METHOD 103 - BERYLLIUM SCREENING METHOD

6.2 Measurement of

Stack Conditions.

8.0 Sample Collection,

Preservation, Transport, and Storage.

8.1 Selection of a

Sampling Site and Number of Sample Runs.

8.2 Measurement of

Stack Conditions.

8.3 Preparation of

Sampling Train.

9.0 Quality Control.

[Reserved]

10.0 Calibration and

Standardization.

12.0 Data Analysis and

Calculations.

13.0 Method

Performance. [Reserved]

14.0 Pollution

Prevention. [Reserved]

15.0 Waste Management.

[Reserved]

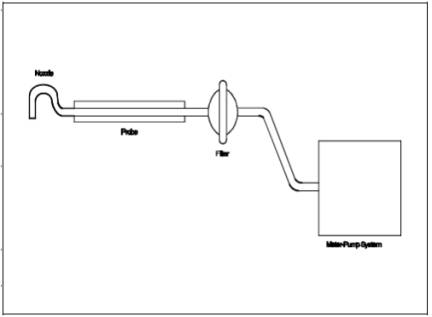

17.0 Tables, Diagrams,

Flow Charts, and Validation Data.

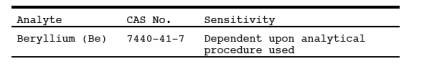

1.0 Scope and Application.

1.1 Analytes.

1.2 Applicability.

This procedure

details guidelines and requirements for methods acceptable for use in

determining Be emissions in ducts or stacks at stationary

sources.

1.3 Data Quality Objectives.

Adherence to the

requirements of this method will enhance the quality of the data obtained from

air pollutant sampling methods.

2.0 Summary of Method.

2.1 Particulate Be

emissions are withdrawn isokinetically from three points in a duct or stack and

are collected on a filter. The collected sample is analyzed for Be using an appropriate

technique.

3.0 Definitions. [Reserved]

4.0 Interferences. [Reserved]

5.0 Safety.

5.1 Disclaimer.

This method may

involve hazardous materials, operations, and equipment. This test method may

not address all of the safety problems associated with its use. It is the

responsibility of the user of this test method to establish appropriate safety

and health practices and determine the applicability of regulatory limitations

prior to performing this test method.

5.2 Hydrochloric Acid (HCl).

Highly corrosive and

toxic. Vapors are highly irritating to eyes, skin, nose, and lungs, causing

severe damage. May cause bronchitis, pneumonia, or edema of lungs. Exposure to

concentrations of 0.13 to 0.2 percent can be lethal to humans in a few minutes.

Provide ventilation to limit exposure. Reacts with metals, producing hydrogen

gas. Personal protective equipment and safe procedures are useful in preventing

chemical splashes. If contact occurs, immediately flush with copious amounts of

water at least 15 minutes. Remove clothing under shower and decontaminate.

Treat residual chemical burn as thermal burn.

6.0 Equipment and Supplies.

6.1 Sample Collection.

A schematic of the

required sampling train configuration is shown in Figure

103-1 in Section 17.0. The essential components of the train are as

follows:

6.1.1 Nozzle.

Stainless steel, or equivalent, with sharp, tapered leading edge.

6.1.2 Probe. Sheathed

borosilicate or quartz glass tubing.

6.1.3 Filter.

Millipore AA, or equivalent, with appropriate filter holder that provides a

positive seal against leakage from outside or around the filter. It is

suggested that a Whatman 41, or equivalent, be placed immediately against the

back side of the Millipore filter as a guard against breakage of the Millipore.

Include the backup filter in the analysis. To be equivalent, other filters

shall exhibit at least 99.95 percent efficiency (0.05 percent penetration) on

0.3 micron dioctyl phthalate smoke particles, and be amenable to the Be

analysis procedure. The filter efficiency tests shall be conducted in

accordance with ASTM D 2986-71, 78, 95a (incorporated by reference ) see ¤61.18). Test data from the supplier's

quality control program are sufficient for this purpose.

6.1.4 Meter-Pump

System. Any system that will maintain isokinetic sampling rate, determine

sample volume, and is capable of a sampling rate of greater than 14 lpm

6.2 Measurement of Stack Conditions.

The following

equipment is used to measure stack conditions:

6.2.1 Pitot Tube.

Type S, or equivalent, with a constant coefficient (±5 percent) over the

working range.

6.2.2 Inclined

Manometer, or Equivalent. To measure velocity head to ±10 percent of the

minimum value.

6.2.3 Temperature

Measuring Device. To measure stack temperature to ±1.5 percent of the minimum

absolute stack temperature.

6.2.4 Pressure

Measuring Device. To measure stack pressure to ±2.5 mm Hg (0.1 in. Hg).

6.2.5 Barometer. To

measure atmospheric pressure to ±2.5 mm Hg (0.1 in. Hg).

6.2.6 Wet and Dry

Bulb Thermometers, Drying Tubes, Condensers, or Equivalent. To determine stack

gas moisture content to ±1 percent.

6.3 Sample Recovery.

6.3.1 Probe Cleaning

Equipment. Probe brush or cleaning rod at least as long as probe, or equivalent.

Clean cotton balls, or equivalent, should be used with the rod.

6.3.2 Leakless Glass

Sample Bottles. To contain sample.

6.4 Analysis.

All equipment

necessary to perform an atomic absorption, spectrographic, fluorometric,

chromatographic, or equivalent analysis.

7.0 Reagents and Standards.

7.1 Sample Recovery.

7.1.1 Water.

Deionized distilled, to conform to ASTM D 1193-77, 91 (incorporated by

reference - see ¤61.18), Type 3.

7.1.2 Acetone.

Reagent grade.

7.1.3 Wash Acid, 50

Percent (V/V) Hydrochloric Acid (HCl). Mix equal volumes of concentrated HCl

and water, being careful to add the acid slowly to the water.

7.2 Analysis.

Reagents and

standards as necessary for the selected analytical procedure.

8.0 Sample Collection, Preservation, Transport, and Storage.

Guidelines for source

testing are detailed in the following sections. These guidelines are generally

applicable; however, most sample sites differ to some degree and temporary

alterations such as stack extensions or expansions often are required to insure

the best possible sample site. Further, since Be is hazardous, care should be

taken to minimize exposure. Finally, since the total quantity of Be to be

collected is quite small, the test must be carefully conducted to prevent

contamination or loss of sample.

8.1 Selection of a Sampling Site and Number of Sample Runs.

Select a suitable

sample site that is as close as practicable to the point of atmospheric

emission. If possible, stacks smaller than one foot in diameter should not be

sampled.

8.1.1 Ideal Sampling

Site. The ideal sampling site is at least eight stack or duct diameters

downstream and two diameters upstream from any flow disturbance such as a bend,

expansion or contraction. For rectangular cross sections, use Equation 103-1 in Section 12.2 to determine an

equivalent diameter, De.

8.1.2 Alternate

Sampling Site. Some sampling situations may render the above sampling site

criteria impractical. In such cases, select an alternate site no less than two

diameters downstream and one-half diameter upstream from any point of flow

disturbance. Additional sample runs are recommended at any sample site not

meeting the criteria of Section 8.1.1.

8.1.3 Number of

Sample Runs Per Test. Three sample runs constitute a test. Conduct each run at

one of three different points. Select three points that proportionately divide

the diameter, or are located at 25, 50, and 75 percent of the diameter from the

inside wall. For horizontal ducts, sample on a vertical line through the

centroid. For rectangular ducts, sample on a line through the centroid and

parallel to a side. If additional sample runs are performed per Section 8.1.2,

proportionately divide the duct to accommodate the total number of runs.

8.2 Measurement of Stack Conditions.

Using the equipment

described in Section 6.2, measure the stack gas

pressure, moisture, and temperature to determine the molecular weight of the

stack gas. Sound engineering estimates may be made in lieu of direct

measurements. Describe the basis for such estimates in the test report.

8.3 Preparation of Sampling Train.

8.3.1 Assemble the

sampling train as shown in Figure 103-1. It is recommended that all glassware

be pre-cleaned by soaking in wash acid for two hours.

8.3.2 Leak check the

sampling train at the sampling site. The leakage rate should not be in excess

of 1 percent of the desired sample rate.

8.4 Sampling Train Operation.

8.4.1 For each run,

measure the velocity at the selected sampling point. Determine the isokinetic

sampling rate. Record the velocity head and the required sampling rate. Place

the nozzle at the sampling point with the tip pointing directly into the gas

stream. Immediately start the pump and adjust the flow to isokinetic

conditions. At the conclusion of the test, record the sampling rate. Again

measure the velocity head at the sampling point. The required isokinetic rate

at the end of the period should not have deviated more than 20 percent from

that originally calculated. Describe the reason for any deviation beyond 20

percent in the test report.

8.4.2 Sample at a

minimum rate of 14 liters/min (0.5 cfm). Obtain samples over such a period or

periods of time as are necessary to determine the maximum emissions which would

occur in a 24-hour period. In the case of cyclic operations, perform sufficient

sample runs so as to allow determination or calculation of the emissions that

occur over the duration of the cycle. A minimum sampling time of two hours per

run is recommended.

8.5 Sample Recovery.

8.5.1 It is

recommended that all glassware be pre-cleaned as in Section 8.3. Sample

recovery should also be performed in an area free of possible Be contamination.

When the sampling train is moved, exercise care to prevent breakage and

contamination. Set aside a portion of the acetone used in the sample recovery

as a blank for analysis. The total amount of acetone used should be measured

for accurate blank correction. Blanks can be eliminated if prior analysis shows

negligible amounts.

8.5.2 Remove the

filter (and backup filter, if used) and any loose particulate matter from

filter holder, and place in a container.

8.5.3 Clean the probe

with acetone and a brush or long rod and cotton balls. Wash into the container

with the filter. Wash out the filter holder with acetone, and add to the same

container.

9.0 Quality Control. [Reserved]

10.0 Calibration and Standardization.

10.1

Sampling Train. As a procedural check, compare the sampling rate regulation

with a dry gas meter, spirometer, rotameter (calibrated for prevailing

atmospheric conditions), or equivalent, attached to the nozzle inlet of the

complete sampling train.

10.2 Analysis.

Perform the analysis standardization as suggested by the manufacturer of the

instrument, or the procedures for the analytical method in use.

11.0 Analytical Procedure.

Make the necessary

preparation of samples and analyze for Be. Any currently acceptable method (e.g., atomic absorption, spectrographic,

fluorometric, chromatographic) may be used.

12.0 Data Analysis and Calculations.

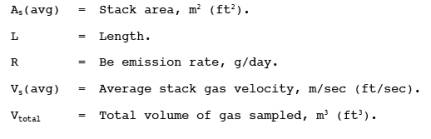

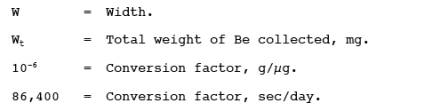

12.1 Nomenclature.

12.2

Calculate the equivalent diameter, De, for a rectangular cross section as

follows:

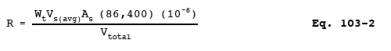

12.3 Calculate the Be

emission rate, R, in g/day for each stack using Equation 103-2. For cyclic

operations, use only the time per day each stack is in operation. The total Be

emission rate from a source is the summation of results from all stacks.

12.4 Test Report. Prepare

a test report that includes as a minimum: A detailed description of the

sampling train used, results of the procedural check described in Section 10.1 with all data and calculations made, all

pertinent data taken during the test, the basis for any estimates made,

isokinetic sampling calculations, and emission results. Include a description

of the test site, with a block diagram and brief description of the process,

location of the sample points in the stack cross section, and stack dimensions

and distances from any point of disturbance.

13.0 Method Performance. [Reserved]

14.0 Pollution Prevention. [Reserved]

15.0 Waste Management. [Reserved]

16.0 References. [Reserved]

17.0 Tables, Diagrams, Flow Charts, and Validation Data.

Figure

103-1. Beryllium Screening Method Sampling Train Schematic.