Method 10 - Determination of Carbon Monoxide Emissions from Stationary Sources

1. PRINCIPLE AND APPLICABILITY

9. CALCULATION--CONCENTRATION OF CARBON MONOXIDE

10. ALTERNATIVE PROCEDURE--INTERFERENCE TRAP

A. Performance

Specifications for NDIR Carbon Monoxide Analyzers.

B. Definitions of

Performance Specifications.

1. PRINCIPLE AND APPLICABILITY

1.1 Principle.

An

integrated or continuous gas sample is extracted from a sampling point and

analyzed for carbon monoxide (CO) content using a Luft-type nondispersive

infrared analyzer (NDIR) or equivalent.

1.2 Applicability.

This

method is applicable for the determination of carbon monoxide emissions from

stationary sources only when specified by the test procedures for determining

compliance with new source performance standards. The test procedure will

indicate whether a continuous or an integrated sample is to be used.

2. RANGE AND SENSITIVITY

2.1

Range. 0 to 1000

ppm.

2.2

Sensitivity. Minimum

detectable concentration is 20 ppm for a 0- to 1000Ρppm span.

3. INTERFERENCES

Any

substance having a strong absorption of infrared energy will interfere to some

extent. For example, discrimination ratios for water (H2O) and carbon dioxide (CO2) are 3.5 percent H2O per 7 ppm CO and 10 percent CO2 per 10 ppm CO, respectively, for

devices measuring in the 1500- to 3000-ppm range. For devices measuring in the

0- to 100-ppm range, interference ratios can be as high as 3.5 percent H2O per 25 ppm CO and 10 percent CO2 per 50 ppm CO. The use of silica gel

and ascarite traps will alleviate the major interference problems. The measured

gas volume must be corrected if these traps are used.

4. PRECISION AND ACCURACY

4.1

Precision. The

precision of most NDIR analyzers is approximately ±2 percent of span.

4.2

Accuracy. The

accuracy of most NDIR analyzers is approximately ±5 percent of span after

calibration.

5. APPARATUS

Note:

Mention of trade names or specific products does not constitute endorsement by

the Environmental Protection Agency.

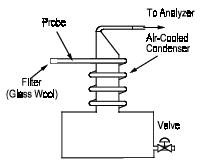

5.1 Continuous Sample

(Figure 10-1).

5.1.1

Probe. Stainless

steel or sheathed Pyrex glass, equipped with a filter to remove particulate

matter.

5.1.2

Air-Cooled Condenser or Equivalent. To

remove any excess moisture.

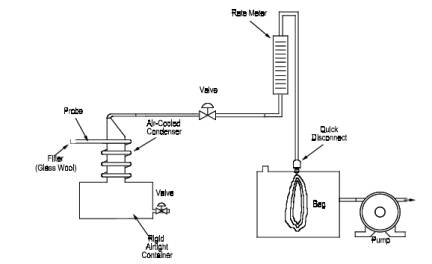

5.2 Integrated Sample

(Figure 10-2).

5.2.1

Probe. Same as in

Section 5.1.1.

5.2.2

Air-Cooled Condenser or Equivalent. Same

as in Section 5.1.2.

5.2.3

Valve. Needle valve,

or equivalent, to adjust flow rate.

5.2.4

Pump. Leak-free

diaphragm type, or equivalent, to transport gas.

5.2.5

Rate Meter. Rotameter,

or equivalent, to measure a flow range from 0 to 1.0 liter per minute (0 to

0.035 cfm).

5.2.6

Flexible Bag. Tedlar,

or equivalent, with a capacity of 60 to 90 liters (2 to 3 ft3). Leak-test the bag in the

laboratory before using by evacuating bag with a pump followed by a dry gas

meter. When evacuation is complete, there should be no flow through the meter.

5.2.7

Pitot Tube. Type S,

or equivalent, attached to the probe so that the sampling rate can be regulated

proportional to the stack gas velocity when velocity is varying with time or a

sample traverse is conducted.

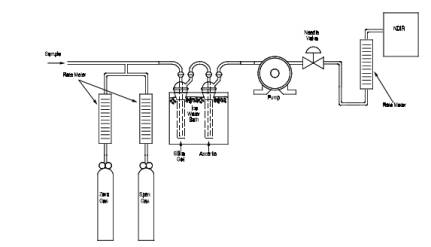

5.3 Analysis

(Figure 10-3).

5.3.1

Carbon Monoxide Analyzer. Nondispersive

infrared spectrometer, or equivalent. This instrument should be demonstrated,

preferably by the manufacturer, to meet or exceed manufacturer's specifications

and those described in this method.

5.3.2

Drying Tube. To

contain approximately 200 g of silica gel.

5.3.3

Calibration Gas. Refer

to Section 6.1.

5.3.4

Filter. As

recommended by NDIR manufacturer.

5.3.5

CO2

Removal Tube. To contain approximately 500 g of

ascarite.

5.3.6

Ice Water Bath. For

ascarite and silica gel tubes.

5.3.7

Valve. Needle valve,

or equivalent, to adjust flow rate.

5.3.8

Rate Meter. Rotameter,

or equivalent, to measure gas flow rate of 0 to 1.0 liter/min (0 to 0.035 cfm)

through NDIR.

5.3.9

Recorder (Optional). To

provide permanent record of NDIR readings.

6. REAGENTS

6.1

Calibration Gases. Known

concentration of CO in nitrogen (N2)

for instrument span, prepurified grade of N2 for

zero, and two additional concentrations corresponding approximately to 60

percent and 30 percent of span. The span concentration shall not exceed 1.5

times the applicable source performance standard. The calibration gases shall

be certified by the manufacturer to be within 2 percent of the specified

concentration.

6.2

Silica Gel. Indicating

type, 6- to 16-mesh, dried at 175‘C (347‘F) for 2 hours.

6.3

Ascarite. Commercially

available.

7. PROCEDURE

7.1 Sampling.

7.1.1 Continuous Sampling.

Set up the

equipment as shown in Figure 10-1 making sure all connections are leak free.

Place the probe in the stack at a sampling point, and purge the sampling line.

Connect the analyzer, and begin drawing sample into the analyzer. Allow 5

minutes for the system to stabilize, then record the analyzer reading as

required by the test procedure. (See Sections 7.2 and 8). CO2 content of the gas may be determined

by using the Method 3 integrated sampling

procedure, or by weighing the ascarite CO2 removal

tube and computing CO2

concentration from the

gas volume sampled and the weight gain of the tube.

7.1.2 Integrated Sampling.

Evacuate

the flexible bag. Set up the equipment as shown in Figure 10-2 with the bag

disconnected. Place the probe in the stack, and purge the sampling line.

Connect the bag, making sure that all connections are leak free. Sample at a

rate proportional to the stack velocity. CO2 content

of the gas may be determined by using the Method 3 integrated sample

procedures, or by weighing the ascarite CO2 concentration

from the gas volume sampled and the weight gain of the tube.

7.2 CO Analysis.

Assemble

the apparatus as shown in Figure 10-3, calibrate the instrument, and perform

other required operations as described in Section 8. Purge analyzer with N2 prior to introduction of each sample.

Direct the sample stream through the instrument for the test period, recording

the readings. Check the zero and the span again after the test to assure that

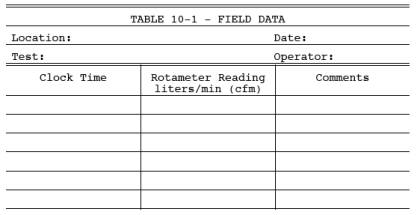

any drift or malfunction is detected. Record the sample data on Table 10-1.

8. CALIBRATION

Assemble

the apparatus according to Figure 10-3. Generally an instrument requires a

warm-up period before stability is obtained. Follow the manufacturer's

instructions for specific procedure. Allow a minimum time of 1 hour for

warm-up. During this time check the sample conditioning apparatus, i.e.,

filter, condenser, drying tube, and CO2 removal

tube, to ensure that each component is in good operating condition. Zero and

calibrate the instrument according to the manufacturer's procedures using, respectively,

N2 and the calibration gases.

9. CALCULATION--CONCENTRATION OF CARBON MONOXIDE

Calculate

the concentration of carbon monoxide in the stack using

Equation

10Ρ1.

![]()

where:

CCO(stack) = Concentration of CO in stack, ppm by

volume, dry basis.

CCO(NDIR) = Concentration of CO measured by

NDIR analyzer, ppm by volume, dry basis.

FCO2 = Volume fraction of CO2 in sample, i.e., percent CO2 from Orsat analysis divided by 100.

10. ALTERNATIVE PROCEDURE--INTERFERENCE TRAP

The sample

conditioning system described in Method 101A, Sections 2.1.2 and 4.2, may be

used as an alternative to the silica gel and ascarite traps.

BIBLIOGRAPHY

1. McElroy, Frank. The Intertech NDIR-CO

Analyzer. Presented at 11th Methods Conference on Air Pollution, University of

California, Berkeley, CA. April 1, 1970.

2. Jacobs, M.B., et al. Continuous

Determination of Carbon Monoxide Infrared Analyzer. J. Air Pollution Control

Association. 9(2):110-114. August 1959.

3. Mine Safety Appliance Co. MSA LIRA Infrared

Gas and Liquid Analyzer Instruction Book. Technical Products Division,

Pittsburgh, PA.

4. Beckman Instruments, Inc. Models

215A, 315A, and 415A Infrared Analyzers. Beckman Instructions 1635-B,

Fullerton, CA. October 1967.

5. Intertech Corporation. Continuous CO

Monitoring System, Model A5611. Princeton,NJ.

6. Bendix Corp. UNOR Infrared Gas

Analyzers. Ronceverte, WV.

Figure 10-1. Continuous Sampling Train

Figure

10-2. Integrated Gas Sampling Train.

Figure

10-3. Analytical Equipment.

ADDENDA

A. Performance Specifications for NDIR Carbon Monoxide Analyzers.

TABLE A-1.

Performance Specifications for NDIR CO Analyzers

ΡΡΡΡΡΡΡΡΡΡΡΡΡΡΡΡΡΡΡΡΡΡΡΡΡΡΡΡΡΡΡΡΡΡΡΡ

Range

(minimum) 0-1000

ppm

Output

(minimum) 0-10

mV

Minimum

detectable sensitivity 20

ppm

Rise time,

90 percent (maximum) 30

seconds

Fall time,

90 percent (maximum) 30

seconds

Zero drift

(maximum) 10%

in 8 hours

Span drift

(maximum) 10%

in 8 hours

Precision

(maximum) ±2%

of full scale

Noise

(maximum) ±1%

of full scale

Linearity

(maximum deviation) 2%

of full scale

Interference

rejection ratio CO2 - 1000:1; H2O - 500:1

ΡΡΡΡΡΡΡΡΡΡΡΡΡΡΡΡΡΡΡΡΡΡΡΡΡΡΡΡΡΡΡΡΡΡΡΡ

B. Definitions of Performance Specifications.

1. Range - The minimum and

maximum measurement limits.

2. Output - Electrical signal

which is proportional to the measurement; intended for connection to readout or

data processing devices. Usually expressed as millivolts or milliamps full

scale at a given impedance.

3. Full Scale - The maximum

measuring limit for a given range.

4. Minimum Detectable Sensitivity

- The smallest amount of input concentration that can be detected as the

concentration approaches zero.

5. Accuracy - The degree of agreement

between a measured value and the true value; usually expressed as ± percent of

full scale.

6. Time to 90 Percent Response -

The time interval from a step change in the input concentration at the

instrument inlet to a reading of 90 percent of the ultimate recorded

concentration.

7. Rise Time (90 Percent) - The

interval between initial response time and time to 90 percent response after a

step increase in the inlet concentration.

8. Fall Time (90 Percent) - The

interval between initial response time and time to 90 percent response after a

step decrease in the inlet concentration.

9. Zero Drift - The change in

instrument output over a stated time period, usually 24 hours, of unadjusted

continuous operation when the input concentration is zero; usually expressed as

percent full scale.

10. Span Drift - The change in

instrument output over a stated time period, usually 24 hours, of unadjusted

continuous operation when the input concentration is a stated upscale value;

usually expressed as percent full scale.

11. Precision - The degree of

agreement between repeated measurements of the same concentration, expressed as

the average deviation of the single results from the mean.

12. Noise - Spontaneous deviations

from a mean output not caused by input concentration changes.

13. Linearity - The maximum

deviation between an actual instrument reading and the reading predicted by a

straight line drawn between upper and lower calibration points.