

Chromatography/High-Resolution Mass Spectrometry. In: Test Methods for

Evaluating Solid Waste. Washington, DC. SW-846.

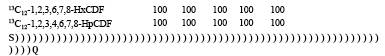

TABLE

23-1. COMPOSITION OF THE SAMPLE FORTIFICATION AND RECOVERY STANDARDS SOLUTIONS

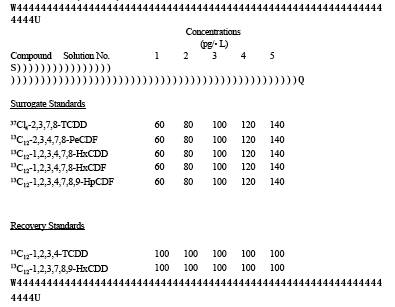

TABLE

23-2. COMPOSITION OF THE INITIAL CALIBRATION SOLUTIONS

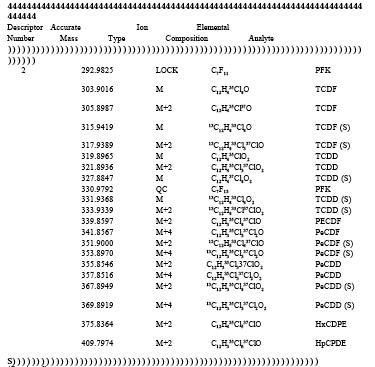

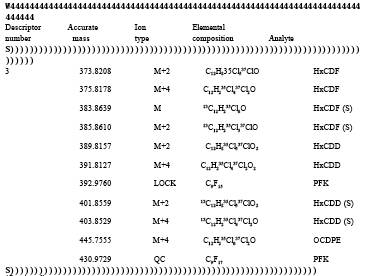

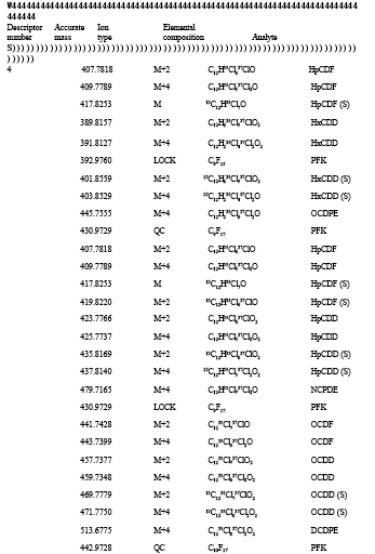

TABLE 23-3. ELEMENTAL COMPOSITIONS AND EXACT MASSES OF THE IONS MONITORED BY HIGH RESOLUTION MASS SPECTROMETRY FOR PCDD's AND PCDF's

TABLE 23-4. ACCEPTABLE RANGES FOR ION-ABUNDANCE RATIOS OF PCDD's AND PCDF's

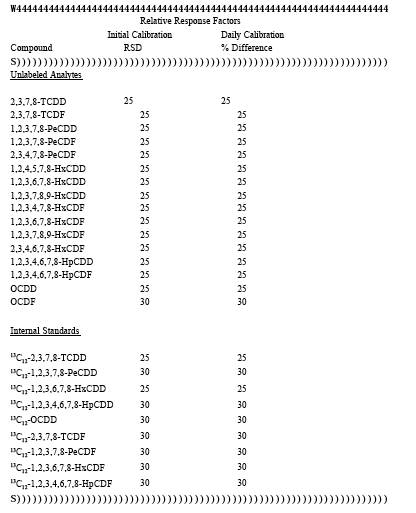

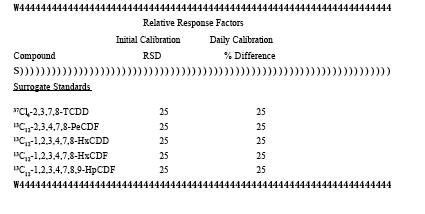

TABLE 23-5. MINIMUM REQUIREMENTS FOR INITIAL AND DAILY CALIBRATION RESPONSE FACTORS